Transformer fault detection device based on infrared imaging technology

A technology of transformer fault and detection device, applied in the direction of measuring device, instrument, measuring electricity, etc., can solve problems such as waste of manpower and material resources, large transformer volume, delay in fault diagnosis time, etc., to achieve good flexibility, good adaptability, and avoid faults The effect of diagnosis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

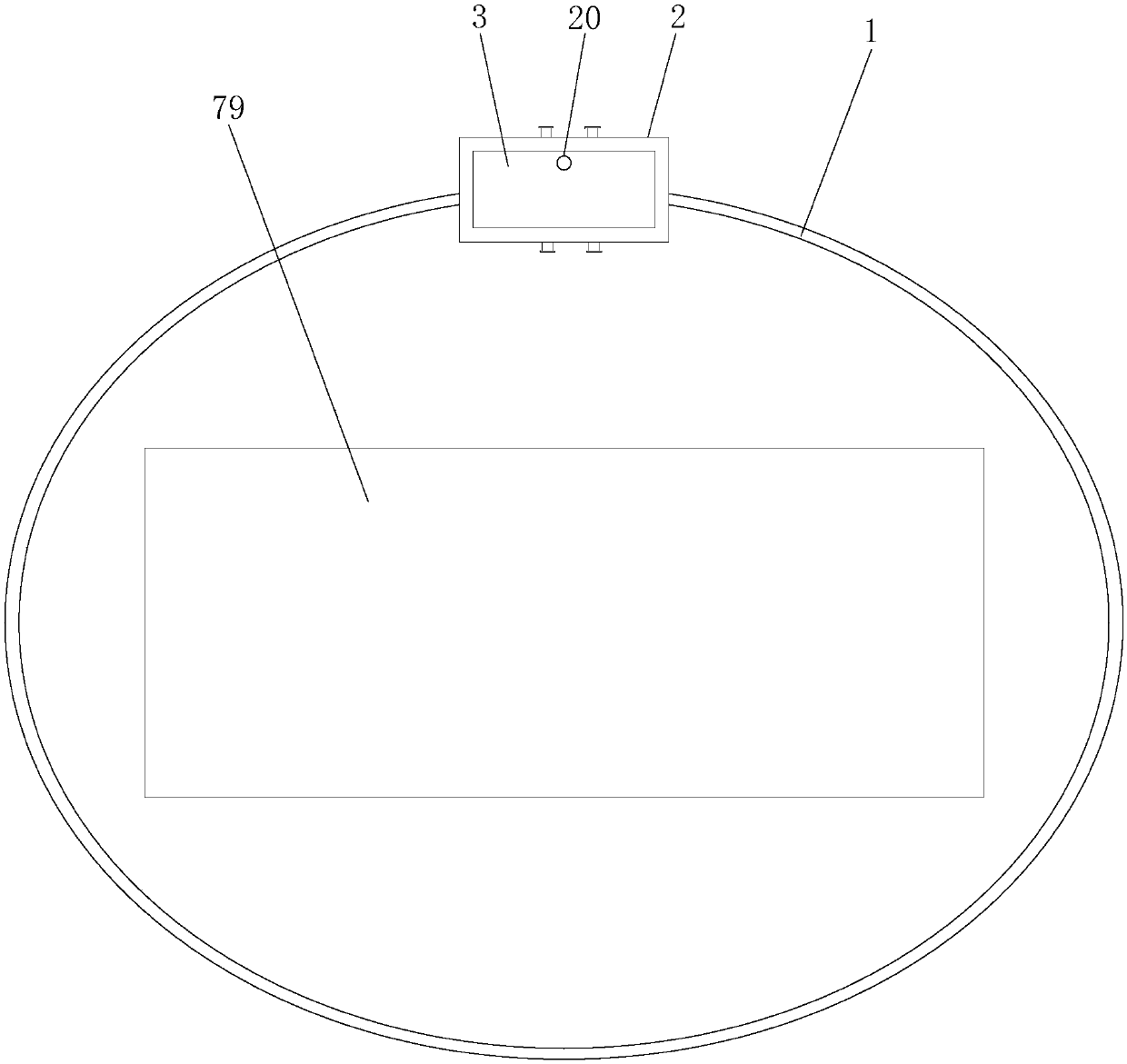

