Atomization motor having automatic water absorption function and provided with suction feeding type atomizing disc

An atomizing disc and function technology, applied in the field of atomizers, can solve the problems of complicated installation and poor sealing, and achieve the effects of simple structure, easy sealing and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

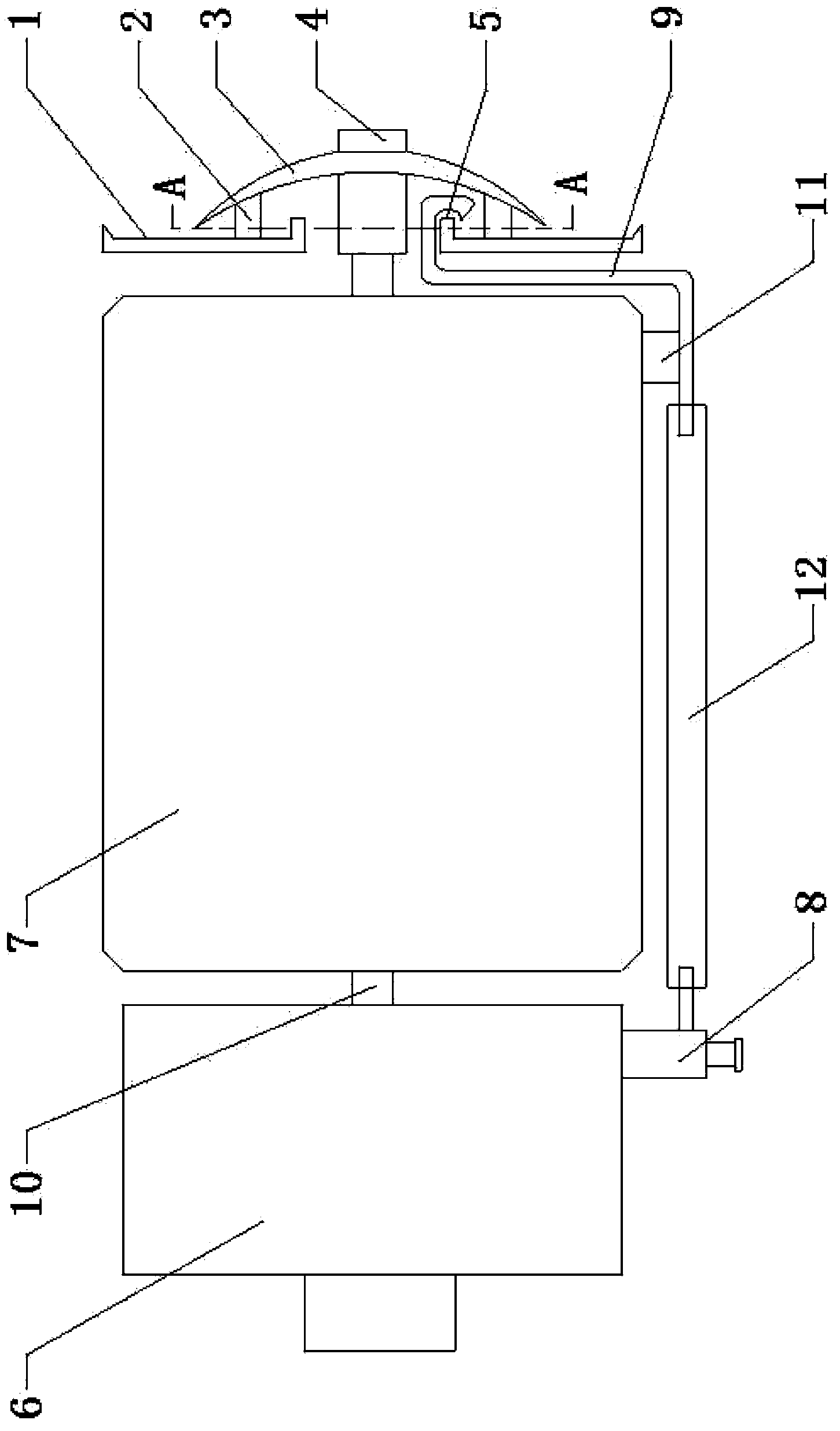

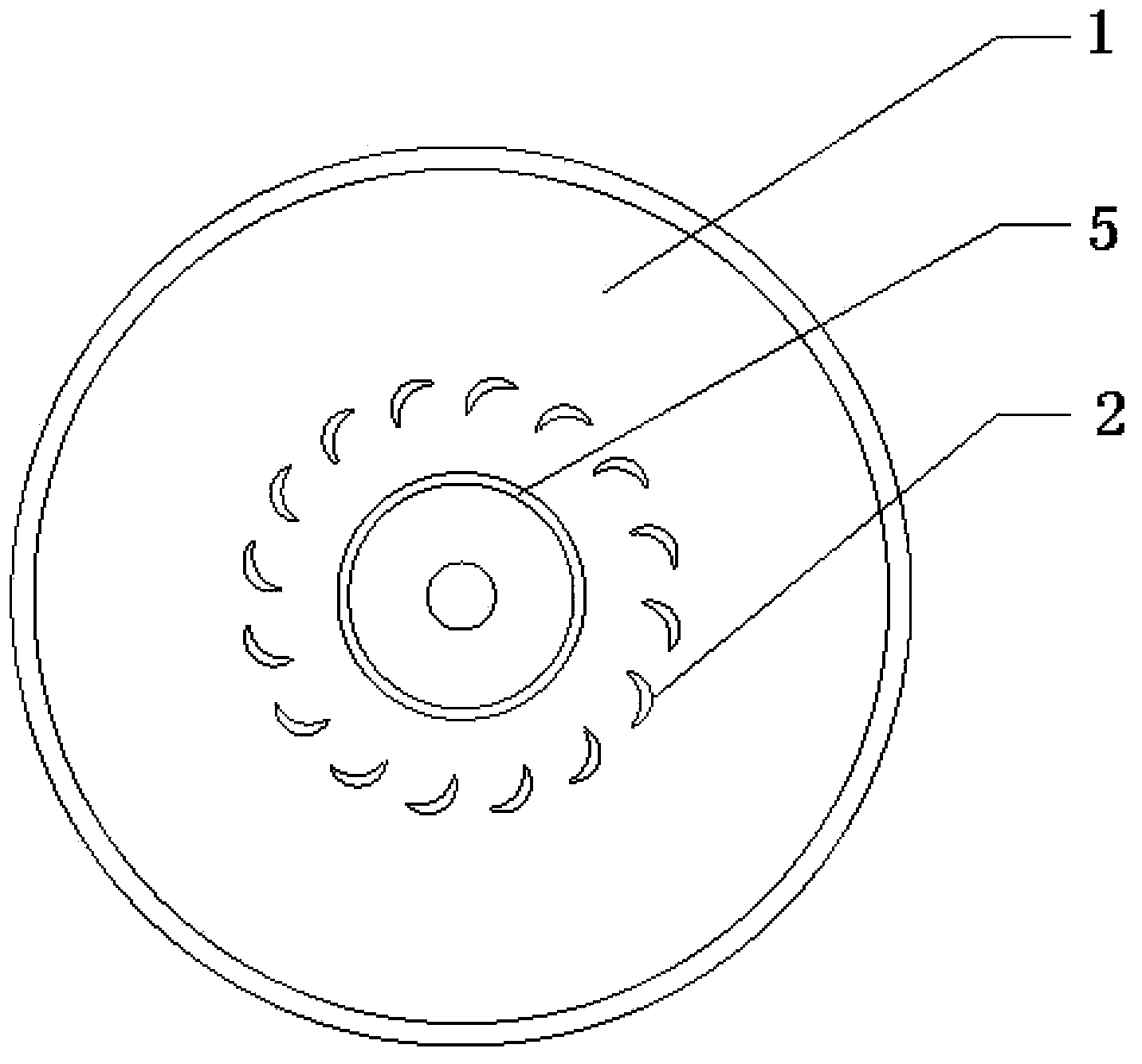

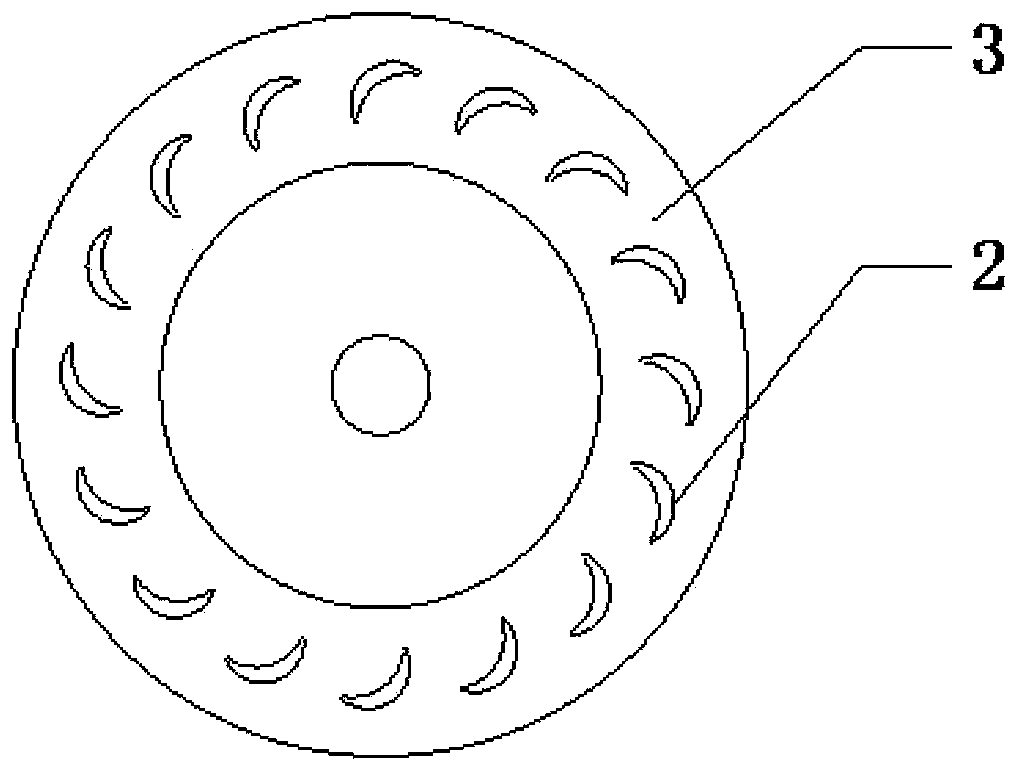

[0023] Such as Figure 1-3 The present invention shows an atomization motor with self-absorbing water function and a suction-feeding atomization disc, which includes an atomization disc. Cap 4, the center of the atomizing disc main body 1 is provided with a through hole, and the edge of the through hole is provided with an annular protrusion 5, and the upper ring of the atomizing disc main body 1 near the annular protrusion 5 is provided with a number of sucking blades 2, and the guide plate 3 One side is covered and fixed on all the sucking blades 2, and the fixed cap 4 is set at the center of the guide plate 3; it also includes a water pump 6, a motor 7, a water volume regulating valve 8 and a water delivery device 9, and the motor 7 has a pair of rotating shafts 10 One end of the rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com