Steel-plastic geo-grid network connecting device

A technology of geogrid and connecting device, applied in soil protection, infrastructure engineering, roads, etc., can solve the problems of grid belt connection parts being broken, wire drawing, grid mesh displacement, etc., to improve the reinforcement quality, Improve the integrity and continuity, avoid the effect of concentrated stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation

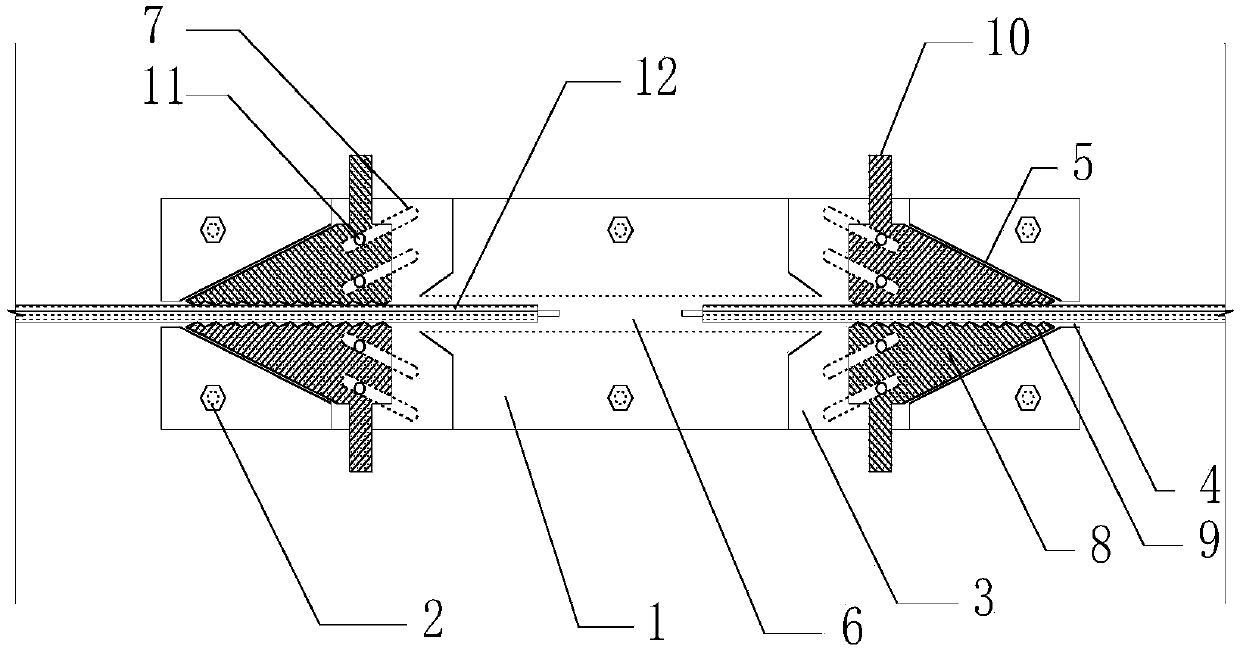

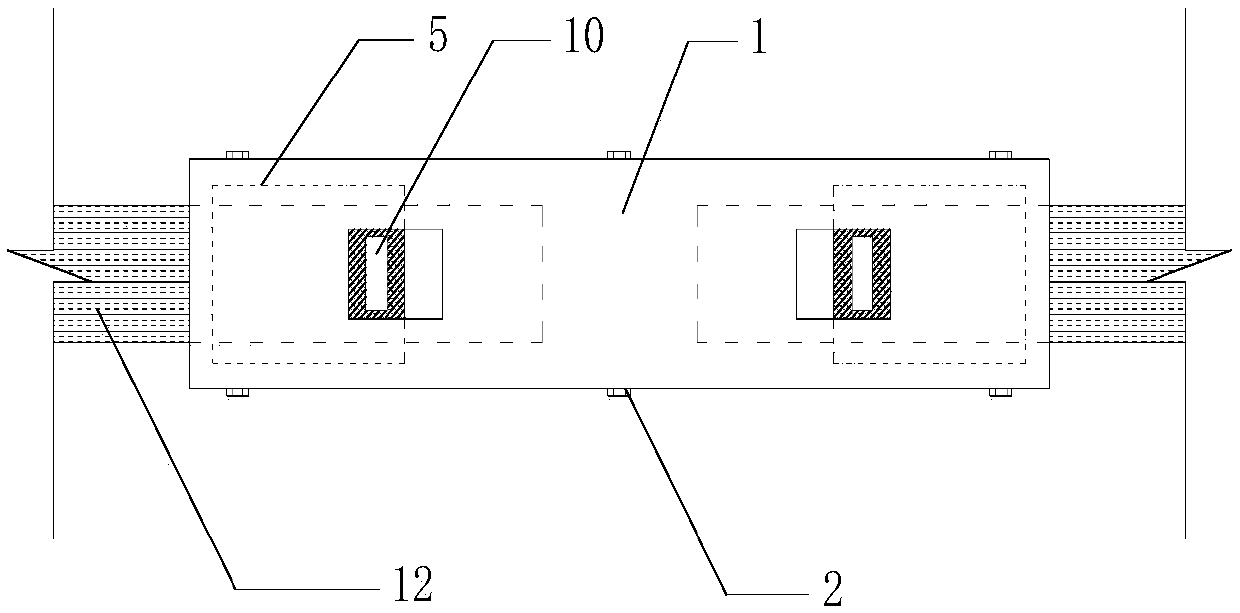

[0014] exist figure 1 Among them, the shell body (1) is provided with a clip chamber (3), a socket (4) and a communication groove (6), the socket (4) communicates with the communication groove (6), and the geogrid joint (12) can pass through The socket (4) and the connecting groove (6), the clip chamber (3) are provided with a clip groove (5) and a sliding groove (7), and the taper of the clip groove (5) is the same as the curvature of the clip (8) , used to clamp the clip (8), so that the clip (8) generates a bite force, thereby tightly clamping the geogrid joint (12), the width of the sliding groove (7) is slightly larger than the outer surface of the sliding shaft (11) Diameter, the sliding shaft (11) can be snapped into the sliding groove (7) and slide freely in the sliding groove (7). There are 8 sliding grooves (7) on a single shell body (1), such as figure 1 shown. Each clip chamber (3) is equipped with 2 clips (8). The clips (8) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com