Flue gas plume removing system and plume removing method thereof

A flue gas and dewhitening technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high countercurrent tower height, easy height limitation, and large countercurrent resistance, etc. Dry bulb temperature, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

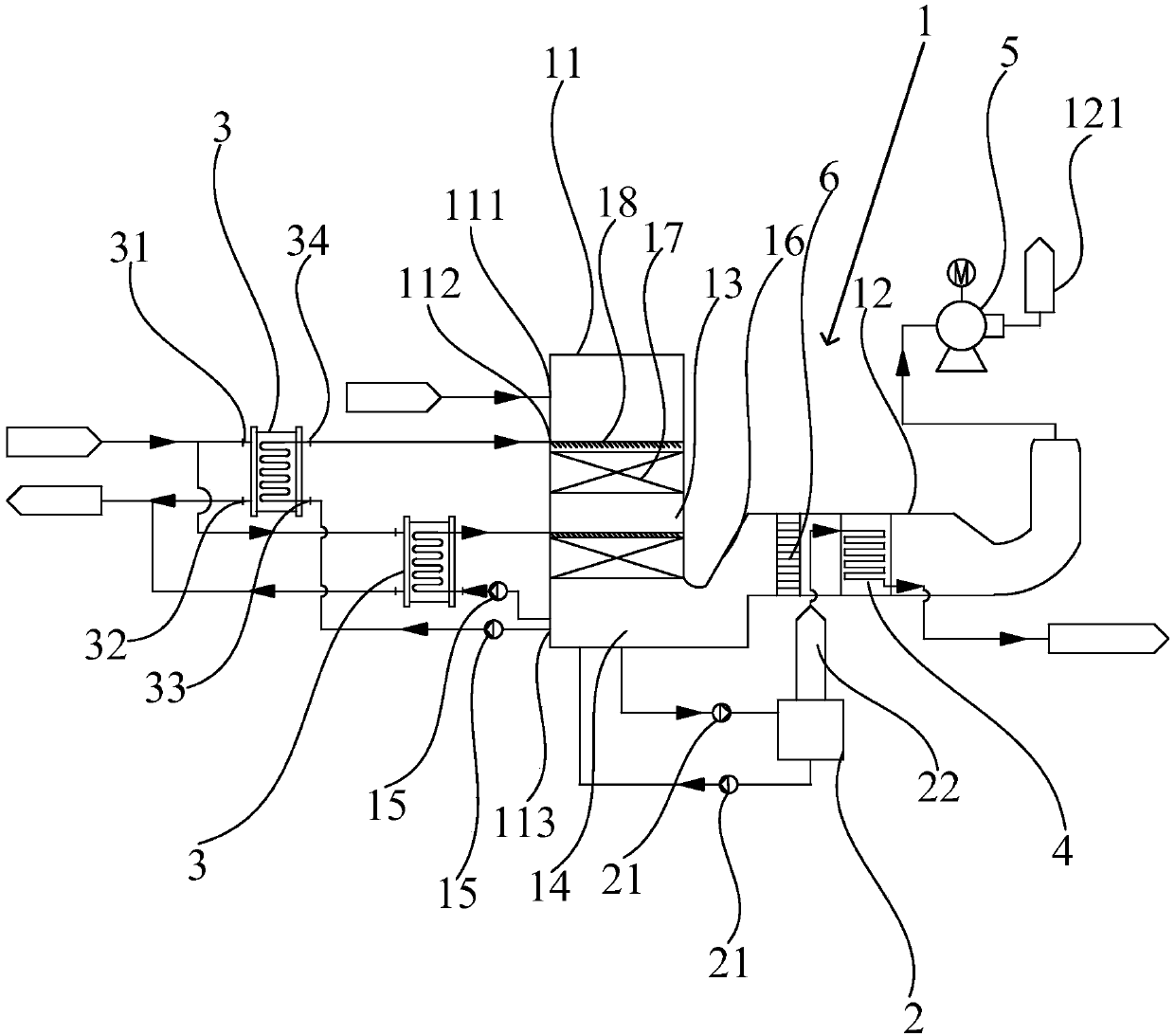

[0064] Such as figure 1 As shown, this embodiment discloses a flue gas de-whitening system, the flue gas de-whitening system includes a de-whitening tower 1 and a regeneration device 2, the de-whitening tower 1 includes a downstream part 11 and a cross-current part 12, the downstream part The top of 11 is provided with a smoke inlet 111 , one end of the cross-flow part 12 is connected to the bottom of the downstream part 11 , and the other end of the cross-flow part 12 is provided with a smoke outlet 121 . The flue gas to be dewhitened enters into the dewhitening tower 1 through the flue gas inlet 111, moves downstream from top to bottom at the upper end of the downstream part 11, and then enters the cross-flow part 12, moves cross-flow in the cross-flow part 12 and flows from The flue gas outlet 121 is discharged. The flue gas is discharged after passing through the downstream part 11 and the cross-flow part 12, the wind speed is low, the power consumption is low, the height...

