A kind of extracting method and application of neem bark pigment

A technology of neem bark and pigment, applied in dyeing method, chemical instrument and method, resistance to vector-borne diseases, etc., can solve the problems of high cost, difficult to accurately control temperature, difficult to improve yield, etc., and achieve strong anti-ultraviolet performance. , the effect of strong fluorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for extracting neem bark pigment, comprising the following steps:

[0056] 10g 20 order neem bark powder is added in the mixed solvent of 400g water and ethanol (concentration of ethanol is 40%), adopt high-speed wall breaker to mix, extract; Extract pH (add sodium hydroxide solution to adjust) be 11, The extraction temperature is 65°C, and the extraction time is 60 minutes (the blade rotation speed is 42000r / min for 10 minutes, and then the blade rotation speed is reduced to 20500r / min for 50 minutes); Solid-liquid separation; then use rotary evaporation to recover ethanol and concentrate the feed solution (solid content is 4.80%), after concentration, freeze-dry (temperature is -40 ° C, time is 36h), to obtain brown powder, that is, neem bark pigment.

Embodiment 2

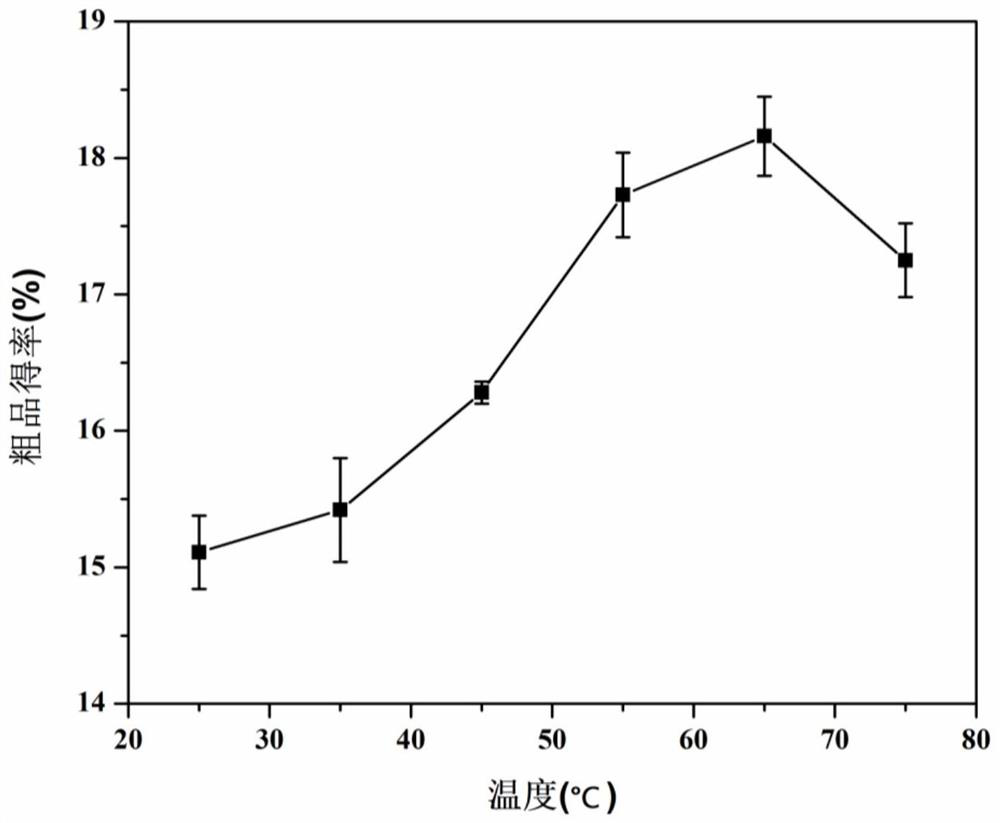

[0057] The optimization of embodiment 2 extraction temperature

[0058] Adjust the extraction temperature in Example 1 to be 25, 35, 45, 55, 75°C, and keep the others consistent with Example 1 to obtain the neem bark pigment.

