An electroplating fixture

A technology of electroplating fixtures and balance bars, applied in the direction of electrolytic components, electrolytic process, etc., can solve the problems of electroplating solution residue, inconvenient, inaccessible electroplating solution, etc., and achieve the effect of increasing utilization rate and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

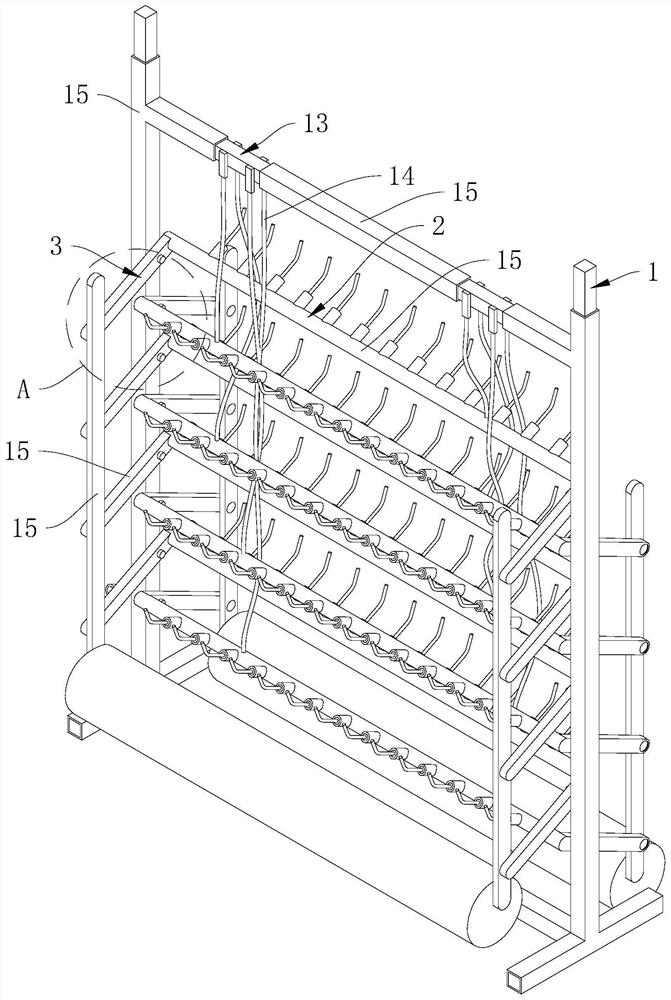

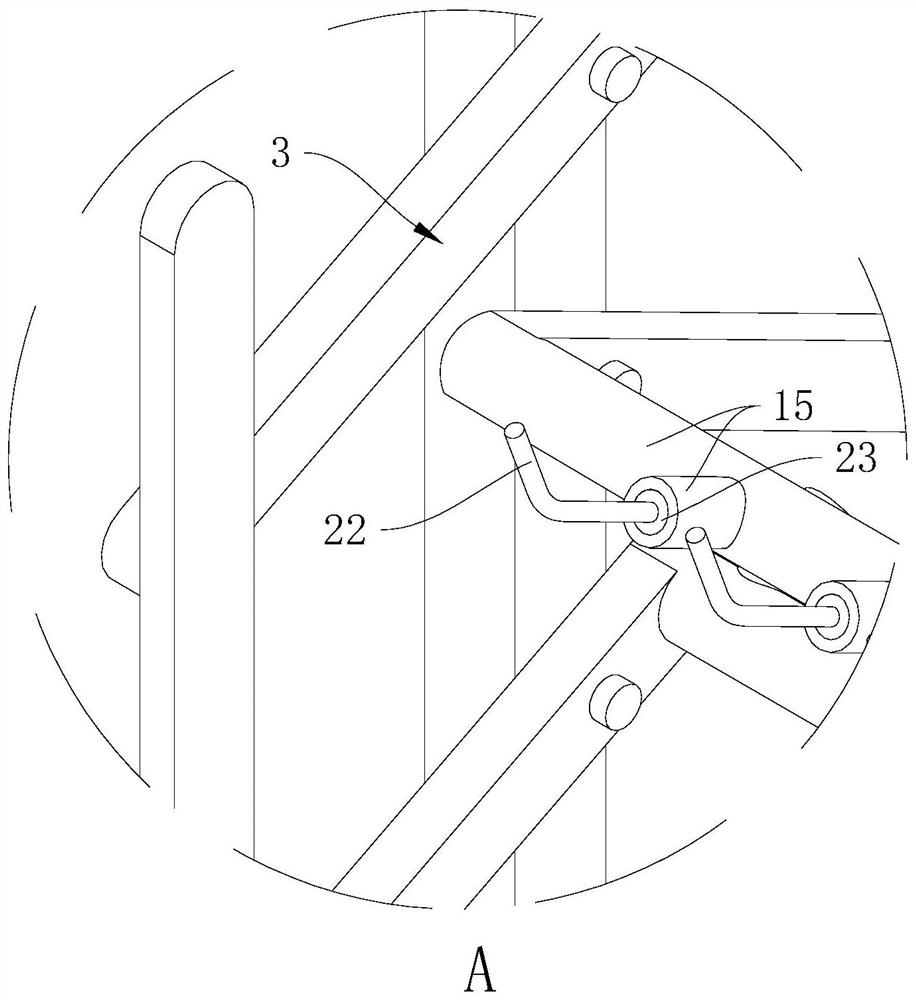

[0041] An electroplating fixture, such as figure 2 As shown, it includes a frame body 1 , a movable part 3 arranged on the frame body 1 , and a fixing part 2 arranged on the movable part 3 .

[0042] Such as Figure 4 As shown, the frame body 1 includes a horizontally arranged I-shaped underframe 11, two vertical rods 12 vertically fixed on the underframe 11, and an I-shaped conductive frame 13 vertically fixed on the upper ends of the vertical rods 12. . Two vertical rods 12 are respectively fixed on both sides of the chassis 11, and the vertical rods 12 and the conductive frame 13 are located on the same vertical plane. The conductive frame 13 includes two vertical sections 131 parallel to the two vertical bars 12, a horizontal section 132 connecting the two vertical sections 131, and the horizontal section 132 is connected with a wire 14 (see figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com