Injection mold for multi-color spectacle frame

A technology for injection molds and spectacle frames, applied in the field of injection molds for multi-color spectacle frames, can solve problems such as easy contamination, manual spraying, and large workload, and achieve the effects of ensuring molding quality, reducing workload, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

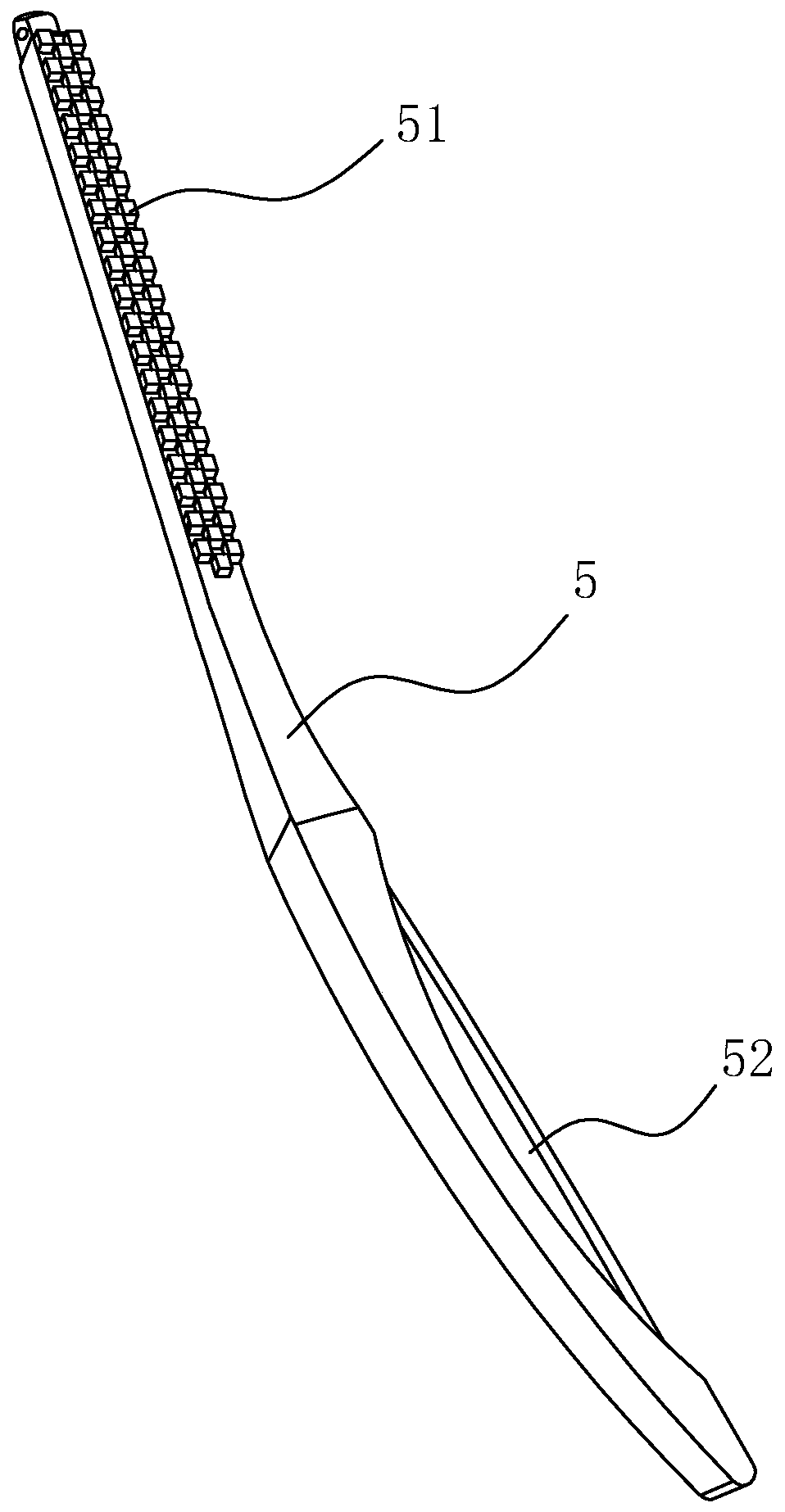

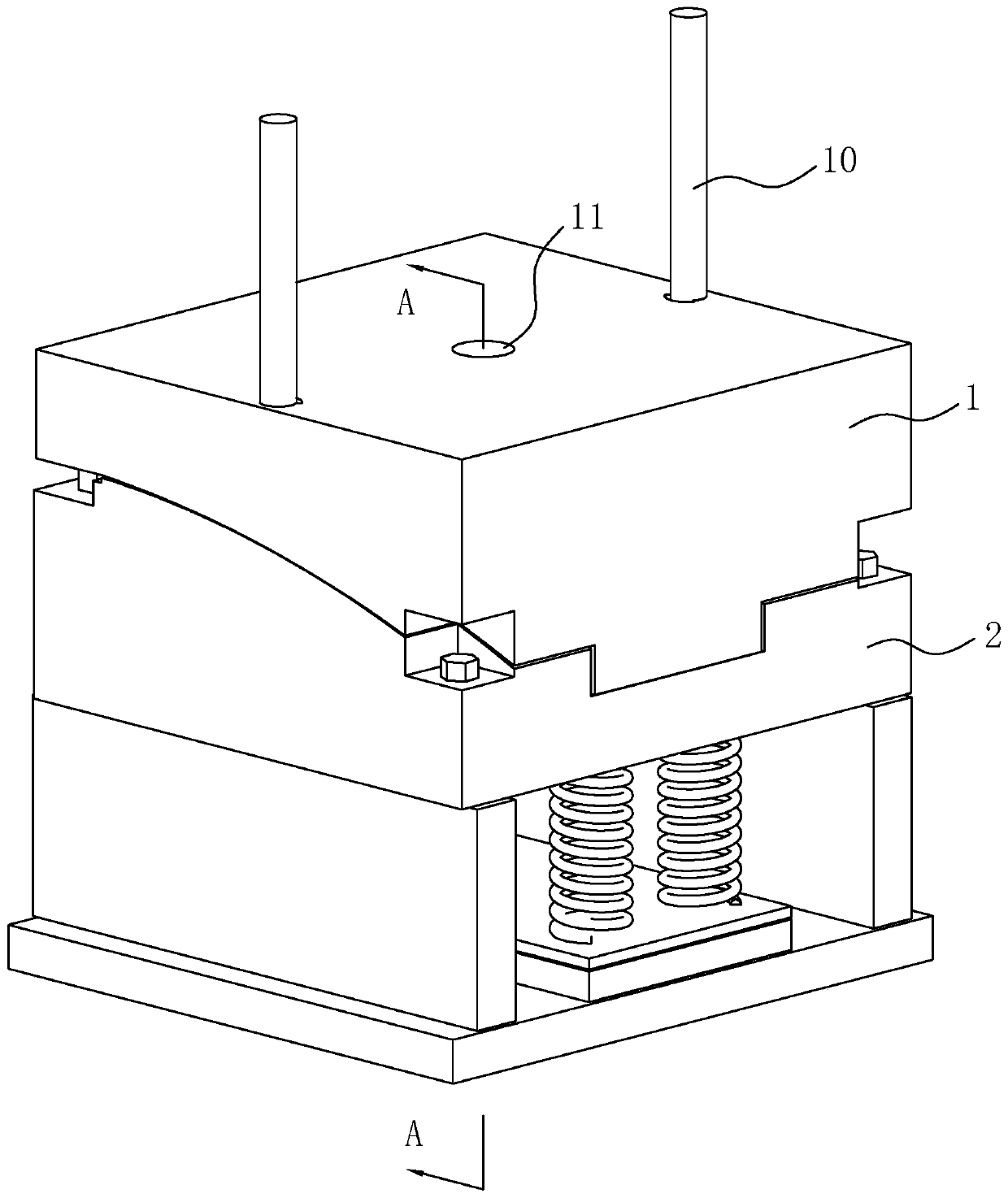

