Discharge and mining method for coal-seam gas horizontal well of low-permeability coal reservoir

A technology for horizontal wells and coal reservoirs, which is applied to wellbore/well valve devices, production fluids, earth-moving drilling, etc. The effect of decompression and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

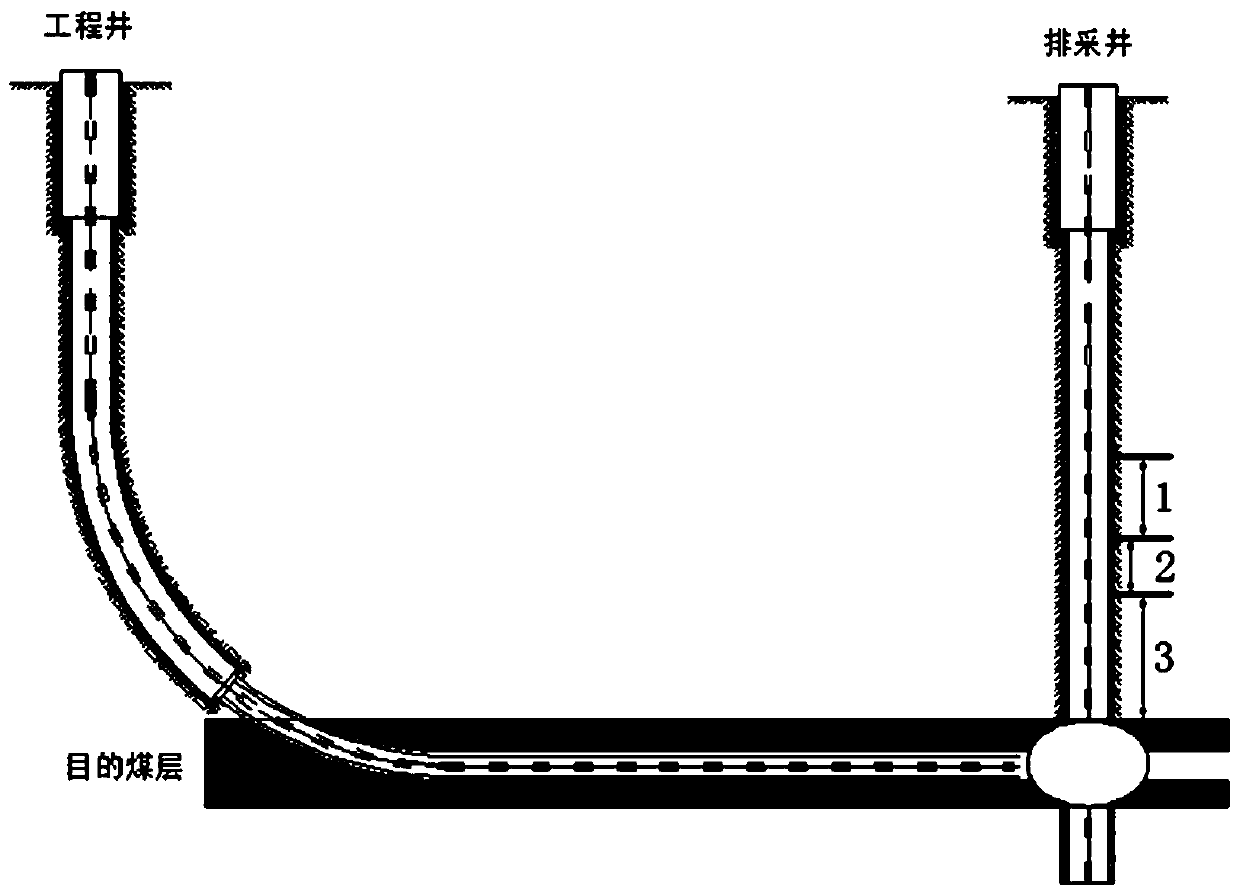

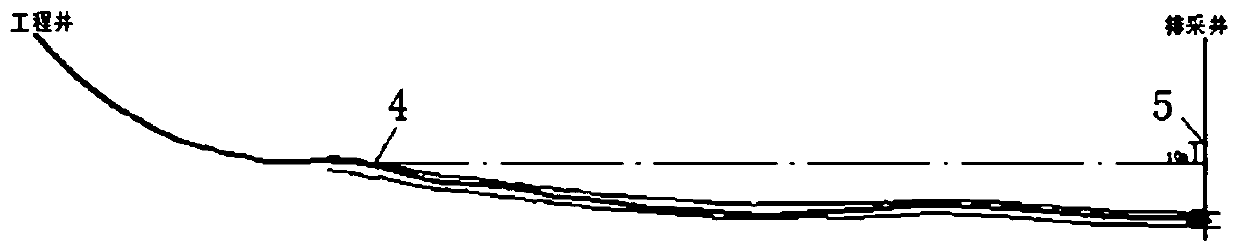

[0021] The present invention formulates a quantitative drainage system according to the different drainage stages of horizontal wells in low-permeability coal seams; for coal seams with large inclination angles, the highest position of the coal seam section of the horizontal well is taken as a key point of drainage, and then repairs wells for coalbed methane wells. The choice of time provides a way.

[0022] When the liquid level drops to 10m from the roof of the highest point of the coal seam section (the highest position of the coal seam section of the horizontal well), the bottom hole pressure should be maintained to make it gradually desorb and avoid premature exposure of the coal seam section.

[0023] When workover is really necessary, the pump should be stopped in advance to restore the liquid level above the critical desorption pressure before workover.

[0024] Concrete control technique of the present invention is as follows:

[0025] (1) Saturated water unidirectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com