Flame-retardant and anti-ultraviolet nylon fabric and its preparation method

A nylon fabric and anti-ultraviolet technology, which is applied in the direction of flame-retardant fibers, textiles, papermaking, fiber types, etc., can solve the problems of poor flame-retardant and anti-ultraviolet effects of nylon fabrics, and achieve improved anti-ultraviolet and anti-aging properties, raw materials Environmentally friendly and easy to obtain, the effect of improving the anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

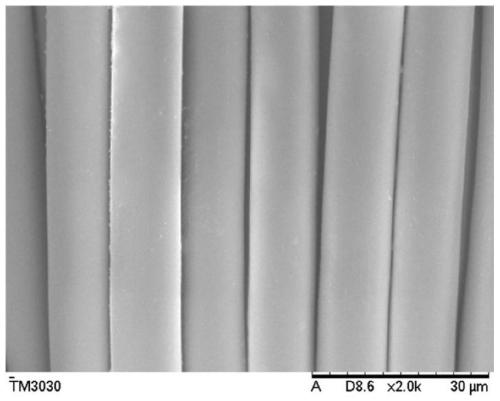

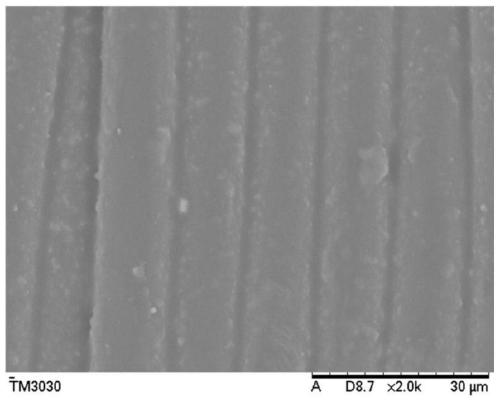

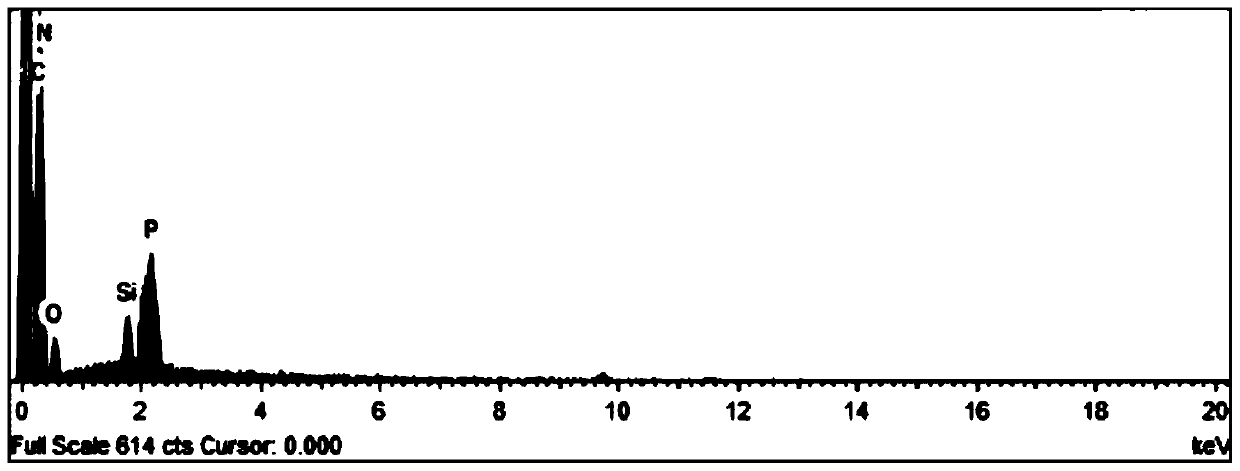

Image

Examples

Embodiment 1

[0042] A method for preparing a flame-retardant and anti-ultraviolet nylon fabric, the specific preparation steps are as follows:

[0043] (1) According to the bath ratio of 1:80, adopt the dopamine aqueous solution with a pH value of 8.5 to impregnate and finish the washed nylon fabric to obtain dopamine-modified nylon fabric, wherein the immersion temperature is 50 ° C, the immersion time is 20h, and the concentration of the dopamine aqueous solution is 1g / L.

[0044] (2) The dopamine-modified nylon fabric was impregnated with KH550 solution, and the modified nylon fabric modified by KH550 was obtained after drying. , The solvent in the KH550 solution is a mixed solution of ethanol and water (mass ratio is 7:3).

[0045] (3) The modified nylon fabric modified with CEPPA solution padding KH550 is used to obtain the flame-retardant and anti-ultraviolet nylon fabric, wherein the padding finishing adopts the mode of two dipping and two rolling, and the pre-drying temperature is...

Embodiment 2

[0050] A method for preparing a flame-retardant and anti-ultraviolet nylon fabric, the specific preparation steps are as follows:

[0051] (1) According to the bath ratio of 1:80, the dopamine aqueous solution with a pH value of 8.5 was used to impregnate and finish the washed nylon fabric to obtain a dopamine-modified nylon fabric. 1g / L.

[0052] (2) After impregnating and finishing the dopamine-modified nylon fabric with KH550 solution, dry it to obtain the modified nylon fabric modified by silane coupling agent, wherein the immersion temperature is 70°C, the immersion time is 2h, and the concentration of KH550 solution is 120g / L. Drying, the solvent in the KH550 solution is a mixed solution of ethanol and water (mass ratio is 3:1).

[0053] (3) The modified nylon fabric modified by the silane coupling agent is obtained by padding with CEPPA solution to obtain a flame-retardant and anti-ultraviolet nylon fabric, wherein the padding finishing adopts the method of two dipping...

Embodiment 3

[0056] A method for preparing a flame-retardant and anti-ultraviolet nylon fabric, the specific preparation steps are as follows:

[0057] (1) According to the bath ratio of 1:60, adopt the dopamine aqueous solution with a pH value of 9.0 to impregnate and finish the washed nylon fabric to obtain dopamine-modified nylon fabric, wherein the immersion temperature is 45 ° C, the immersion time is 20h, and the concentration of the dopamine aqueous solution is 2g / L.

[0058] (2) After impregnating the dopamine-modified nylon fabric with KH550 solution, dry it to obtain the modified nylon fabric modified by silane coupling agent, wherein the immersion temperature is 80°C, the immersion time is 2h, and the concentration of KH550 solution is 150g / L. Drying, the solvent in the KH550 solution is a mixed solution of ethanol and water (mass ratio is 5:3).

[0059] (3) The modified nylon fabric modified by the silane coupling agent is adjusted by padding with CEPPA solution, and the metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com