Patents

Literature

31results about How to "Reduce chance of bruising" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

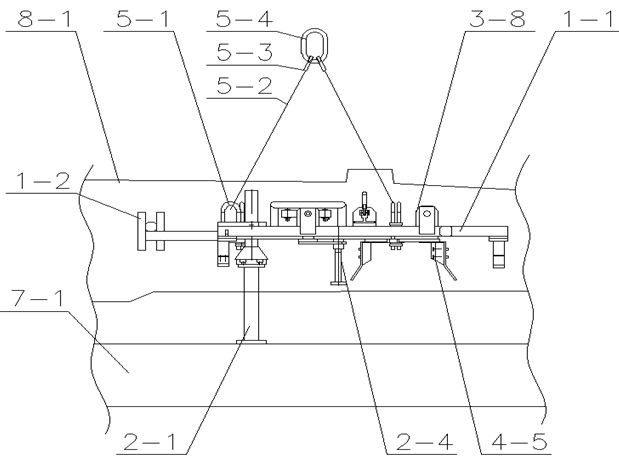

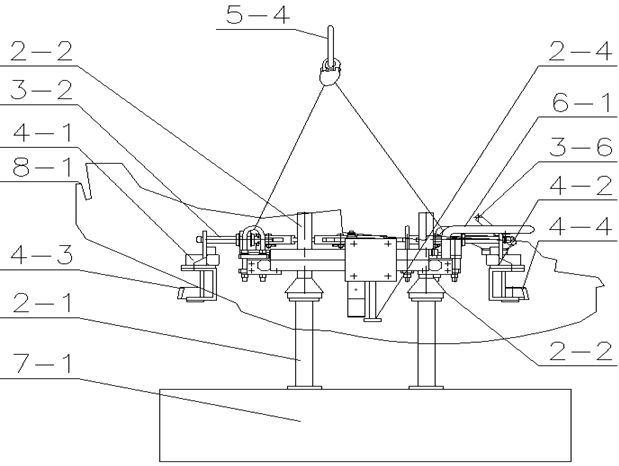

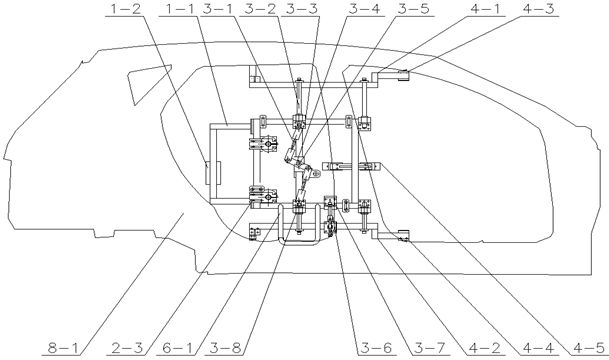

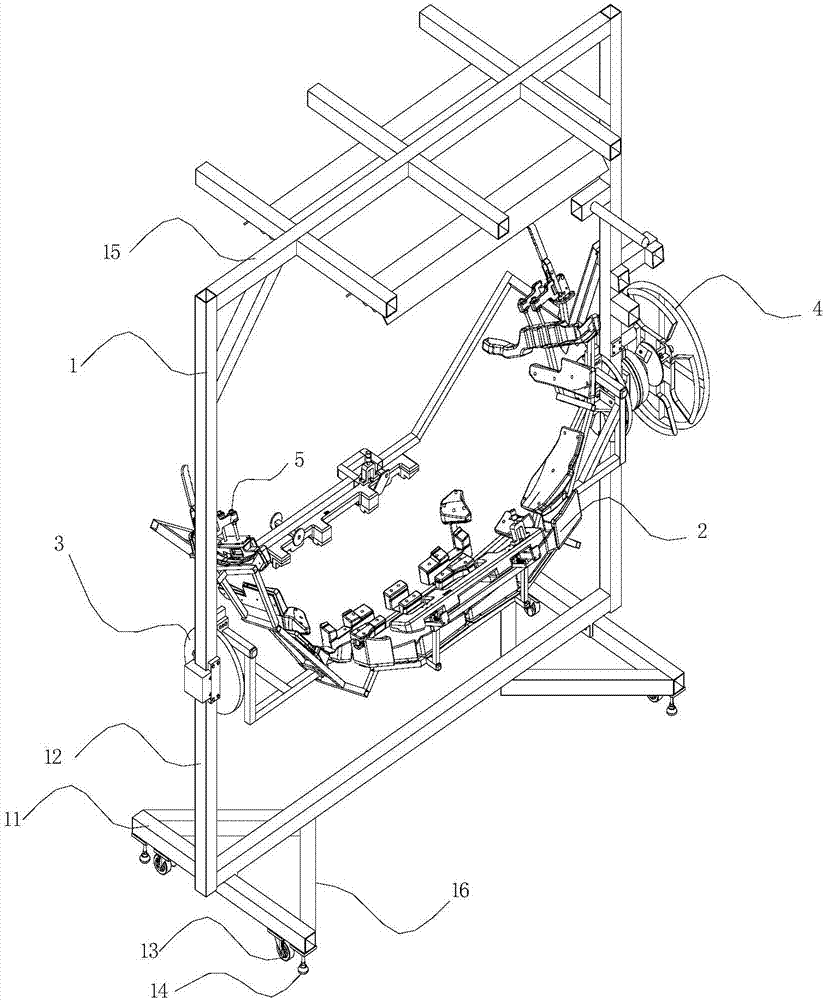

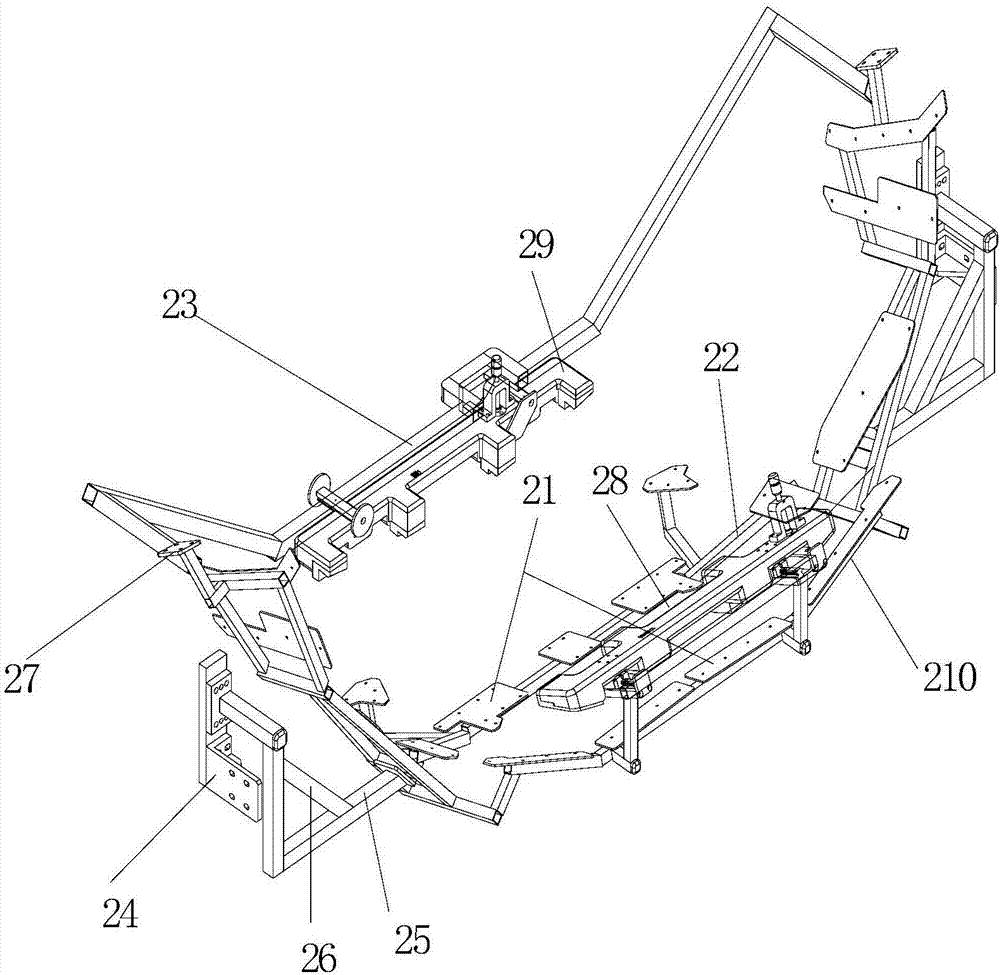

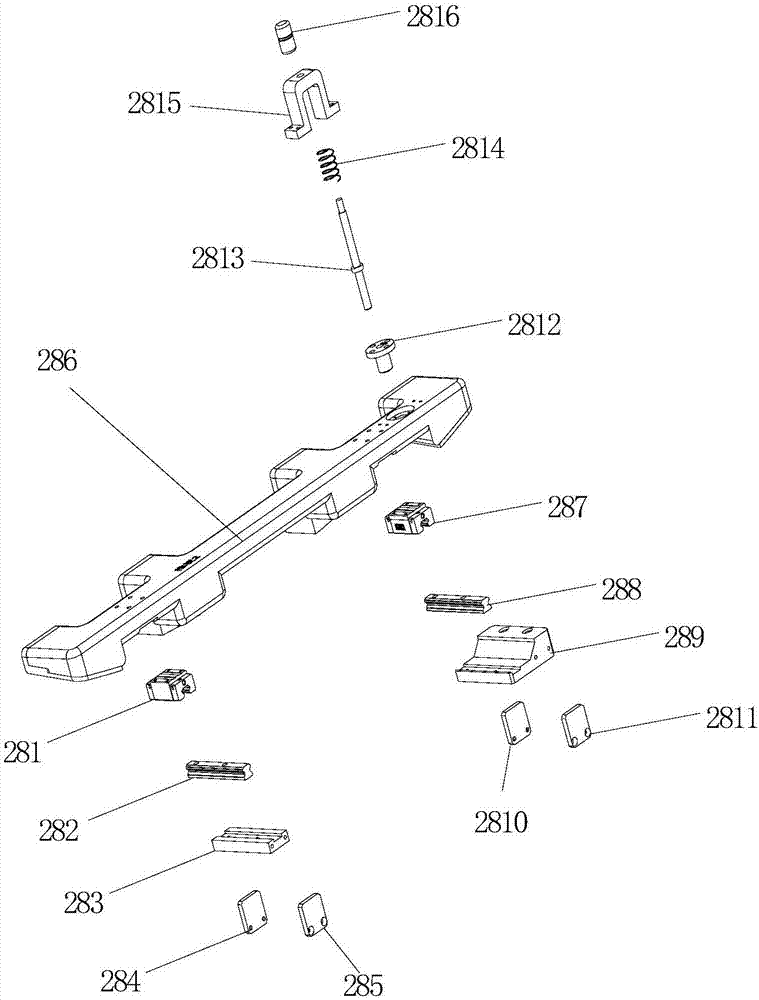

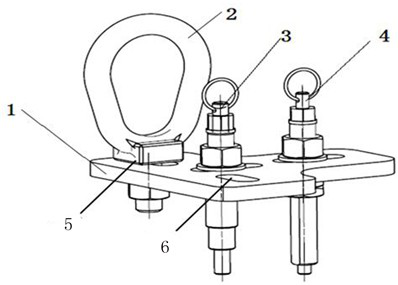

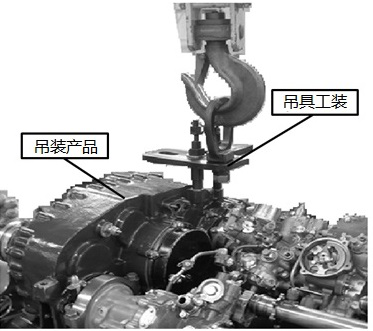

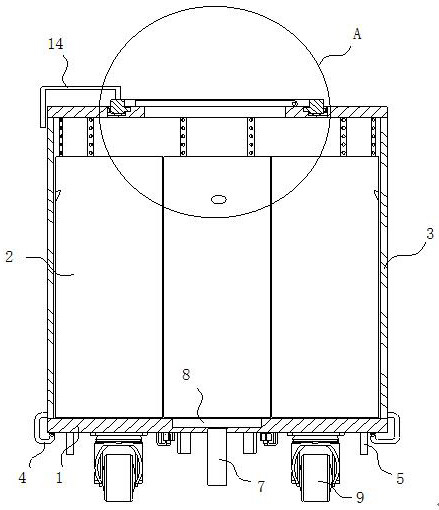

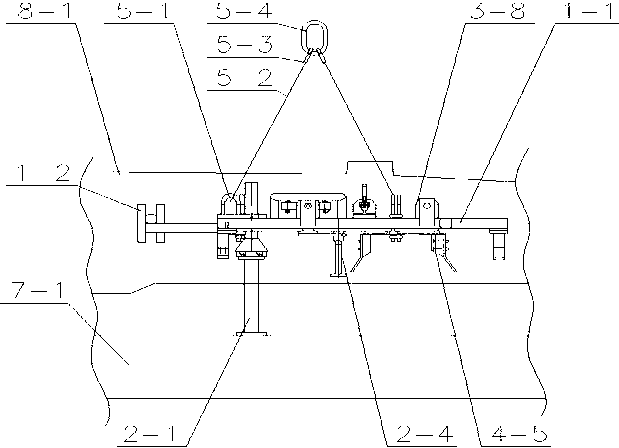

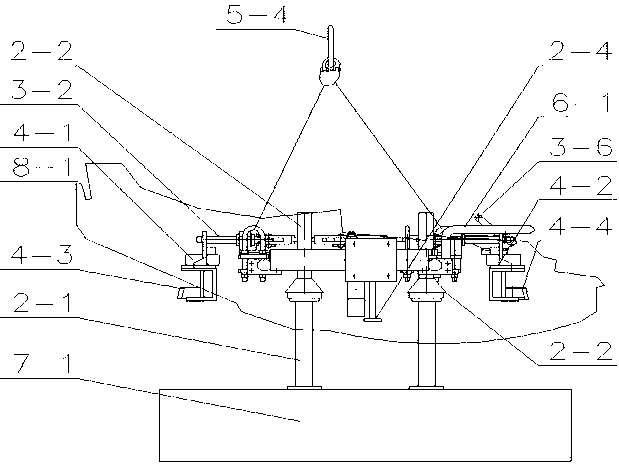

Manual drive conveying equipment used for side shell plate material of automobile body in white

