A scanning micro-arc oxidation treatment device and method

A technology of micro-arc oxidation and processing equipment, which is applied in the direction of anodic oxidation, coating, electrolytic components, etc., and can solve the problem of electrolyte composition, concentration, temperature, and pH value changes, the inability to process micro-arc oxidation, and the stability of micro-arc discharge process Influence and other issues to achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

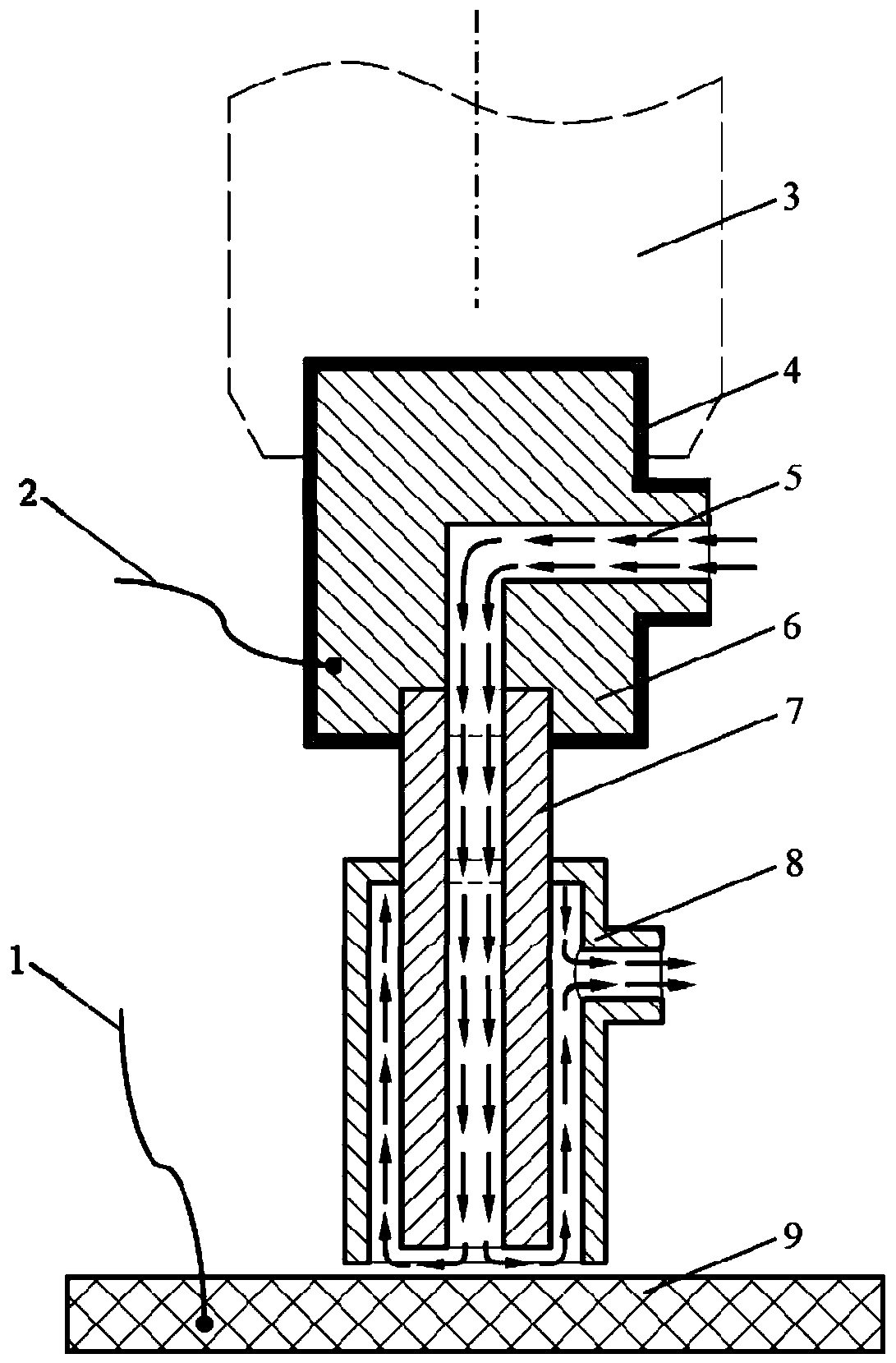

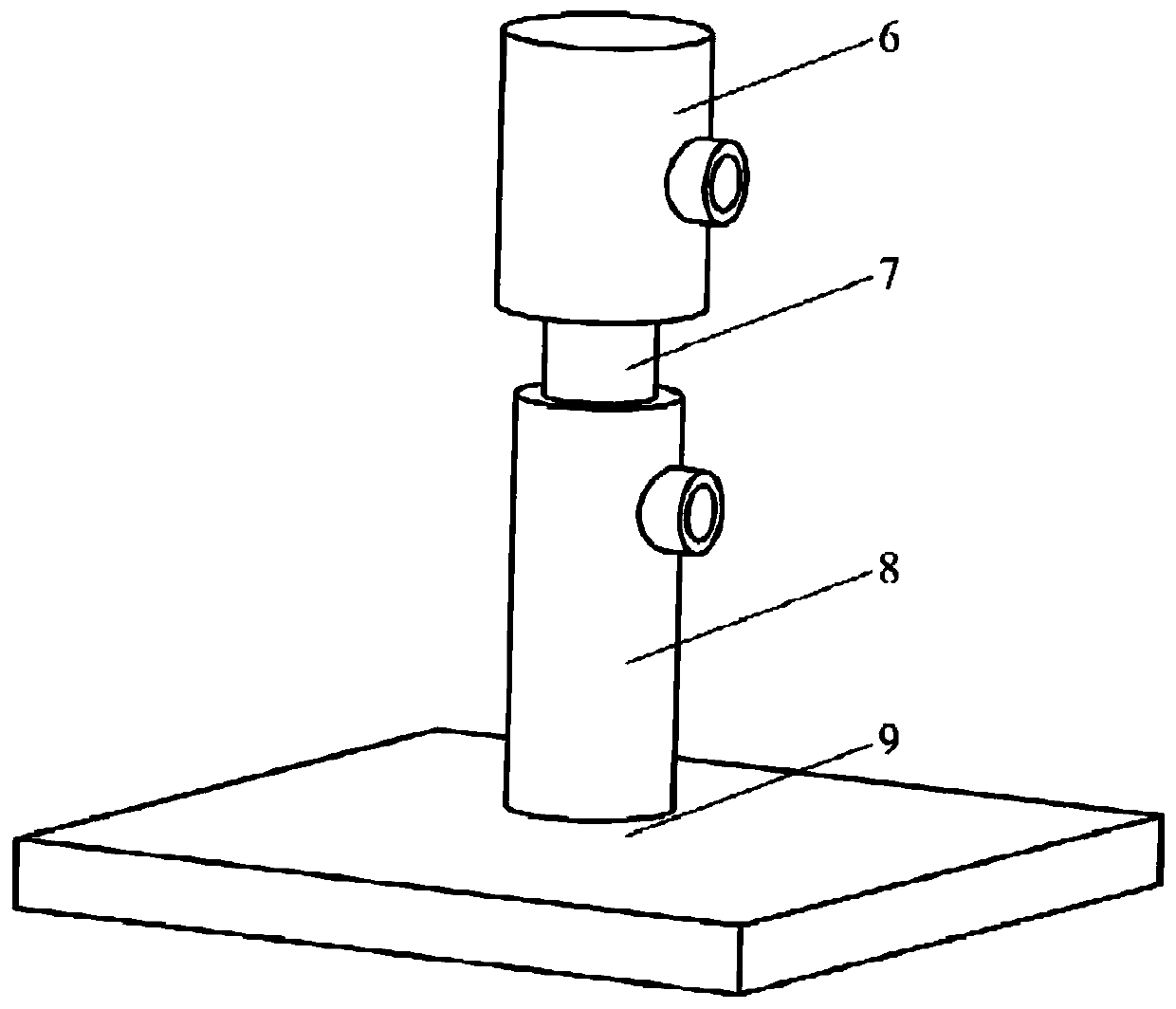

[0040] Embodiment 1: The device used in a scanning micro-arc oxidation treatment method consists of a fixed head 6 , a liquid supply pipe 7 and a liquid suction pipe 8 . The fixed head 6 is clamped on the Z-axis chuck 3 of the vertical machine tool, one end of the liquid supply pipe 7 is inserted into the bottom groove of the fixed head 6, and the liquid suction pipe 8 is set on the liquid supply pipe 7, as figure 1and 2 shown.

