Aeroengine fan blade external object impact test platform

A technology for aero-engine and fan blades, which is used in impact testing, mechanical component testing, machine/structural component testing, etc., to achieve the effect of improving engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following describes the structure of the aero-engine fan blade foreign object impact test platform of the present invention in conjunction with the accompanying drawings, and describes the design idea and implementation method.

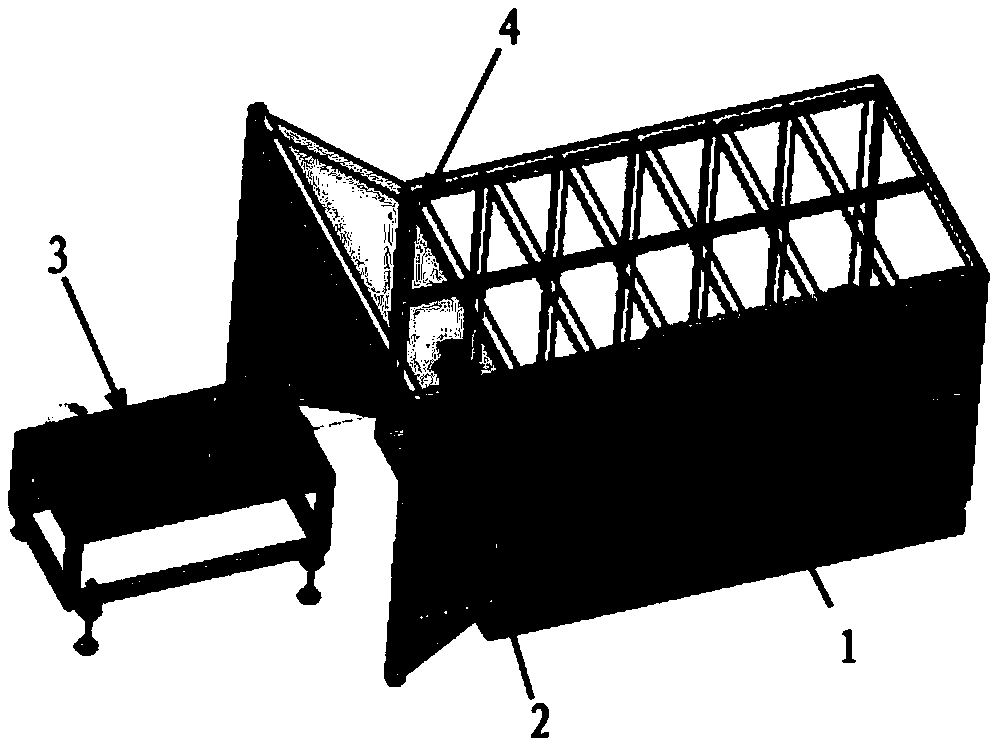

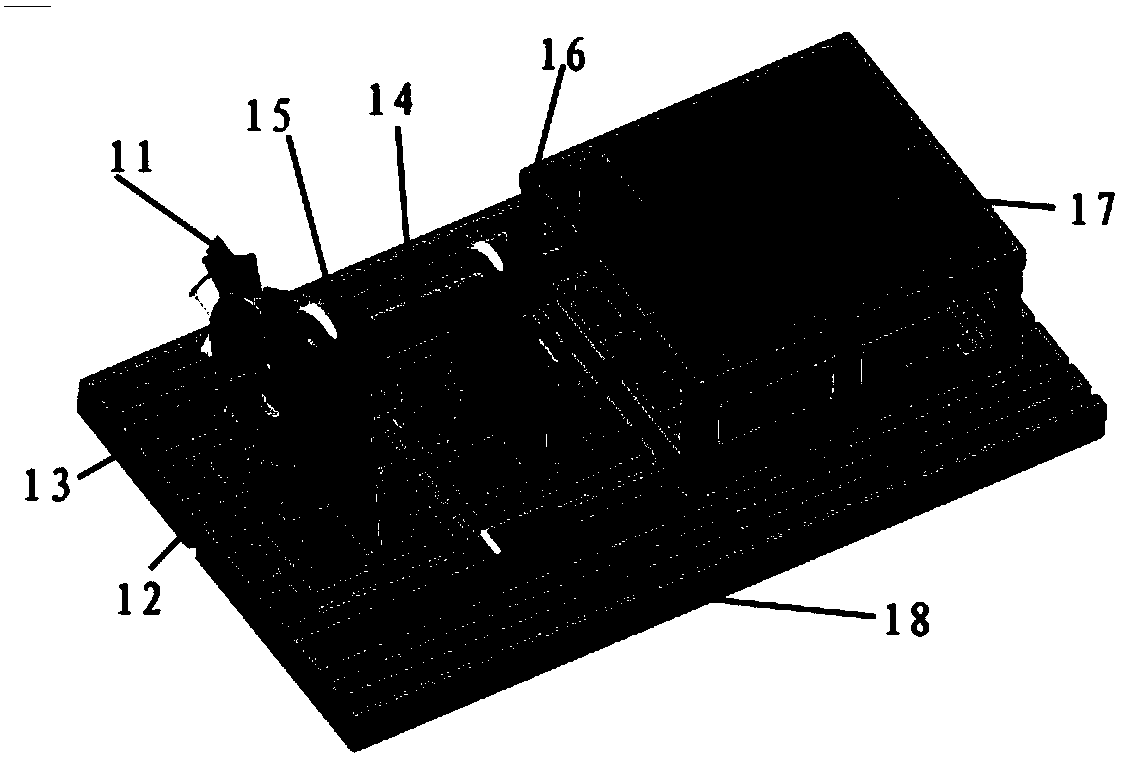

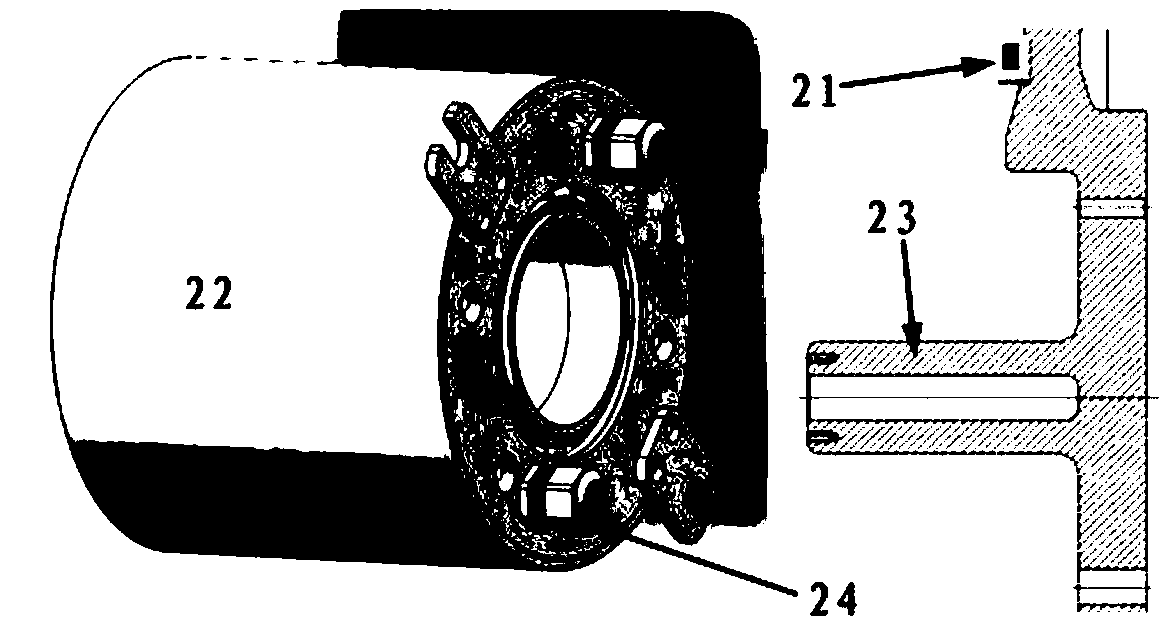

[0026] Schematic diagram of the structure of the aero-engine fan blade foreign object impact test platform: figure 1 As shown, it mainly includes the following parts: fan rotor tester 1, fan blade dynamic stress measurement unit 2, test protection unit 3, and foreign object launching device 4. The fan rotor tester 1 and the fan blade dynamic stress measurement unit 2 are located inside the test protection unit 3, and the test protection unit plays a protective role in the impact test of foreign objects; the schematic diagram of the fan blade dynamic stress measurement unit 2 is as follows image 3 As shown, it is assembled on the fan rotor tester 1; the schematic diagram of the foreign object launching device 4 is shown in Figure 4 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com