A sealing mechanism of a sharps box for general practice

A sealing mechanism and a sharp tool box technology, applied in the field of medical devices, can solve the problems of weak seal of sharp tool boxes, medical needles, blades falling out, personnel injuries, etc., to ensure the safety of use and transportation, and to improve compression and collision resistance. ability, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

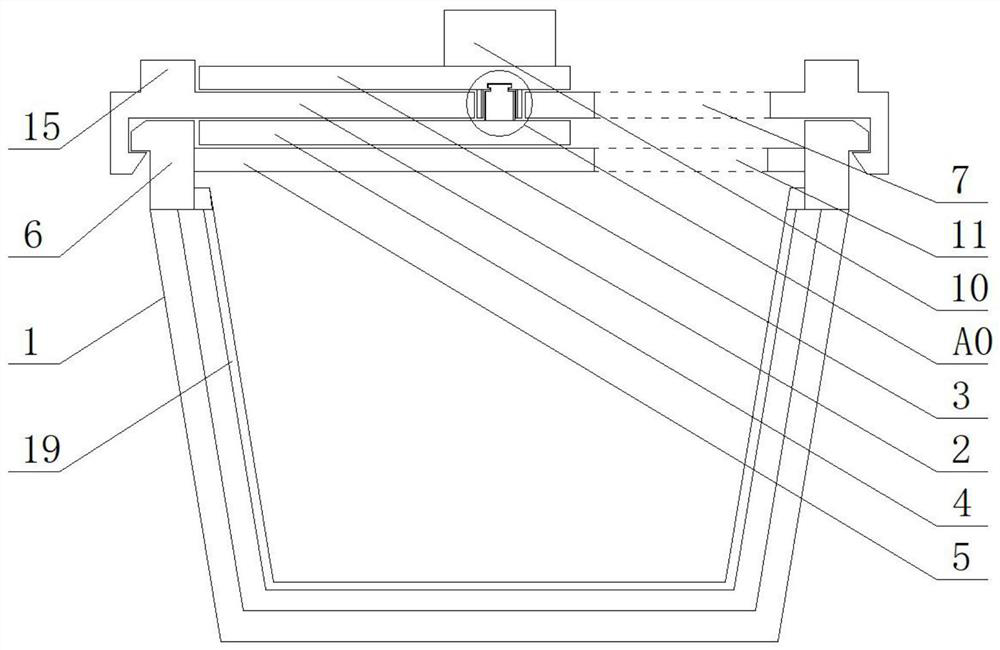

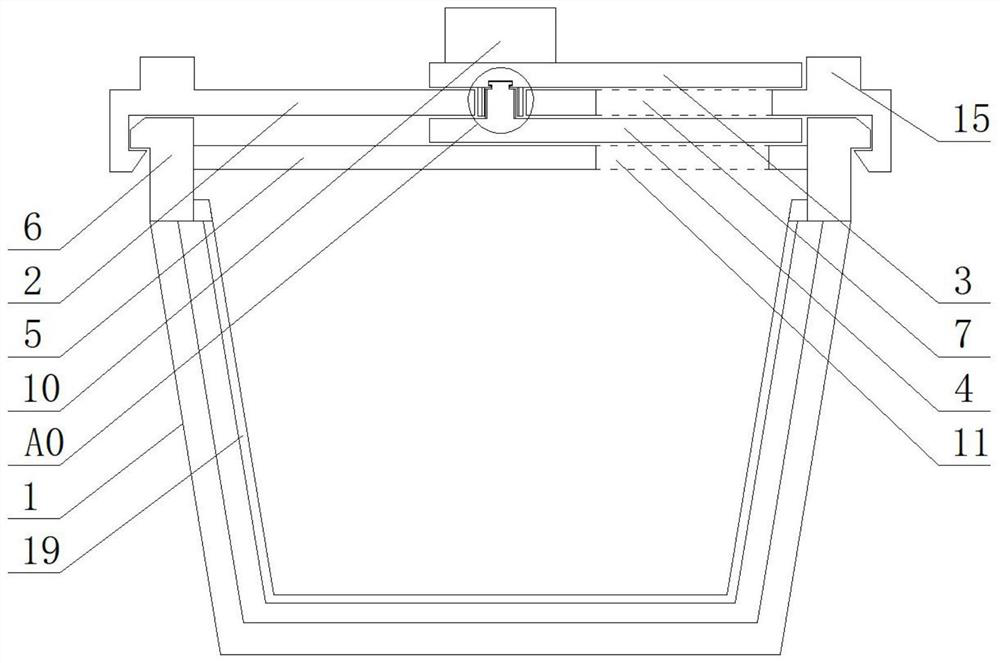

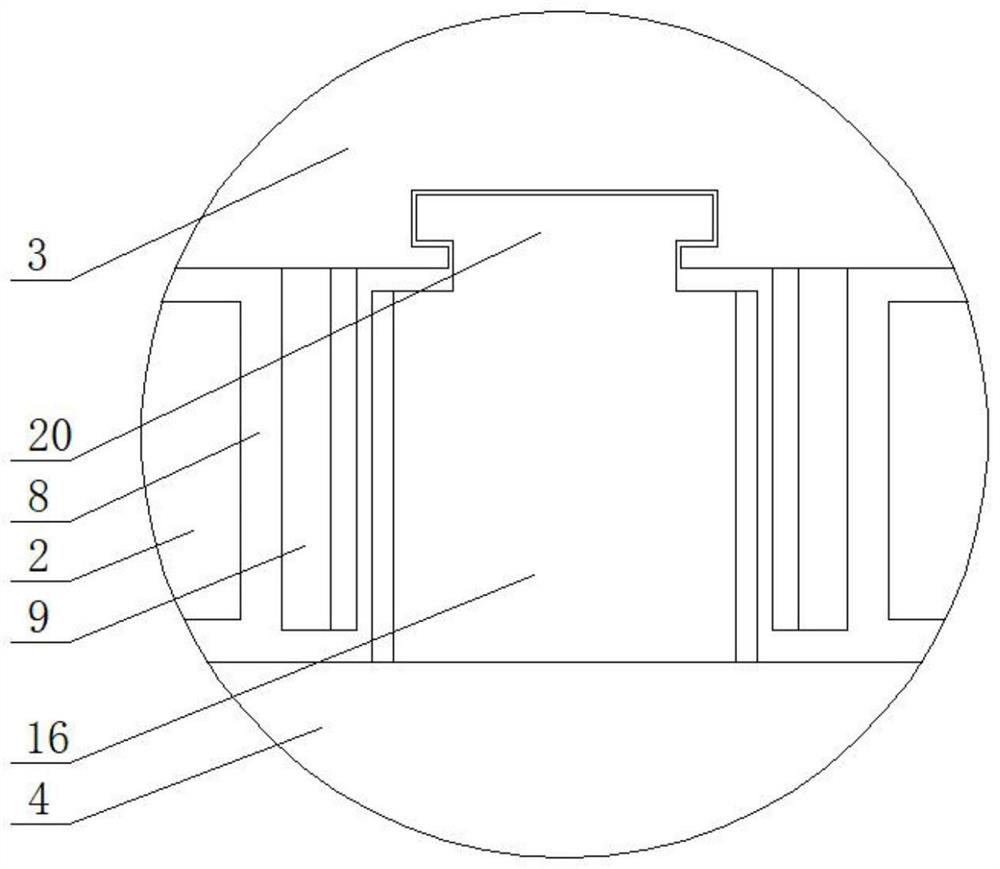

[0020] see Figure 1-6 , a sealing mechanism for a sharps box for general practice, including a cylinder body 1, a barrel cover 2, a No. 1 sealing rotating plate 3, a No. 2 sealing rotating plate 4, and an inner lining plate 5, and a mounting block is fixedly connected to the top edge of the cylinder body 1 6. The barrel cover 2 is clamped and connected to the installation block 6. A sealing ring is provided on the edge of the outer clamping part of the installation block 6 to enhance the sealing performance between the barrel cover 2 and the cylinder body 1. The upper end of the barrel cover 2 is provided with a fan-shaped No. 1 The input port 7 is used to put in medical sharp tools. The middle part of the barrel cover 2 is provided with a connecting hole 8, and a movable sleeve 9 is connected to the connecting hole 8 for relative rotation. The upper end of the movable sleeve 9 is fixedly connected to a No. The rotating plate 3 is in a semicircular structure, and the No. 1 in...

Embodiment 2