ActiveCN102491082AReduce chance of bruisingReduce safety incidentsWelding/cutting auxillary devicesAuxillary welding devicesProduction lineShackle

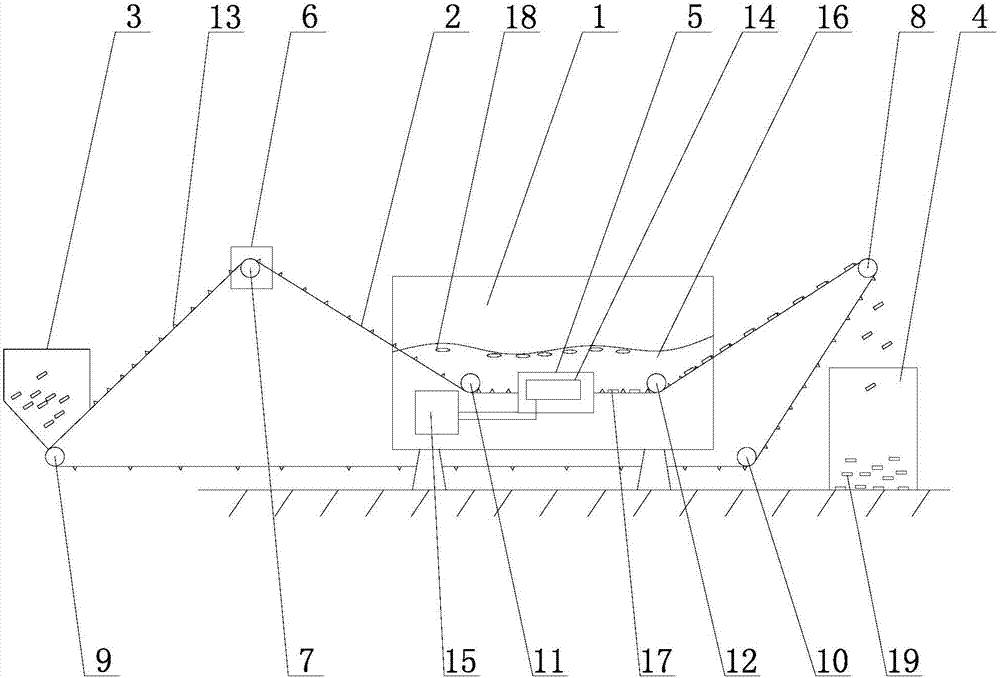

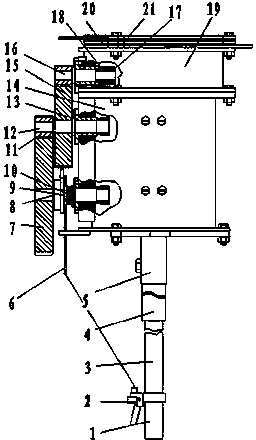

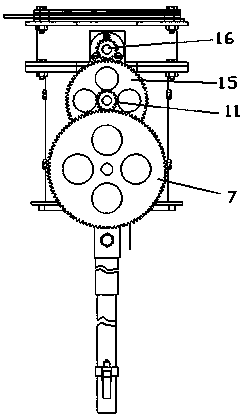

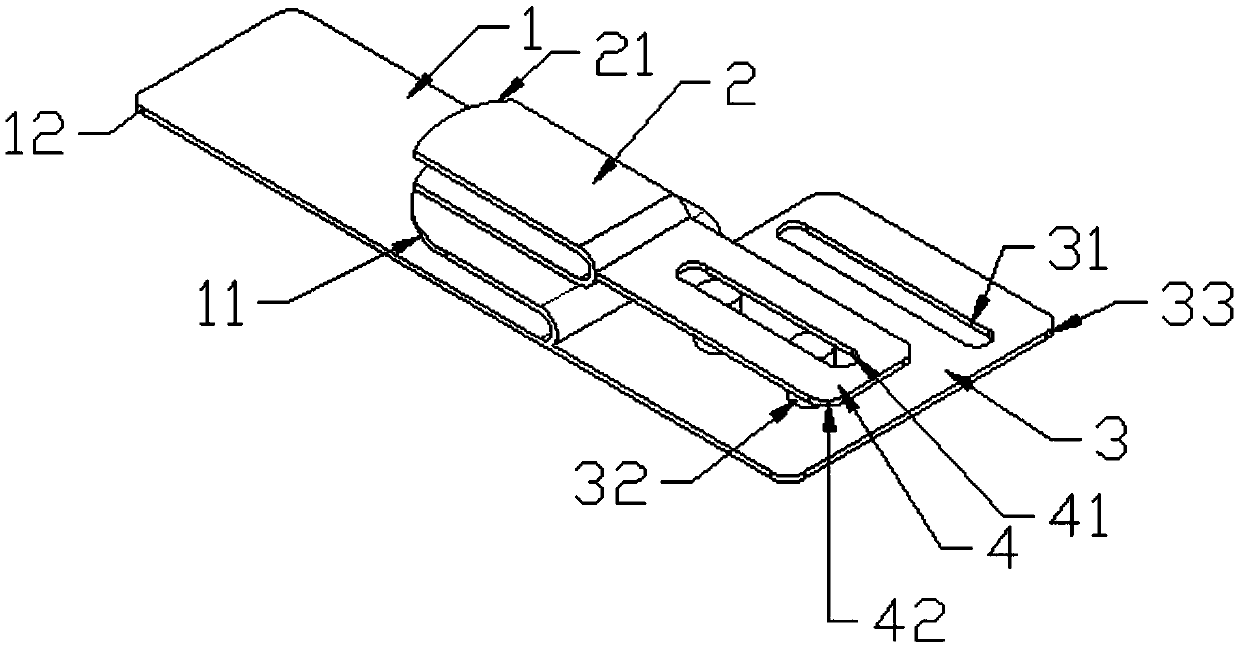

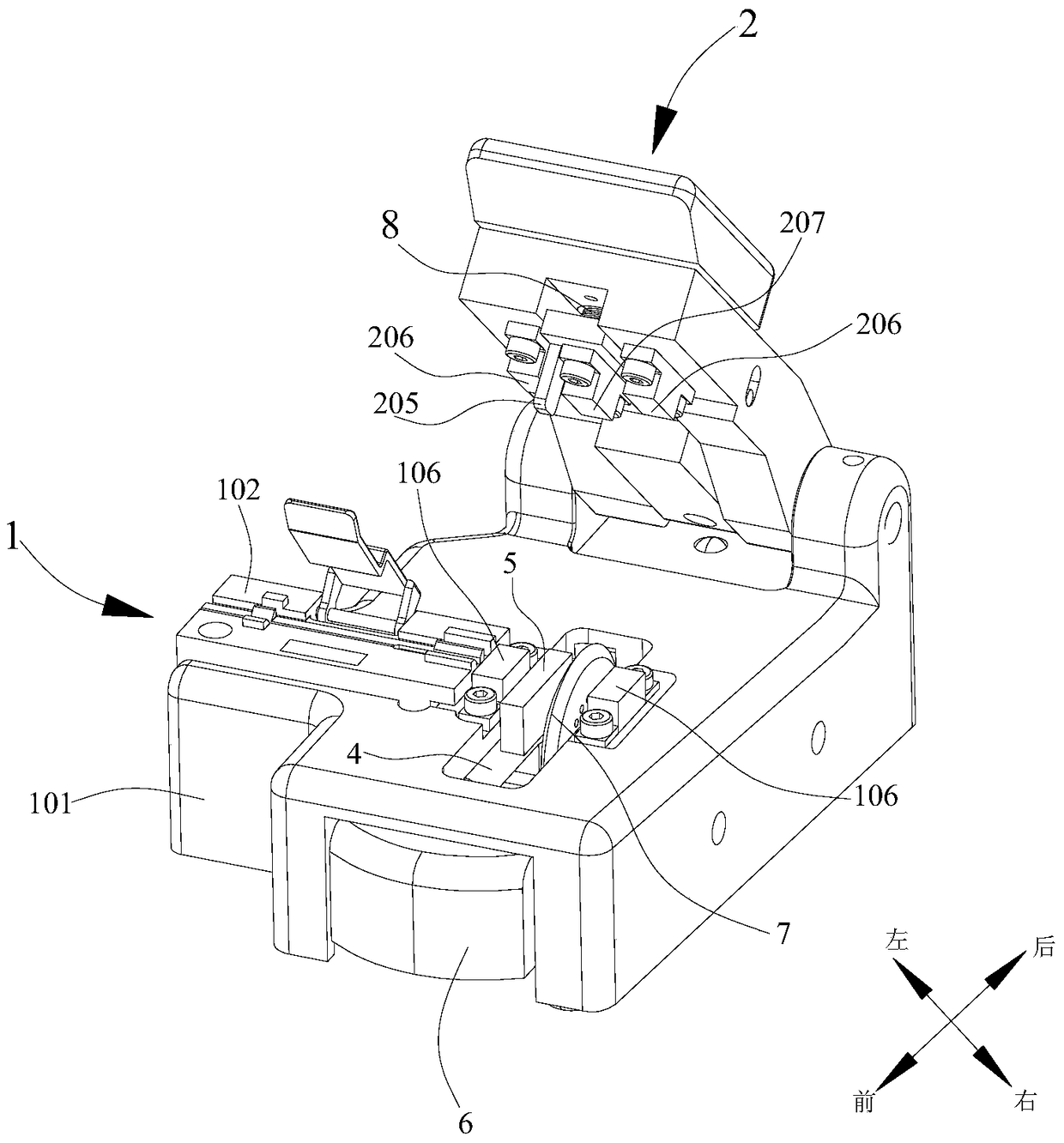

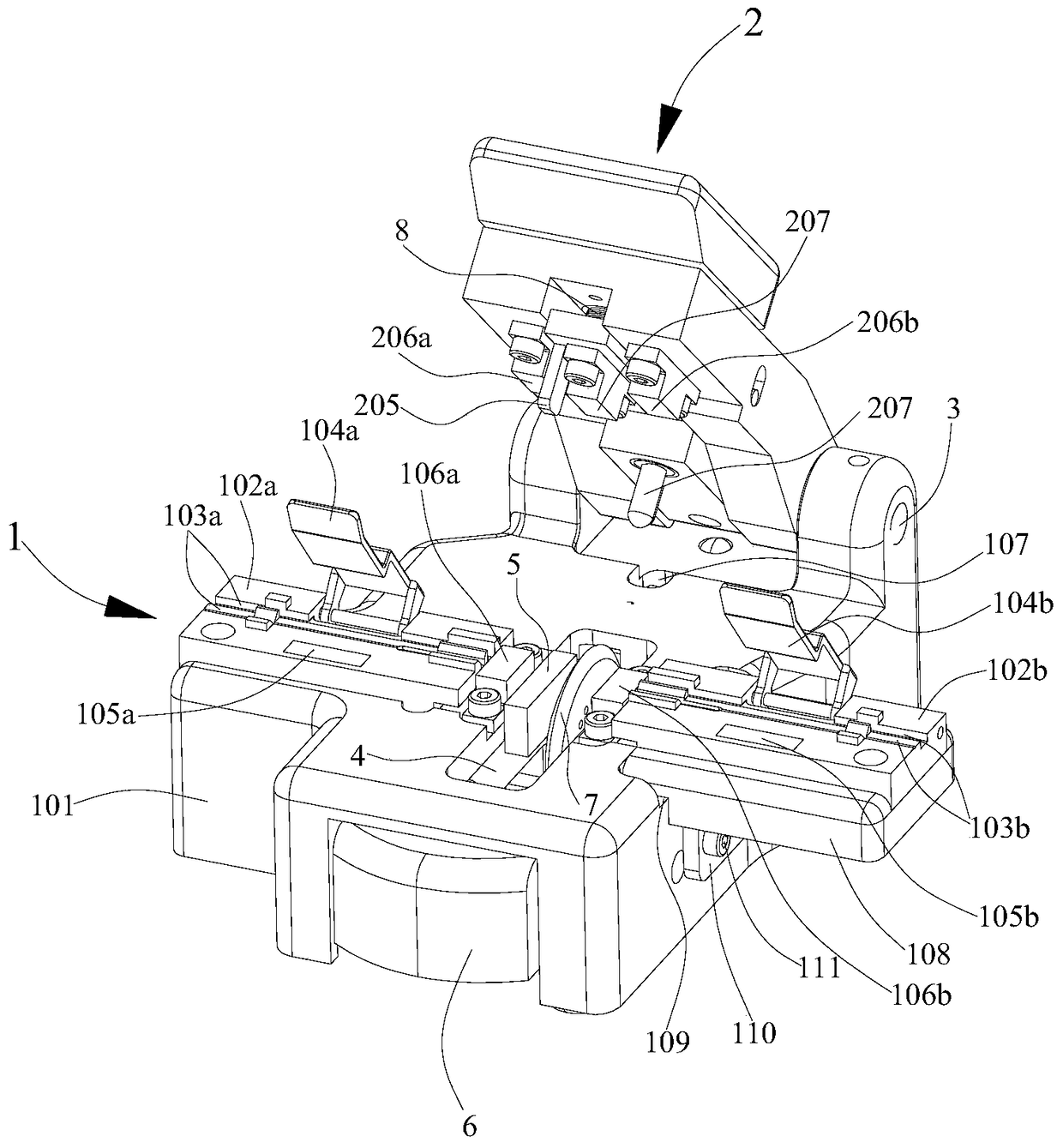

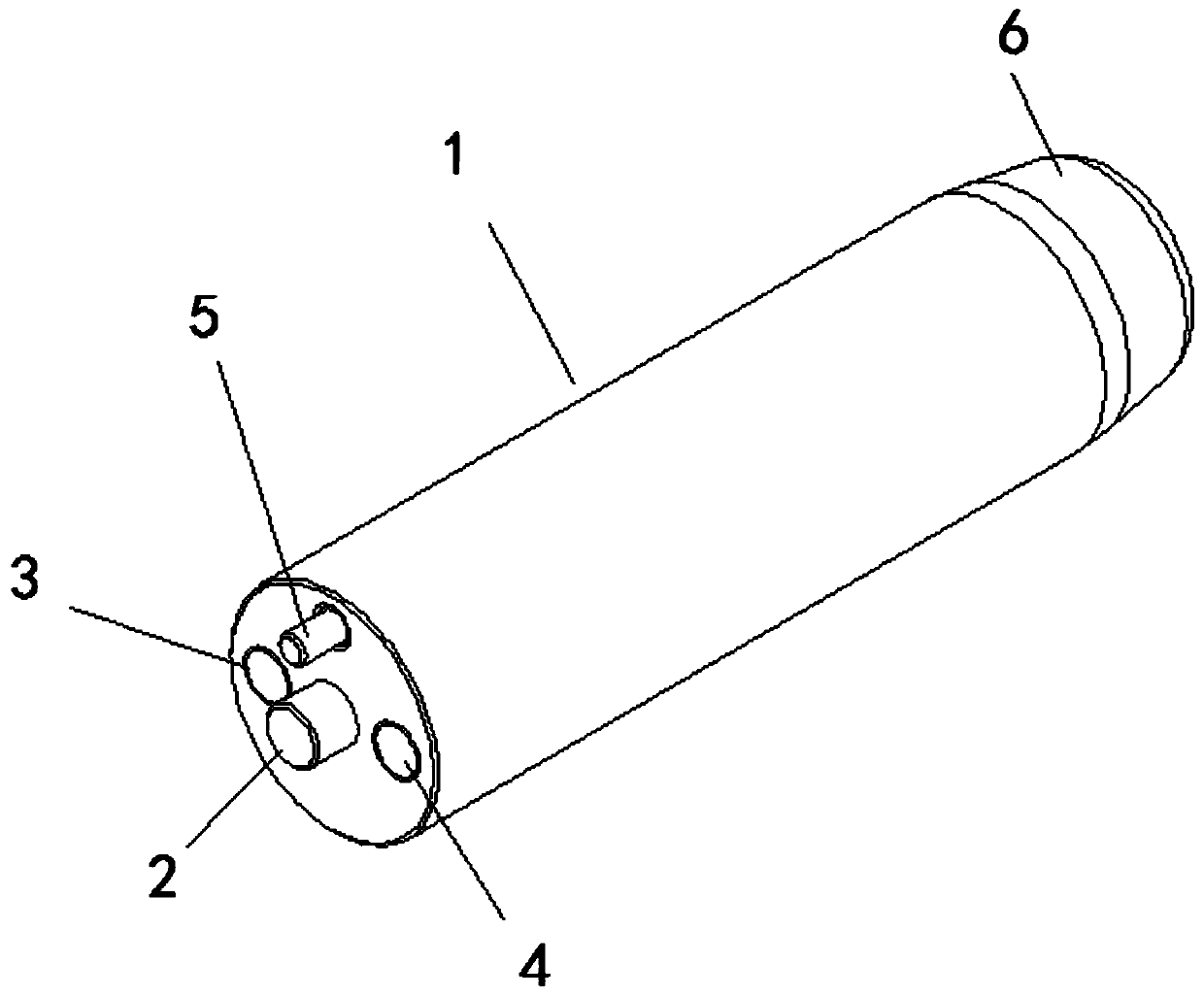

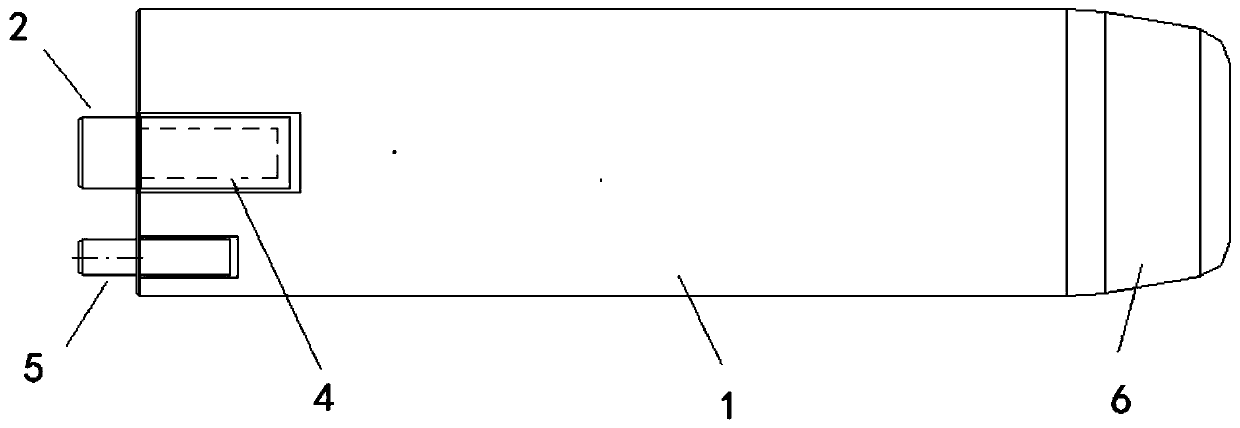

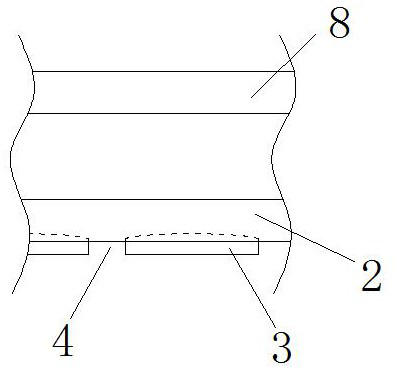

The invention relates to manual drive conveying equipment used for a side shell plate material of an automobile body in white. The equipment is composed of a chassis, a positioning guide mechanism, a supporting block stretching mechanism, a workpiece lifting positioning assembly, a lifting appliance hoisting assembly and an operating handle which are connected, wherein the chassis comprises a fixing chassis and a counter weight; the positioning guide mechanism comprises a guide base, a guide sleeve, an adjustable guide sleeve mounting plate and an adjustable positioning rod; the supporting block stretching mechanism comprises a connecting rod, a telescopic shaft, a stretching linear bearing block, a connecting rod drive rod, a connecting rod drive rod installing base, a hand clamp, a handclamp mounting plate and a linear bearing; the workpiece lifting positioning assembly comprises a lower supporting block mounting plate, an upper