Breakable connection device

A connecting device and connecting bolt technology, which is applied in the direction of shipping equipment, etc., can solve problems such as broken cables, broken ship columns, broken anchor bolts, etc., to achieve the effects of protection from damage, reduced maintenance costs, and simple and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is further described in detail through specific implementation methods:

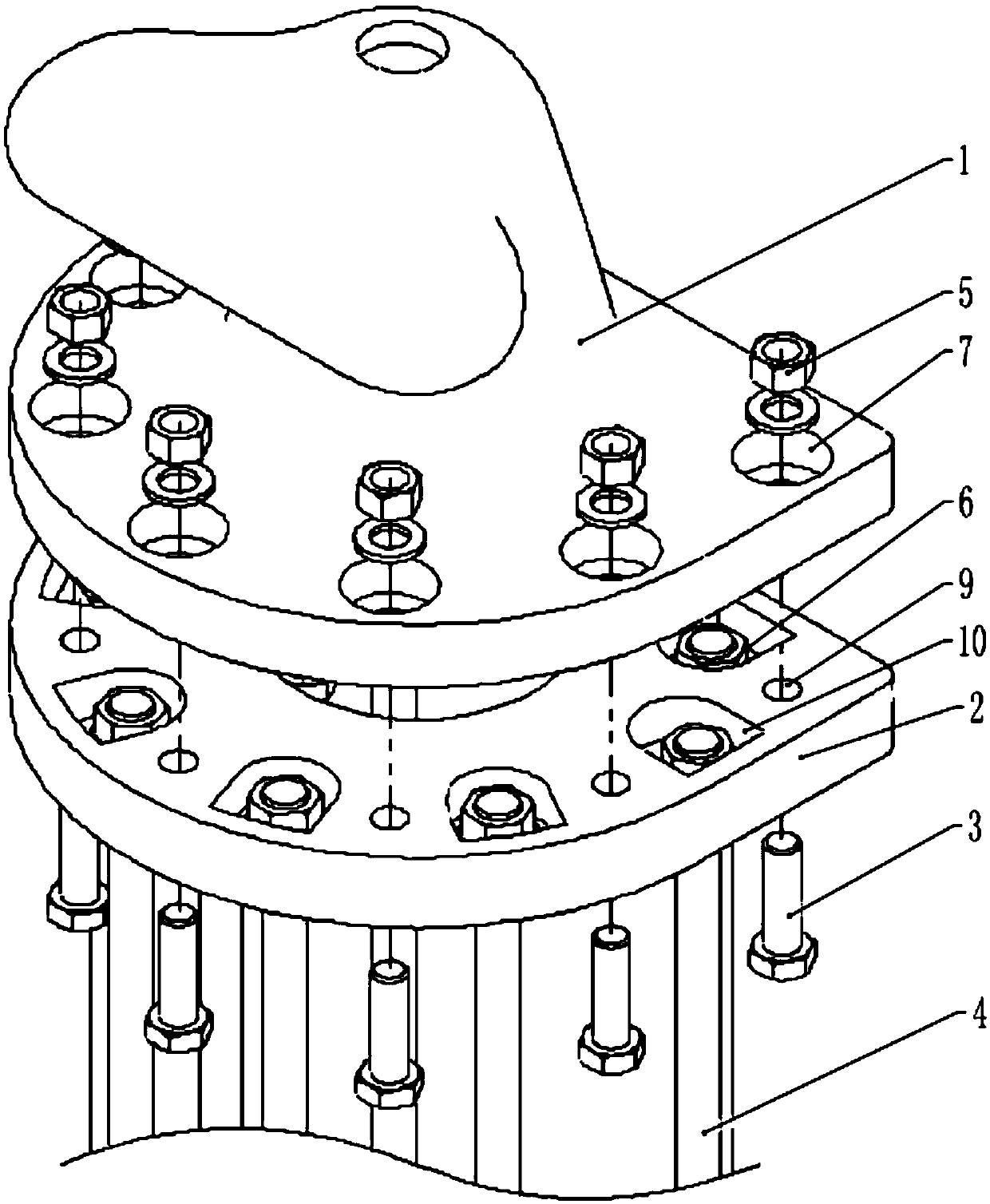

