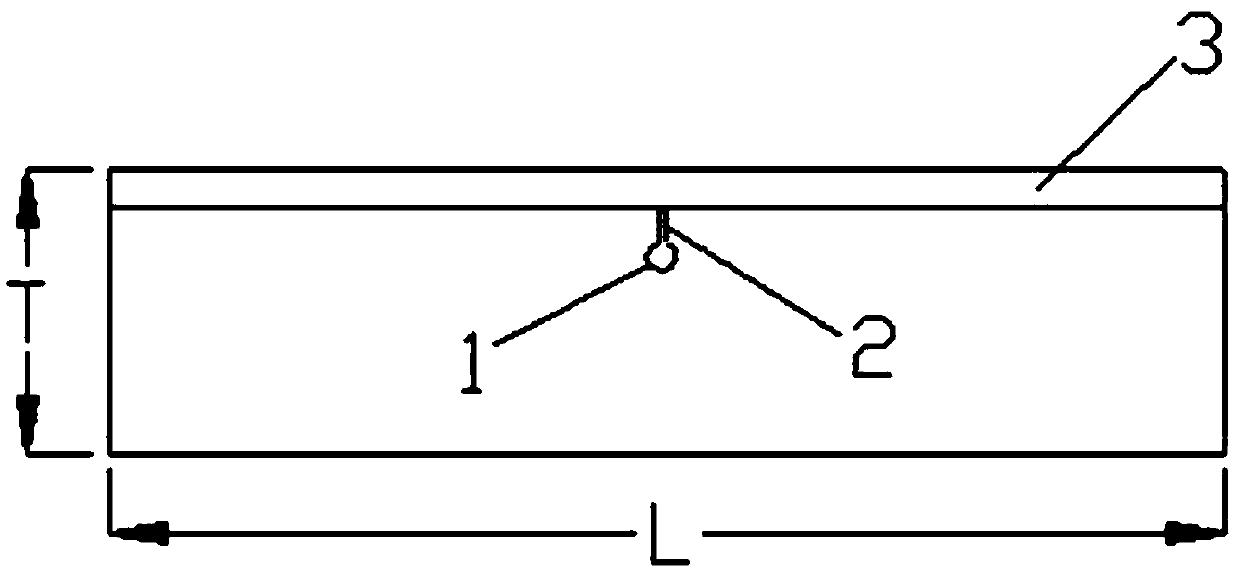

Testing block for magnetic particle inspection depth testing and testing method thereof

A technology of magnetic particle inspection and depth test, applied in the direction of material magnetic variables, etc., can solve the problems of difficult test block processing, inaccurate measurement, poor reliability, etc., and achieve the effect of accurate and reliable test data, simple operation, and avoidance of interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

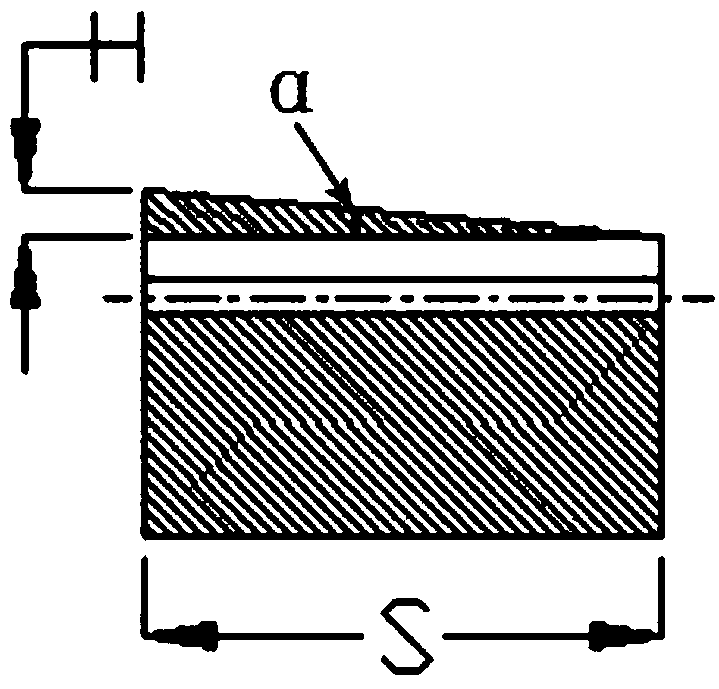

[0042] In this embodiment, the application of the present invention is described by taking the supplementary detection of the near-surface blind area in the TOFD detection of the butt weld of our company as an example. TOFD detection is ultrasonic diffraction time-of-flight method, which is a method to detect defects by relying on the diffraction energy obtained from the "end angle" and "end point" of the internal structure of the test piece (mainly refers to the defect), and is used for defect detection , quantification and positioning, but this method has a detection blind area near the surface, and the detection reliability of the near surface area is not enough. Therefore, after TOFD testing, magnetic particle testing can be used for supplementary testing of the near-surface area.

[0043] According to the requirements of NB / T47013.10-2015 "Ultrasonic Testing of Diffraction Time-of-flight for Non-destructive Testing of Pressure Equipment", it is necessary to implement supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com