Transporting equipment of stones for repairing road

A technology for transportation equipment and stones, which is applied in the field of stone transportation equipment for road repairs, and can solve the problems of stone residues and inconvenient pouring of stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

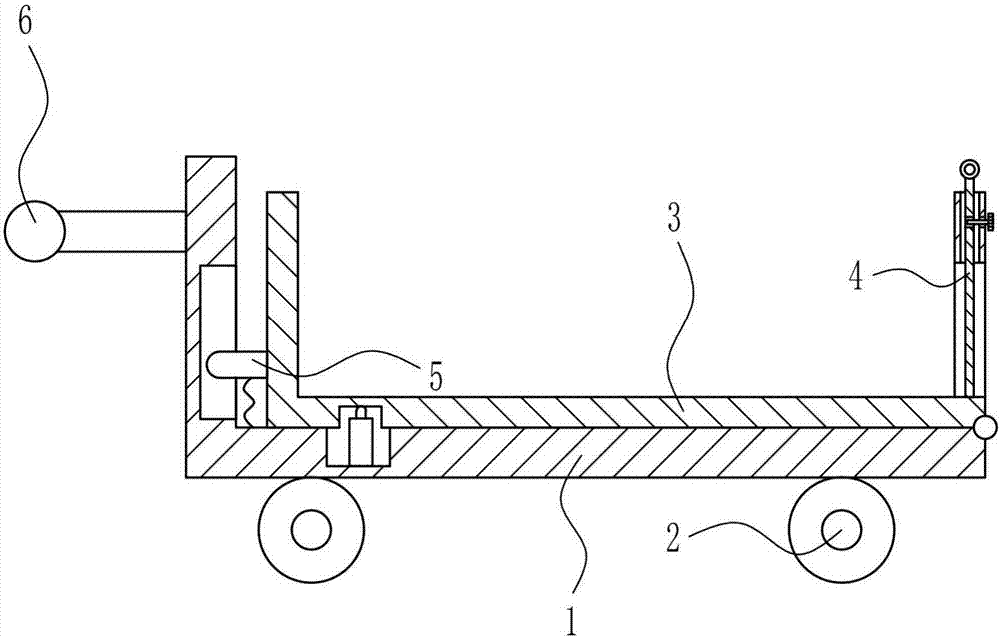

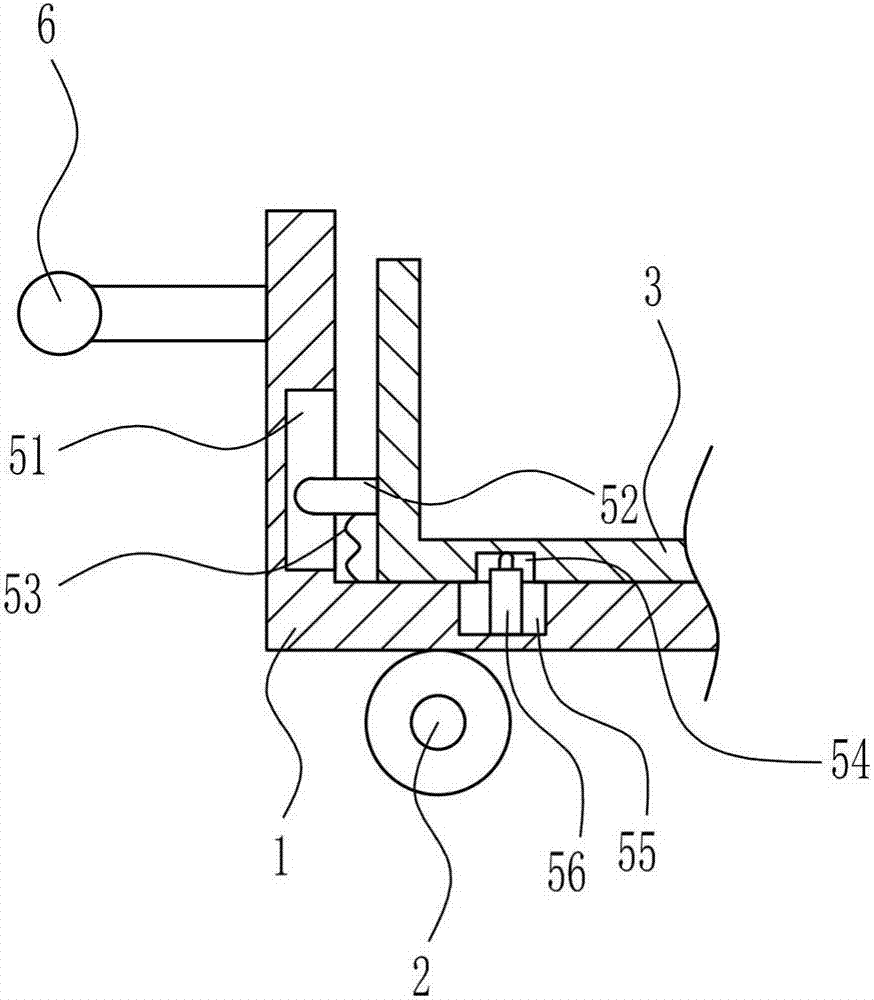

[0029] A kind of gravel transportation equipment for road repair, such as Figure 1-5 As shown, it includes a car body 1, wheels 2, frame body 3, discharge device 4, lifting device 5 and T-shaped push rod 6, the bottom of the car body 1 is symmetrically arranged with wheels 2, and the inner bottom of the car body 1 passes through the lifting device. 5 is connected with a frame body 3, a discharge device 4 is provided on the right wall of the frame body 3, and a T-shaped push rod 6 is provided on the upper left side of the car body 1.

Embodiment 2

[0031] A kind of gravel transportation equipment for road repair, such as Figure 1-5 As shown, it includes a car body 1, wheels 2, frame body 3, discharge device 4, lifting device 5 and T-shaped push rod 6, the bottom of the car body 1 is symmetrically arranged with wheels 2, and the inner bottom of the car body 1 passes through the lifting device. 5 is connected with a frame body 3, a discharge device 4 is provided on the right wall of the frame body 3, and a T-shaped push rod 6 is provided on the upper left side of the car body 1.

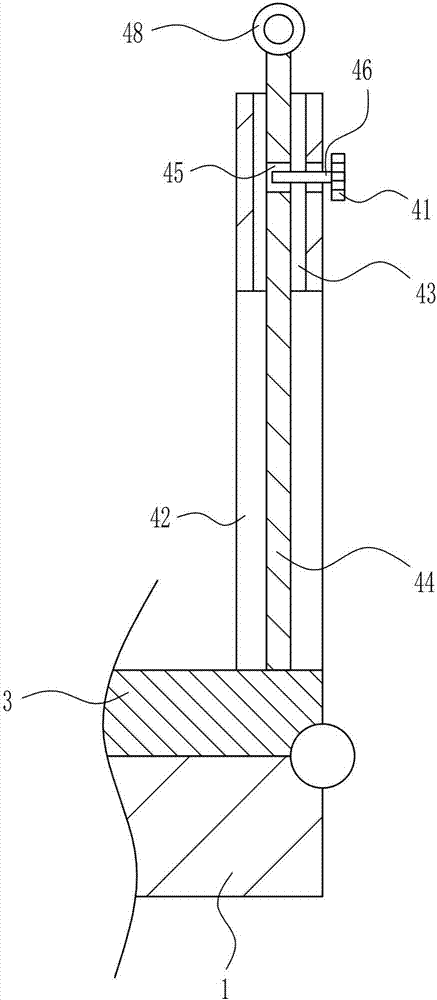