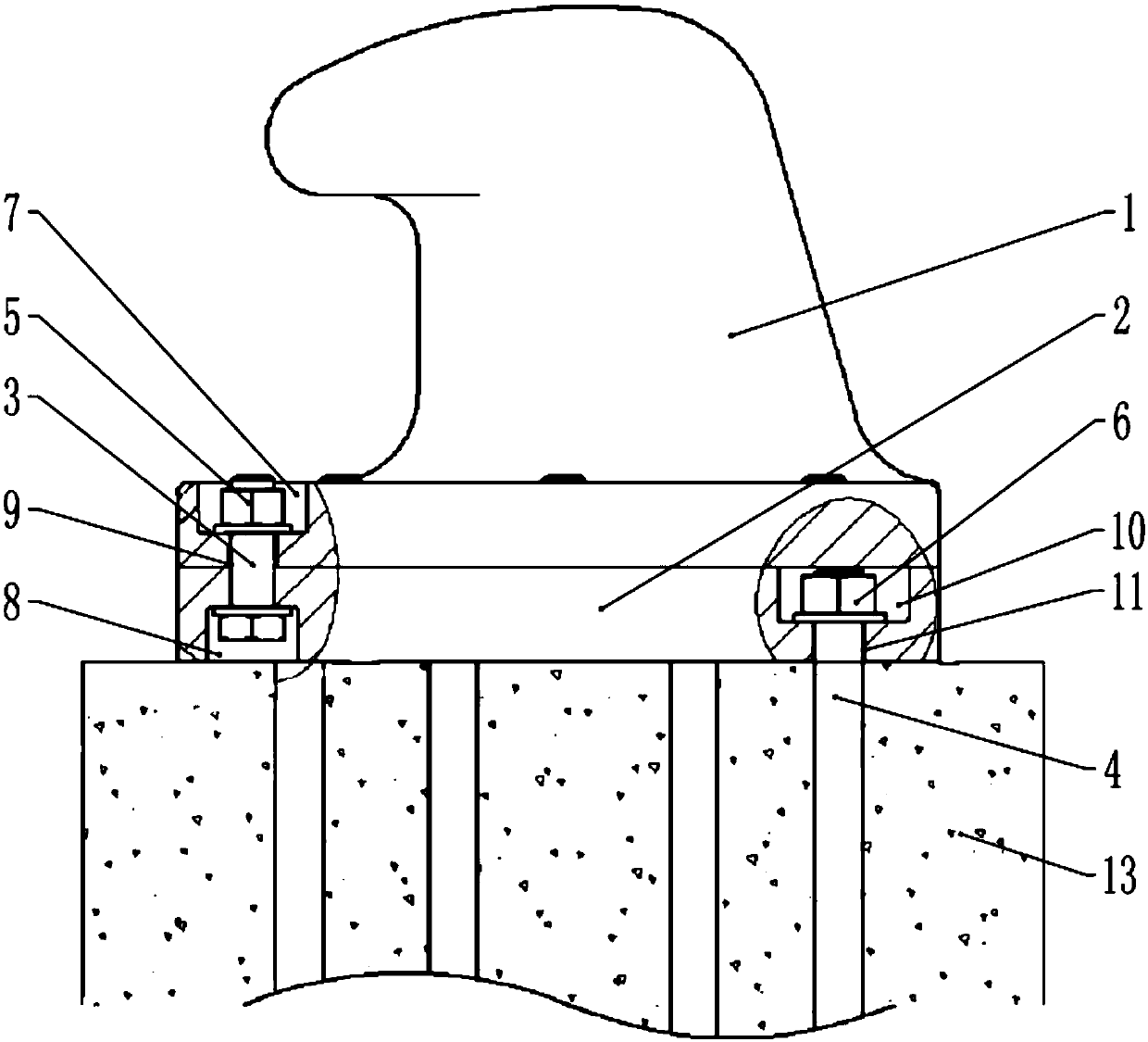

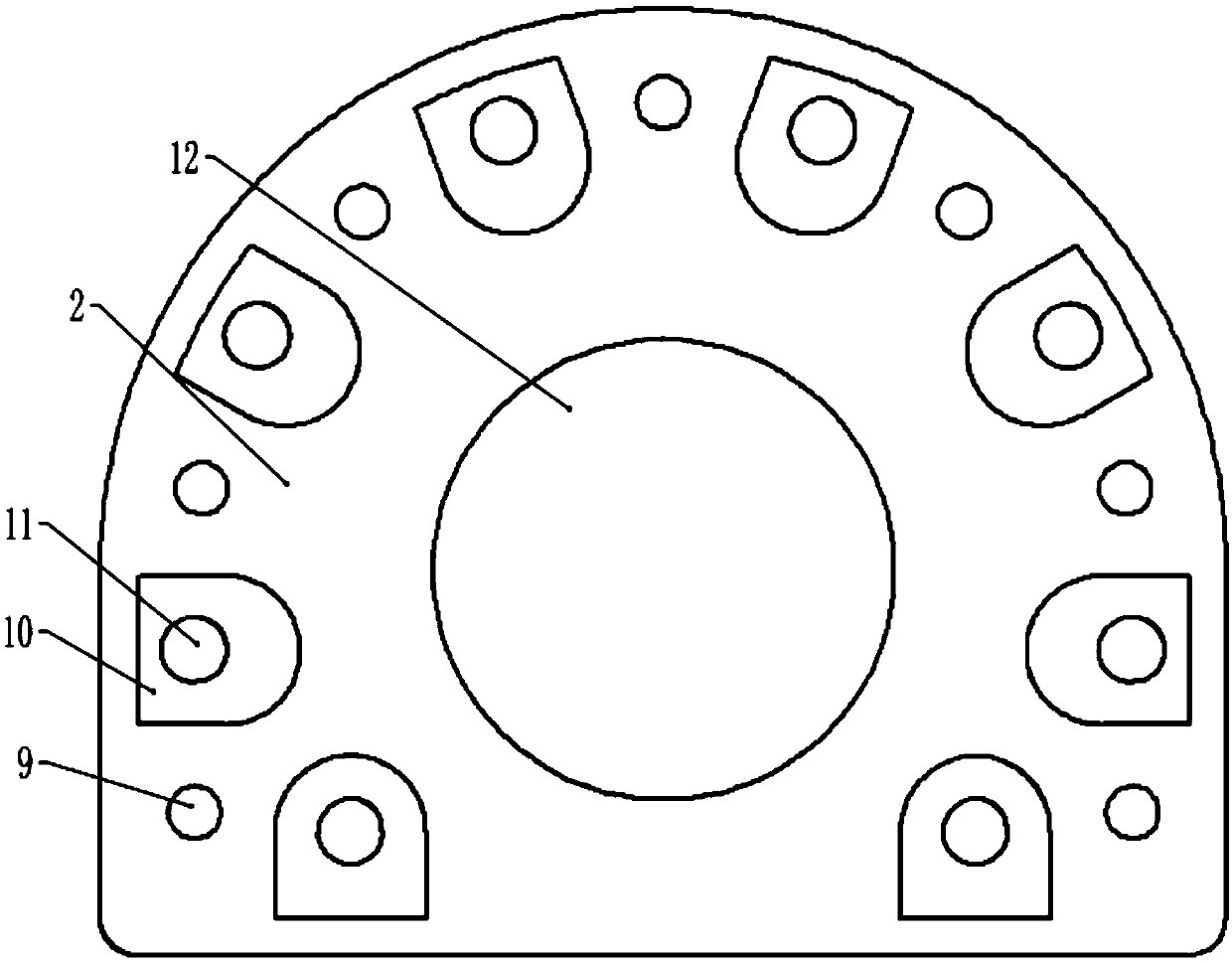

[0031] The reference signs in the drawings of the description include: bollard 1, base 2, connecting bolt 3, fixing bolt 4, connecting nut 5, fixing nut 6, third groove 7, first groove 8, first through hole 9. The second groove 10, the second through hole 11, the third through hole 12, and the concrete 13.

[0032] The embodiment is basically as Figure 1 to Figure 4 Shown:

[0033] The breakable connection device includes a bollard 1, a base 2, a first fixing member and a second fixing member, the first fixing member forms a fixed connection between the base 2 and the bollard 1, and the second fixing member connects the base 2 and the wharf The concrete 13 forms a fixed connection, and the bollard 1 is located above the base 2.

[0034] The first fixing member includes connecting bolts 3 and connecting nuts 5, and the second fixing member includes fixing bolts 4 and fixing nuts 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com