Lace sewing machine

A technology for sewing machines and ribbons, which is applied to sewing machine components, sewing equipment, textiles and papermaking, etc. It can solve the problems of inability to sew multiple ribbons and achieve the effect of improving sewing processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described in further detail below with reference to the accompanying drawings.

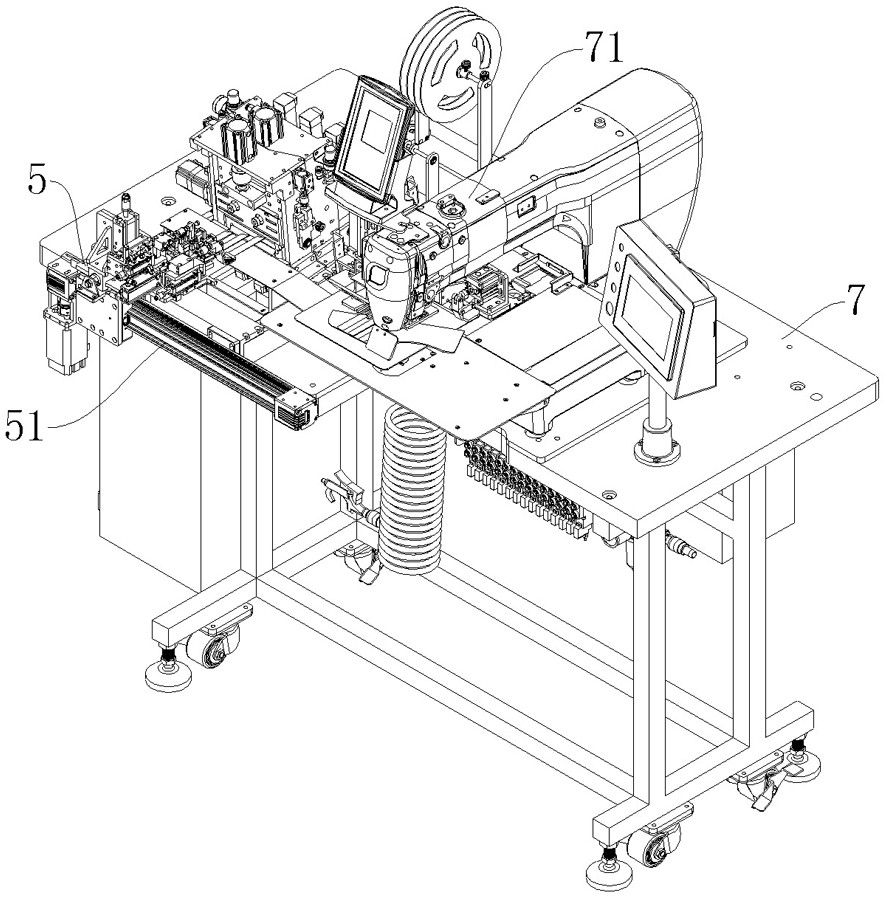

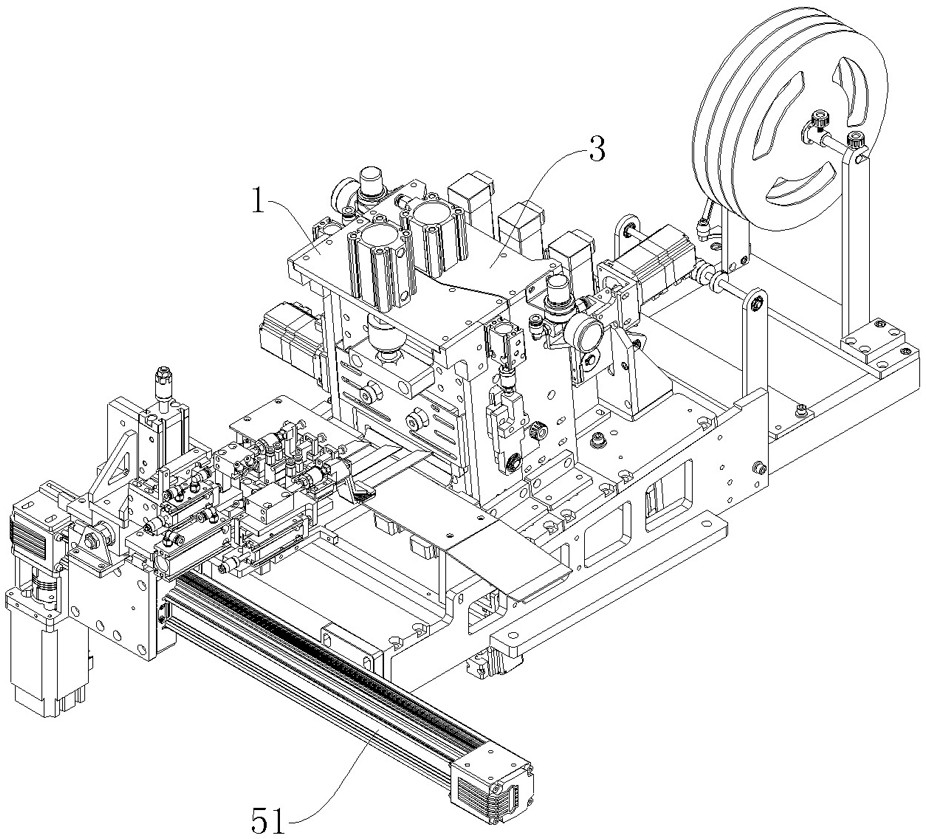

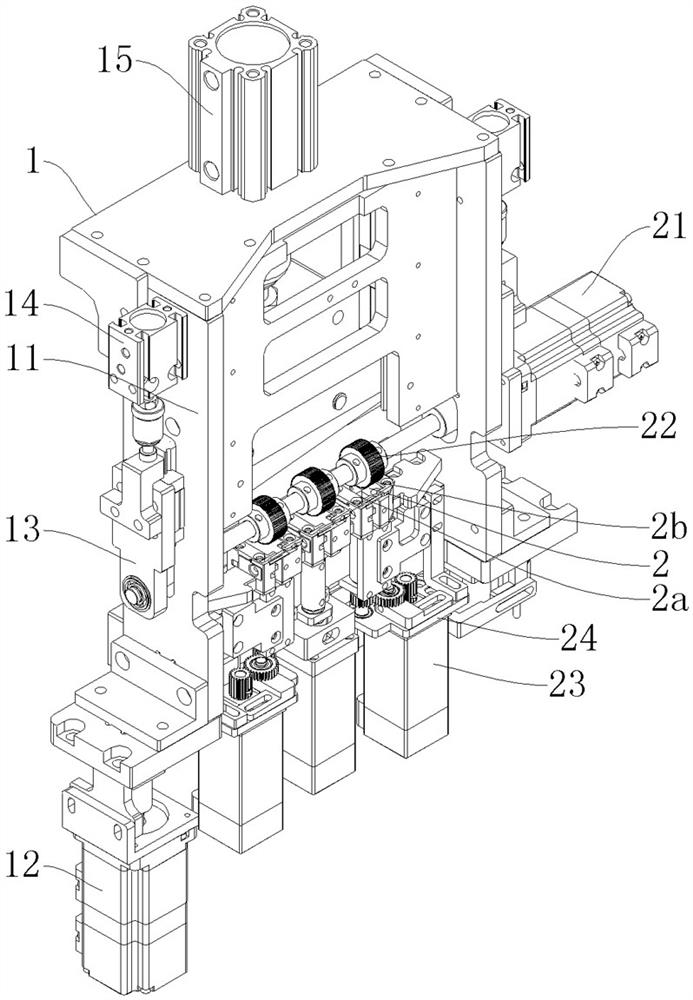

[0025] Figure 1 to 8 Schematic structure of the present invention shown in FIG.

[0026] Wherein the reference numerals are: 1 a feed mount, side mounting plate 11, a first spacing adjustment motor 12, lift the mounting plate 13, the lift drive cylinder 14, a first cutting blade drive cylinder 15, a first adjustment timing belt 16, a first cutter 17, the first feed rail 2, a first stopper 2a, a second stopper 2B, the feed motor 21, feed rollers 22, a first bandwidth adjustment motor 23, the first mounting seat adjustment 24, the cutter mounting bracket 3, lateral support plate 31, a second cylinder mounting plate cutter 32, the cutter driving the second cylinder 33, chamfered blade 34, the cutting blade holder 35 is connected, a second feed rail 4, the third the stopper 41, the stopper 42 of the fourth, third rack gear 43, a fourth rack gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com