Injection die and injection method used for preparing multi-orientation anisotropic plastic magnetic body

An anisotropic, injection mold technology, applied in the field of magnetic materials, can solve the problem of single orientation of magnetic rings or magnetic tiles, and achieve the effect of prolonging service life, realizing multi-orientation application and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

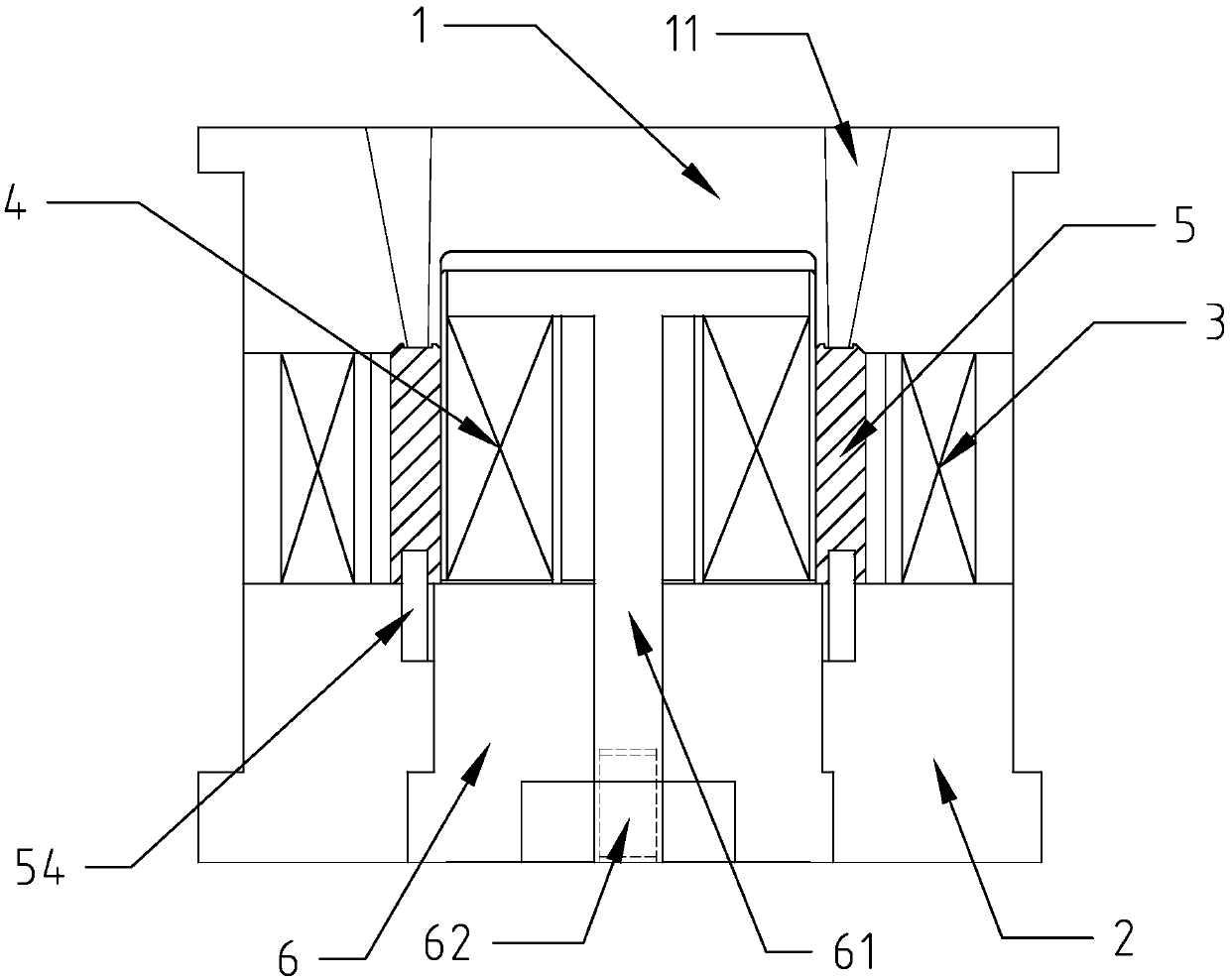

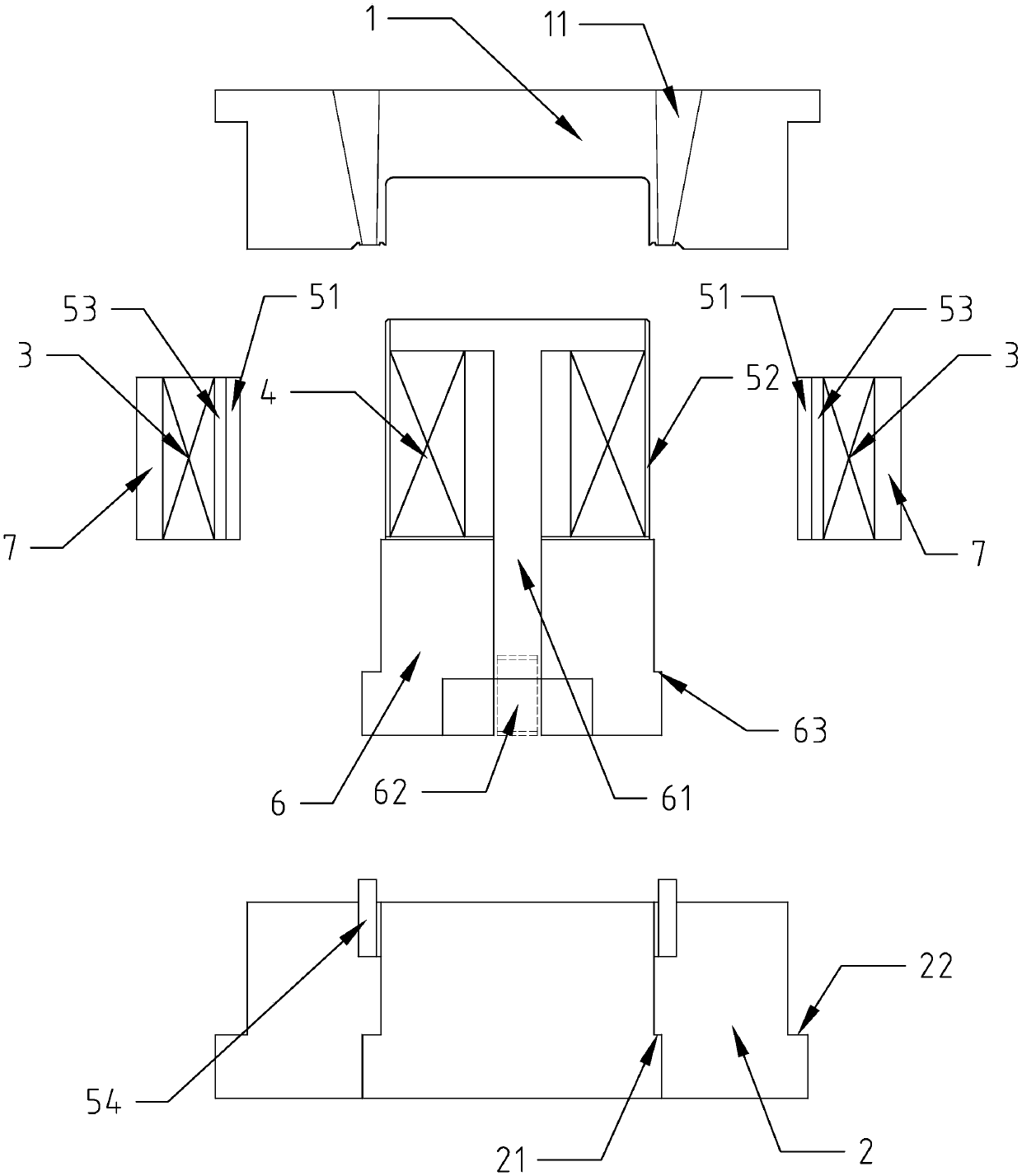

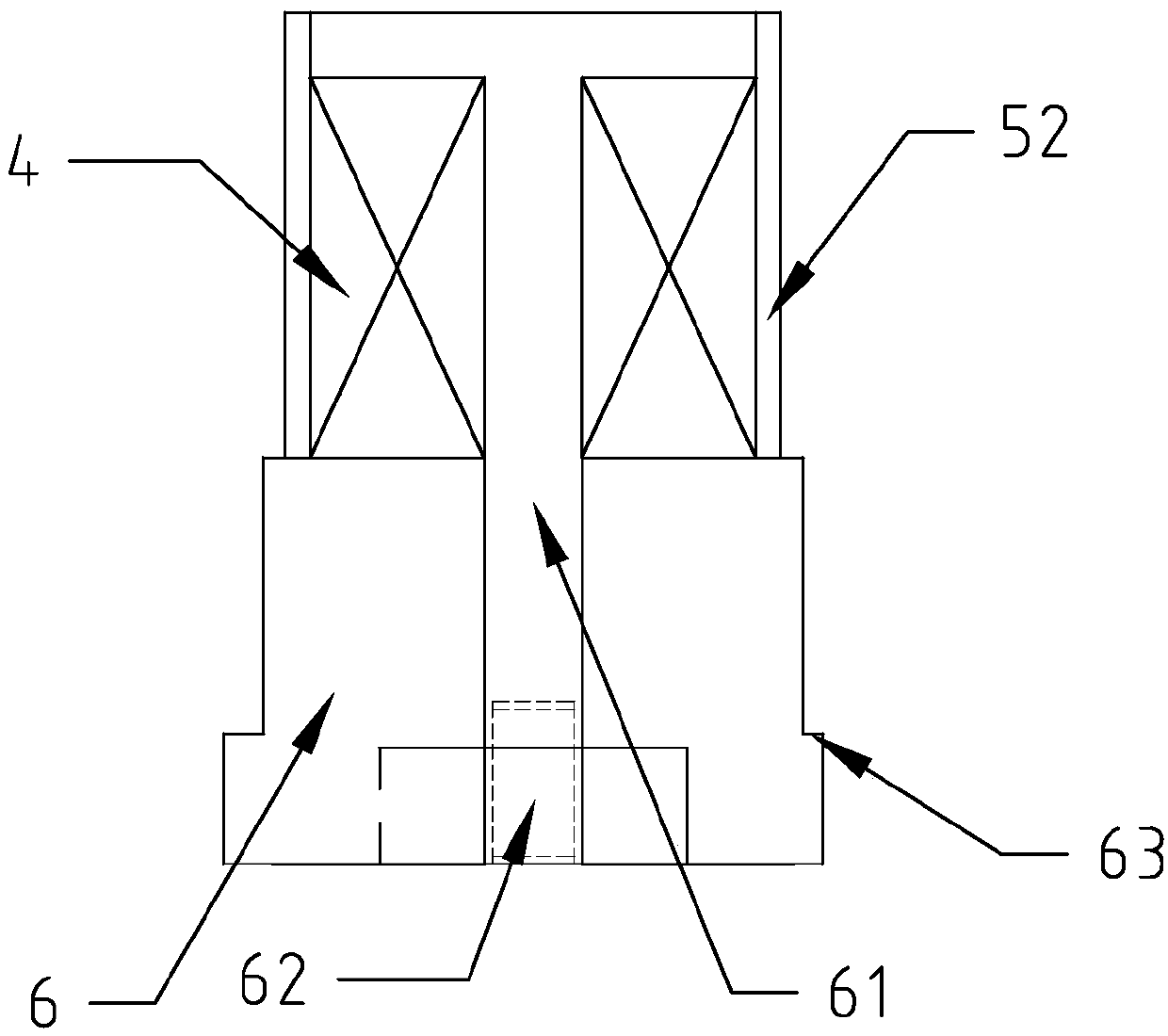

[0044]An injection mold for preparing multi-oriented anisotropic plastic magnets, which consists of a front mold 1, a rear mold 2, an outer diameter orientation magnetized part 3 and an inner diameter orientation magnetized part 4; the inner diameter orientation magnetized part is made of Made of SM-32 samarium cobalt magnetic material, the outer diameter oriented magnetized part is made of EH42 NdFeB magnetic material; a mold cavity 5 is formed between the inner diameter oriented magnetized part and the outer diameter oriented magnetized part, and the mold cavity The magnetic field strength along half of its radial direction is 800GS; an outer