Embodiment 2

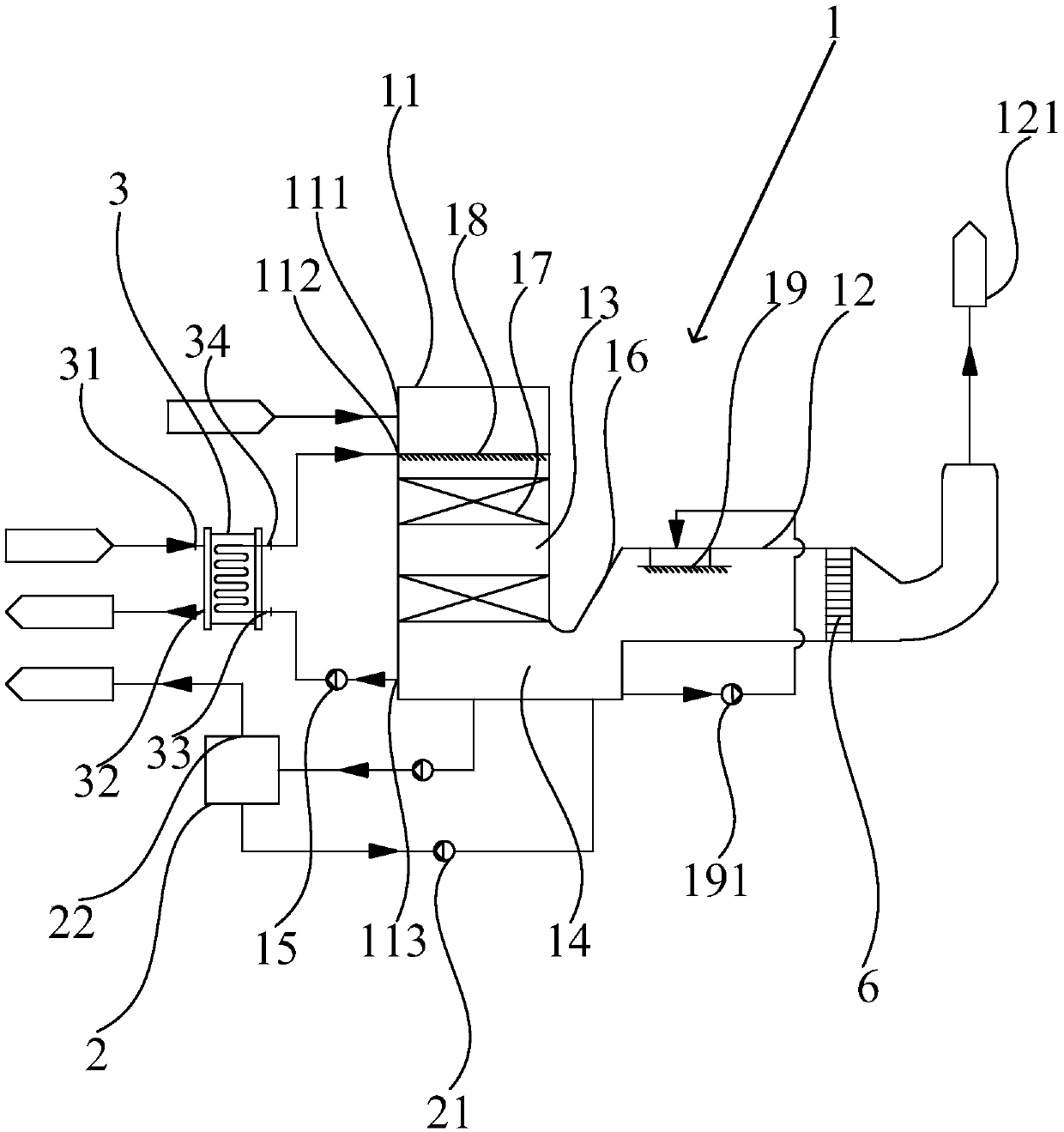

[0086] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that in the flue gas de-whitening system of this embodiment, at least one second solution spraying device 19 is arranged in the cross flow part 12, and the second solution spraying device 19 is connected to the top of the cross-flow part 12, and the second solution spraying device 19 communicates with the solution storage area 14 through a pipeline, and a third solution pump 191 is provided on the pipeline. Through the second solution spraying device 19, the flue gas is directly and fully contacted with the solution again to ensure the removal of water vapor in the flue gas, further enhancing the effect of removing white feathers from the flue gas. After the solution is in contact with the flue gas, it will flow to the solution storage area 14 through the guide part 16, so as to achieve the effect of circulation on the whitening of the flue gas. At the same time, the pressure of the ...