supporting block mounting plate, a supporting block, a lower supporting block and a B pillar guide block; and the lifting appliance hoisting assembly comprises an adjustable hoisting loop chain fixed ring, a hoisting loop chain, a hoisting loop chain shackle and a hoisting ring. The equipment is arranged on an upper pneumatic or electric elevator of a side shell welding production line of an automobile body in white. The conveying equipment providedby the invention has the advantages of reasonable design, rapidness and high accuracy in operation and safe and reliable performance.

Owner:TIANJIN FUZHEN IND EQUIP

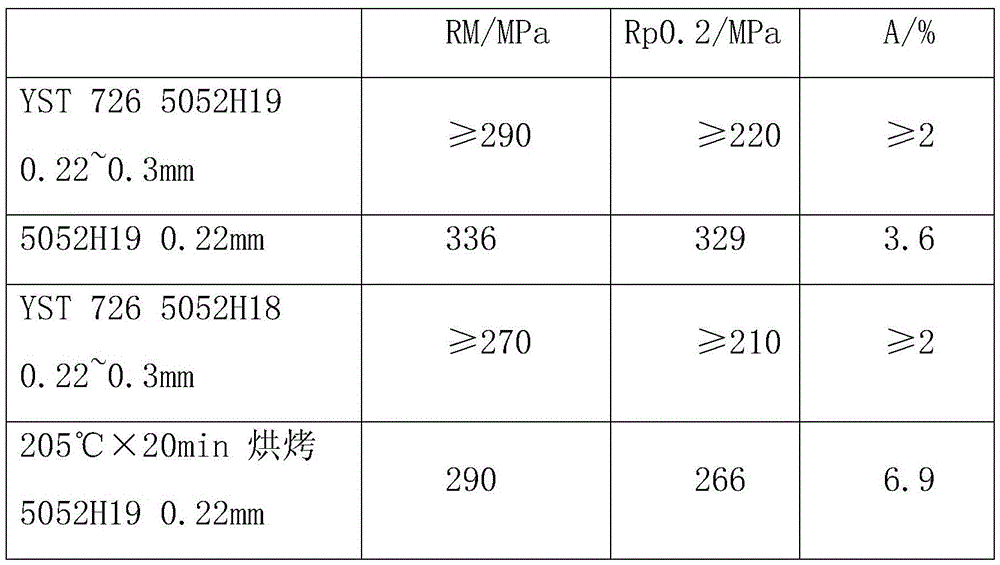

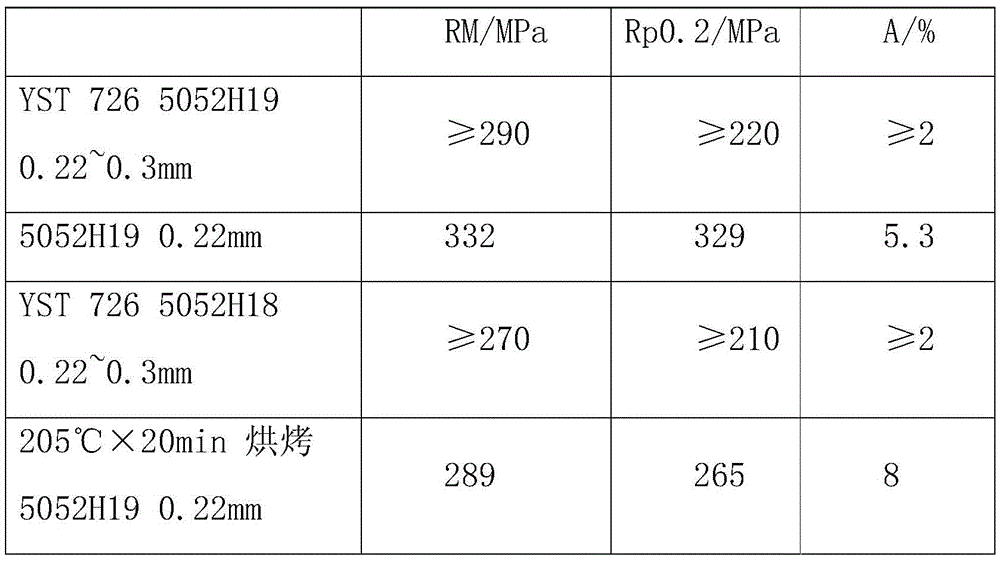

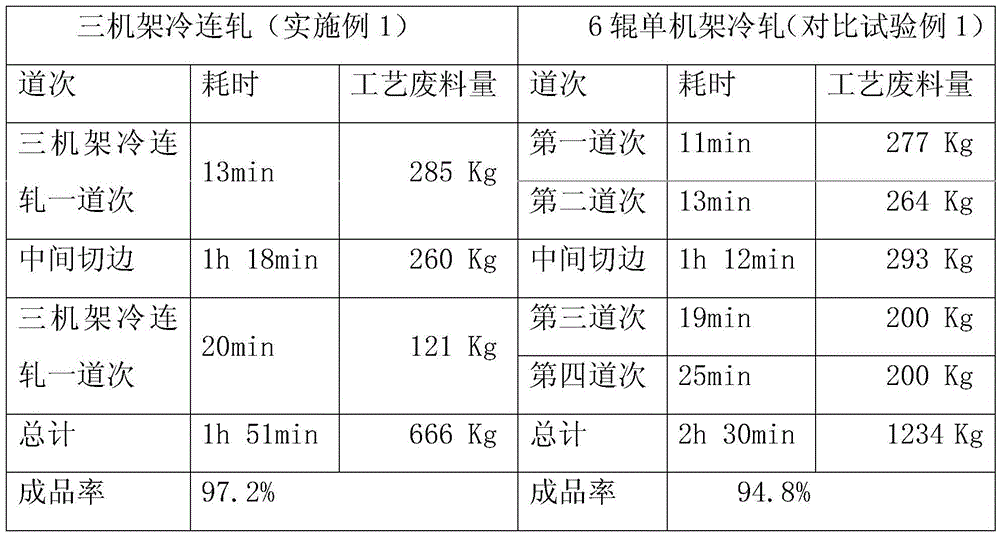

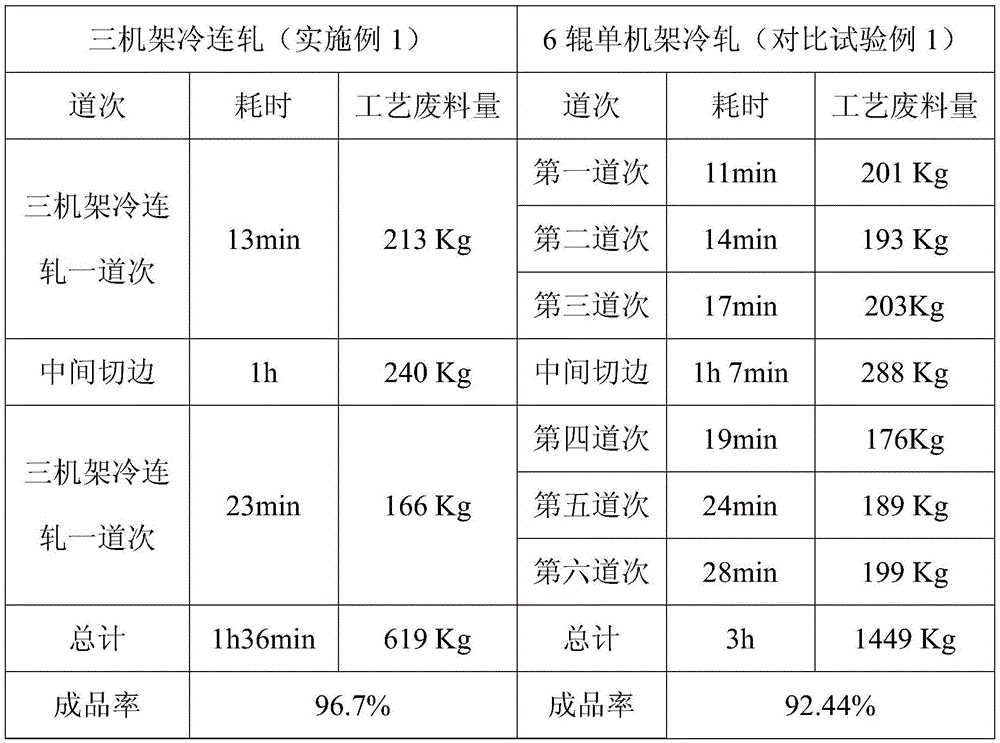

Production method of 5052 aluminum alloy tank cover base material

The invention discloses a production method of a 5052 aluminum alloy tank cover base material. The production method of the 5052 aluminum alloy tank cover base material comprises the steps of melting and casting, sawing, surface milling, soaking, (1+4) hot continuous rolling, three-rack cold continuous rolling, cut edge cleaning, and single-rack cold rolling. By the adoption of the production method, it is guaranteed that the mechanical property of the 5052 aluminum alloy tank cover base material is stable and qualified; in addition, the production process is shortened, and the production efficiency is improved.