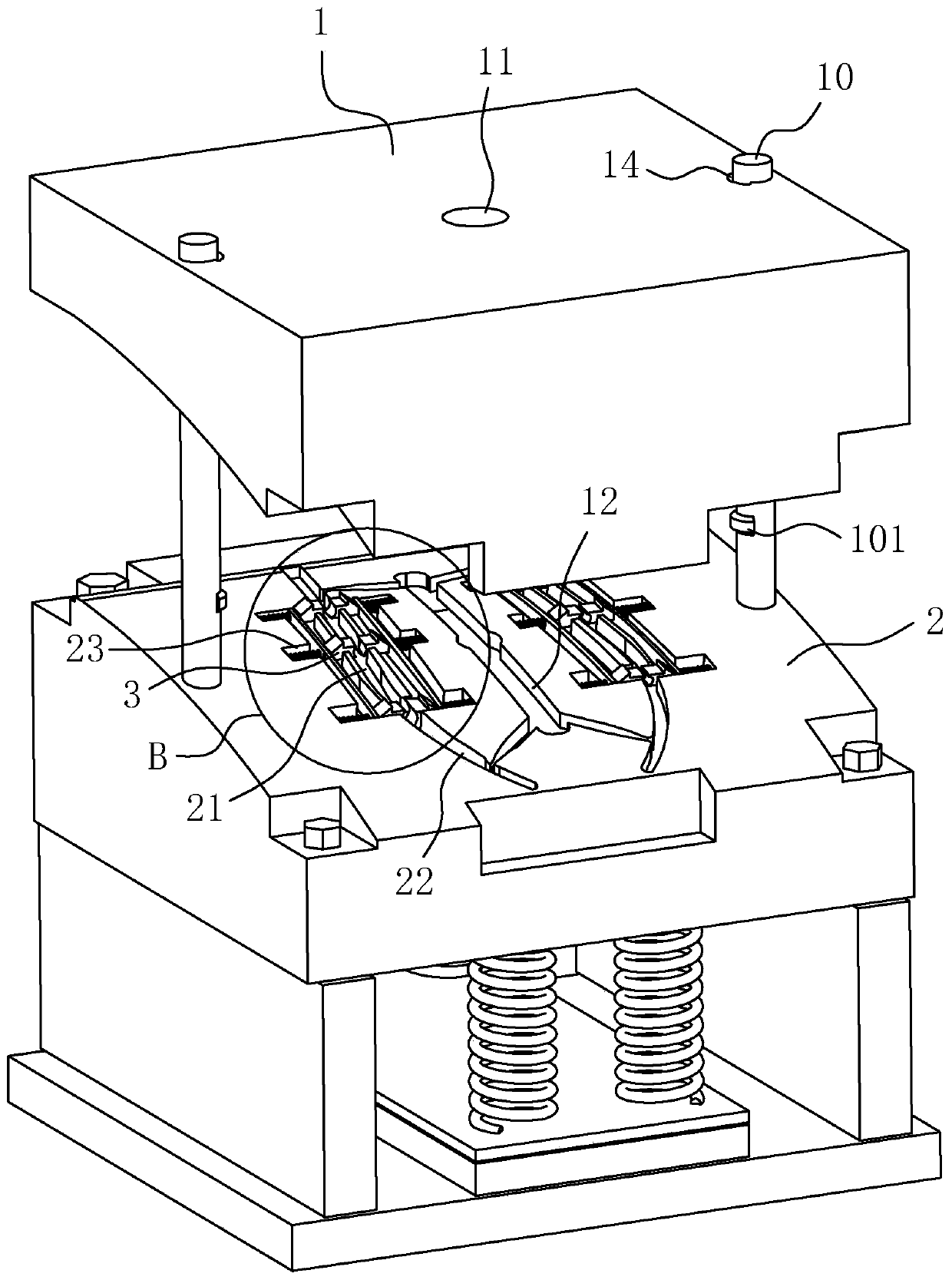

[0036] refer to figure 2 and image 3 , is an injection mold for a multi-color spectacle frame disclosed by the present invention, comprising an upper mold 1, a lower mold 2, and a guide column 10 arranged between the upper mold 1 and the lower mold 2. The top of the upper mold 1 is provided with an injection port 11 for the injection molding of the injection molding machine. The upper mold 1 and the lower mold 2 are all provided with a hot runner 12 and a positioning cavity 21 for placing the temples. The upper mold 1 and the lower mold 2 are also provided with There is a cavity 22 for forming the non-slip section 51 and the different-color part of the bending section 52 . Wherein the length direction of the hot runner 12 of the upper mold 1 is along the vertical direction (refer to Image 6 ), the hot runner 12 of the lower mold 2 is distributed to each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com