A supersonic gas atomizing spray disc for metal powder preparation

A metal powder and supersonic technology, applied in the field of gas atomization to prepare metal powder, can solve the problems of limiting the adjustment range of the gas atomization process, reducing the adaptability of the metal powder process, reducing the service life of the gas atomization spray plate, etc., to achieve Increase the yield of fine powder, reduce the cost of gas consumption, and narrow the particle size distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

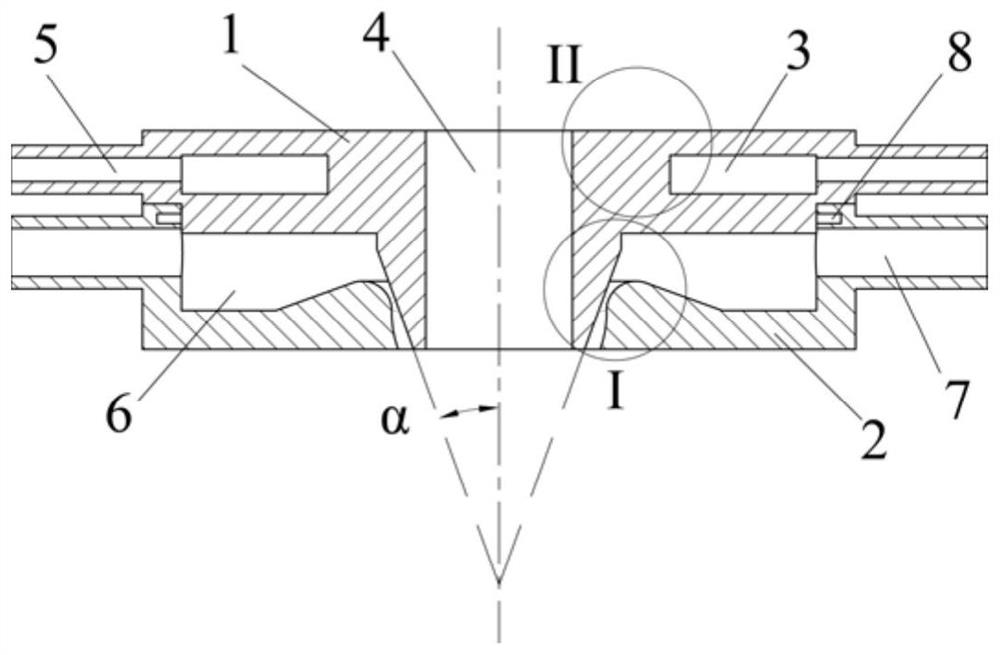

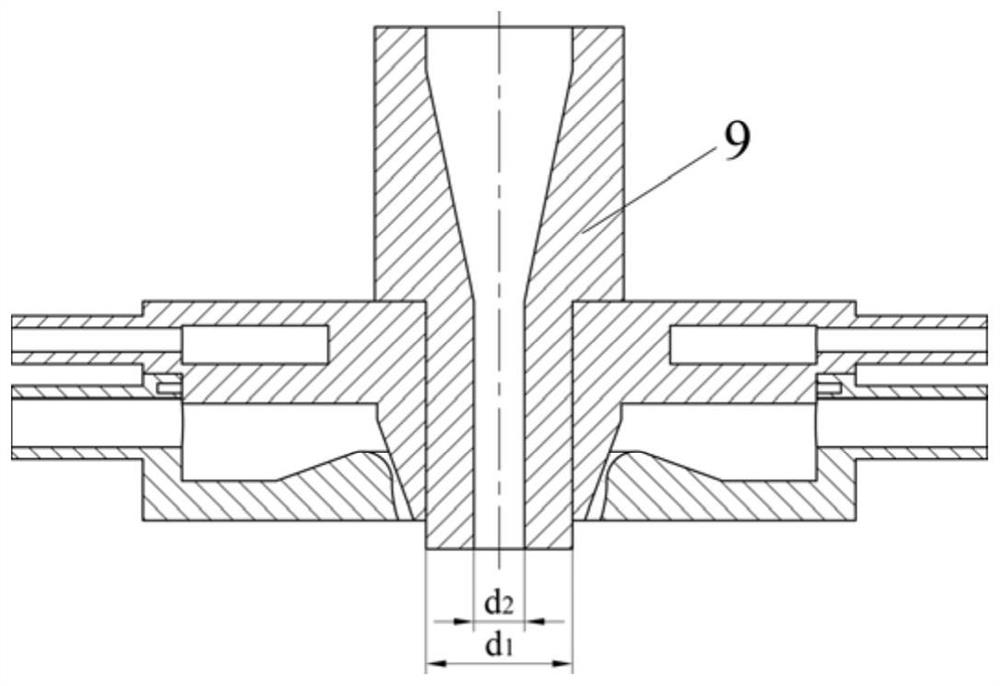

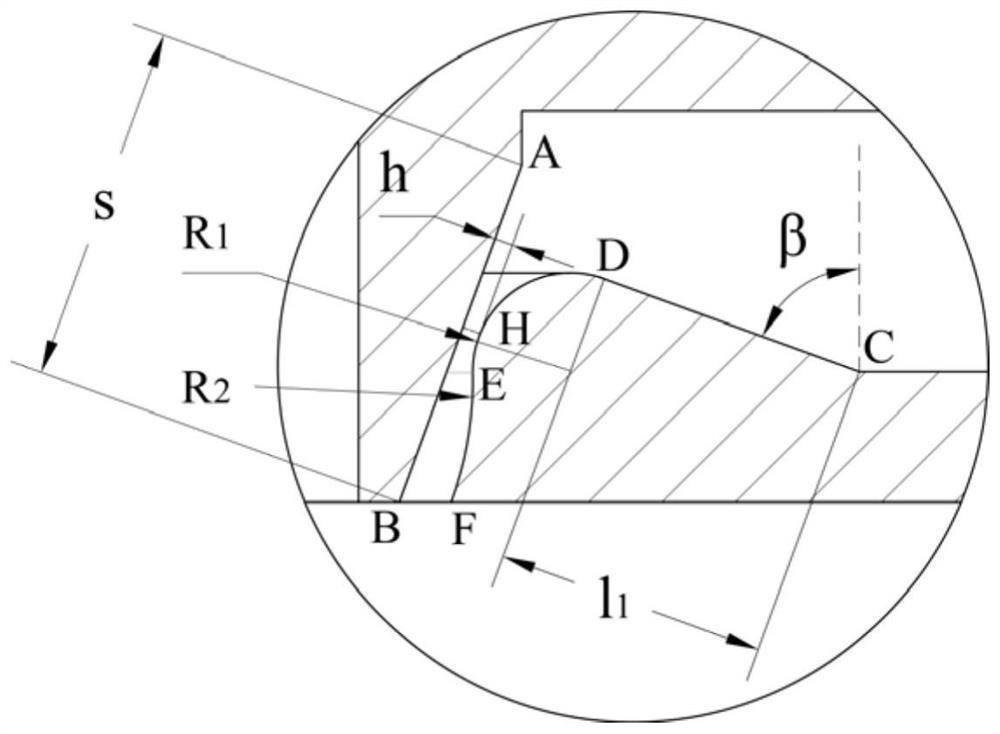

[0047] In this example, 316L stainless steel powder was prepared after the gas atomization spray disc was assembled with the guide nozzle. Annular cooling water chamber l of the upper lip of the spray disc 3 / h 2 for 4:3, h 1 / l 2 is 3:7, l 2 / l 3 3:2. The cooling water pipeline adopts the annular cooling water cavity entered by the tangential water inlet connection method, the water temperature of the circulating cooling water is controlled at 40℃~50℃, and the circulating cooling water pressure is 0.5MPa. The intake duct enters the annular air cavity by means of a tangential intake connection. The temperature of the 316L stainless steel molten metal when it enters the guide nozzle is 1650°C. The α angle of the aerosol spray disc is 30°, the β angle is 70°, R 1 / R 2 is 1:2, d 1 / d 2 is 2:1, l 1 / (R 1 +R 2 ) is 3:1, h / s is 1:17, s / (R 1 +R 2 ) is 2:3, the atomizing gas is nitrogen, the atomizing pressure is 2.0 MPa, the airflow velocity at the outlet of the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com