Wind guiding structure and wind guiding method of electric oven

An air guide structure and technology of an electric oven, applied in the field of ovens, can solve the problems of affecting the cooking effect of food, the temperature of the oven inner tank is too high, and cannot be adjusted, and achieves the effect of ensuring smoothness, avoiding hot air eddy current, and eliminating local high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

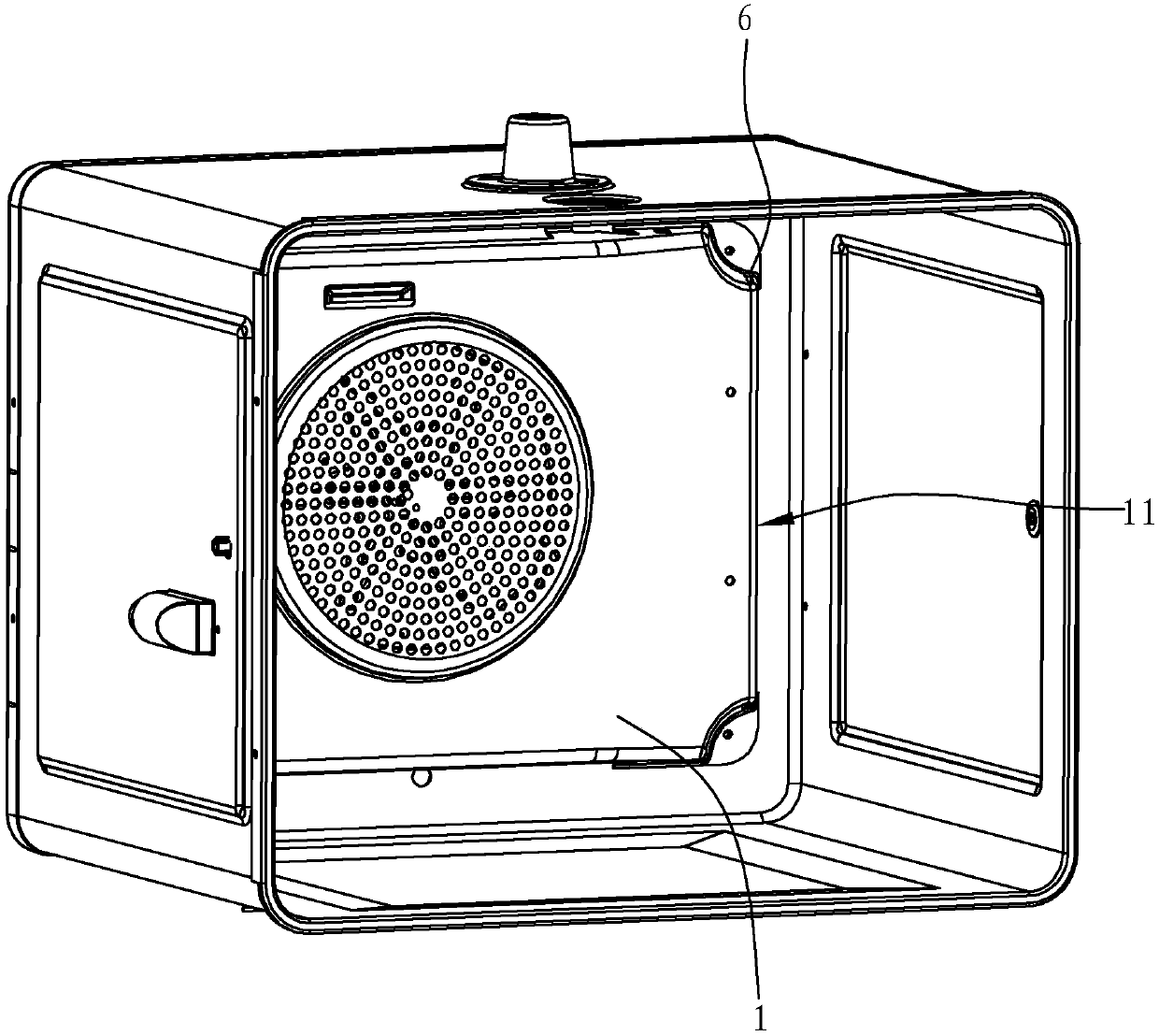