barrier layer 51 is provided between the mold cavity and the outer diameter-oriented magnetized part, and an inner barrier layer 52 is provided between the mold cavity and the inner diameter-oriented magnetized part. The radial thickness of the inner and outer interlayers is 0.5 mm, and the inner and outer interlayers are made of wear-re...

Embodiment 2

[0053] An injection mold for preparing multi-oriented anisotropic plastic magnets, which consists of a front mold 1, a rear mold 2, an outer diameter orientation magnetized part 3 and an inner diameter orientation magnetized part 4; the inner diameter orientation magnetized part is made of Made of SM-32 samarium cobalt magnetic material, the outer diameter oriented magnetized part is made of EH42 NdFeB magnetic material; a mold cavity 5 is formed between the inner diameter oriented magnetized part and the outer diameter oriented magnetized part, and the mold cavity The magnetic field strength at half of the radial direction is 1500GS; an outer barrier layer 51 is provided between the mold cavity and the outer diameter-oriented magnetized part, and an inner barrier layer 52 is provided between the mold cavity and the inner diameter-oriented magnetized part. The radial thickness of the inner interlayer and the outer interlayer is 1mm, and the relative magnetic permeability of the...

Embodiment 3

[0062] An injection mold for preparing multi-oriented anisotropic plastic magnets, which consists of a front mold 1, a rear mold 2, an outer diameter orientation magnetized part 3 and an inner diameter orientation magnetized part 4; the inner diameter orientation magnetized part is made of Made of SM-32 samarium cobalt magnetic material, the outer diameter oriented magnetized part is made of EH42 NdFeB magnetic material; a mold cavity 5 is formed between the inner diameter oriented magnetized part and the outer diameter oriented magnetized part, and the mold cavity The magnetic field strength along half of its radial direction is 1100GS; an outer barrier layer 51 is provided between the mold cavity and the outer diameter-oriented magnetized part, and an inner barrier layer 52 is provided between the mold cavity and the inner diameter-oriented magnetized part. The thickness of the inner spacer and the outer spacer in the radial direction is 0.7mm, and the relative magnetic perme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com