Embodiment 3

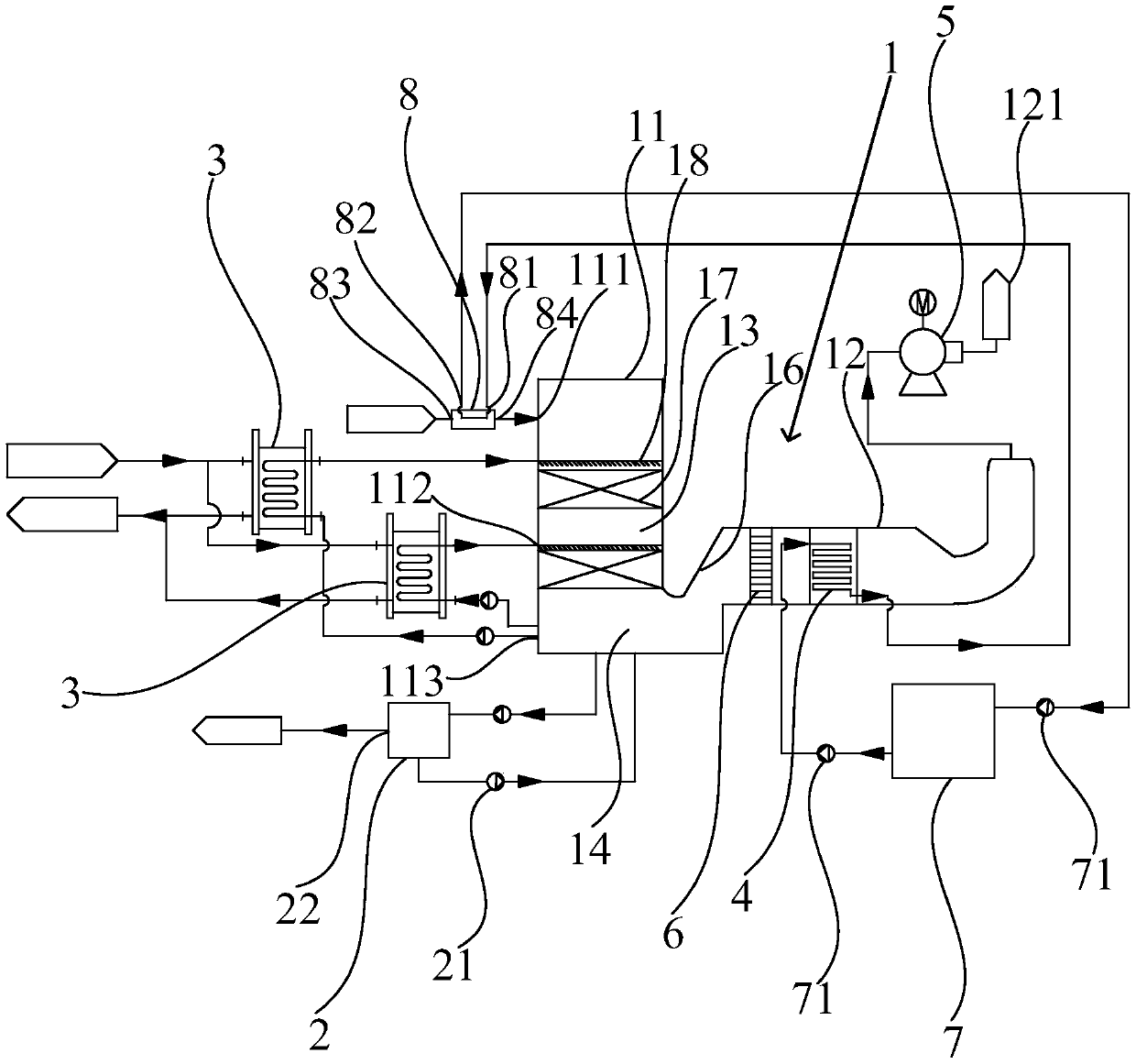

[0090] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that, in the flue gas whitening system of this embodiment, the heat source outlet 22 of the regeneration device 2 is not connected to the flue gas reheater 4, and the regeneration device 2 The secondary steam generated in the process is directly utilized and recovered.

[0091] The flue gas whitening system also includes a flue gas preheater 8 and a water tank 7. The outer wall of the flue gas preheater 8 is provided with a water inlet 81, a water outlet 82, an air inlet 83 and an air outlet 84, and the air outlet 84 is connected to The flue gas inlet 111 is connected to the whitening tower 1, the water inlet 81 is connected to the flue gas reheater 4, the water outlet 82 is connected to the water tank 7, the flue gas preheater 8, the water tank 7 and the flue gas reheater 4 They are connected and form a circulating water circuit. Water is stored in the water tank 7, and the water ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com