Electronic level collimation vertical line offset determination calibration method

An electronic level and calibration method technology, applied in the direction of instruments, measuring devices, etc., can solve the problems of normal measurement, troublesome maintenance, and the inability of the electronic level to accurately target the coding scale, so as to improve the on-site adjustment ability and work efficiency. Accurate and ensure the effect of correct use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

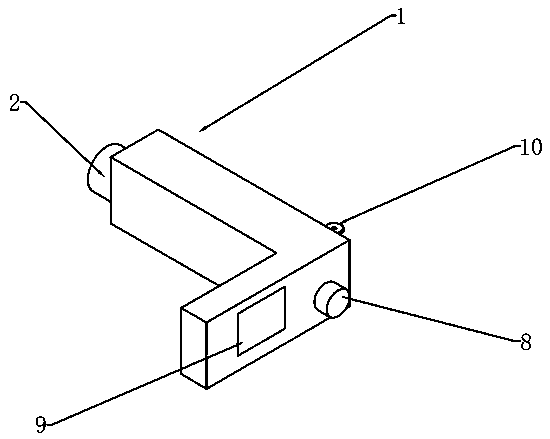

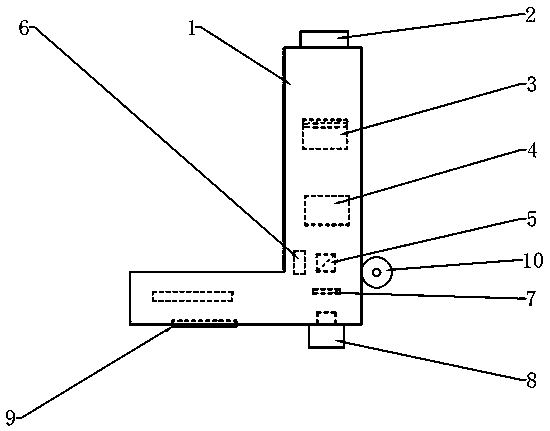

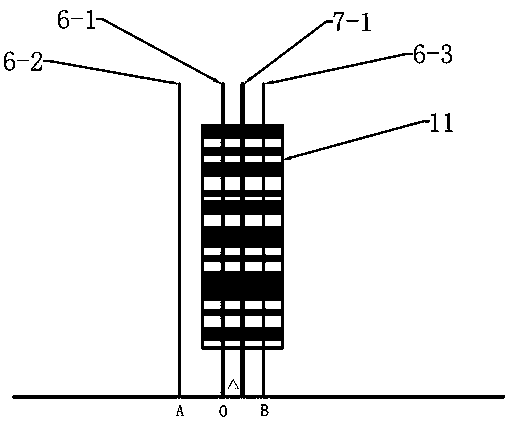

[0015] The method for measuring and calibrating the offset of the electronic level aiming at the vertical line of the present invention has an electronic level, and the structure of the electronic level is as follows: figure 1 , 2 As shown: there is a housing 1, in which there are objective lens 2, focusing lens 3, automatic horizontal line of sight compensator 4, beam splitter 5, electronic reading device 6 (that is, the CCD image decoding used in conjunction with the coding level scale reading device), reticle 7, electronic eyepiece 8, and a display terminal 9 and a level 10 are also provided on the housing 1. The display terminal 9 is composed of a display screen and buttons. The same coding scale 11; follow the steps below in turn:

[0016] a. Use the auxiliary tripod to place the electronic level and the coded scale 11 on two points on the ground respectively according to the method of the prior art, level the electronic level so that the coded scale 11 is vertical and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com