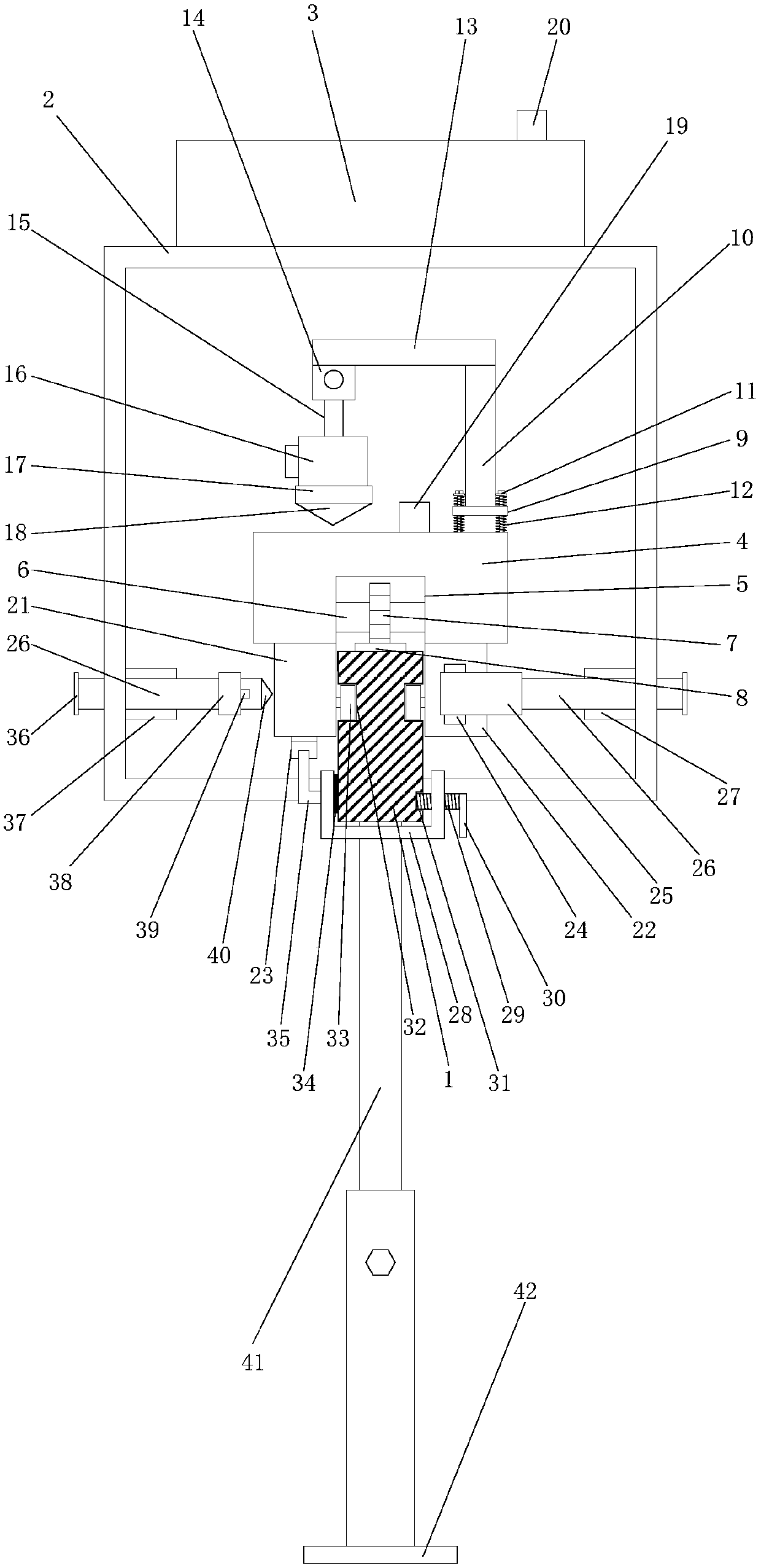

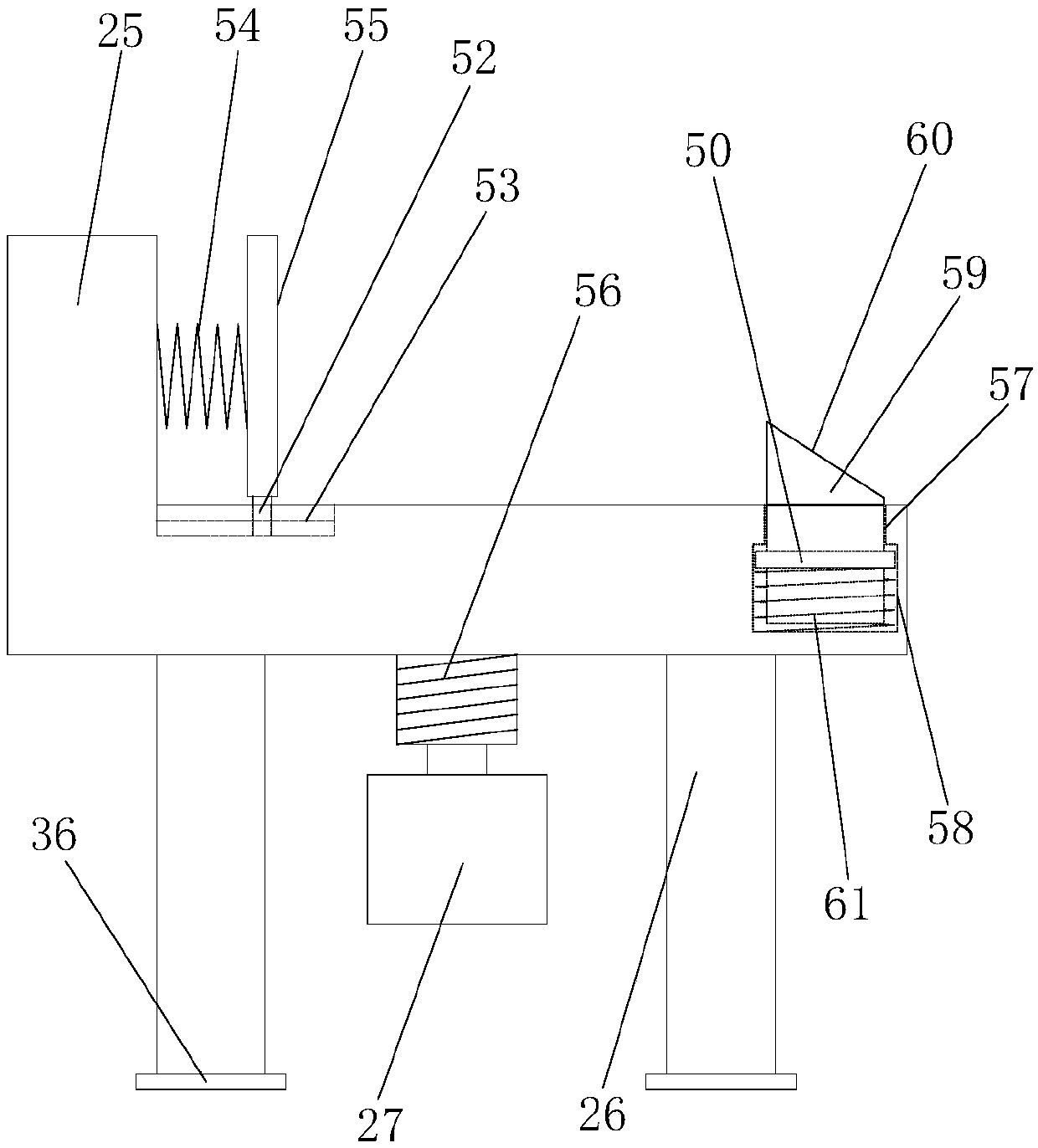

[0022] Such as Figure 1-7 As shown, the transformer fault detection device based on infrared imaging technology disclosed by the present invention includes: a remote server, a cruise track 1, a protective cover 2, a terminal control box 3, a mobile shooting mechanism and each shooting trigger mechanism; the cruise track 1 is a circular track , is arranged around the periphery of the transformer 79 through each track support structure; the track support structure is composed of a vertical support rod 41, a vertical insertion tube, a lower end plate 42 and a height adjustment bolt; the upper end of the vertical support rod 41 is fixedly installed on the cruise On the lower side of the track 1, the lower end is inserted into the vertical insertion tube; the lower end plate 42 is fixedly installed on the lower end of the vertical insertion tube; the height adjustment bolt is threaded and installed on the tube wall of the vertical insertion tube and the screw end of the height adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com