A hydrogen sulfide removal system and desulfurization method

A hydrogen sulfide removal technology, applied in the field of desulfurization, can solve the problem of not being able to directly demonstrate the dynamic removal capacity of hydrogen sulfide gas, and achieve the effects of high utilization rate, high chemical stability and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

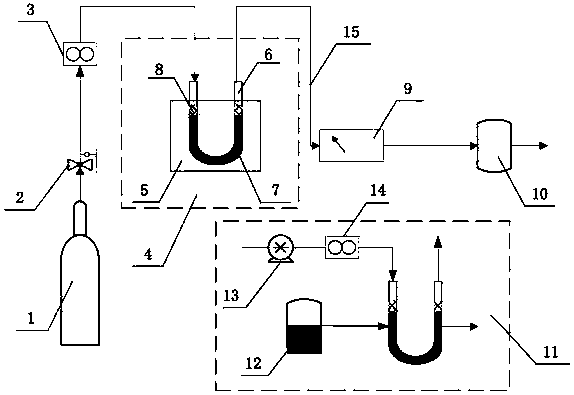

Method used

Image

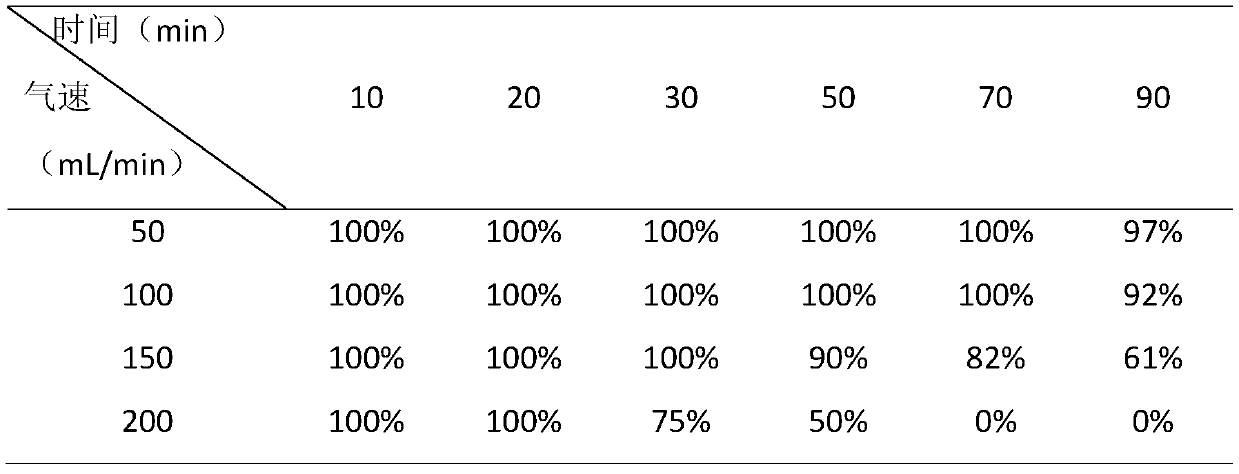

Examples

Embodiment 1

[0040] (1) Take commercially available white carbon black (McLean), grind it with a mortar, sieve it to 280-300 mesh, wash it with water 5 times until the supernatant is free of turbidity, and dry it at 130°C for 4 hours.

[0041] (2) Take 20 g (99%) of anhydrous copper chloride and 20 g (99%) of anhydrous triethylamine hydrochloride, mix them into a pear-shaped flask, and stopper the air. Under the condition of magnetic stirring at 20r / min, heat at 90°C for 12h.

[0042] (3) Add 110 g of absolute ethanol (AR) to the dark green viscous liquid obtained in step (2), and use a power of 130 W to sonicate for 8 minutes to obtain a uniform green solution.

[0043] (4) Add 210 g of the white carbon black obtained in step (1) to the ethanol solution of copper chloride-triethylamine hydrochloride obtained in step (3), shake for 5 seconds, and use 130W ultrasonic treatment for 10 minutes to impregnate evenly.

[0044] (5) The yellow-green mixture obtained in (4) was dried under vacuum ...

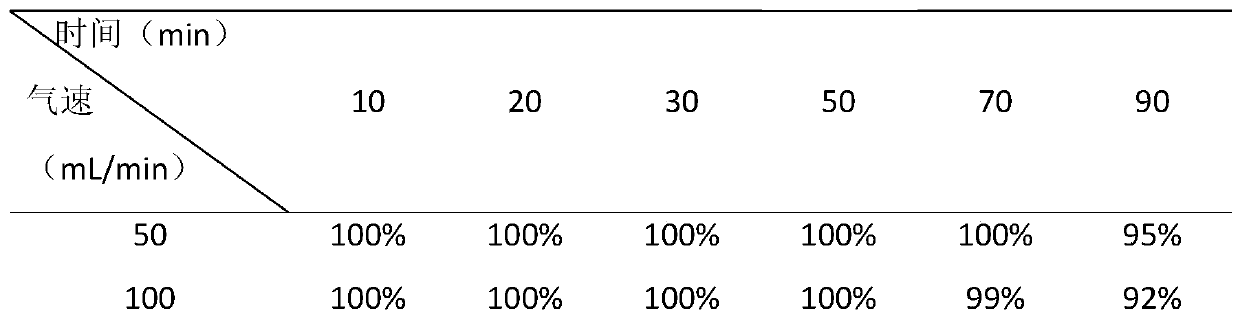

Embodiment 2

[0047] (1) Take commercially available white carbon black, grind it, and sieve it to 280-300 mesh. Rinse the sieved white carbon black with water for 4-6 times until the supernatant is free of turbidity, and dry at 150° C. for 5.5 hours.

[0048] (2) Take 5 g of anhydrous copper bromide (99%) and 5 g of anhydrous triethylamine hydrochloride (99%), and mix them into a three-necked flask. One of the necks is plugged to isolate the air, and the other two necks are ventilated with nitrogen to for protection. Under the condition of 22r / min magnetic stirring, heat at 110°C for 14h.

[0049] (3) Add 25 g of absolute ethanol (AR) to the viscous liquid obtained in step (2), and use a power of 120 W to sonicate for 8 minutes to obtain a homogeneous solution.

[0050] (4) Add 50 g of the white carbon black obtained in step (1) to the ethanol solution of copper bromide-triethylamine hydrochloride obtained in step (3), shake for 5 seconds, and use 120W ultrasonic treatment for 8 minutes....

Embodiment 3

[0054] (1) Take commercially available white carbon black (McLean), grind it with a mortar, sieve it to 280-300 mesh, wash it with water 5 times until the supernatant is free of turbidity, and dry it at 130°C for 4 hours.

[0055] (2) Take 20 g (99%) of anhydrous copper chloride and 20 g (99%) of anhydrous triethylamine hydrobromide, mix them into a pear-shaped flask, and protect with nitrogen. Under the condition of magnetic stirring at 20r / min, heat at 90°C for 12h.

[0056] (3) Add 110 g of absolute ethanol (AR) to the viscous liquid obtained in step (2), and use a power of 120 W to sonicate for 8 minutes to obtain a homogeneous solution.

[0057] (4) Add 210 g of the white carbon black obtained in step (1) to the ethanol solution of copper chloride-triethylamine hydrobromide obtained in step (3), shake for 5 seconds, and use 130W ultrasonic treatment for 8 minutes to impregnate evenly.

[0058] (5) The mixture obtained in (4) was dried under vacuum condition with a rotary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com