Granulator material feeding mechanism and granulator

A technology of feeding mechanism and granulator, which is applied in the direction of mold extrusion granulation, etc., can solve the problems of material 5 overflow, achieve the effects of lower installation height, easy observation of feeding conditions, and high granule forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

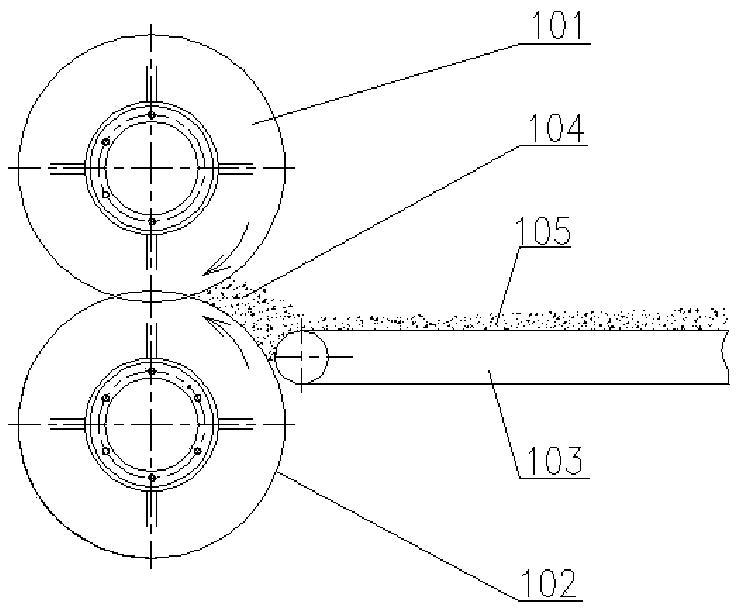

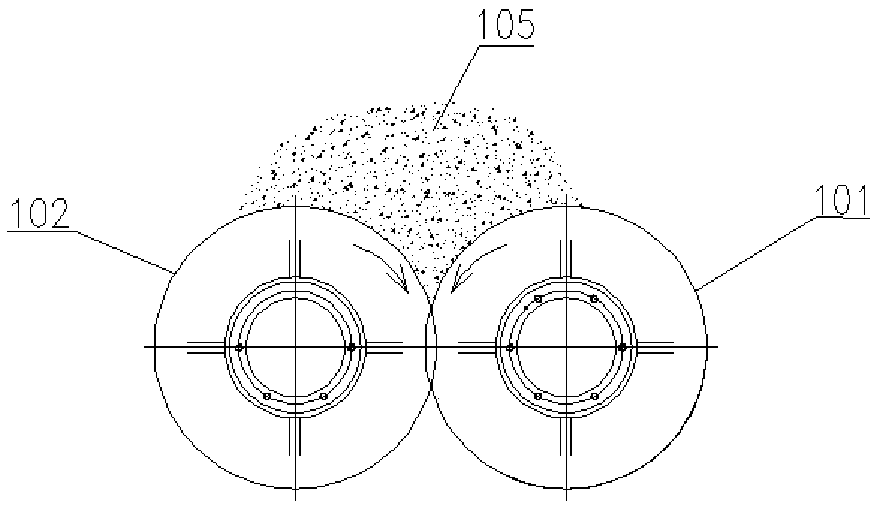

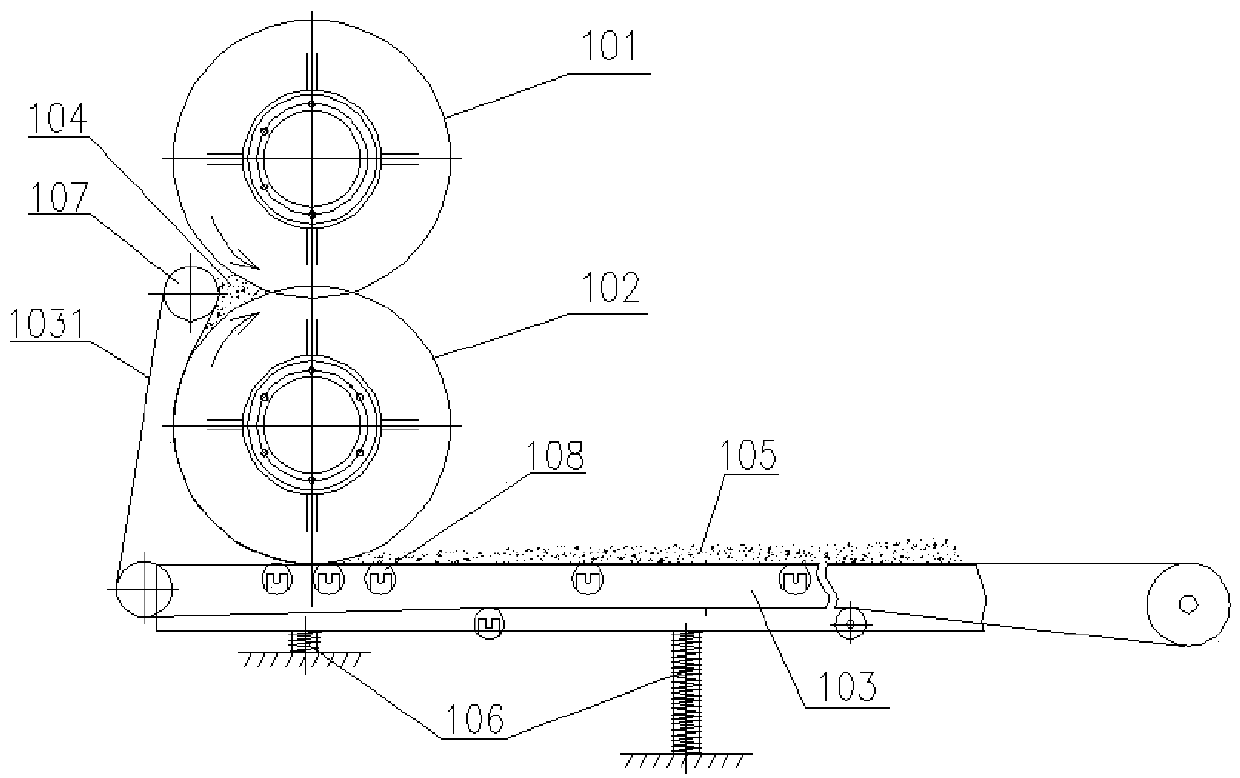

[0031] Such as image 3 As shown, the pellet machine feeding mechanism provided by Embodiment 1 of the present invention includes an upper forming roller 101, a lower forming roller 102 and a conveying device 103;

[0032] The upper forming roll 101 and the lower forming roll 102 are engaged with each other and form a bell mouth feeding area 104, and the conveying device 103 is in contact with the lower forming roll 102 and forms a wrap angle with the lower forming roll 102, so that the lower forming roll 102 and the conveying device 103 The flattened material 105 under co-extrusion is conveyed to the bell mouth feed area 104 .

[0033] It should be noted that the upper forming roll 101 and the lower forming roll 102 may be placed opposite to each other in addition to being placed up and down, and may also be placed facing each other front and back.

[0034] Specifically, an elastic member 106 is installed at the bottom of the conveying device 103 , and the tension between th...

Embodiment 2

[0037] The pellet machine feeding mechanism provided in this embodiment two is a further improvement on the pellet machine feeding mechanism provided in embodiment one, in embodiment one and image 3 On the basis of the above, the pellet machine feeding mechanism provided in the second embodiment includes an upper forming roller 101, a lower forming roller 102 and a conveying device 103;

