A Crack Detection Method in Bridge Quality Inspection

A detection method and bridge technology, which is applied in the field of crack detection, can solve problems such as high technical level requirements for technicians, large subjective errors such as human errors, and difficulty in ensuring the stability and accuracy of measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and specific conditions.

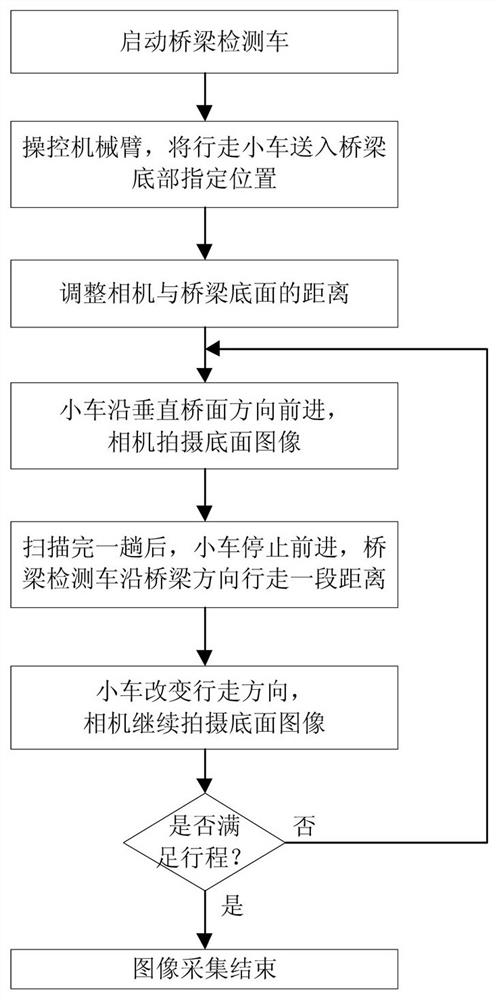

[0053] In the specific implementation of the present invention, a crack detection method in bridge quality detection comprises the following steps:

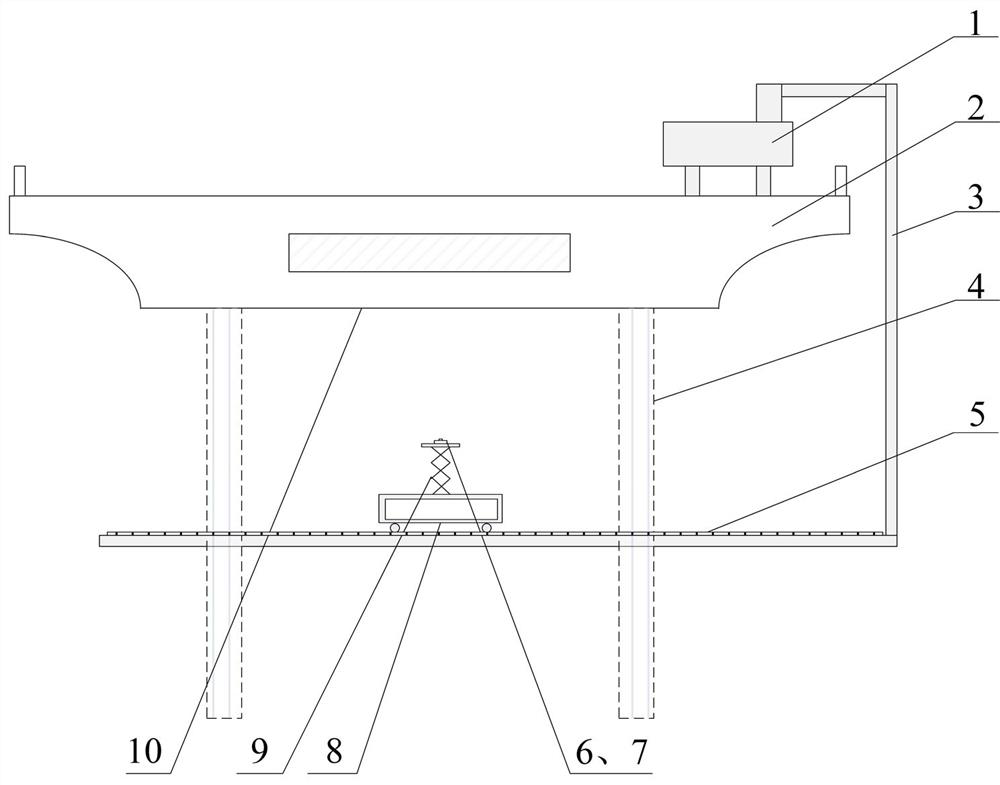

[0054] (1) Installation equipment:

[0055] Depend on figure 1 As shown, the detection vehicle 1 is driven to the top of the area to be detected on the bridge 2, and the downward mechanical arm 3 is installed on the detection vehicle 1, and the linear track 5 parallel to the bridge to be tested part 10 is installed on the lower part of the mechanical arm 3. The track 5 is fixed on the working platform installed on the pier 4, and the traveling trolley 8 is installed on the linear track 5, so that the traveling trolley 8 reciprocates along the linear guide rail 5, and the traveling trolley 8 and the control host (optional, shown in the figure (not shown) are connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frame rate | aaaaa | aaaaa |

| photosensitivity | aaaaa | aaaaa |

| beam angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com