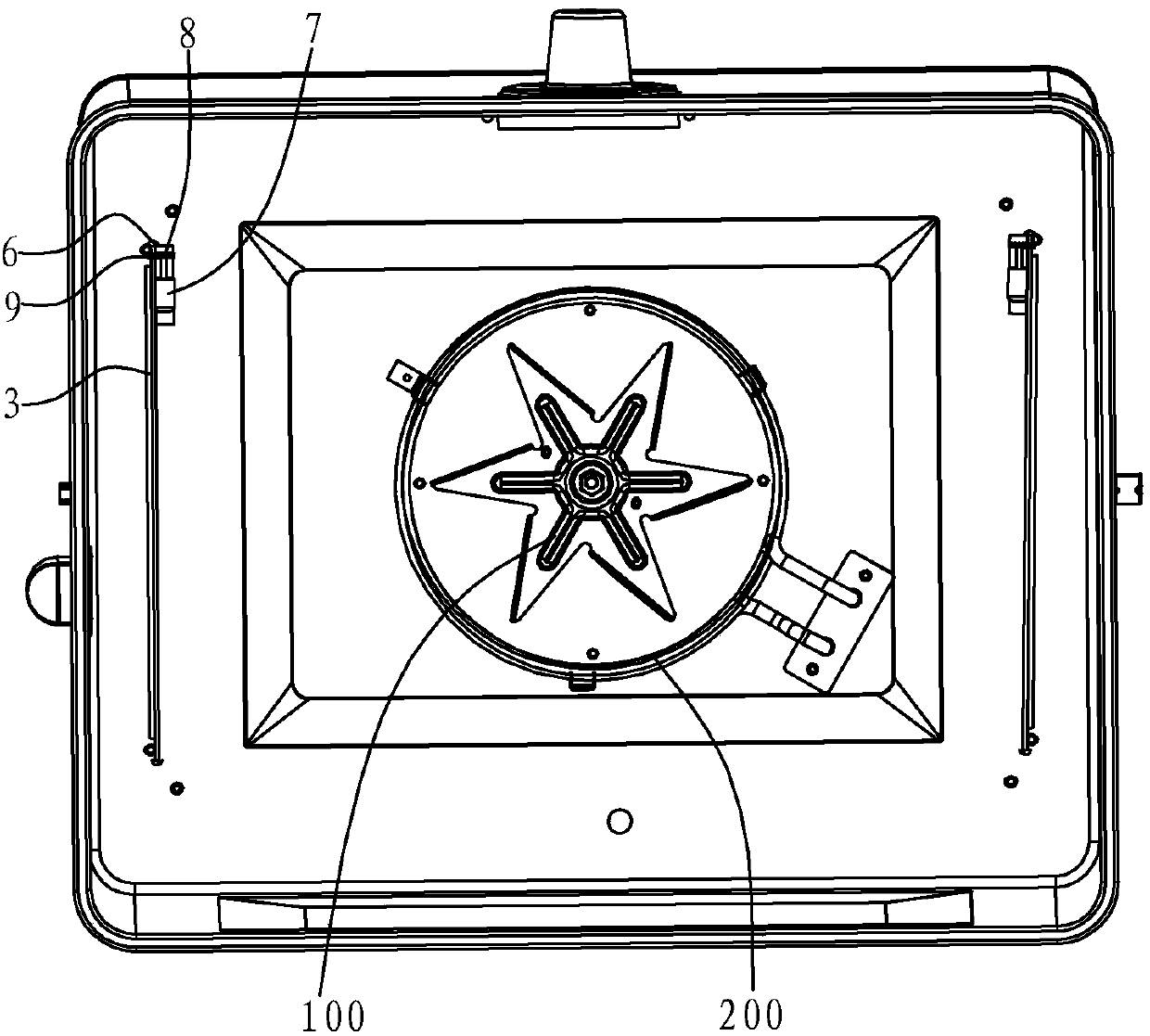

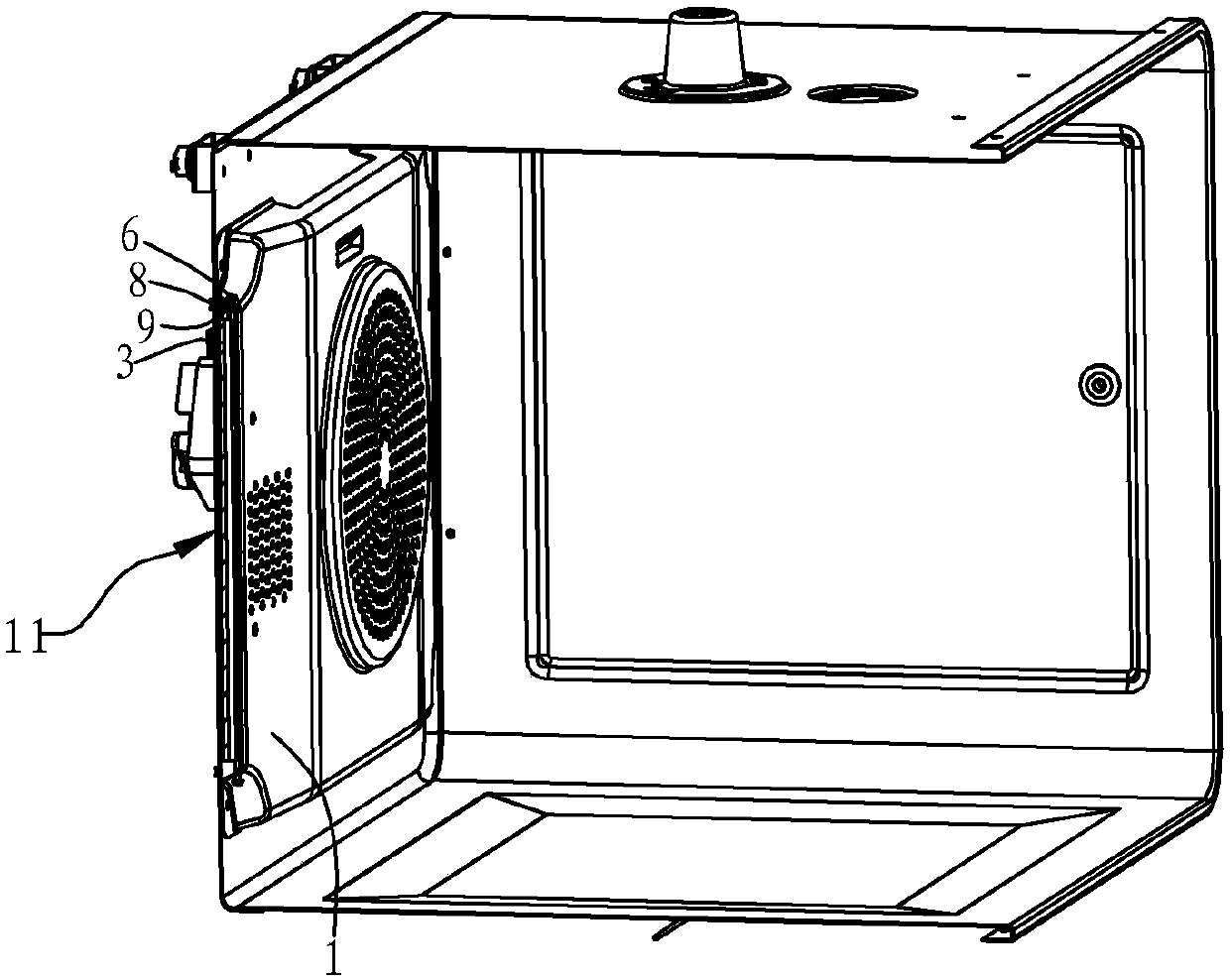

[0029] Such as Figure 1 to Figure 6 As shown, the basic environment for the application of the air guide structure of the electric oven in this embodiment is: a hot air blower baffle 1 is arranged at the rear of the oven liner, and a hot air blower baffle 1 is arranged between the hot air blower baffle 1 and the rear inner wall of the oven liner. The back heating pipe 200, the back heating pipe 200 is arranged basically in a ring shape, and the hot air blower 100 is arranged in the central cavity of the back heating pipe. When the hot air blower 100 works, the back heating pipe 200 is blown out from the air outlet 11 arranged on the hot air blower baffle plate 1 . If the structure of the electric oven is as disclosed in the utility model patent with the authorized notification number CN206026110U in the background art, the air guide structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com