A DRC processing method for deleting Net metal wires

A processing method and metal connection technology, applied in the direction of electrical digital data processing, special data processing applications, CAD circuit design, etc., can solve the problems of time-consuming, limiting the efficiency of chip design, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions in the embodiments of the present invention will be described in detail below with reference to the drawings in the embodiments of the present invention. It should be understood that the specific embodiments described below are only used to explain the present invention, not to limit the present invention.

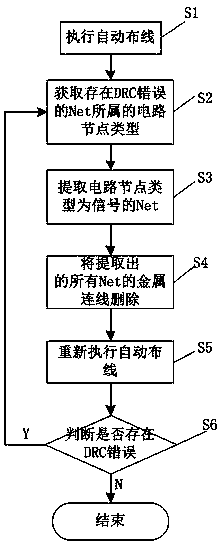

[0012] In order to solve the unreasonable operation of the prior art, the purpose of the present invention is to provide a DRC processing method for deleting the Net metal connection, mainly for the physical DRC problem occurring in the digital chip layout, and the technical solution of the present invention utilizes different metal layers to connect Differentiate between lines, and then provide relevant error location information according to DRC, remove unnecessary metal layer wiring (such as clock and power supply wiring, etc.), and then repeatedly delete wiring and wiring based on the premise of accurate DRC , until the results allowed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com