Owner:SHANDONG NANSHAN ALUMINUM

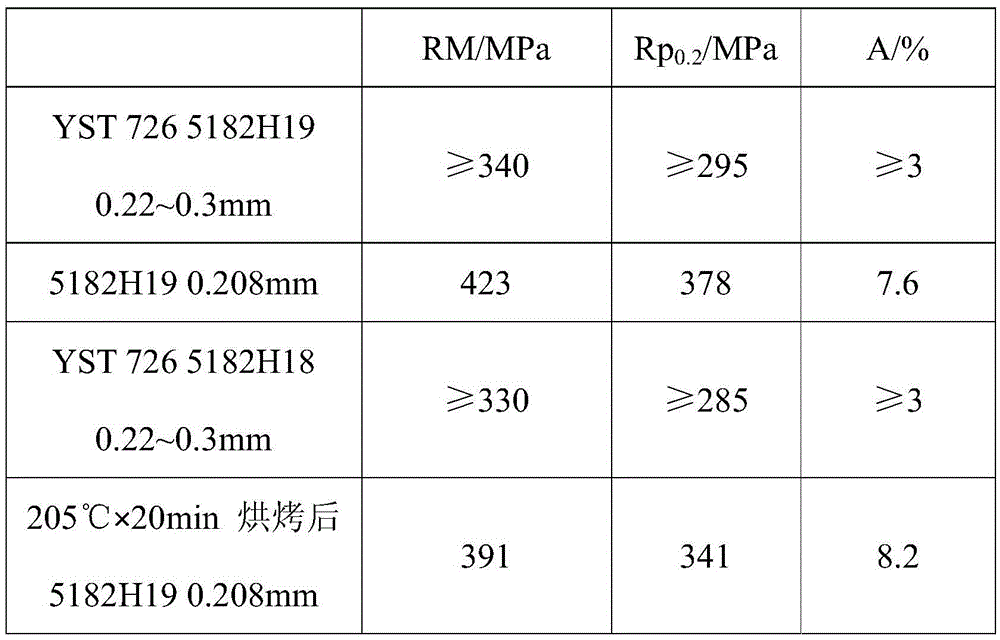

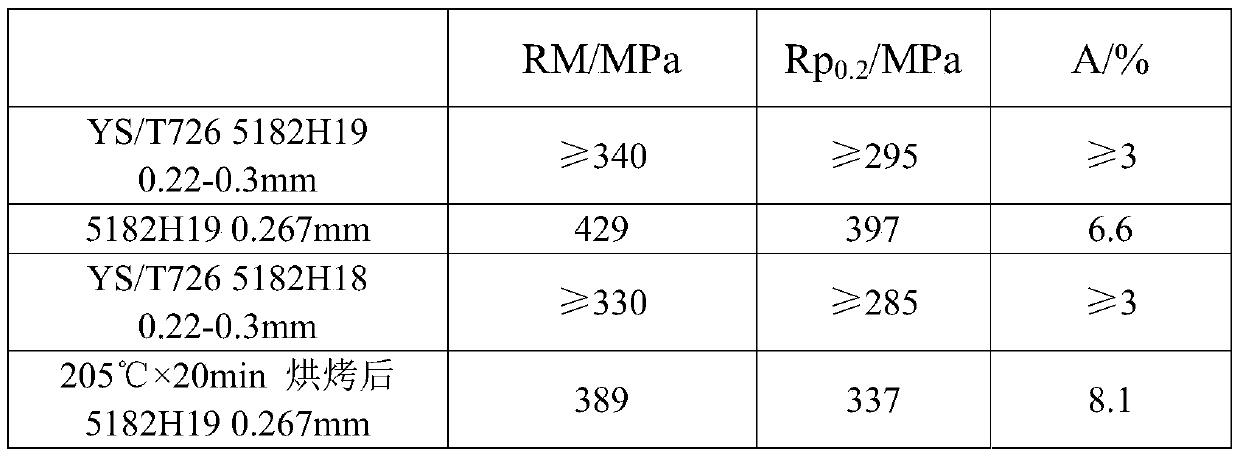

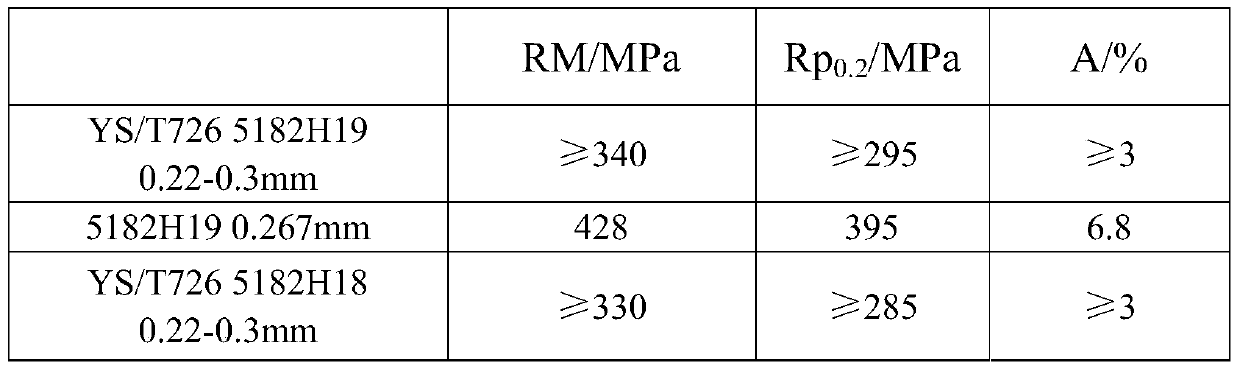

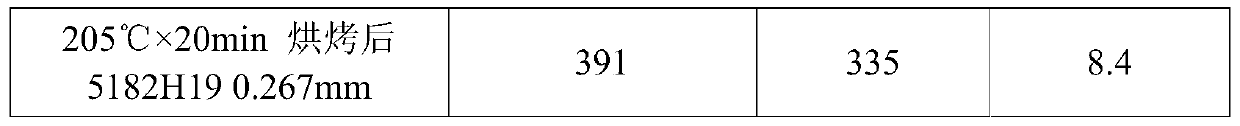

Production method for 5182 aluminum alloy cover base material

InactiveCN105618482AShorten production timeIncrease productivityMetal rolling arrangementsRoll speed control deviceContinuous rollingAluminium alloy

The invention discloses 5182 aluminum alloy cover base material and a production method for the 5182 aluminum alloy cover base material. The production process of the material comprises the steps of casting, sawing, surface milling, soaking, 1+4 hot continuous rolling, three-stand cold continuous rolling, cut side cleaning and single-stand cold rolling. The production method guarantees that the mechanical property of the 5182 aluminum alloy cover base material is stable and qualified, the production procedure is shortened, and the production efficiency is improved.

Owner:SHANDONG NANSHAN ALUMINUM

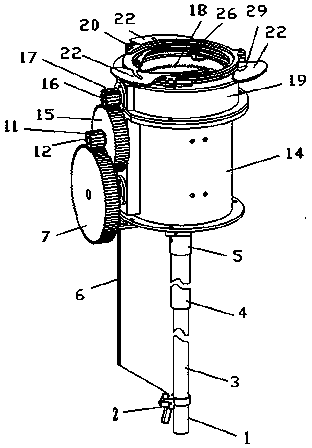

Ultrasonic garlic clove peeling device and method

InactiveCN107006878APeeling achievedImprove peeling efficiencyFood treatmentMechanical engineeringUltrasonic generator

The invention provides an ultrasonic garlic clove peeling device and method. The device comprises a container, a conveying belt penetrates into the container and installed on a driving device, a feed inlet is connected with one end of the conveying belt, a discharge opening is connected with the other end of the conveying belt, and an ultrasonic generator is arranged on the inner wall of the container. The device has the advantages of being simple in structure, capable of achieving peeling through ultrasound, high in peeling efficiency, high in peeling rate, low in bruise rate and the like.

Owner:SHANDONG MARIA MACHINERY

Fruit tree bagging mechanical arm

InactiveCN104082076AImprove securityReduce bruisesPlant protective coveringsFruit treeSocial benefits

The invention provides a fruit tree bagging mechanical arm and belongs to the technical field of fruit tree production machines. The fruit tree bagging mechanical arm is used for conducting bagging operation on fruits on fruit trees on the ground. According to the technical scheme, the fruit tree bagging mechanical arm is composed of a handle, a power handle, a box body, a gear transmission device and a mouth closing device. The gear transmission device and the mouth closing device are installed on the side face and the upper end of the box body respectively. When the fruit tree bagging mechanical arm is used, the gear transmission device is pulled by the power handle to rotate, the gear transmission device drives the mouth closing device to conduct mouth closing action, a mouth closing arm bags the fruits, and then the overhead fruits at different heights are bagged on the ground. According to the fruit tree bagging mechanical arm, the function that the fruits on the high fruit trees are bagged on the ground is achieved, the safety coefficient of a user is increased, the labor intensity is relieved, efficiency is improved, and the probability of the situation that branches of the fruit trees are damaged is reduced. The fruit tree bagging mechanical arm is an innovation in the field of fruit tree production machines, fruit tree bagging operation becomes mechanical from manual, the economic benefits and the social benefits are quite remarkable, and the application and popularization value is quite high.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