[0041] The fixed head 6 is made of metal material and coated with an insulating layer 4 around it. Its shape is a cylinder, which is connected to the negative electrode of the micro-arc oxidation power supply through a wire 2. A circular groove is processed at the bottom of the cylinder, and an external electrolyte is processed on the side of the cylinder. Inlet, the inside of the cylinder is machined with a flow channel connecting the bottom circular groove and the side electrolyte inlet.

[0042] The liquid supply pipe 7 is a cylindrical pipe made...

specific Embodiment approach 4

[0047] Embodiment 4: As a specific embodiment, the liquid suction pipe and the liquid supply pipe can also be made as a whole.

specific Embodiment approach 5

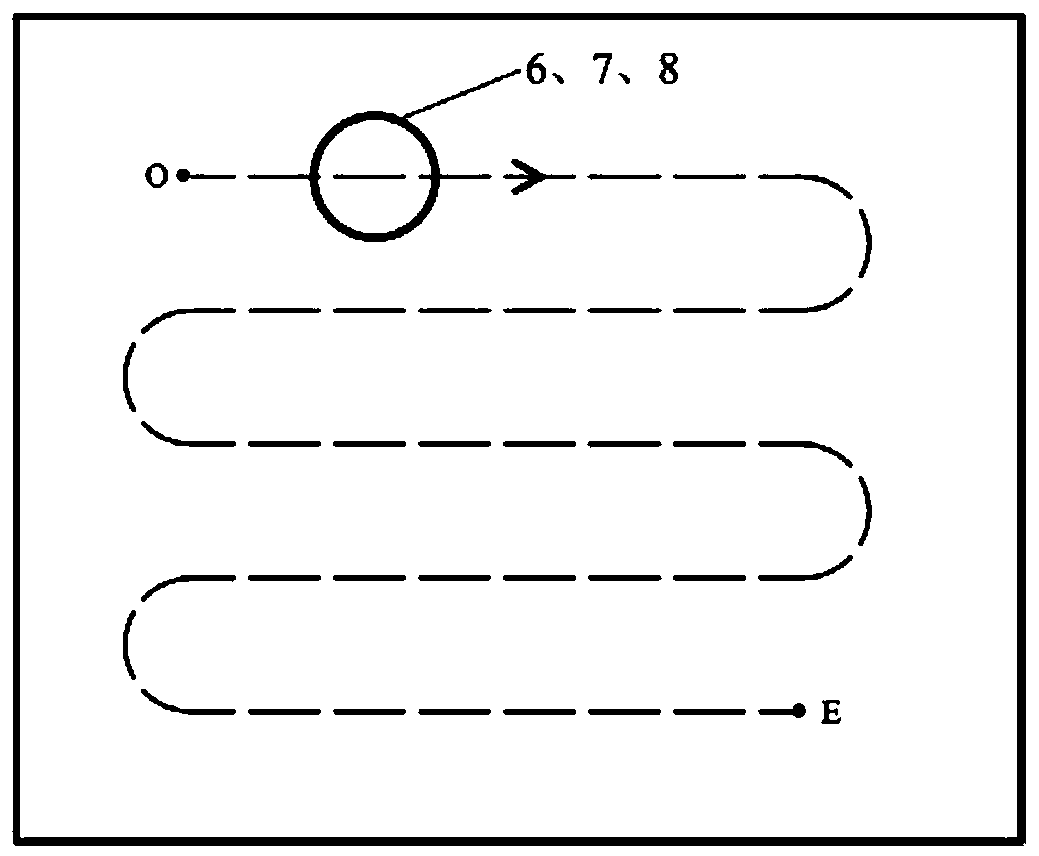

[0048] Specific implementation mode five: as figure 1 and image 3 As shown, a scanning micro-arc oxidation treatment method comprises the following steps:

[0049] Step 1: Clamp the fixed head 6 of the device of the present invention on the Z-axis chuck 3 of the vertical machine tool, place the workpiece on the workbench of the vertical machine tool, and ensure that the workpiece is electrically isolated from the workbench of the machine tool;

[0050] Step 2: Connect the workpiece 9 to the positive pole of the micro-arc oxidation power supply through the wire 1, and connect the fixed head 6 to the negative pole of the micro-arc oxidation power supply through the wire 2;

[0051] Step 3: Connect the electrolyte inlet of the fixed head 6 with the external liquid supply pump, and connect the electrolyte outlet of the suction pipe 8 with the external liquid pump;

[0052] Step 4: According to the micro-arc oxidation area that needs to be formed on the surface of the workpiece,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com