Aramide primary amine fluorescent whitening agent suitable for silk and preparation method thereof

A technology of fluorescent whitening agent and primary aramide, applied in chemical instruments and methods, luminescent materials, organic chemistry, etc., can solve the problems of poor washing fastness and few varieties of fluorescent whitening agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

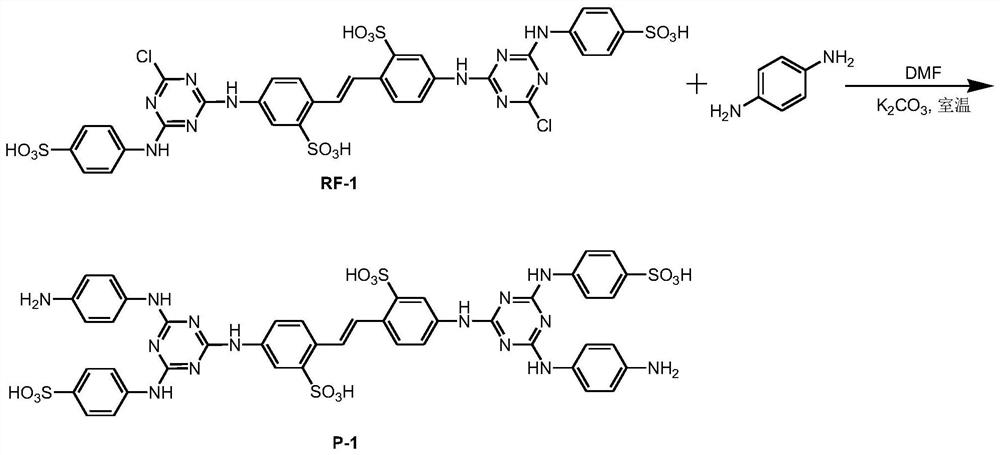

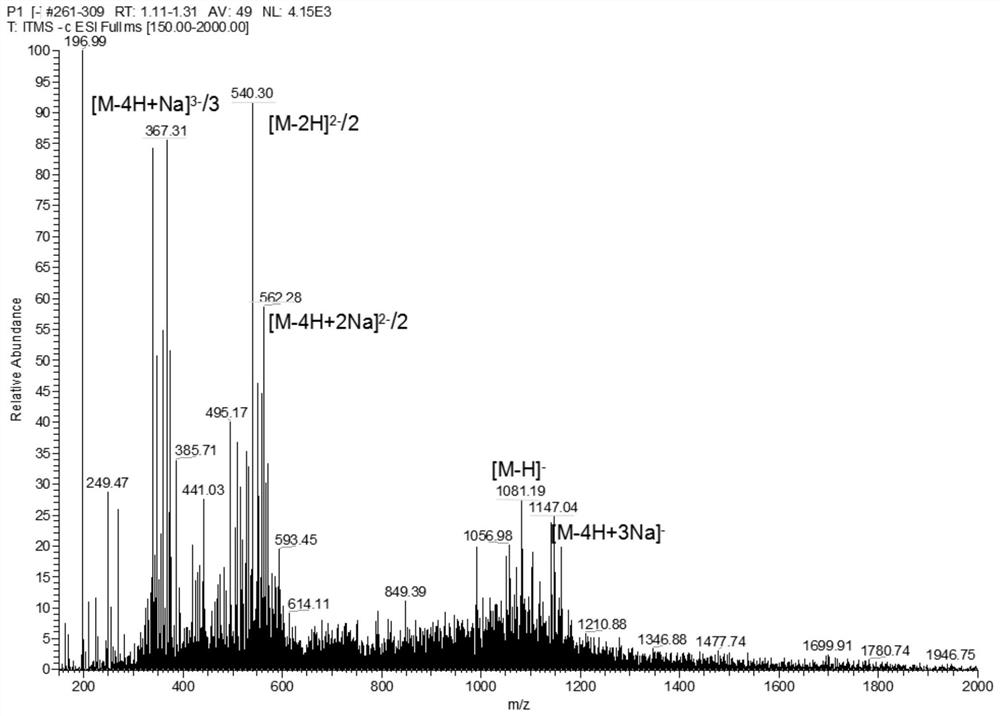

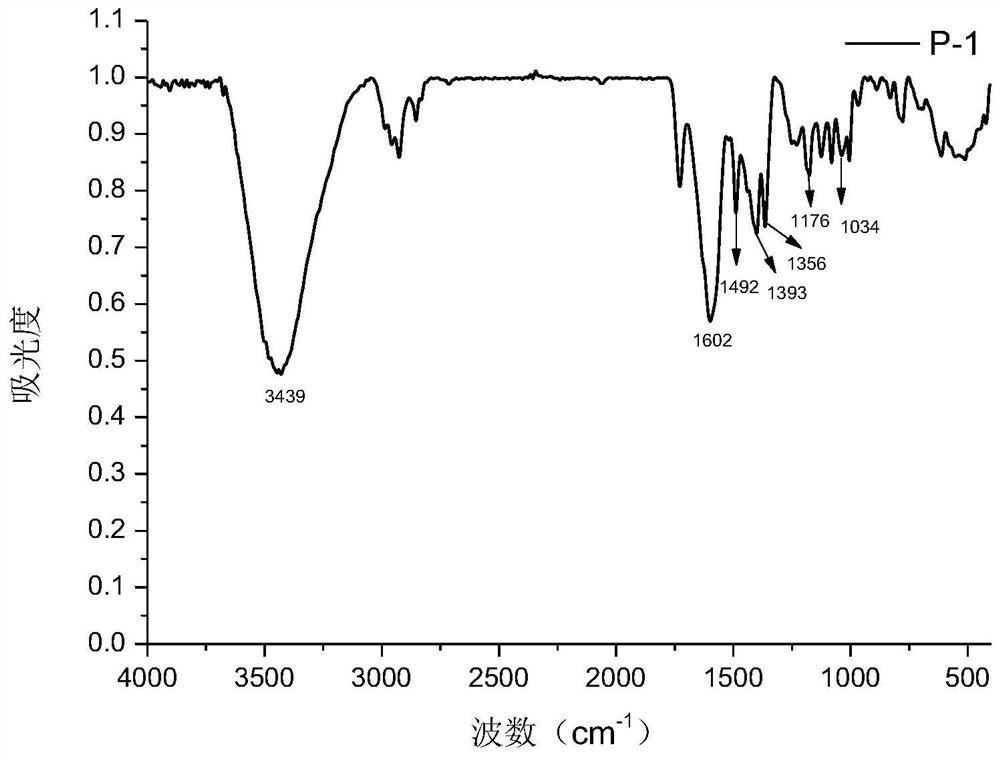

[0039] Embodiment 1, fluorescent whitening agent P-1,

[0040]

[0041] The synthetic route of fluorescent whitening agent P-1 is as follows figure 1 Shown, its preparation method is specifically as follows:

[0042] Under ice bath conditions, weigh RF-1 (CAS: 33963-93-8) (5.41g, 5mmol), anhydrous potassium carbonate (1.39g, 10mmol) in a 250mL three-necked flask, and replace with nitrogen (vacuum / Nitrogen replacement was repeated 3 times to remove oxygen and water vapor), after N 2 Add p-phenylenediamine (2.16g, 20mmol) under protection and stirring conditions, and then add 30mL of anhydrous DMF as a solvent for reaction. After 1 hour of reaction, remove the ice bath, and react at room temperature (15-25°C) for 23 hours in light; Filter out the salt, add 90ml of acetone to the gained filtrate so that the solid is precipitated, leave to stand for 0.5h and filter, the gained filter cake is rinsed with ethyl acetate (10ml×3) to remove excess p-phenylenediamine, and the gain...

Embodiment 2

[0055] Embodiment 2, fluorescent whitening agent P-2

[0056]

[0057] The synthetic route of fluorescent whitening agent P-2 is as follows Figure 6 Shown, its preparation method is specifically as follows:

[0058] Under ice-bath conditions, weigh RF-2 (CAS: 2116527-08-1) (5.24g, 0.005mol), anhydrous potassium carbonate (1.39g, 0.01mol) in a 250mL three-necked flask, and replace with nitrogen (pumping Vacuum / nitrogen replacement was repeated 3 times to remove oxygen and water vapor), after N 2 Under protection and stirring conditions, p-phenylenediamine (2.16 g, 0.02 mol) was added, and then 30 mL of anhydrous DMF was added as a solvent for reaction. After 1 h of reaction, the ice-water bath was removed, and the reaction was carried out at room temperature for 23 h in light. After the reaction was completed, the solution obtained from the reaction was filtered to remove salt, and the obtained filtrate was added with 90ml of acetone to precipitate the solid. After standi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com