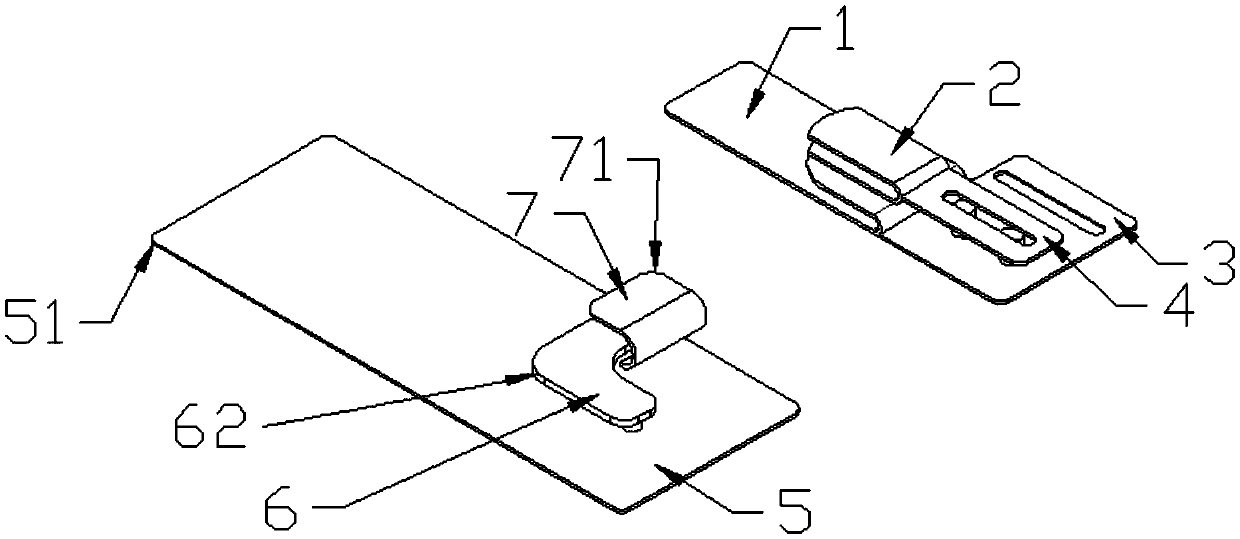

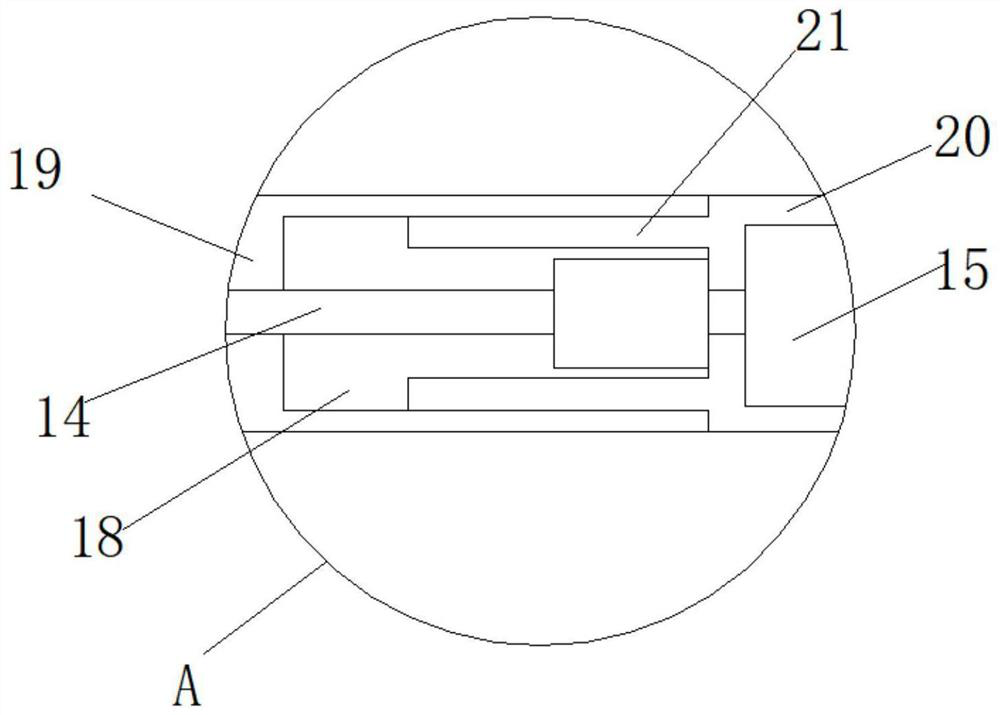

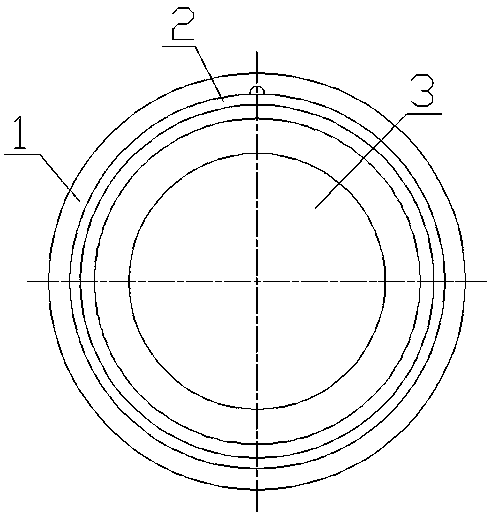

Optical fiber cutter with bilateral cutting function

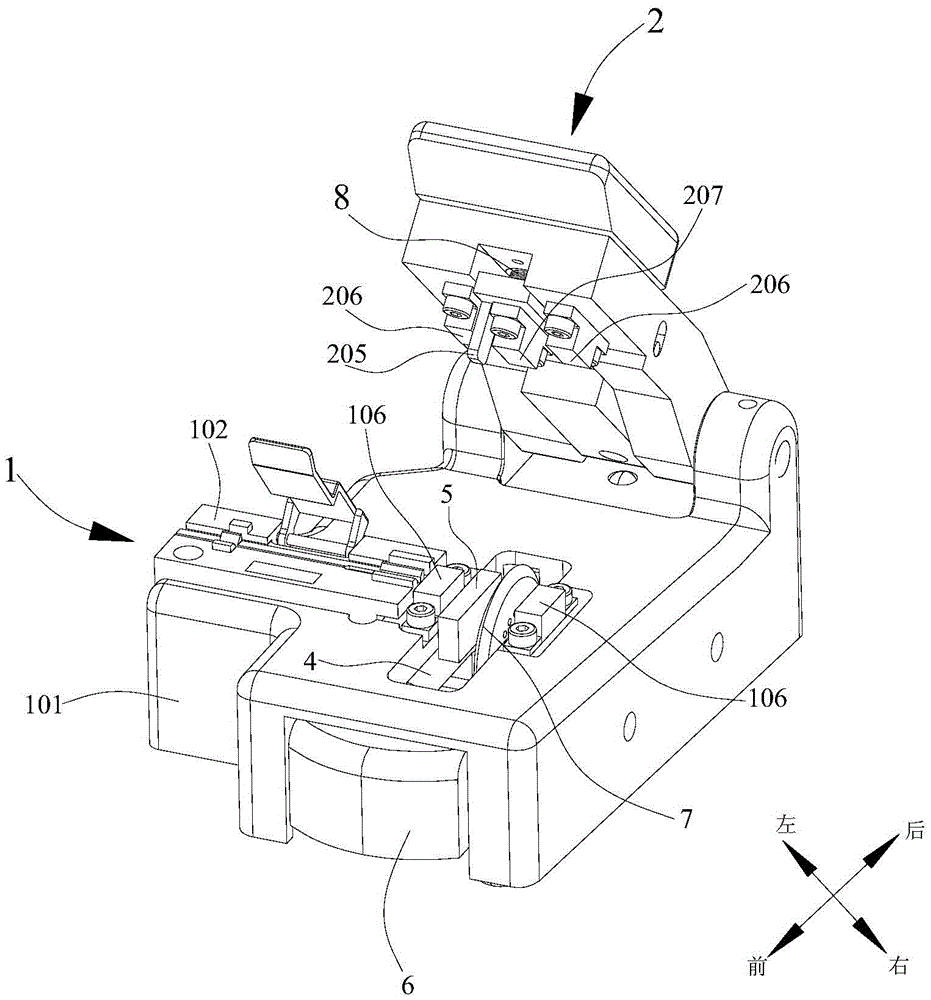

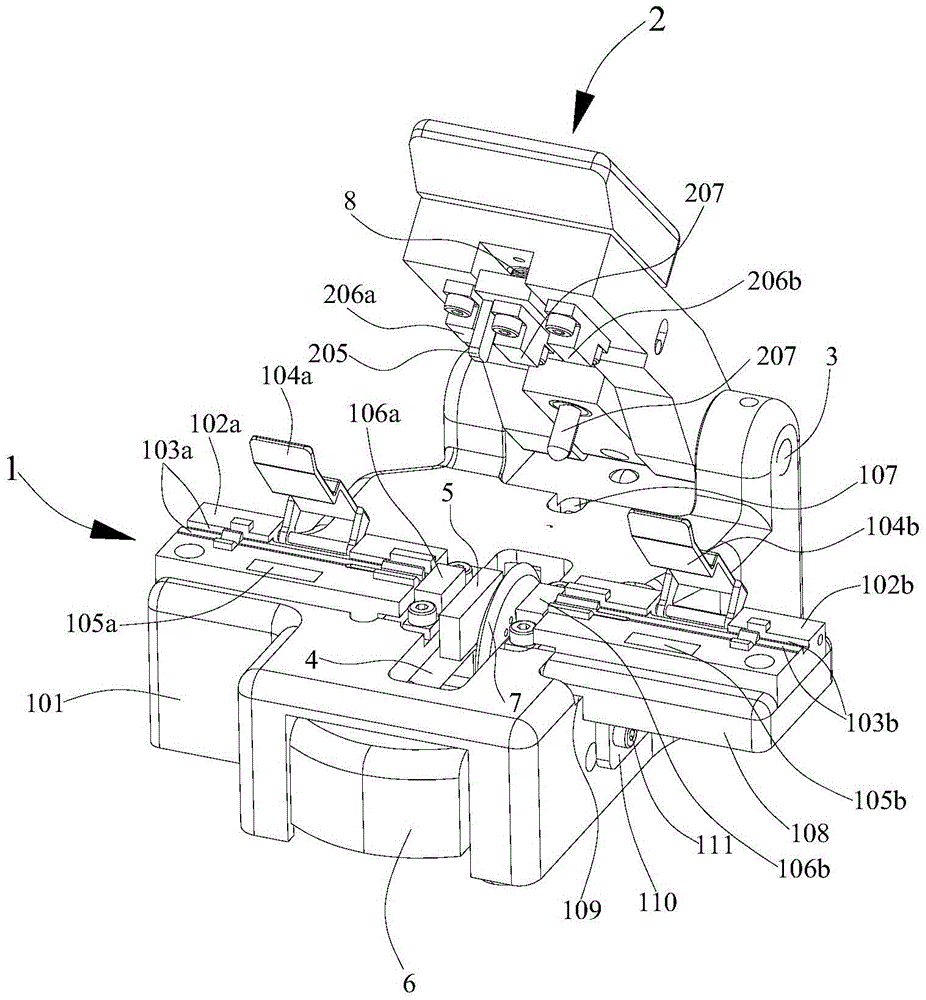

The invention relates to an optical fiber cutter with a bilateral cutting function. The optical fiber cutter comprises a main body and a cover body; the cover body is connected with the rear side of the main body in a unfoldable and foldable manner; the main body comprises a base, optical fiber clamping components, a cutter and one pair of lower clamping devices; an opening is formed in the base; the lower clamping devices are symmetrically fixed to the left side and right side of the opening; the optical fiber clamping components comprise a left optical fiber clamping component and a right optical fiber clamping component; the left optical fiber clamping component is fixed on the upper surface of the base and is located at the left side of a corresponding lower clamping device; a carrier stage is fixed to the right side wall of the base; the right optical fiber clamping component is fixed to the upper surface of the carrier stage; the left optical fiber clamping component and the right optical fiber clamping component are symmetrically fixed to the left side and right side of the opening; the cutter comprises a cutter frame and a circular blade; the cutter frame is located in the space of the lower part of the base; the circular blade is attached on the cutter frame; one part of the circular blade protrudes upwards from the opening; and the circular blade can move back and forth in the opening. With the optical fiber cutter of the invention adopted, bilateral cutting can be realized, operation steps can be reduced, collision probability can be reduced, and cutting efficiency can be improved.

Owner:NANJING JILONG OPTICAL COMM

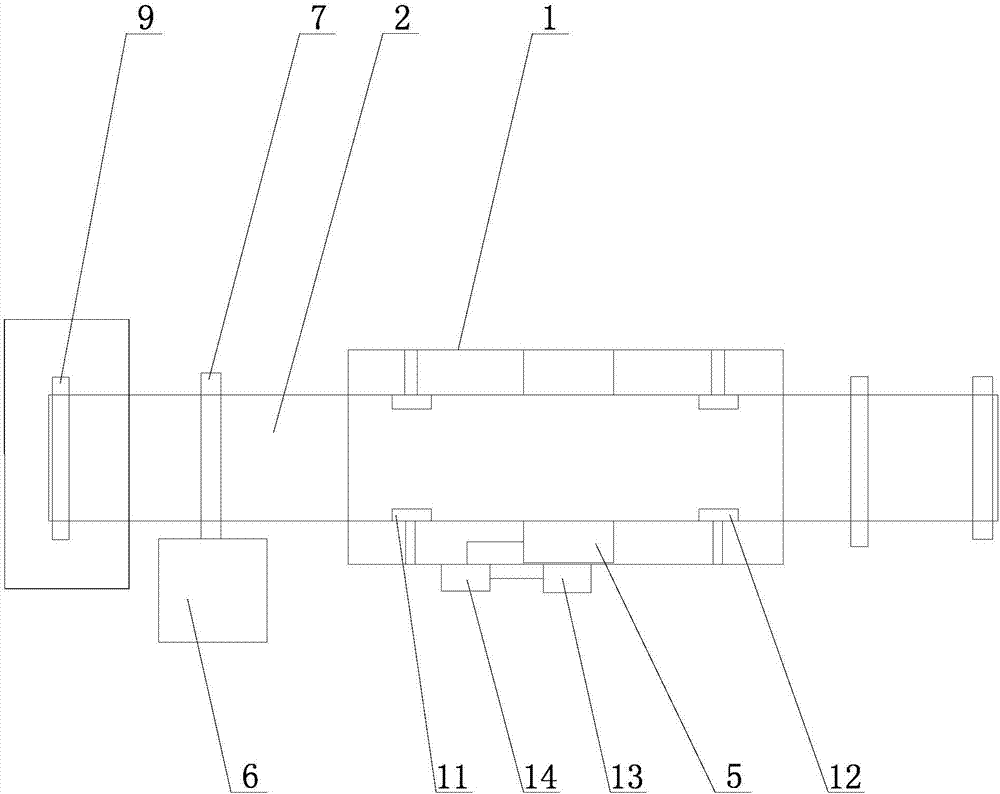

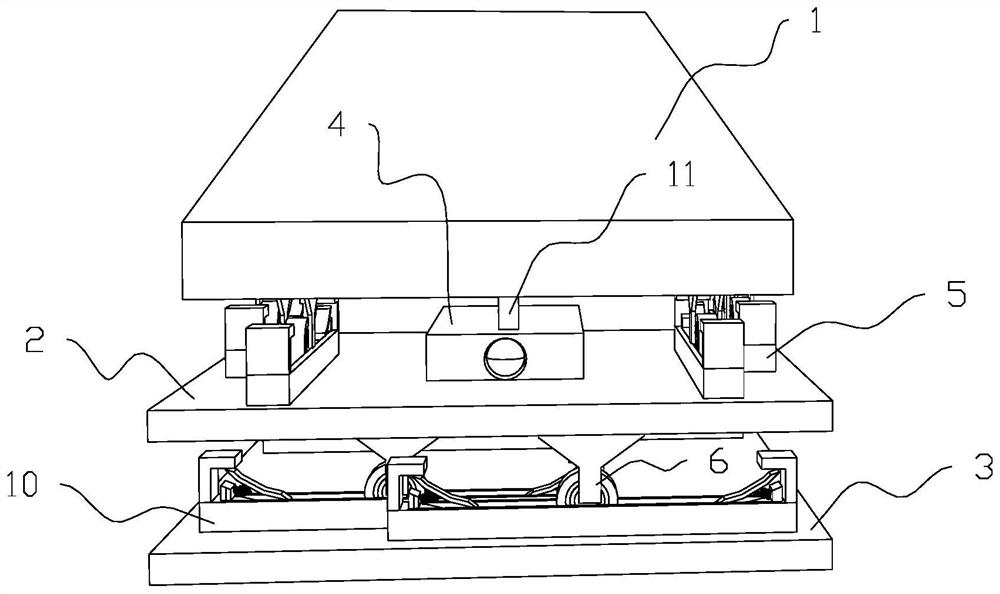

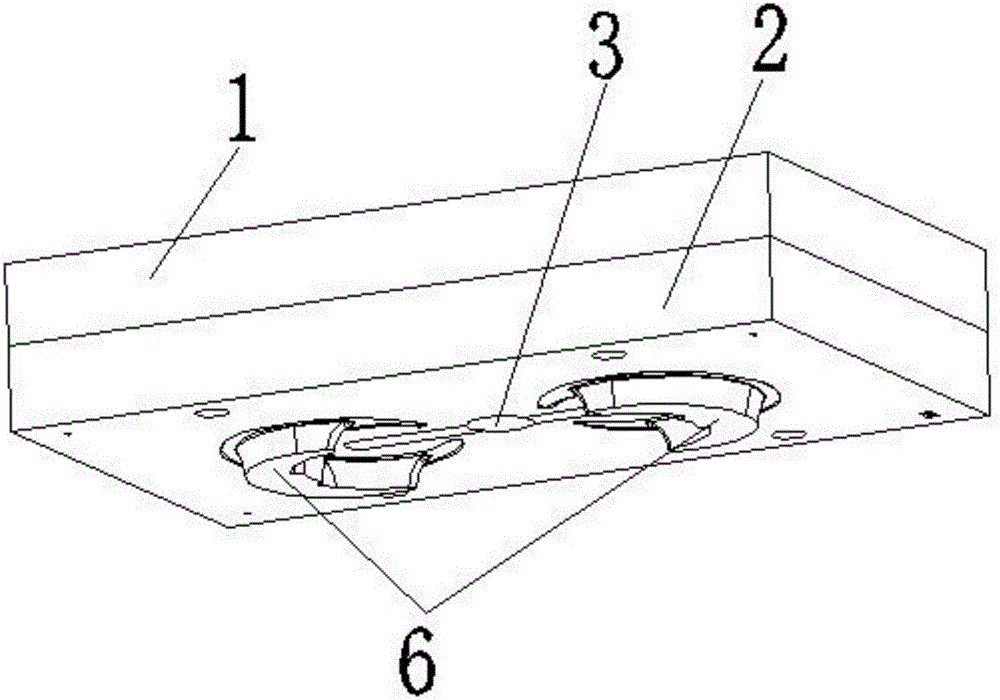

Rotary assembly tooling for bumper

ActiveCN107234571AReduce labor intensityReduce the chance of bruisingWork holdersMetal-working hand toolsTool steelEngineering

The invention discloses a rotary assembly tooling for a bumper. The rotary assembly tooling comprises a tooling body, a tooling clamping mechanism, tooling rotating mechanisms and a tooling steel structure, wherein the tooling body comprises a left vertical column and a right vertical column; both the left vertical column and the right vertical column are vertically arranged; the tooling rotating mechanisms comprise a left rotating mechanism and a right rotating mechanism; the left rotating mechanism is mounted on the left vertical column; the right rotating mechanism is mounted on the right vertical column; a rotating hand wheel and a braking mechanism are arranged on the right rotating mechanism; the tooling steel structure comprises a tooling steel structure body; tooling steel structure connecting plates are arranged at two ends of the tooling steel structure body; and the two tooling steel structure connecting plates are rotationally connected with the left rotating mechanism and the right rotating mechanism correspondingly. By adoption of the rotary assembly tooling disclosed by the invention, the concave surface and the convex surface of the bumper can be simultaneously assembled on the same tooling.

