Accurate Modeling and Modulus Calculation Method for Microstructure of Fiber Reinforced Ceramic Matrix Composites

A composite material, fiber reinforced technology, applied in design optimization/simulation, special data processing applications, etc., can solve problems such as differences in test results and differences in weaving methods, and achieve the effect of accurate macroscopic effective modulus values.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

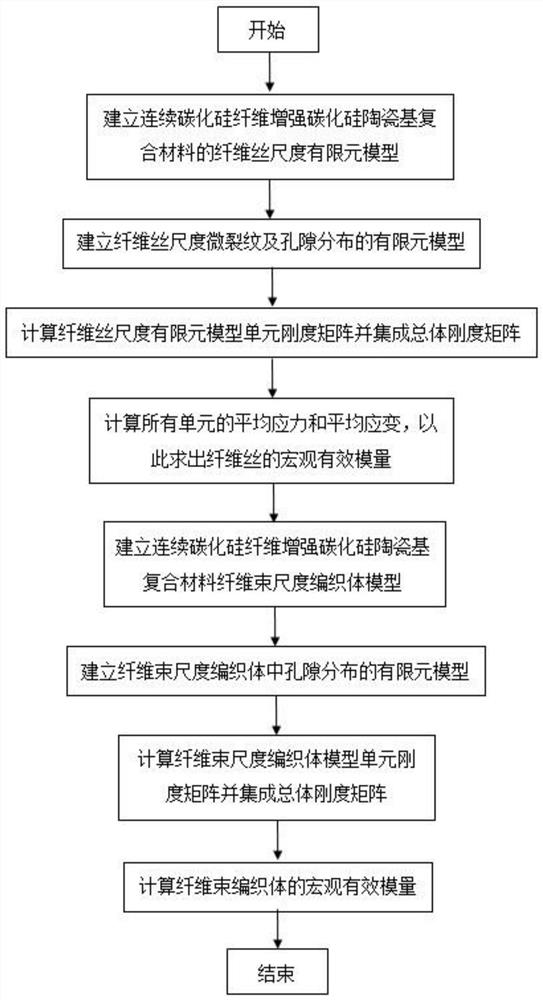

[0085] Such as figure 1 As shown, a method for accurate modeling and modulus calculation of the microstructure of fiber-reinforced ceramic matrix composites includes the following steps:

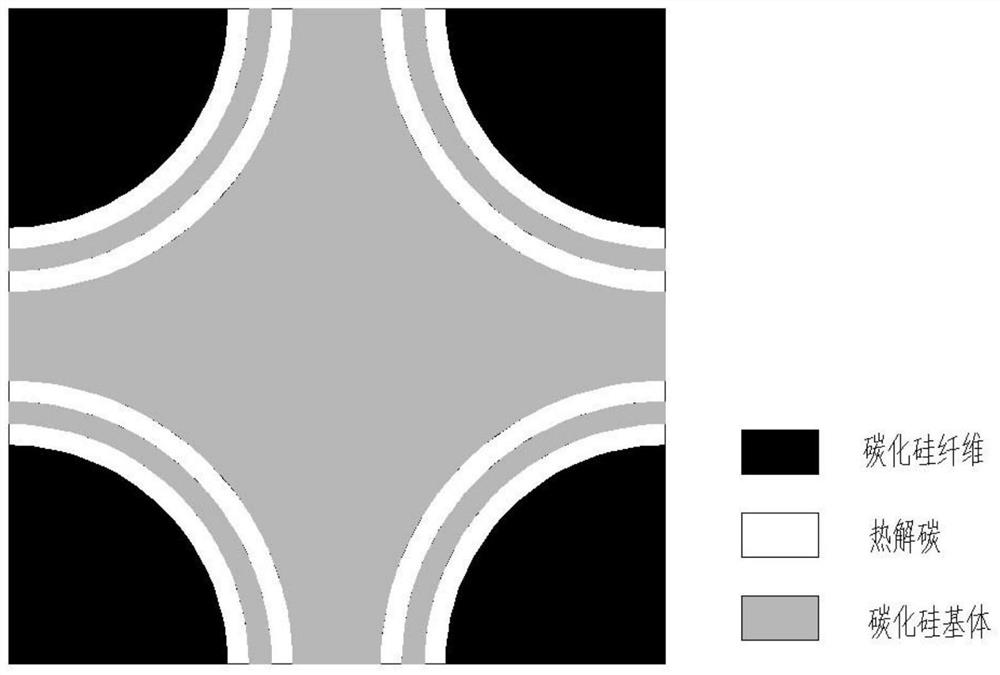

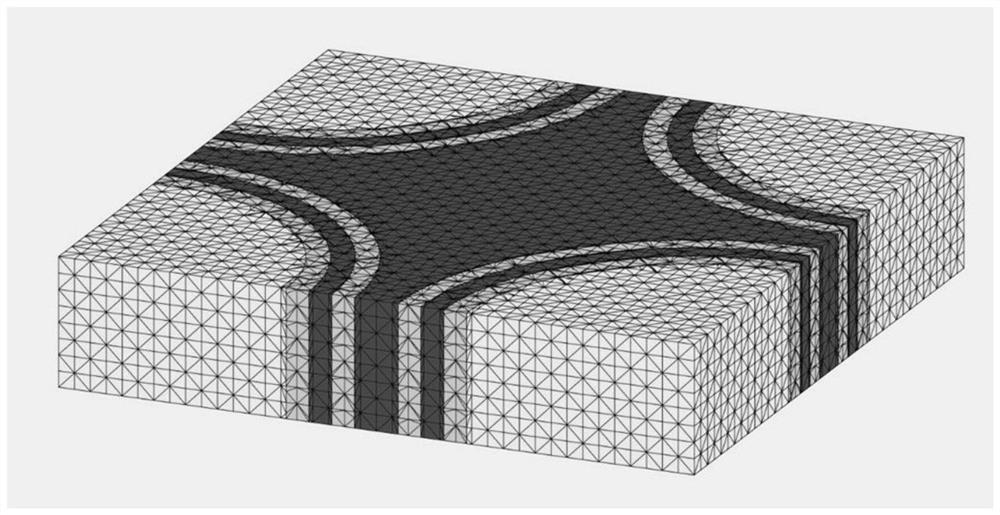

[0086] S1. Establish the fiber-scale finite element model of continuous silicon carbide fiber-reinforced silicon carbide ceramic matrix composites; the specific implementation method is: use the level set method and unit automatic discrete technology to cut and distinguish the fiber-scale model into carbon fiber, Three components of pyrolytic carbon and SiC matrix. According to related studies, the cross-sectional structure of tooth enamel at the micron scale is as follows: figure 2 As shown, based on the level set method and element automatic discretization technology, the fiber scale model is cut and divided into three components: carbon fiber, pyrolyti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com