[0032] The discharge device 4 includes a rubber sleeve 41, a baffle plate 44 and a bolt 46. The lower part of the right wall of the frame body 3 has a discharge hole 42, and the upper part of the right wall of the frame body 3 has a first guide hole 43. The first guide hole 43 is connected with the A baffle plate 44 is placed in the discharge hole 42, and the upper part of the baffle plate 44 and the right wall of the frame body 3 on the upper r...

Embodiment 3

[0034] A kind of gravel transportation equipment for road repair, such as Figure 1-5 As shown, it includes a car body 1, wheels 2, frame body 3, discharge device 4, lifting device 5 and T-shaped push rod 6, the bottom of the car body 1 is symmetrically arranged with wheels 2, and the inner bottom of the car body 1 passes through the lifting device. 5 is connected with a frame body 3, a discharge device 4 is provided on the right wall of the frame body 3, and a T-shaped push rod 6 is provided on the upper left side of the car body 1.

[0035] The discharge device 4 includes a rubber sleeve 41, a baffle plate 44 and a bolt 46. The lower part of the right wall of the frame body 3 has a discharge hole 42, and the upper part of the right wall of the frame body 3 has a first guide hole 43. The first guide hole 43 is connected with the A baffle plate 44 is placed in the discharge hole 42, and the upper part of the baffle plate 44 and the right wall of the frame body 3 on the upper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com