Owner:东风彼欧(成都)汽车外饰系统有限公司

Jacket processing equipment

InactiveCN105506869AGuaranteed accuracyGuaranteed to be tidy and beautifulWork-feeding meansEngineeringSewing machine

The invention provides jacket processing equipment comprising a first guide assembly, a second guide assembly, a first guide bottom plate and a second guide bottom plate, wherein the first guide assembly and the second guide assembly are M-shaped, the first guide assembly is fixed on the first guide bottom plate, an opening of the first guide assembly is far away from the first guide bottom plate, the first guide bottom plate is fixed on a sewing machine, the second guide assembly is fixed on the second guide bottom plate, an opening of the second guide assembly is far away from the second guide bottom plate, and the first guide bottom and the second guide bottom plate are separated. The jacket processing equipment is simple in structure and short in processing period, can quickly sew sleeves at different levels and can greatly improve the working efficiency and increase the percent of pass of jackets.

Owner:天津市宝坻区志远制衣有限公司

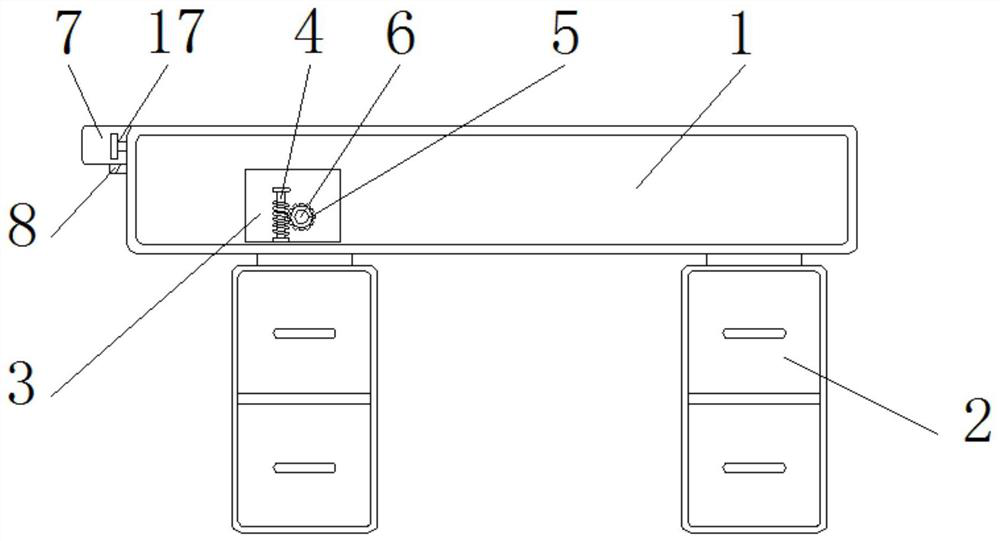

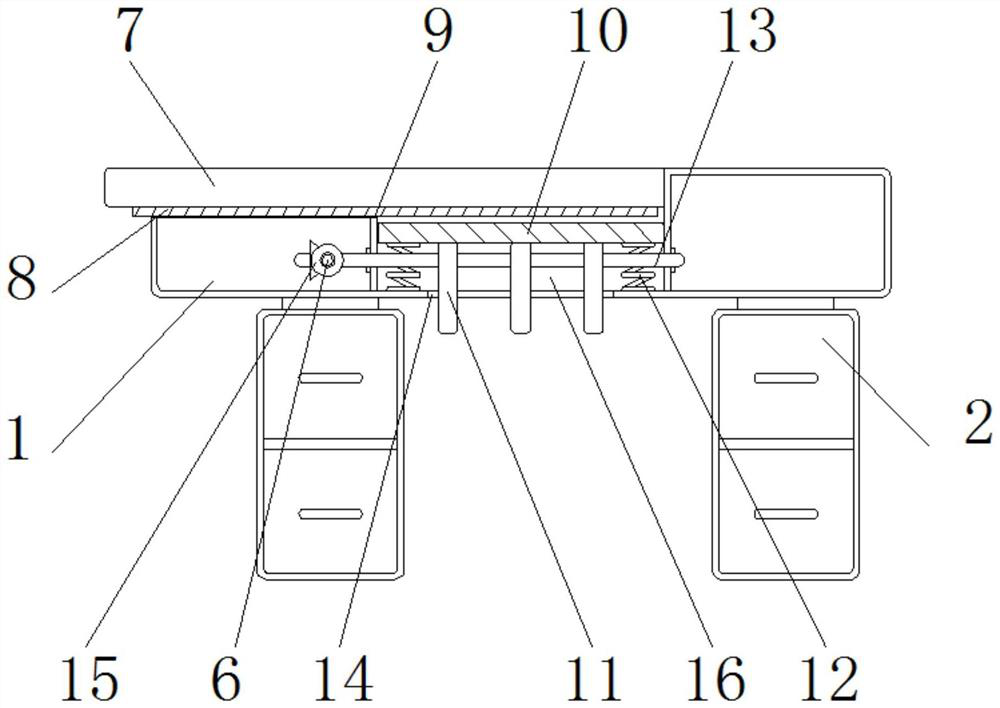

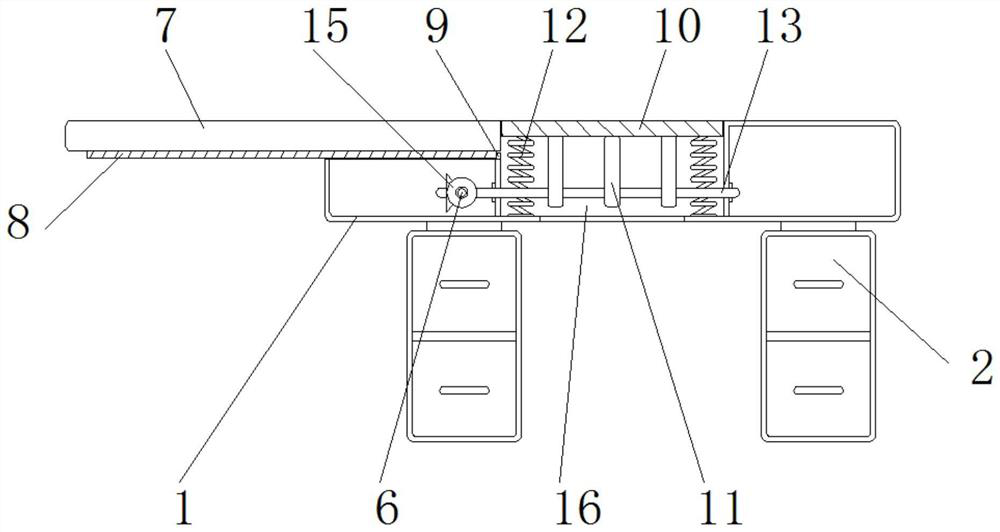

A desk table capable of adjusting the suspended length

ActiveCN111407072BAdjust the suspension lengthIncrease the lengthOffice tablesExtensible tablesEngineeringDesk

The invention discloses a desk desk capable of adjusting the suspended length, comprising a desk desk main body and a connecting rod. Support drawers are installed on the left and right sides under the bottom of the desk desk main body, and the front side of the desk desk main body is provided with support drawers. A groove is fixed, and a worm is connected inside the groove, and a worm gear is engaged with the right side of the worm. A support rod is fixed, and a top block is fixed on the outer side of the support rod, a through groove is provided below the top block, a storage groove is installed on the outer side of the through groove, and a return spring is installed above the storage groove, and the return spring is A second horizontal plate is installed at the top. The desk table capable of adjusting the suspended length is provided with a first horizontal plate and a second horizontal plate, and the length of the suspended end of the entire desk is increased through the splicing of the first horizontal plate and the second horizontal plate.

Owner:上海美稷家具科技有限公司

Fiber cleaver for bilateral cutting

The invention relates to an optical fiber cutter with a bilateral cutting function. The optical fiber cutter comprises a main body and a cover body; the cover body is connected with the rear side of the main body in a unfoldable and foldable manner; the main body comprises a base, optical fiber clamping components, a cutter and one pair of lower clamping devices; an opening is formed in the base; the lower clamping devices are symmetrically fixed to the left side and right side of the opening; the optical fiber clamping components comprise a left optical fiber clamping component and a right optical fiber clamping component; the left optical fiber clamping component is fixed on the upper surface of the base and is located at the left side of a corresponding lower clamping device; a carrier stage is fixed to the right side wall of the base; the right optical fiber clamping component is fixed to the upper surface of the carrier stage; the left optical fiber clamping component and the right optical fiber clamping component are symmetrically fixed to the left side and right side of the opening; the cutter comprises a cutter frame and a circular blade; the cutter frame is located in the space of the lower part of the base; the circular blade is attached on the cutter frame; one part of the circular blade protrudes upwards from the opening; and the circular blade can move back and forth in the opening. With the optical fiber cutter of the invention adopted, bilateral cutting can be realized, operation steps can be reduced, collision probability can be reduced, and cutting efficiency can be improved.

