Coal bed gas U-shaped well segmented step-by-step drainage method

A technology for coalbed methane wells and coalbed methane, which is applied in the direction of mining fluids, earthwork drilling, wellbore/well components, etc., can solve problems such as unreasonable drainage system, poor gas production effect, and unstable production, and prevent large coal seams. The effect of bare area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

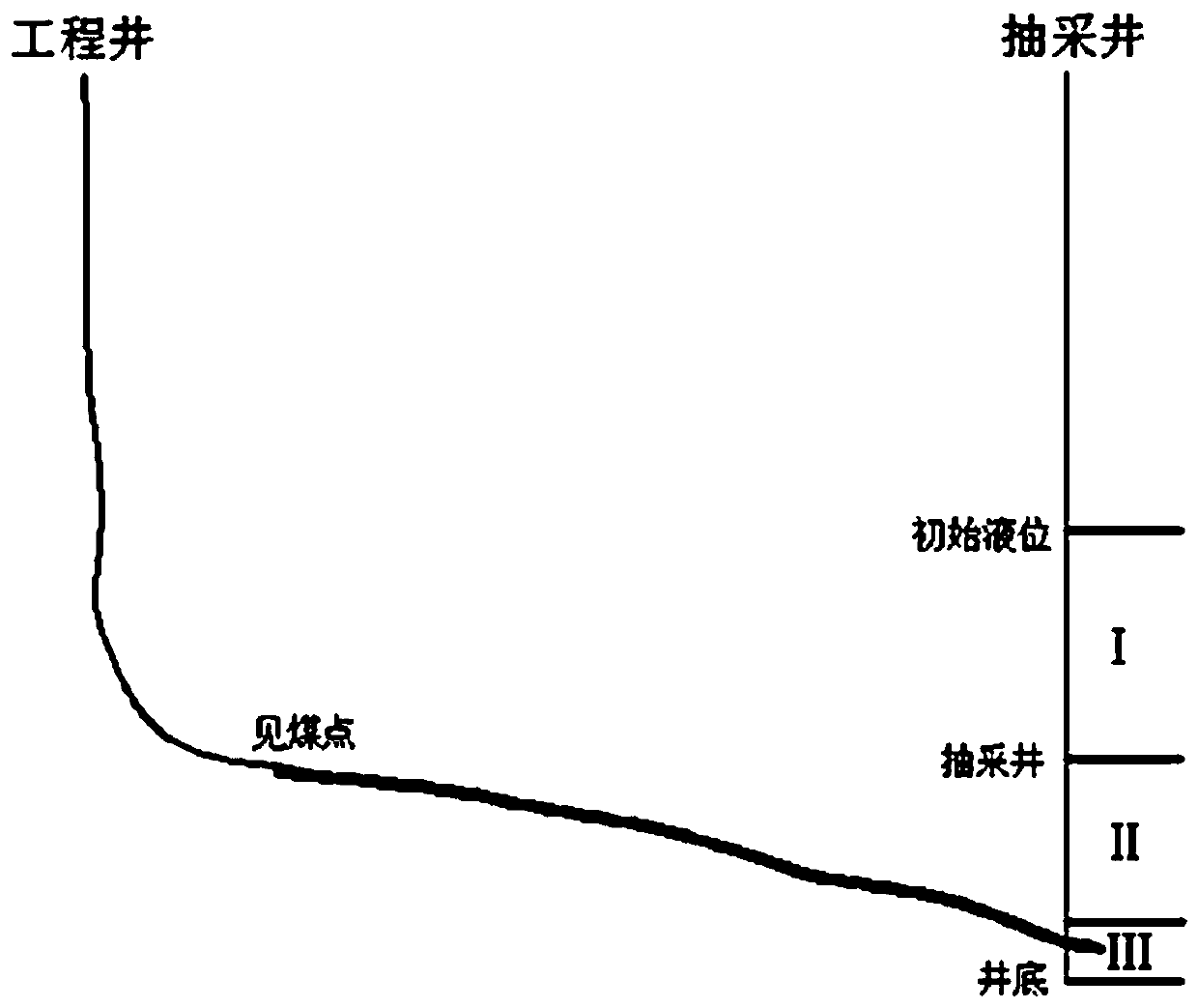

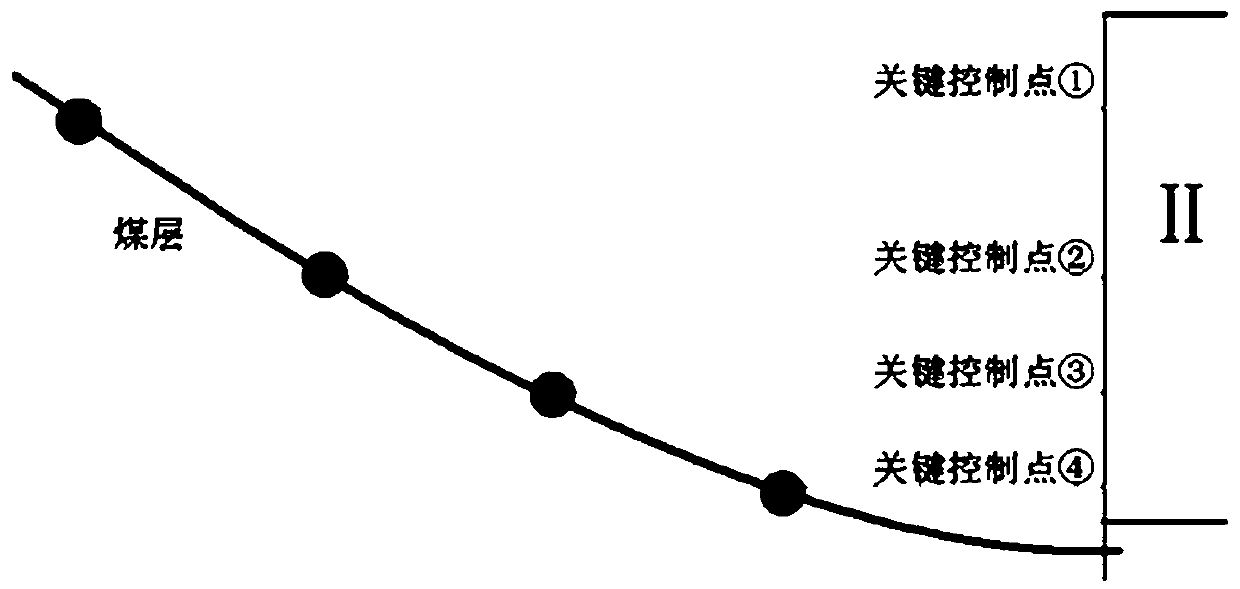

[0017] The present invention is aimed at the characteristics of the coal seam with a large dip angle, and uses the fracturing point of the U-shaped well as the key point of drainage control, and depressurizes step by step, and the specific process is as follows:

[0018] (1) The principle of gas production first in the remote butt joint horizontal well project. Since the horizontal section of the far-end docking well is generally drilled in the downhill manner, the coal seam section near the engineering well reaches the desorption condition first. If the coal seam dip angle is large, this phenomenon is more obvious.

[0019] (2) Three-stage drainage stage. The stage from the initial liquid level of the CBM well to the critical desorption pressure point is regarded as the first drainage stage; the liquid level from the critical desorption pressure point to the liquid level 20m above the roof of the target coal seam is regarded as the second drainage stage; subsequent drainage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com