A length detection device for finished metal round tubes

A detection device and a circular tube technology, applied in the direction of solid separation, sorting, grading, etc., can solve the problems of large error rate and increase labor intensity, and achieve the effect of ingenious and reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

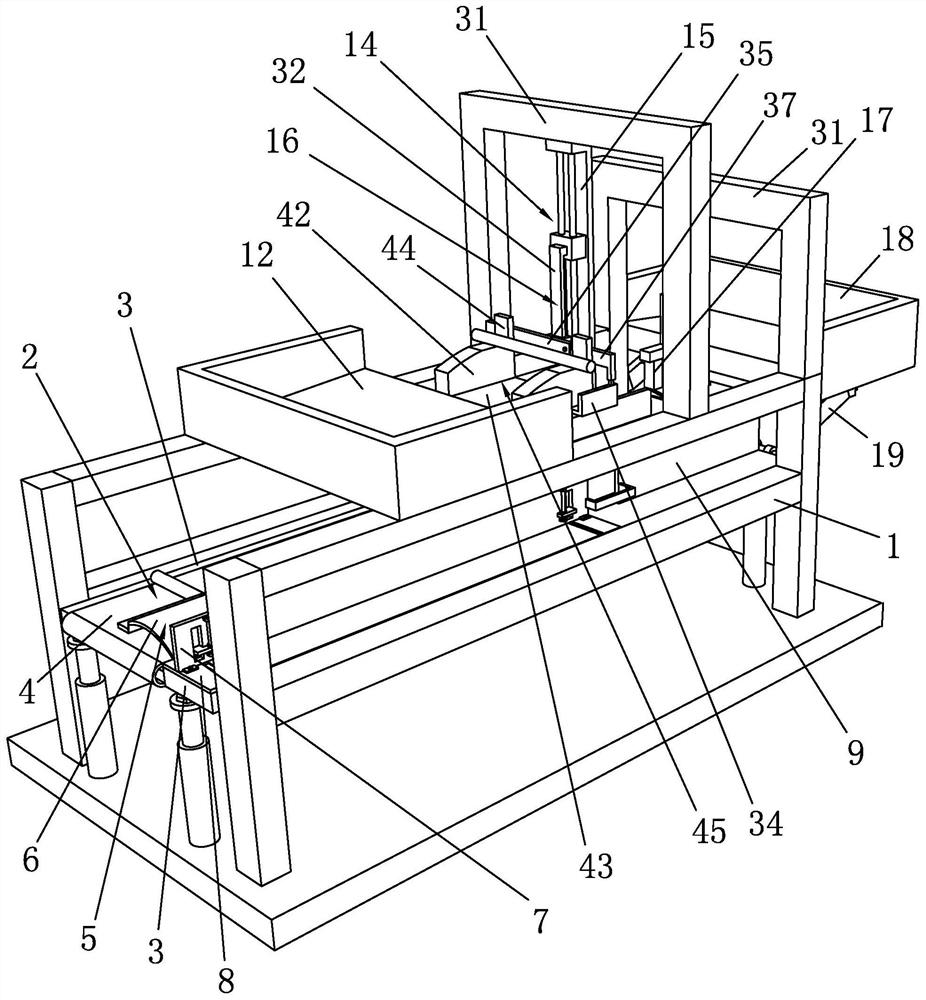

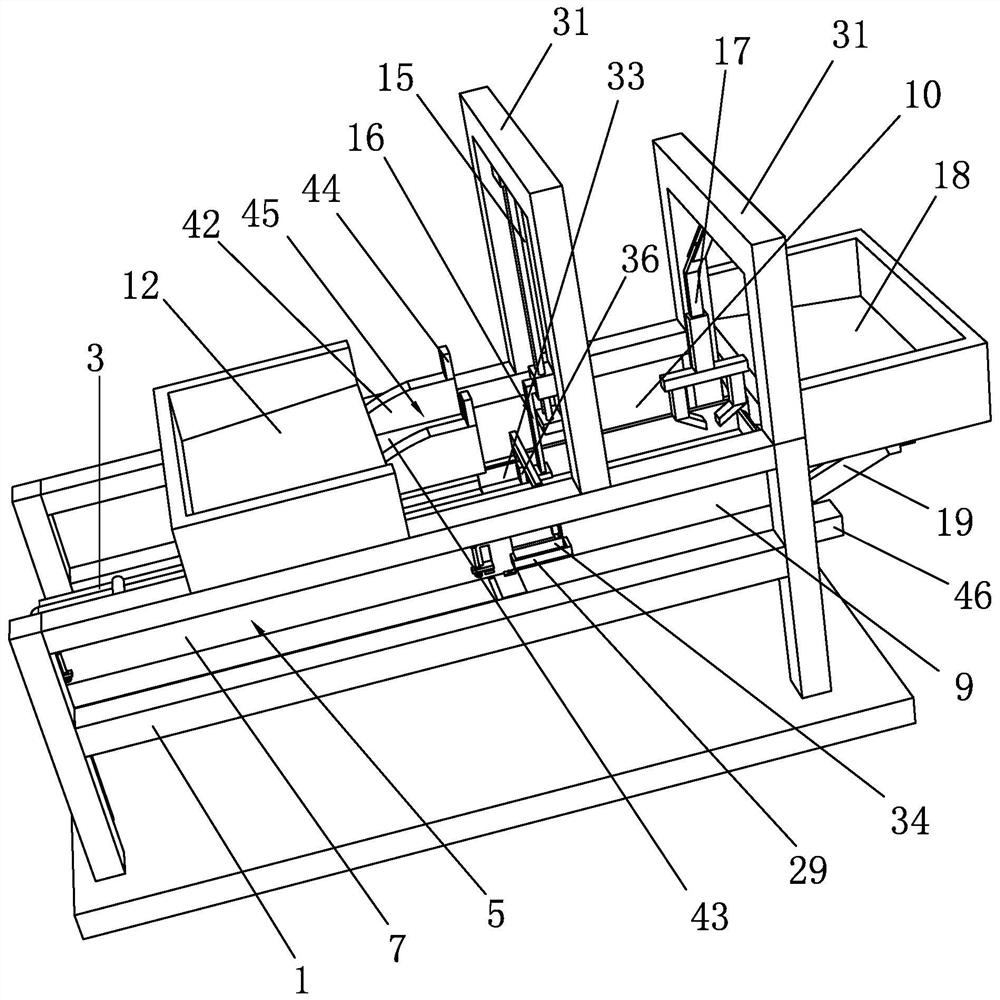

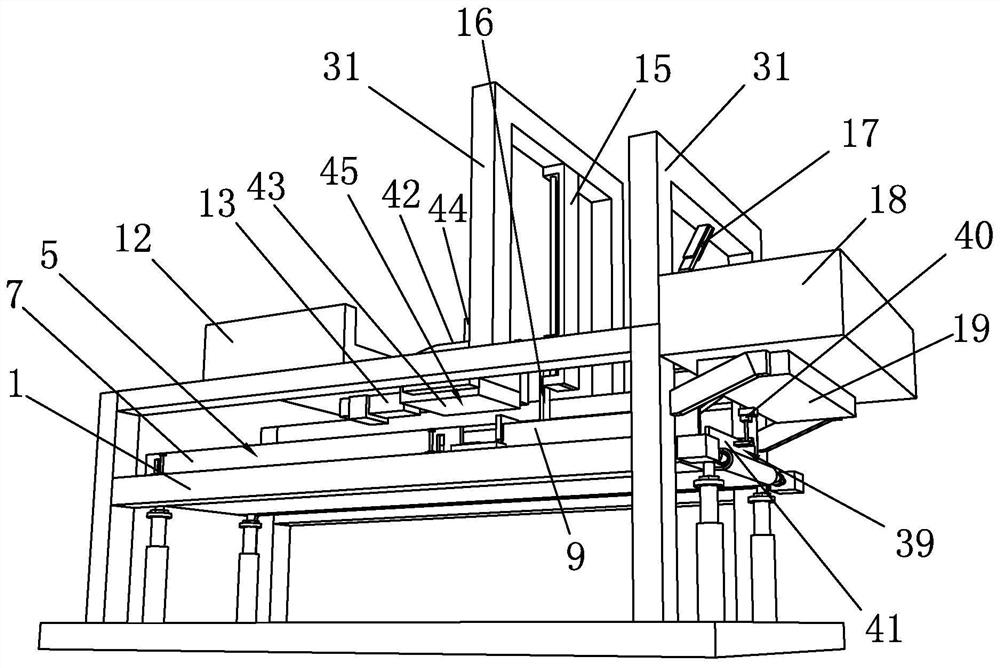

[0030] Such as Figure 1 to Figure 6 As shown, it is a length detection device for a metal round tube product of the present invention, including a limit frame 1 and a transmission platform 2, the transmission platform 2 runs through the limit frame 1, the transmission platform 2 includes a frame 3 and a conveyor belt group 4, and the conveyor belt group 4 on rack 3. The conveyor belt set 4 is driven by a driving motor 46 to realize the delivery of the round pipes on the conveyor belt set 4 .

[0031] The transfer table 2 is provided with a positioning and flattening device 5, the positioning and flattening device 5 includes a pressing plate 6, a vertical adjustment plate 7, a horizontal adjustment plate 8 and an auxiliary side plate 9, the pressing plate 6 is connected with the vertical adjustment plate 7, The vertical adjustment plate 7 is provided with a vertical adjustment groove 20, and the pressing plate 6 is provided with an adjustment block 21. The adjustment block 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com