Owner:NANJING JILONG OPTICAL COMM

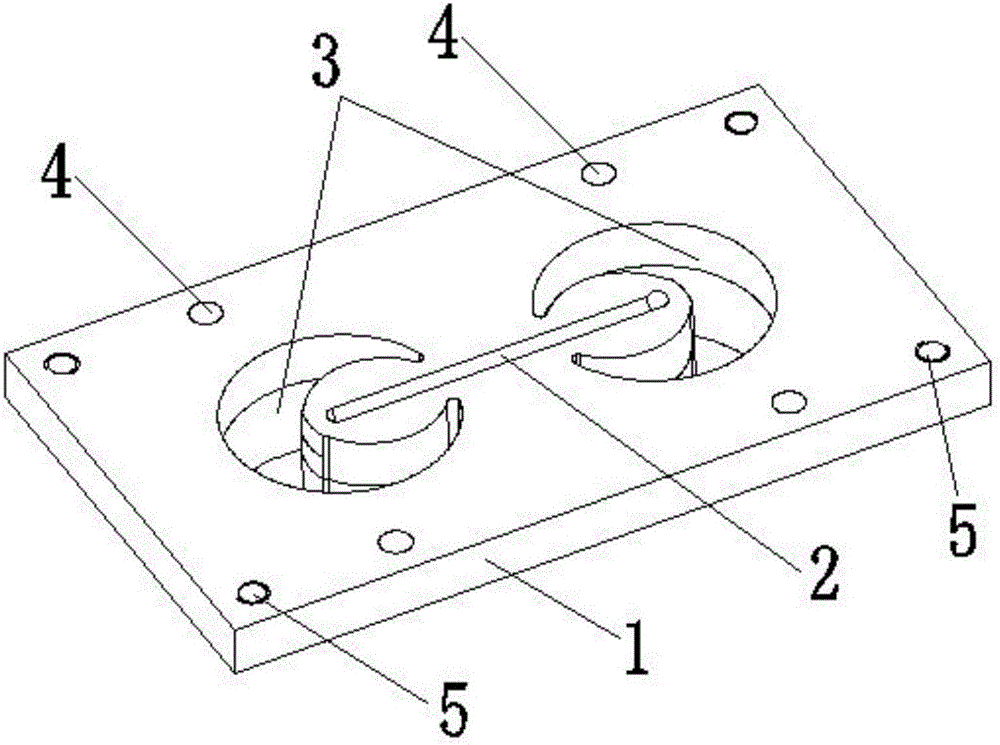

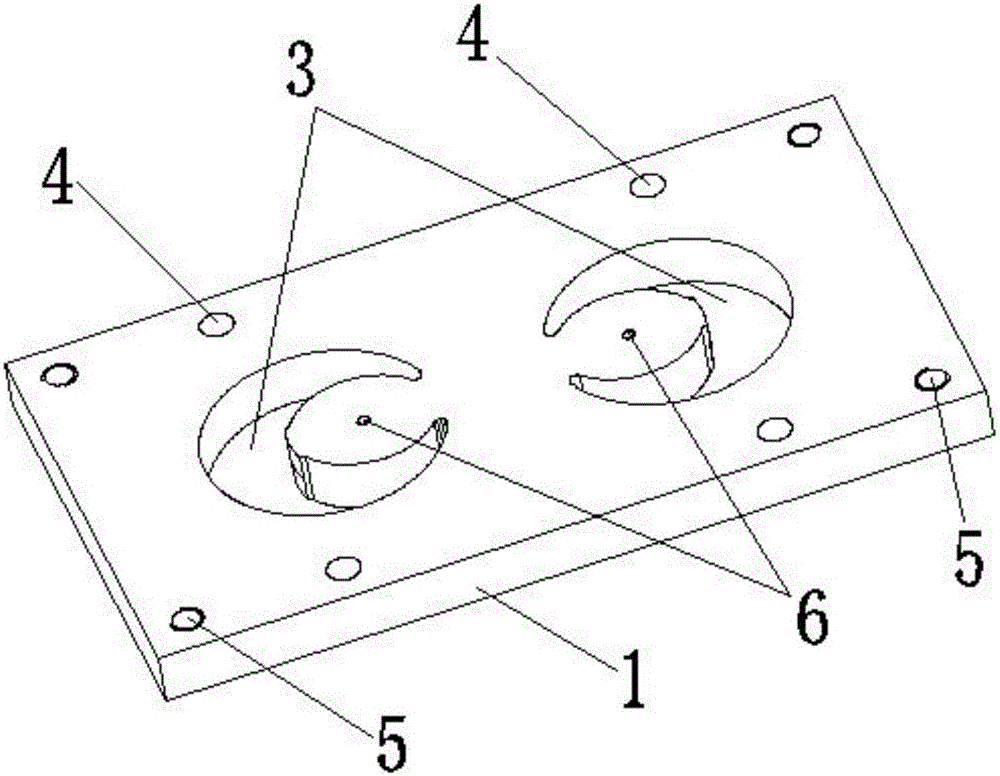

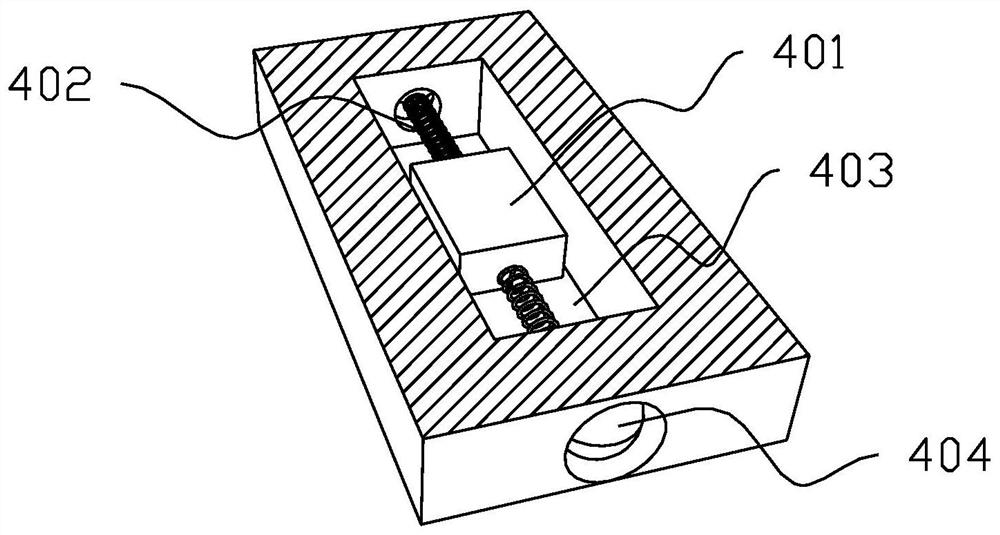

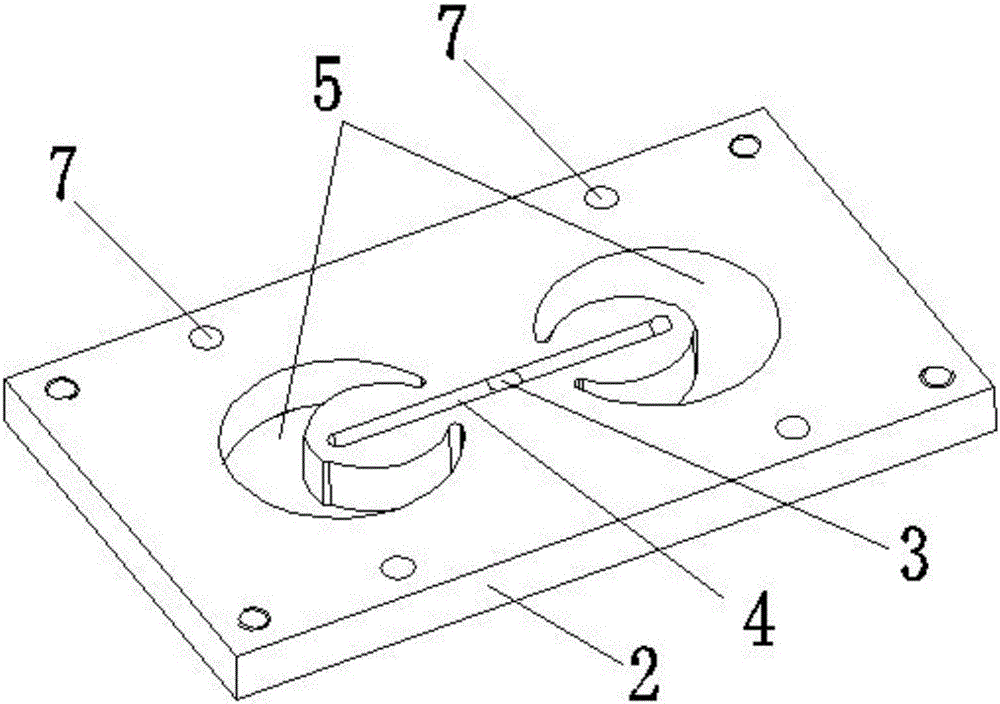

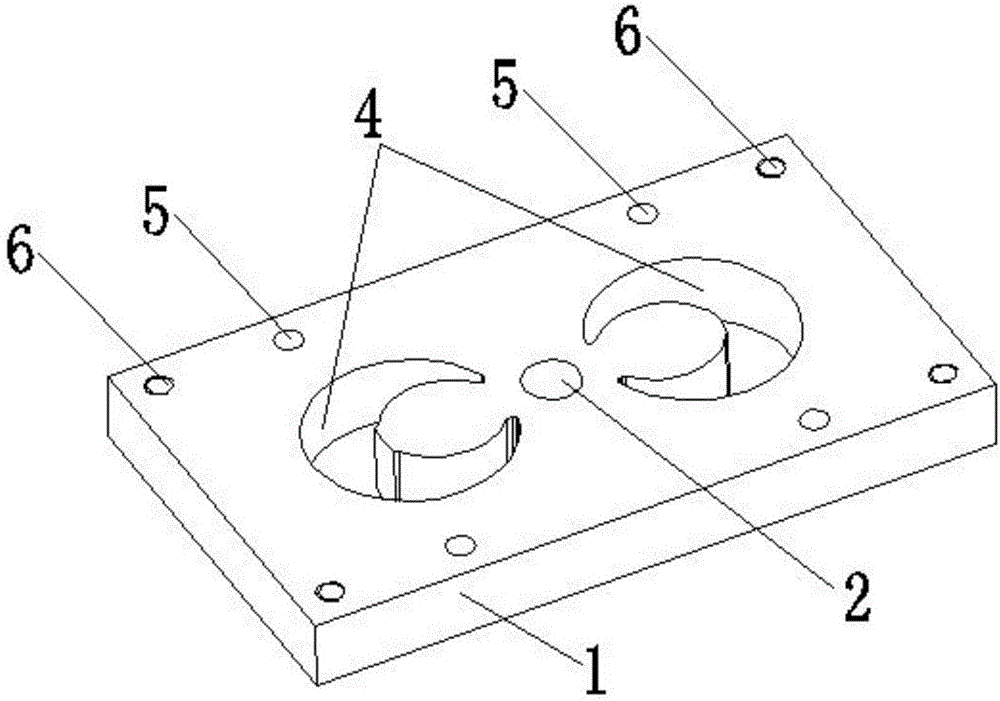

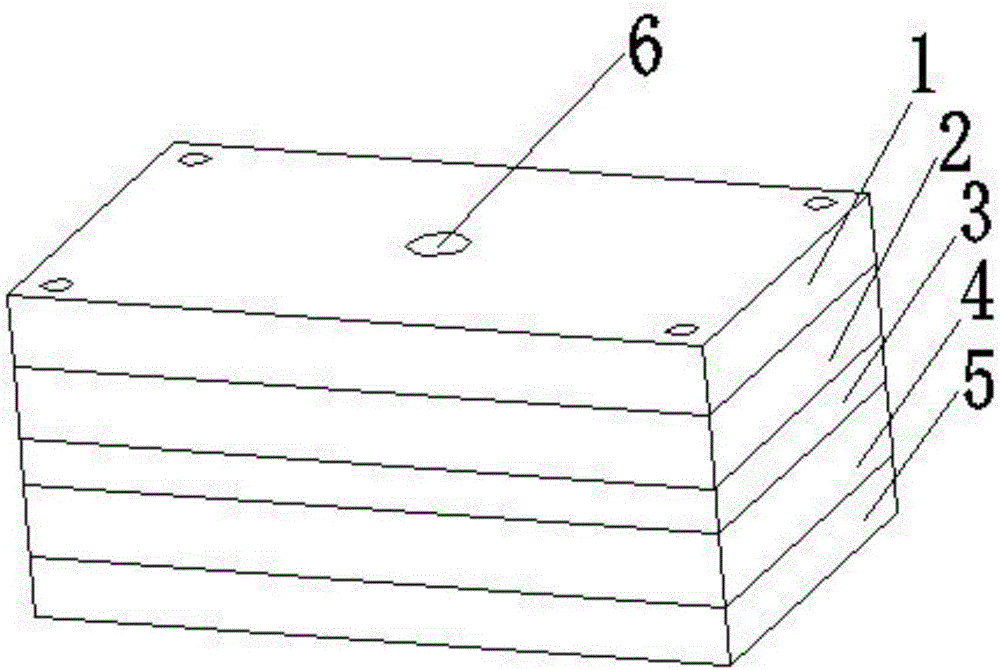

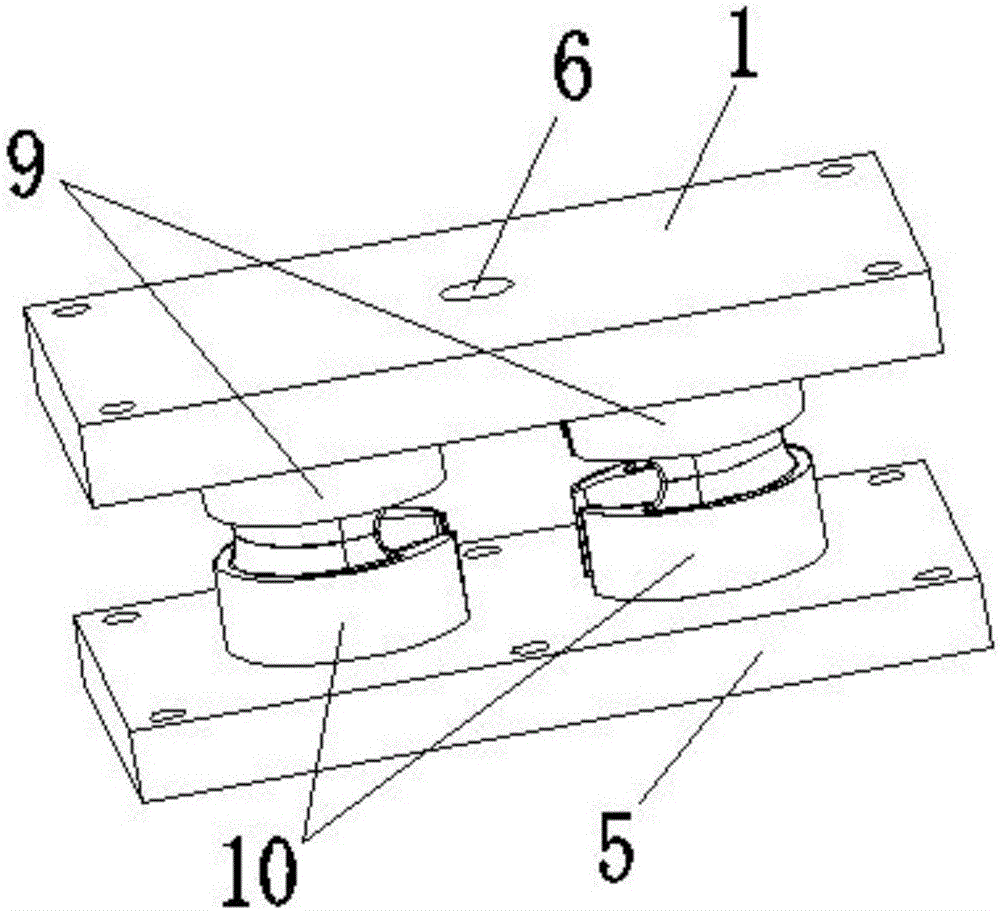

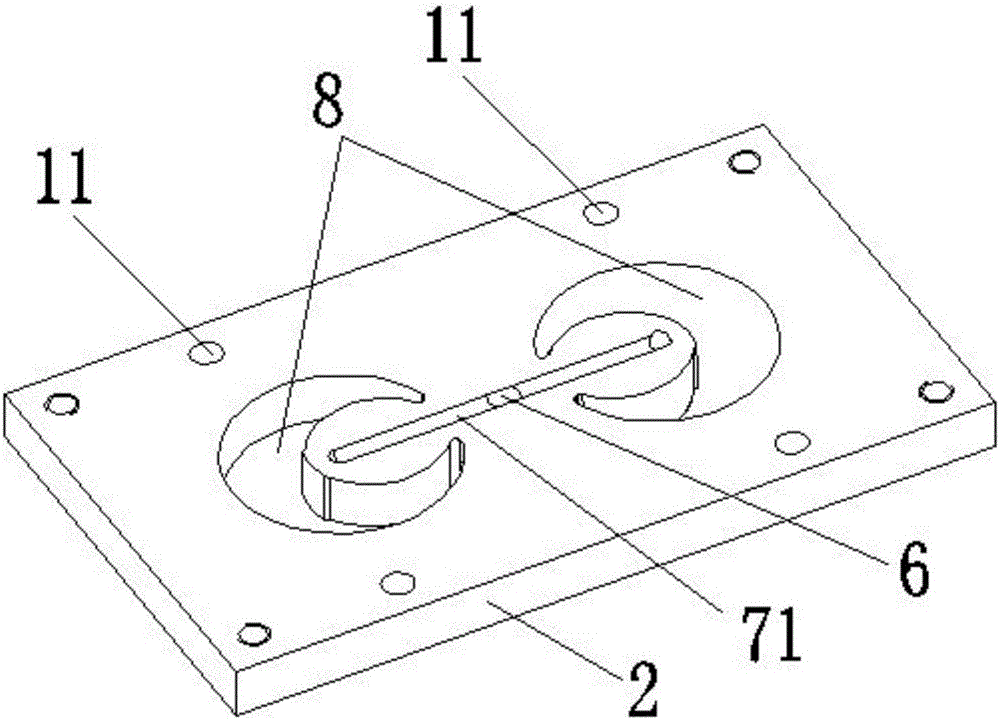

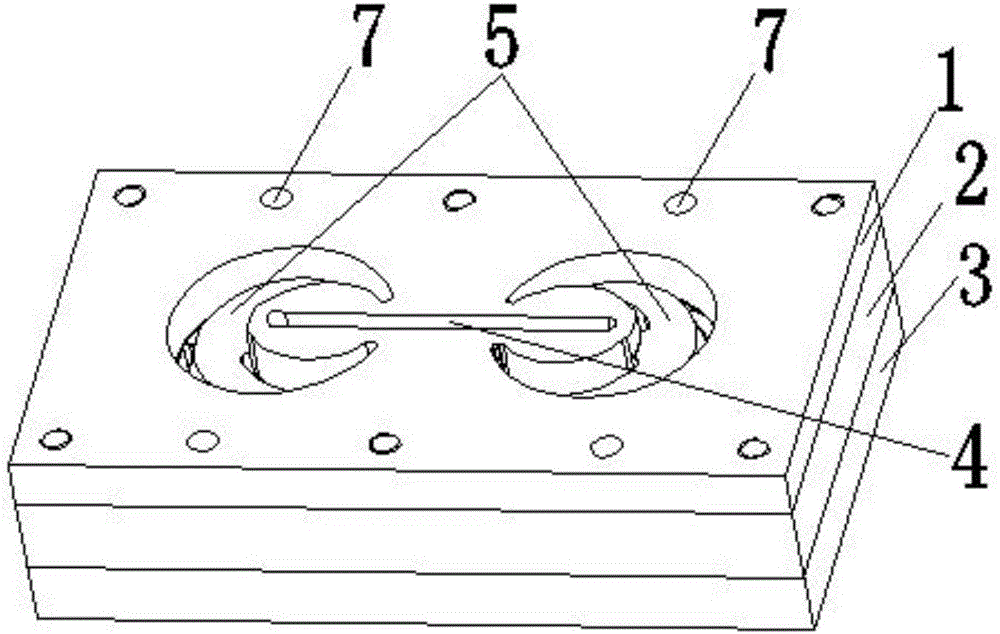

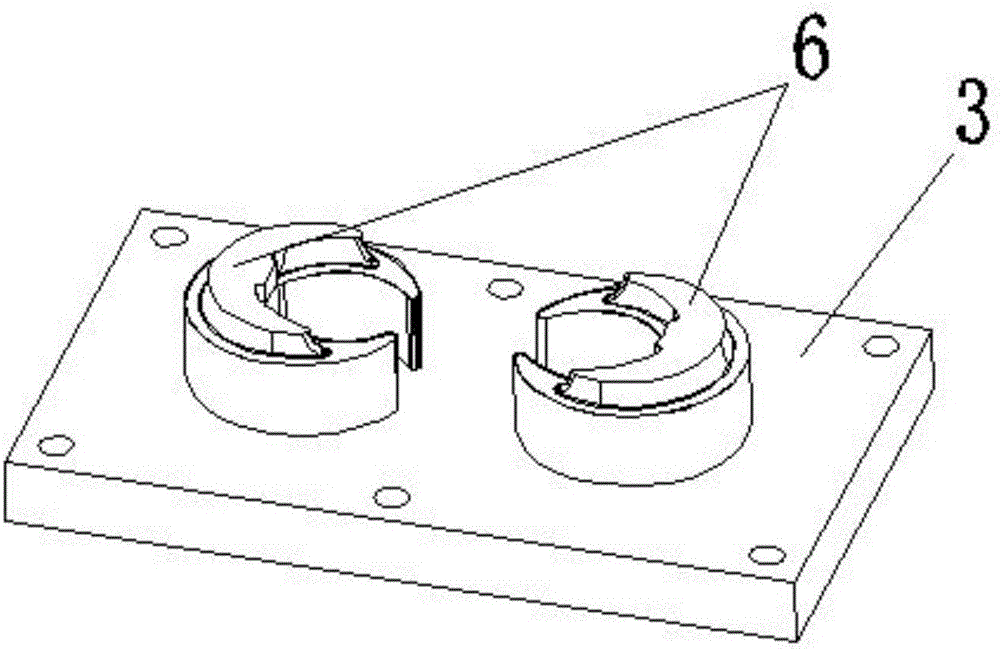

Subsurface type feeding mold cavity plate

The invention discloses a subsurface type feeding mold cavity plate which comprises a cuboid mold cavity plate body. A transverse runner is arranged in the middle of the upper end face of the mold cavity plate body. Two insert cavities in bilateral symmetry are formed in the mold cavity plate body and located in the left side and the right side of the transverse runner. Two subsurface type feeding openings in bilateral symmetry are further formed in the mold cavity plate body and enable the insert cavities in the left side and the right side to communicate with the transverse runner