Combined safety inner tube

A combined and inner tube technology, applied to tire parts, transportation and packaging, segmented casing, etc., can solve problems such as property loss, vehicle loss of balance, and driver's lack of time to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further description will be made below in conjunction with the accompanying drawings.

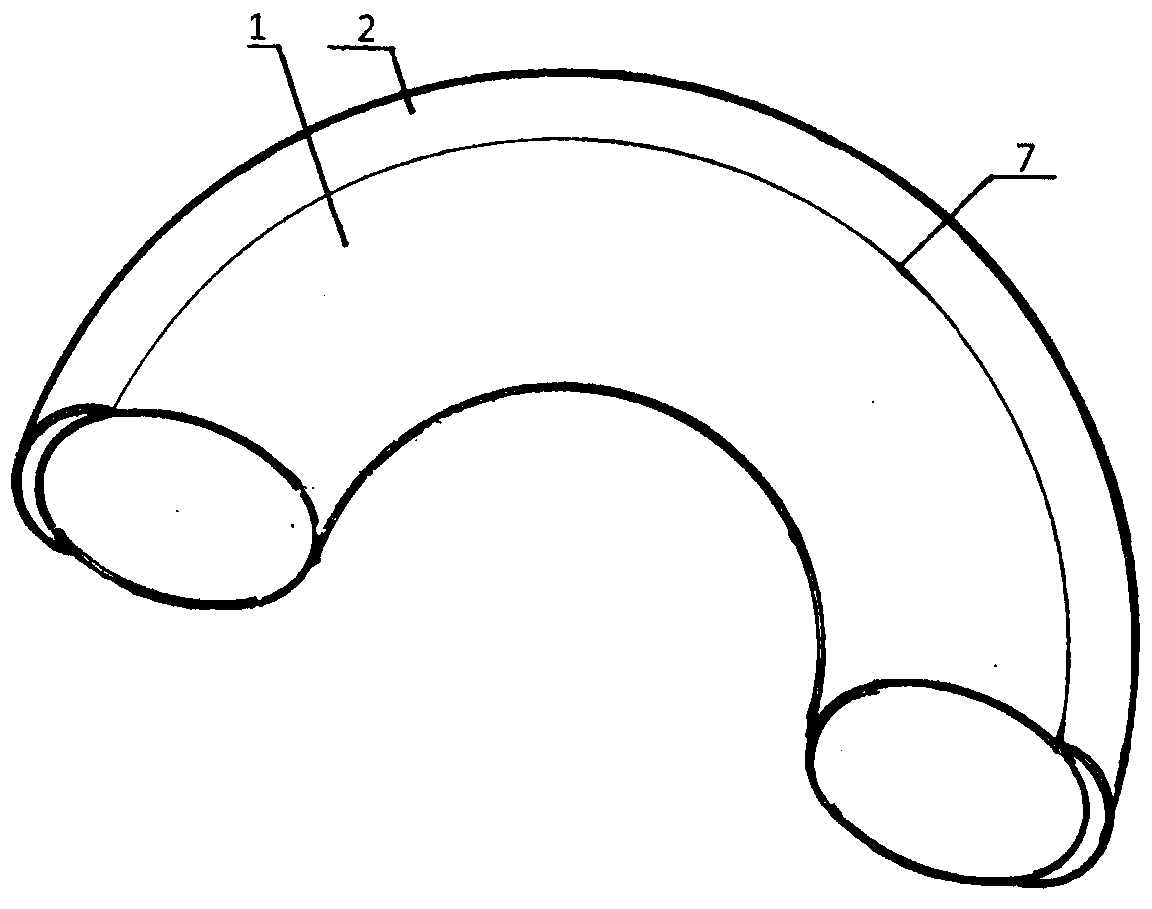

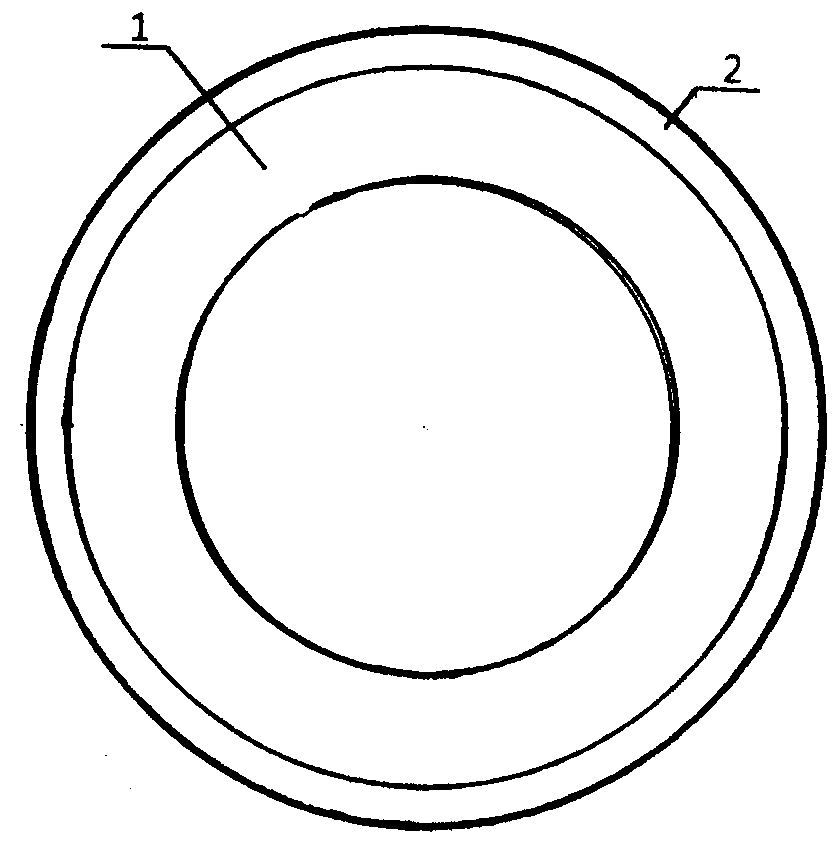

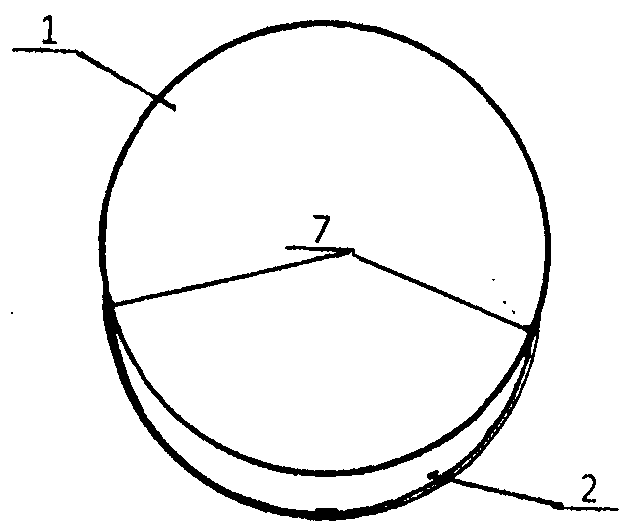

[0020] refer to Figure 1 to Figure 3 , add a layer on the outer circumference of a single inner tube 1, a small gap (20-50mm) is left between the double layers of the inner tire 1 and the outer half tire 2, the specific size of the tire Depending on the outside, the two sides 7 of the half tire are connected as a whole with the both sides of the inner layer full tire outer edge, and inject gas or liquid in the inner layer full tire, and inject gas in the outer layer half tire. When the outer tire and the outer layer half-tire 2 are damaged, because the thickness of the outer layer is much smaller than that of the inner layer, the impact on the balance of the vehicle is very small, so that it is difficult to cause deviation phenomenon, even if there is not too much, if the inner layer is completely The tire 1 is injected with liquid, which will not burst the tire because the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com