Cable digital-type technology pipe column for dispersion under-pressure operation and method

A technology for working under pressure and process pipe strings, which is applied in drilling pipes, casings, earthwork drilling and mining, etc., and can solve problems such as difficult cable running and cable protection, so as to improve long-term application reliability, reduce on-site operation risks, The effect of simplifying the on-site work process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

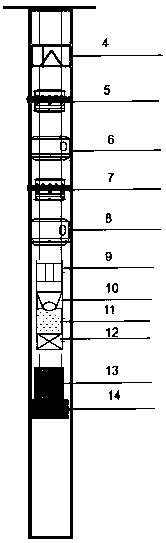

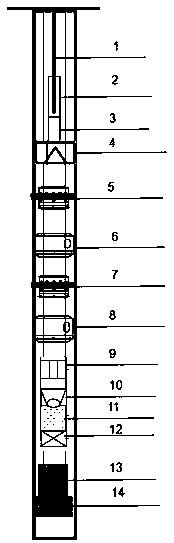

[0026] Such as Figures 1 to 4 As shown, a process tubing string for cabled digital injection with pressure, including a male joint device 4 sequentially connected to the tubing from top to bottom, a first cable packer 5, a first cabled digital Water distributor 6, second cable packer 7, second cable digital water distributor 8, preset mandrel 9, double-acting valve 10, screen pipe 11, plug 12, fishing fish 13 and removable bridge The plug 14 also includes a female connector device 3 matched with the male connector device 4, the upper end of the female connector device 3 is connected with a female connector cable 1, and the other end of the female connector cable 1 extends to the wellhead, and the male connector device 4 is connected to the first process through the cable. The cable packer 5 , the first cabled digital water distributor 6 , the second cabled packer 7 and the second cabled digital water distributor 8 are electrically connected, and the female joint device 3 and ...

Embodiment 2

[0028] A method for working under pressure of a process string with cable digital split injection under pressure, comprising the following steps:

[0029] Step 1: Lower the removable bridge plug to 30-50m below the wellhead, throw the ball and pressurize at 16-18MPa, seal the removable bridge plug; continue to pressurize at 22MPa, lift the string and throw away;

[0030] Step 2: Connect the cabled digital dispensing tool string, the lower end of the male joint device and the first cabled packer, the first cabled digital water distributor, the second cabled packer and the second cabled digital water distributor The packer is connected with an armored cable, and then connected to the male joint device through the upper part of the first cable packer, and the salvage fish is connected below the plug at the bottom of the pipe string;

[0031] Step 3: Lower the tool string, salvage the fish and dock with the fishable bridge, seal the annular space of the oil sleeve according to the...

Embodiment 3

[0035] On the basis of Embodiment 1, the second cabled digital water distributor 8, the prefabricated mandrel 9, the double-acting valve 10, the screen pipe 11 and the plug 12 are screwed sequentially from top to bottom.

[0036] The upper end of the male joint device 4 is connected to the oil pipe, and the oil pipe at the lower end of the male joint device 4 is connected with the first cable packer 5, the first cabled digital water distributor 6, and the second cable packer sequentially from top to bottom. 7. The second cabled digital water distributor 8, preset working cylinder 9, double-acting valve 10, screen tube 11, plug 12, salvaged fish 13 and removable bridge plug 14, and the second cabled digital water distribution The lower end of the device 8 is connected with the upper end of the preset working cylinder 9 with a threaded thread, the lower end of the preset working cylinder 9 is connected with the upper end of the double-acting valve 10 with a threaded thread, the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com