[0027] The working principle of the present invention is: when in use, put the medical sharps into the built-in barrel inside the barrel 1 through the No. 1 input port 7 and the No. 2 input port 11. Rotate the knob block 10 in the inclined direction to rotate the No. 1 seal rotating plate 3 and seal the No. 1 input port 7. When it needs to be used again, continue to turn the knob block 10 in the inclined direction of the No. 2 tooth 18 to make the No. 1 seal rotate The plate 3 opens the No. 1 input port 7. In the above operation, the No. 2 tooth 18 in the movable sleeve 9 is relatively slidingly connected with the No. 1 tooth 17 on the outside of the connecting pipe 16, and the side of the No. 2 sealing rotating plate 4 is due to the limit Block 12 blocks, so that the No. 2 sealing rotating plate 4 is always in a static state relative to the bung 2; when a certain amount of medical sharps is collected in the sharps box and needs to be processed, turn the knob block 10 along the...

Embodiment 3

[0029] This device can further prevent the sharp weapon from piercing the barrel wall through the provided inner lining board 5 and the built-in barrel, improve the anti-pressure and anti-collision ability of the sharp weapon box, and ensure the use and transportation safety of the sharp weapon box. The movable sleeve and the connecting pipe 16 can individually control the No. 1 sealing rotating plate 3, so as to facilitate the temporary sealing of the sharps box, so that when the medical staff take a break, the sharps box will not accidentally drop without causing the sharps to spill out. When a certain amount of medical sharps is collected in the sharps box and needs to be processed, the No. 2 sealing rotating plate 4 is used to seal and seal it, which can ensure that the sharps box will not be opened again during transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com