Agricultural corn sheller

A corn threshing and crushing device technology, applied in threshing equipment, application, agriculture, etc., can solve problems such as insufficient separation of corn cobs and reduction of environmental quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

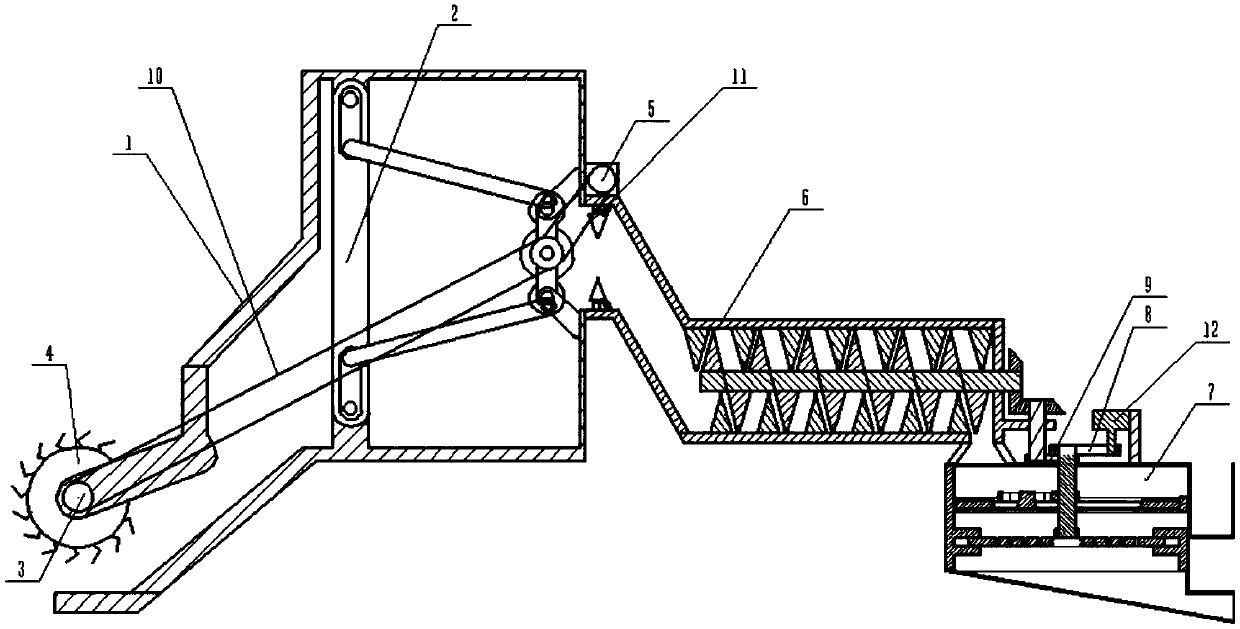

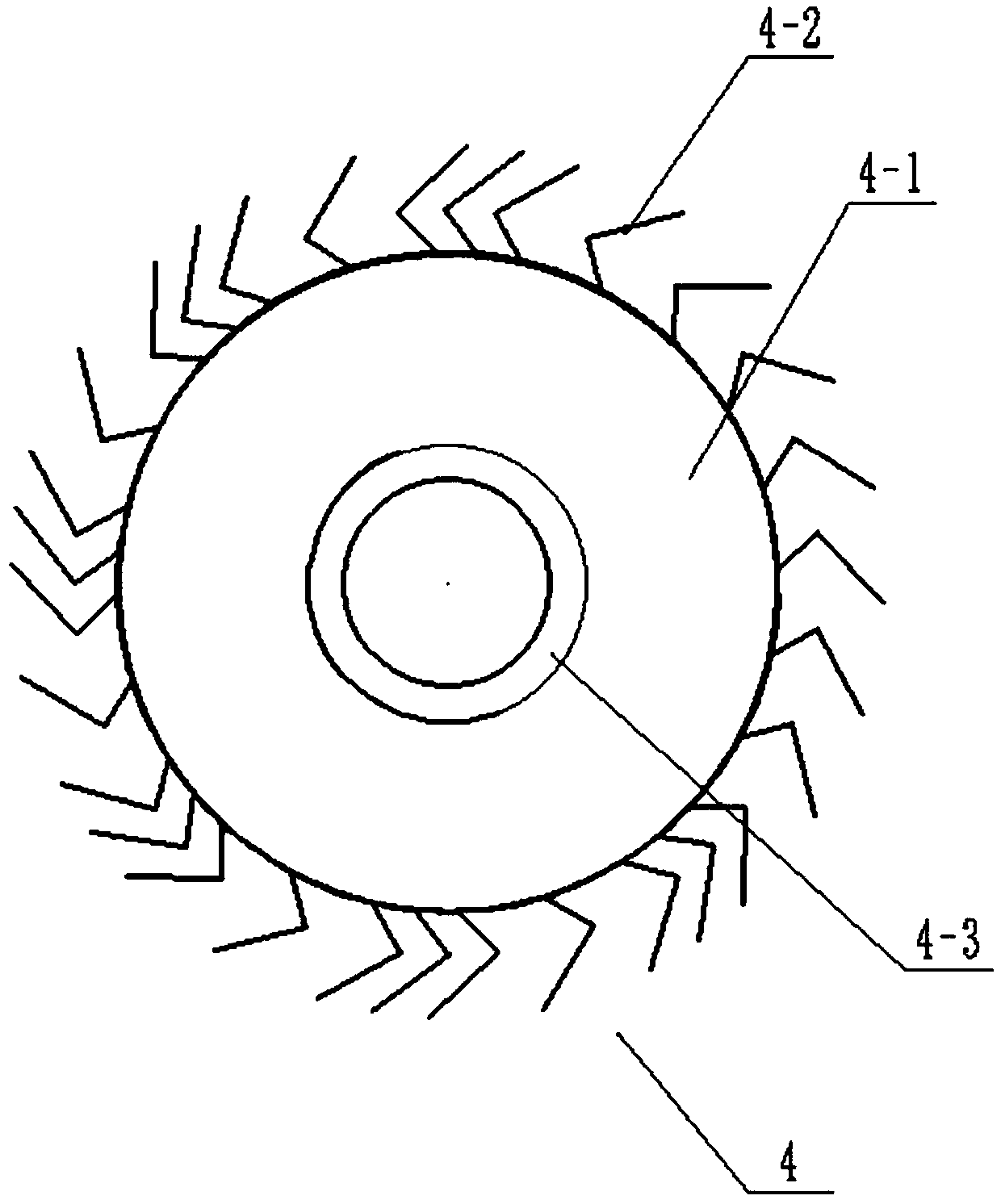

[0032] Combine below Figure 1-15 Describe this embodiment, an agricultural corn threshing device, including a frame assembly 1, an auxiliary push rod assembly 2, a push roller pulley 3, a push roller 4, an input motor 5, a crushing device 6, a screening device 7, and a transmission belt One 8, transmission belt two 9, connecting belt one 10, connecting belt two 11 and right side motor 12, it is characterized in that: the frame assembly 1 is fixedly connected with the auxiliary push rod assembly 2, and the push stick pulley 3 is connected with the push rod assembly 2. The stick 4 is fixedly connected, the push stick 4 is connected to the frame assembly 1 in rotation, the input motor 5 is fixedly connected to the crushing device 6, the crushing device 6 is fixedly connected to the frame assembly 1, the screening device 7 is fixedly connected to the crushing device 6, The transmission belt one 8 is connected between the right motor 12 and the screening device 7, the transmission...