[0059] The neem bark pigment obtained is subjected to a performance test, and the test results are shown in figure 2 ,from figure 2 Can find out: along with the rising of temperature, the crude product yield of neem bark pigment increases gradually, and the crude product yield is the lowest during 25 ℃, is 15.11%, and 65 ℃ (embodiment 1) crude product yield is the highest, is 18.77% . But the yield of crude product of neem bark pigment decreased slightly at 75℃.

Embodiment 3

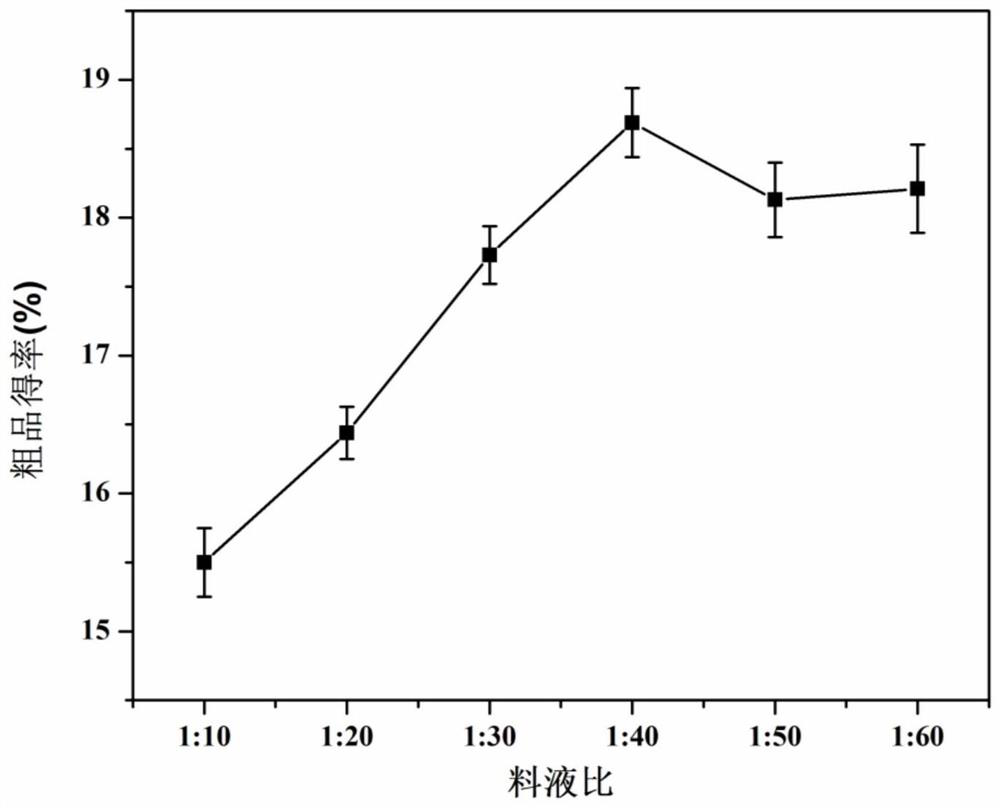

[0060] The optimization of embodiment 3 solid-liquid ratio

[0061] The solid-liquid ratio (mass ratio of neem bark powder and mixed solvent) in adjusting embodiment 1 is 1: 10, 1: 20, 1: 30, 1: 50, 1: 60, and other is consistent with embodiment 1, Get neem bark pigment.

[0062] The neem bark pigment obtained is subjected to a performance test, and the test results are shown in image 3 ,from image 3 It can be seen that: when the solid-liquid ratio was 1:10, the crude product yield was the lowest, which was 15.51%, and when the solid-liquid ratio was 1:40 (embodiment 1), the crude product yield was the highest, which was 18.77%, and the solid-liquid ratio When the ratio is greater than 1:40, the difference in the yield of the crude product is small, indicating that the yield of the crude product becomes stable from the solid-liquid ratio of 1:40, and the neem bark pigment has been basically dissolved. Comprehensive consideration, the ratio of solid to liquid should be 1:4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com