Offshore working ship with variable balance wing

A technology of balance wings and work boats, which is applied in the direction of using hydrofoils to act on the surrounding water to reduce ship motion, ship safety, and equipment to reduce ship motion. Short and other problems, to achieve the effect of improving the ability of special operations at sea, increasing the resistance of the hull to lateral stress, and improving the overall balance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

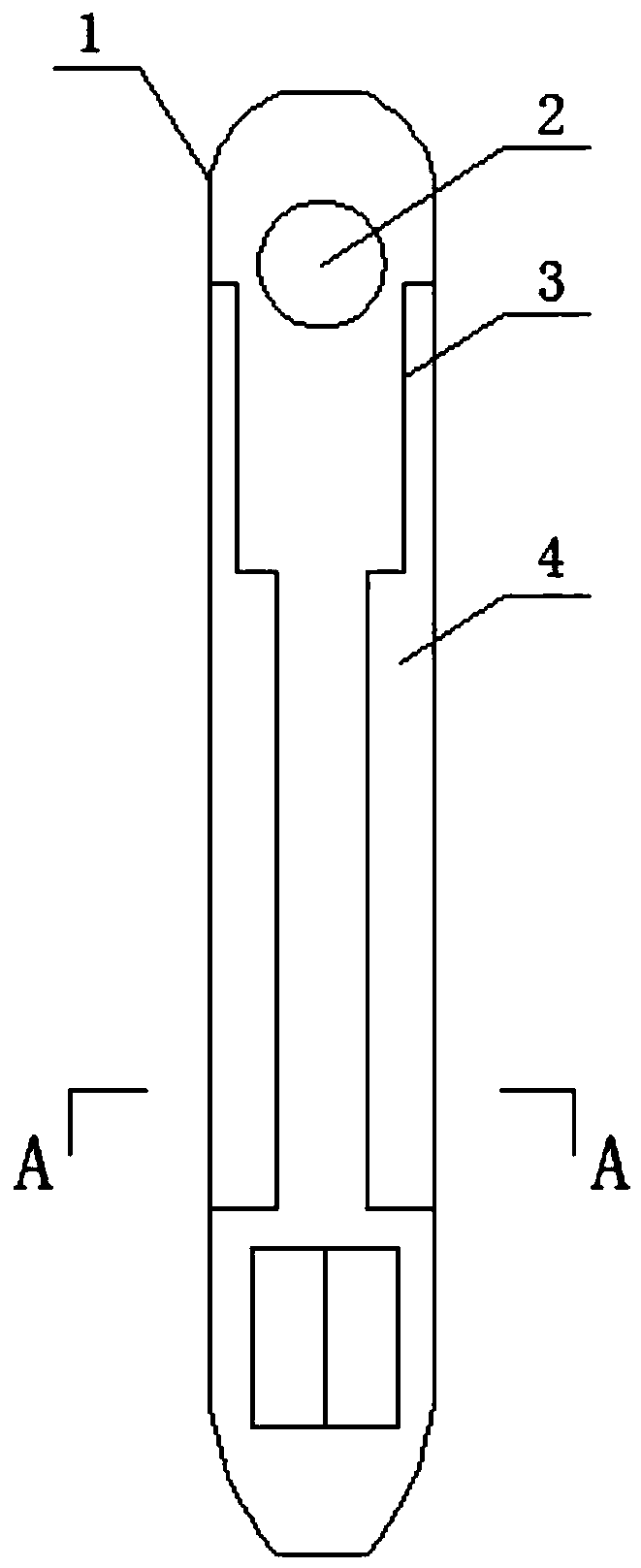

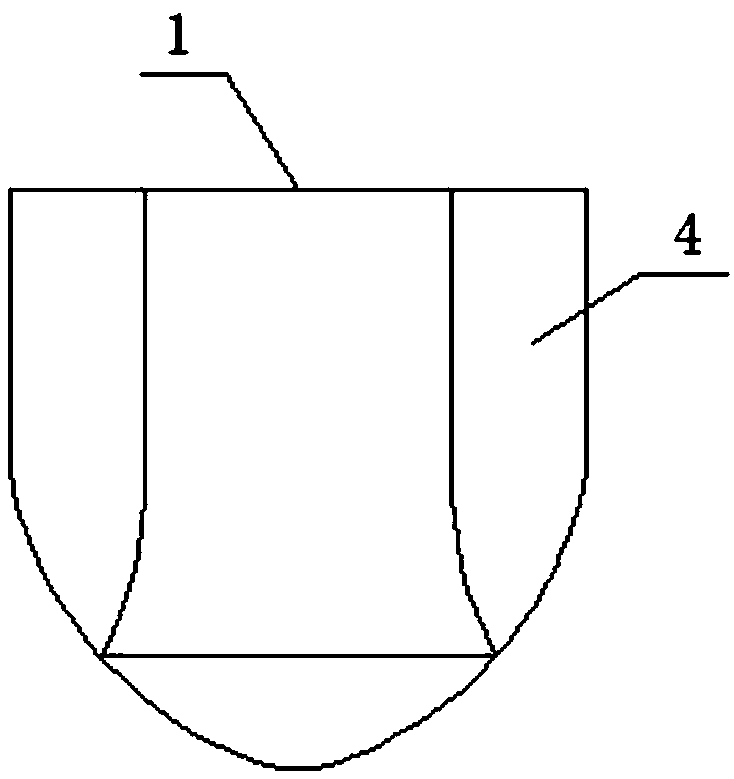

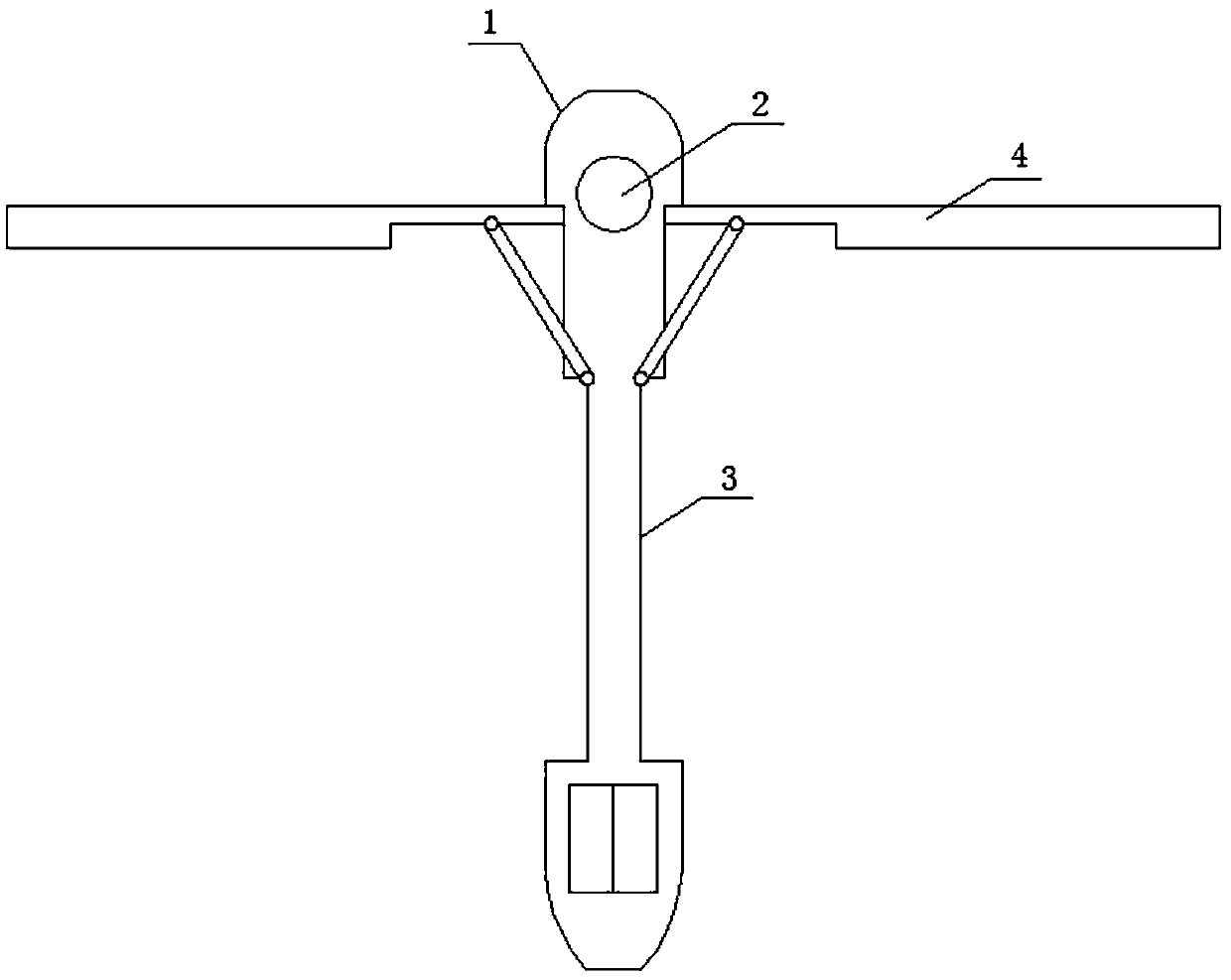

[0021] exist Figure 4 , 5 In the structure shown in , 6, the variable balance wing offshore operation ship provided by the present invention is specifically applied to the crane ship, and the rotating platform base is set on the working platform 2, and the boom 5 is set on the rotating platform base. , the counterweight 6 is set movable on the balance wing 4, and the base of the rotating platform is connected with the counterweight 6 through the traction cable mechanism 7. seat rotation) counterweight 6 moves in the opposite direction to achieve counterweight balance, that is, when the boom 5 rotates clockwise, the counterweight on the left balance wing moves outward, and the counterweight on the right balance wing moves inward Move to achieve counterweight balance and vice versa.

[0022] The variable balance wing marine operation ship provided by the present invention is not only used on crane ships, but also can be applied to engineering work ships such as dredgers, pili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com