specific Embodiment approach 2

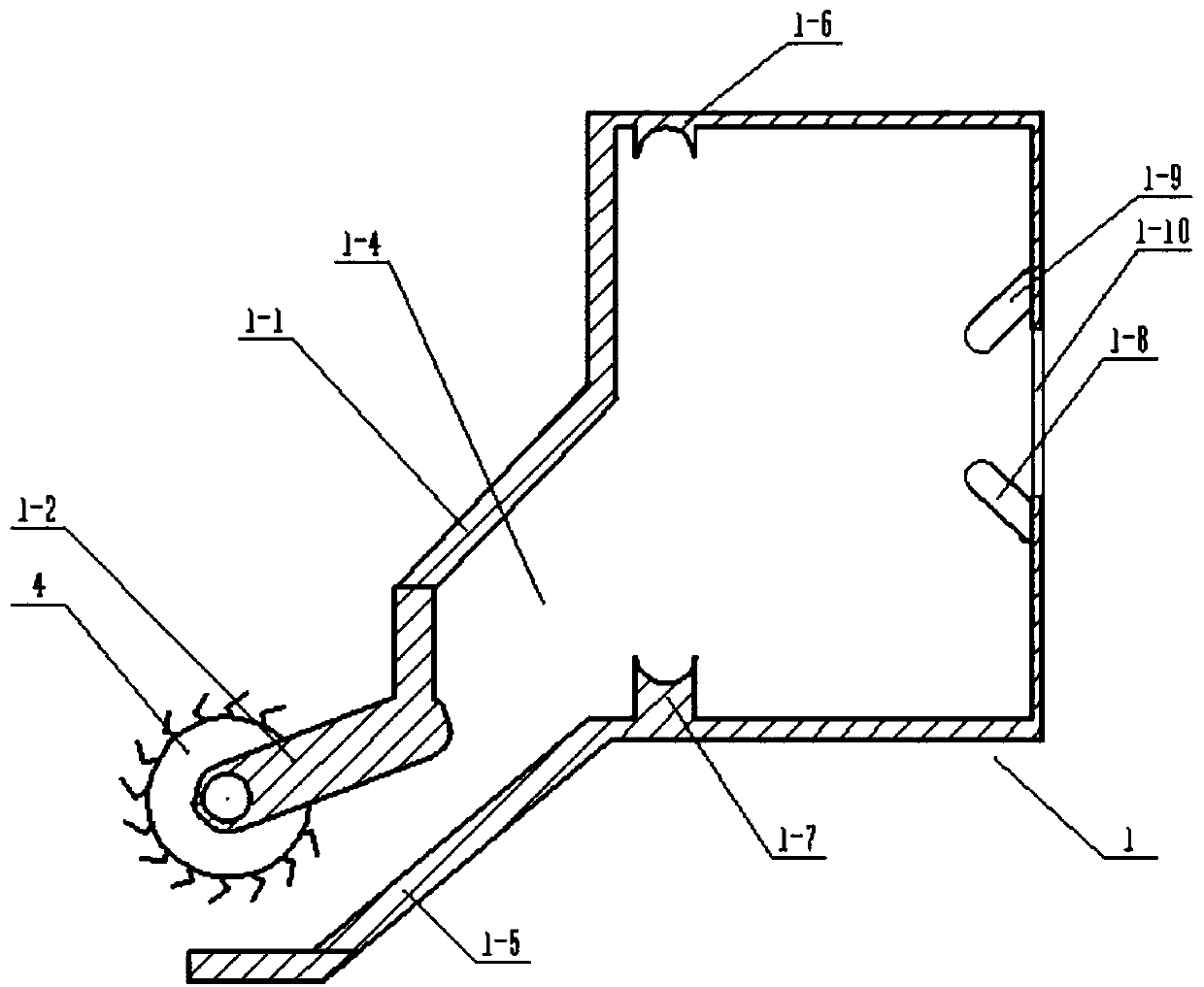

[0033] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain Embodiment 1, the frame assembly 1 includes a frame body 1-1, a push stick bracket 1-2, a frame inner cavity 1-4, and a lower end plate 1 -5, upper side hinged fixing frame 1-6, lower side hinged fixing frame 1-7, lower side hinged connecting frame 1-8, upper side hinged connecting frame 1-9 and rack outlet 1-10, push the stick The bracket 1-2 is fixedly connected to the left end of the rack body 1-1, the rack inner cavity 1-4 is arranged at the inner end of the rack body 1-1, and the lower end plate 1-5 is fixedly connected to the rack body 1-1. 1 The lower side of the left end, the upper side hinged fixing frame 1-6 and the lower side hinged fixing frame 1-7 are respectively fixedly connected to the upper and lower sides of the inner wall of the frame cavity 1-4, the lower side hinged connecting frame 1-8 and the upper side The side hinged connecting frames 1-9 are respectively ...

specific Embodiment approach 3

[0034] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain Embodiment 1, the auxiliary push rod assembly 2 includes an auxiliary frame 2-1, a lower gear 2-2, an auxiliary transmission pulley 2-3, a middle end gear 2- 4. Upper gear 2-5, lower hinged rod 2-6, lower hinged terminal 2-7, left hinged rod 2-8, upper hinged rod 2-9, upper hinged terminal 2-10, upper Side extrusion plate 2-11, two sawtooth push plates 2-12, two push springs 2-13, threaded sleeve 2-14, threaded rotating rod 2-15, rear side hinged pole 2-16 and two The expansion plate 2-17, the upper side extrusion plate 2-11 includes the upper side extrusion plate body 2-11-1, the extrusion plate main chamber 2-11-2, four sleeves 2-11-3 and The spring sleeve 2-11-4, the main cavity 2-11-2 of the extrusion plate is arranged at the inner end of the upper extrusion plate body 2-11-1, and the main cavity 2-11-2 of the extrusion plate does not penetrate the upper Side extrusion plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com