Hydraulic pressure stabilization similar material pressing device and use method thereof

A technology of similar materials and voltage stabilization, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, analyzing materials, etc., can solve the problem of no suitable device, reduce the amount of use, and avoid the steps of manually adjusting the valve , the effect of reducing workmanship requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

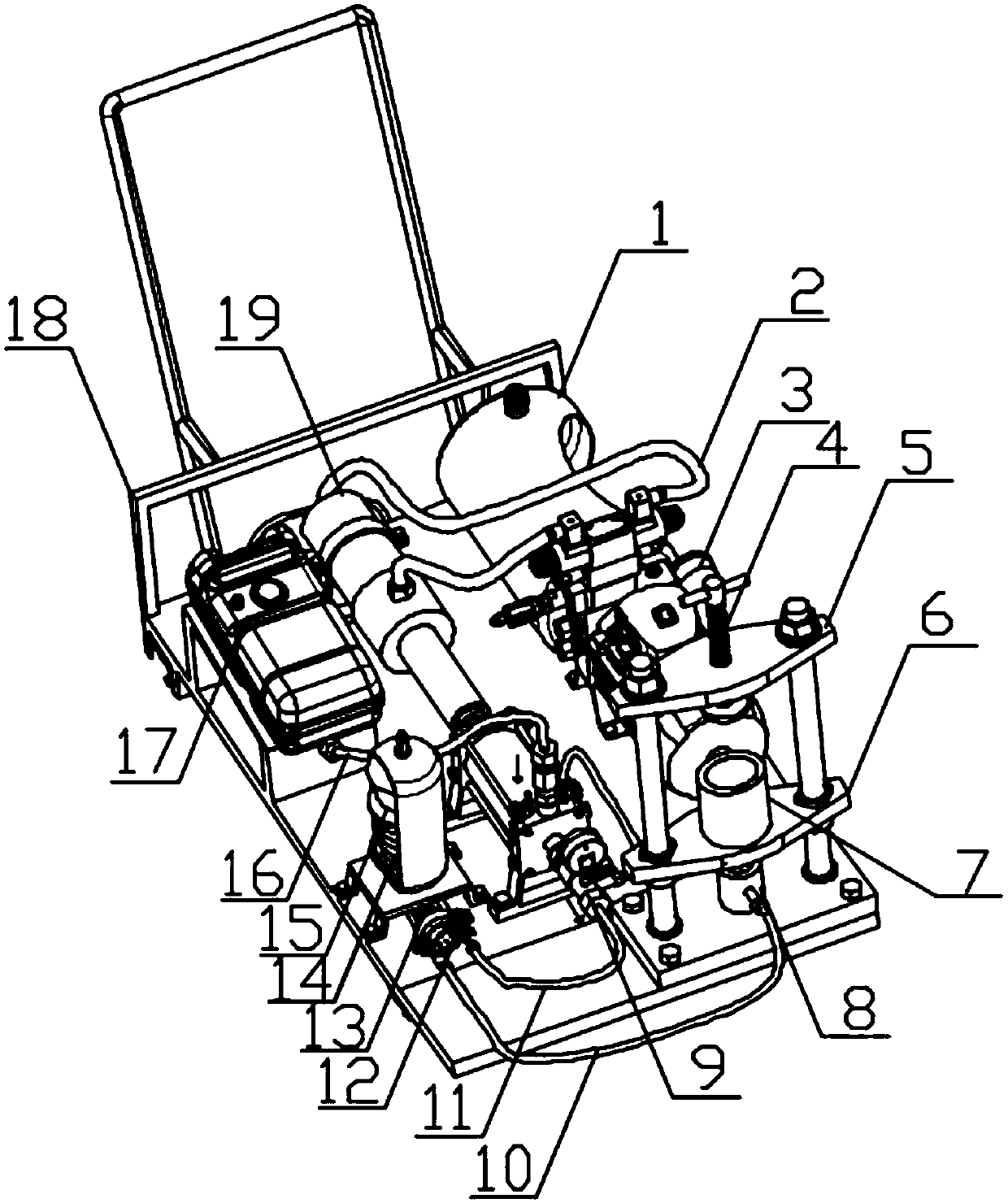

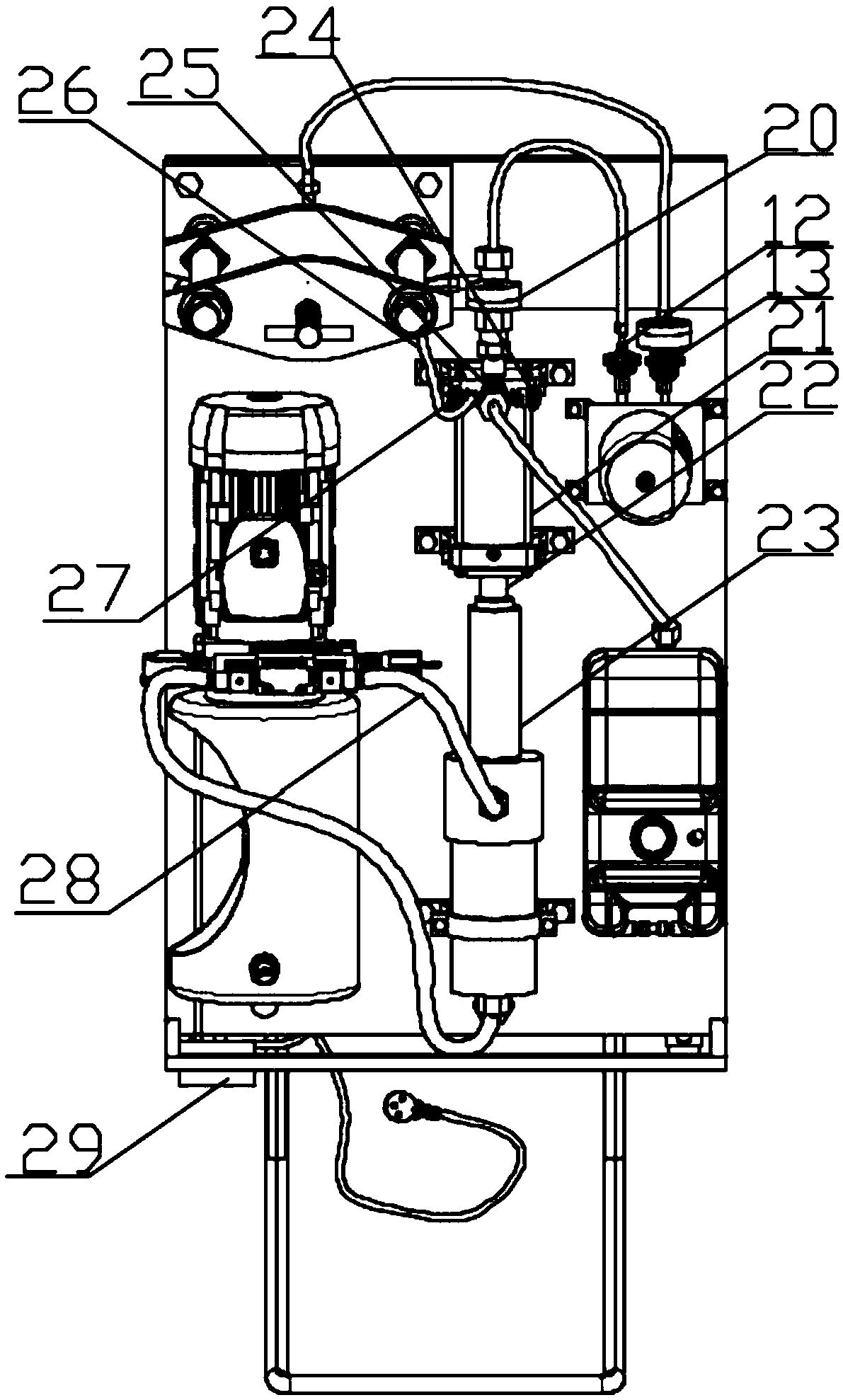

[0025] Such as figure 1 , 2 Shown, a kind of hydraulic pressure stabilizing similar material pressing device comprises trolley 18, electric motor 3, hydraulic pump 1, water tank 17, horizontal hydraulic cylinder 19, horizontal hydraulic cylinder column 23, water cylinder jacket 21, water cylinder column 22, Accumulator, electric control box 29 and pressing mechanism, described motor 3, hydraulic pump 1, water tank 17, horizontal hydraulic cylinder 19, water cylinder liner 21, accumulator and pressing mechanism are fixedly arranged on the trolley 18; The hydraulic cylinder column 23 is installed in the horizontal hydraulic cylinder 19, the water cylinder column 22 is installed in the water cylinder liner 21, and the horizontal hydraulic cylinder column 23 is connected with the water cylinder column 22; the motor 3 is used to drive the hydraulic pump 1 , the hydraulic pump 1 communicates with the front chamber and the rear chamber of the horizontal hydraulic cylinder 19 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com