Marine riser tensioning ring with automatic locking function

An automatic locking and riser technology, which is applied to drilling pipes, casings, drilling equipment, etc., can solve problems such as increased difficulty of operation, increased swing range, and endangering the safety of on-site operators, so as to eliminate potential safety hazards and ensure No separation, realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

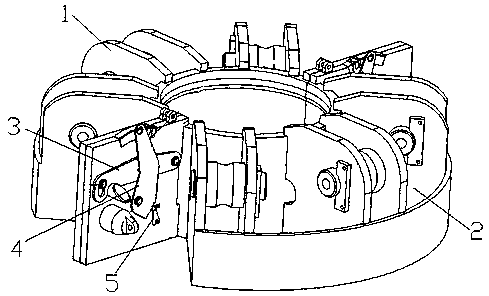

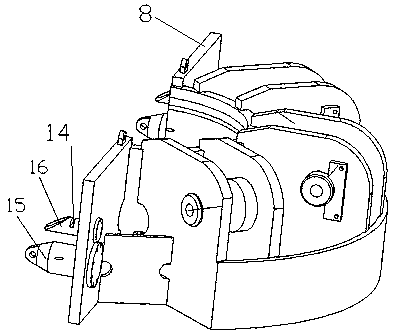

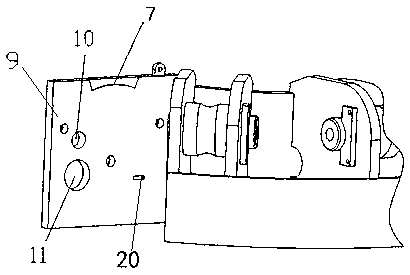

[0029] A riser tensioning ring with an automatic locking function, which includes a tensioning ring male body 1 and a tensioning ring mother body 2 adapted to each other, the two sides of the tensioning ring male body 1 and the tensioning ring mother body 2 are respectively Two matching male butt-joint plates 8 and female butt-joint plates 9 are provided, and guide pins 15 and locking pins 16 are provided on the adjacent side walls of the male butt-joint plates 8 and the female butt-joint plates 9 to guide The pin shaft 15 is located below the locking pin shaft 16. The front end of the locking pin shaft 16 is an inclined cut surface, and the rear part of the cut surface is provided with a groove 14; Pin hole 11, the locking pin hole 10 that is compatible with the locking pin shaft 16, the locking arm 3 is arranged horizontally above the locking pin hole 10, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com