[0038] The upper forming roll 101 and the lower forming roll 102 are engaged with each other and form a bell mouth feeding area 104, and the conveying device 103 is in contact with the lower forming roll 102 and forms a wrap angle with the lower forming roll 102, so that the lower forming roll 102 and the conveying device 103 The flattened material 105 under co-extrusion is conveyed to the bell mouth feed area 104 .

[0039] It should be noted that the upper forming roll 101 and the lower forming roll 102 may be placed opposite to each other in addition to being placed up and down, and may a...

Embodiment 3

[0046] The granulator feeding mechanism provided in the third part of this embodiment is a further improvement on the granulator feeding mechanism provided in the first embodiment. image 3 On the basis of the above, the feeding mechanism of the granulator provided in the third embodiment includes an upper forming roller 101, a lower forming roller 102 and a conveying device 103;

[0047]The upper forming roll 101 and the lower forming roll 102 are engaged with each other and form a bell mouth feeding area 104, and the conveying device 103 is in contact with the lower forming roll 102 and forms a wrap angle with the lower forming roll 102, so that the lower forming roll 102 and the conveying device 103 The flattened material 105 under co-extrusion is conveyed to the bell mouth feed area 104 .

[0048] It should be noted that the upper forming roll 101 and the lower forming roll 102 may be placed opposite to each other in addition to being placed up and down, and may also be pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com