correspondingly. A plurality of locating pin holes are further formed in the mold cavity plate body. According to the subsurface type feeding mold cavity plate, the insert cavities in the middle are designed to be crescent and matched with crescent inserts, and therefore the bumping probability of the inserts during assembly can be lowered to the maximum extent, and mounting and demounting can be facilitated; and slow wire cutting machining is adopted for the insert cavities in the middle of the mold cavity plate, and the mold cavity plate, a front mold core plate and a rear mold core plate are subjected to slow wire cutting machining in place at the same time after being located by locating pins, wherein the front mold core plate and the rear mold core plate are matched with the mold cavity plate; and assembly errors are effectively avoided, and the precision of the mold cavity plate can be improved remarkably.

Owner:SUZHOU HUACHUAN PLASTIC MOLD PROD FACTORY

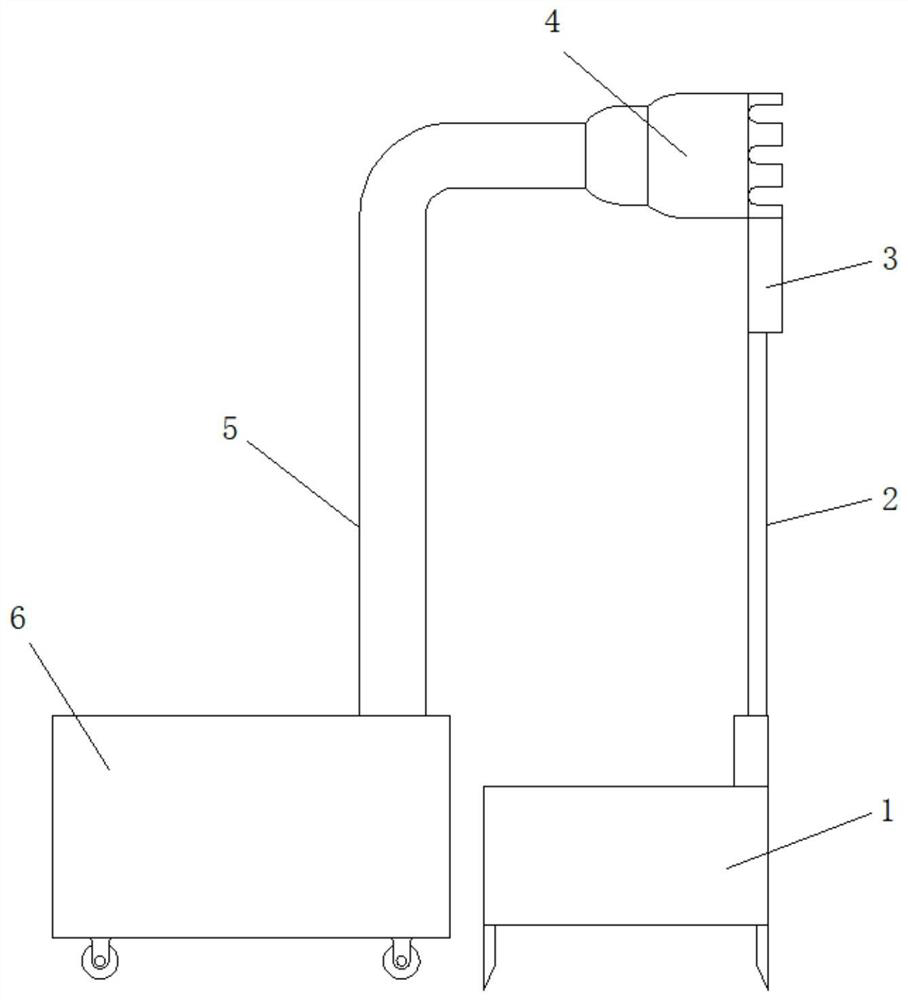

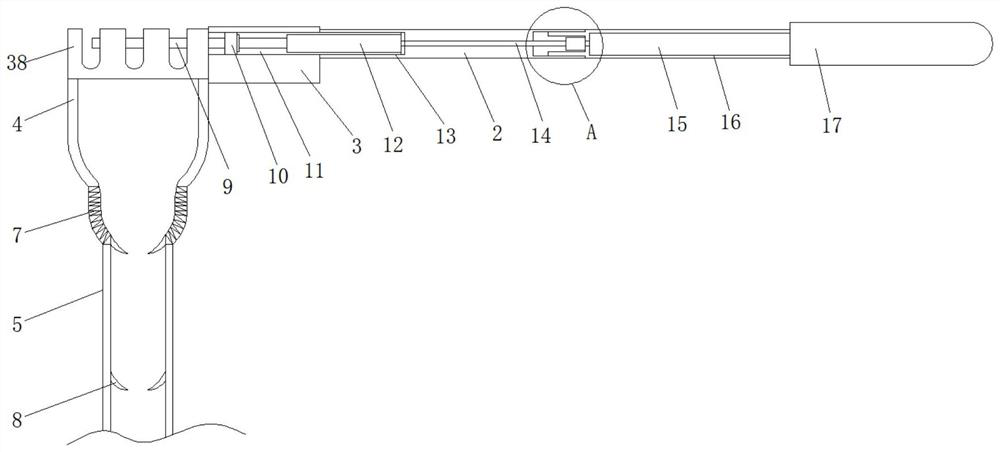

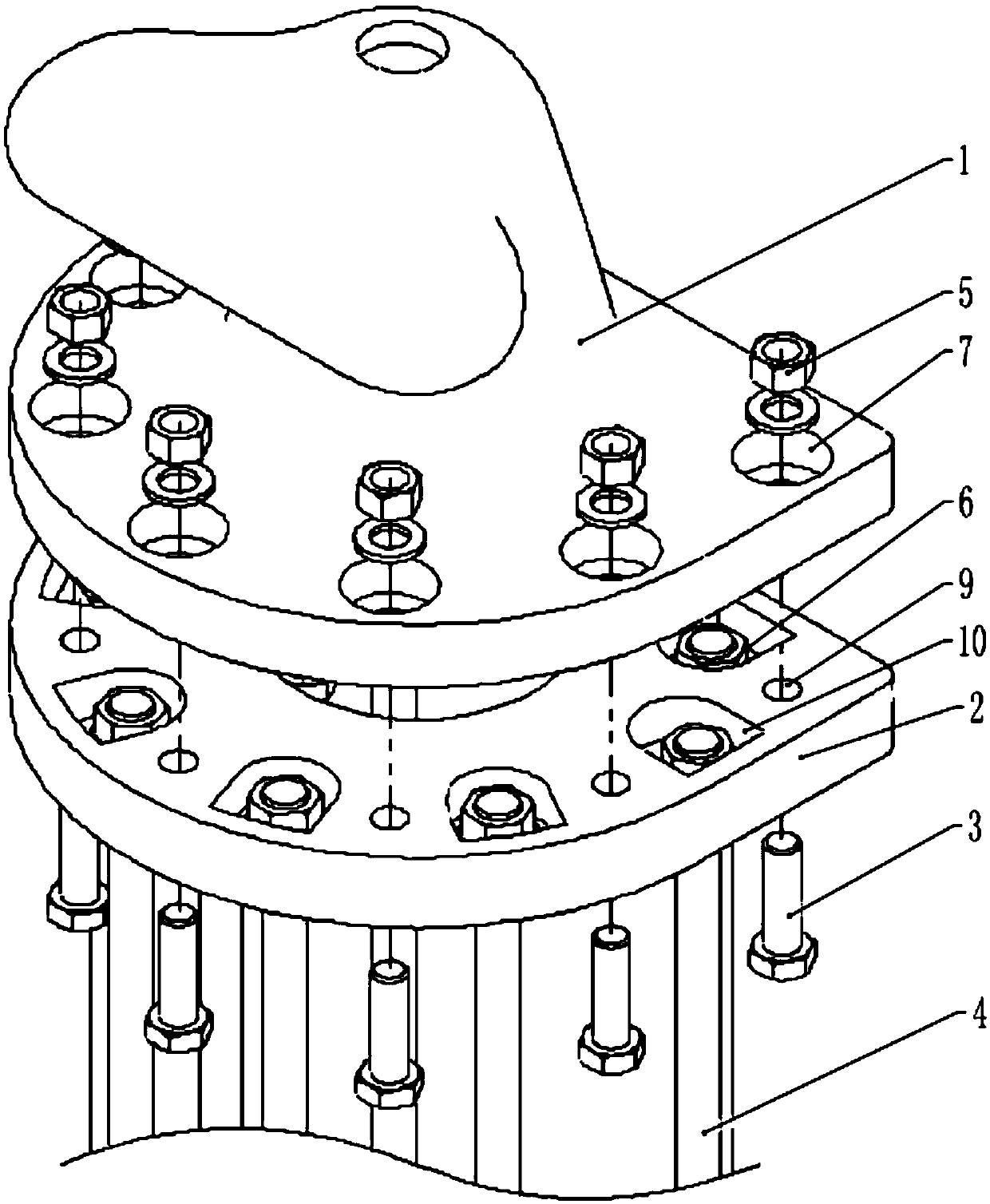

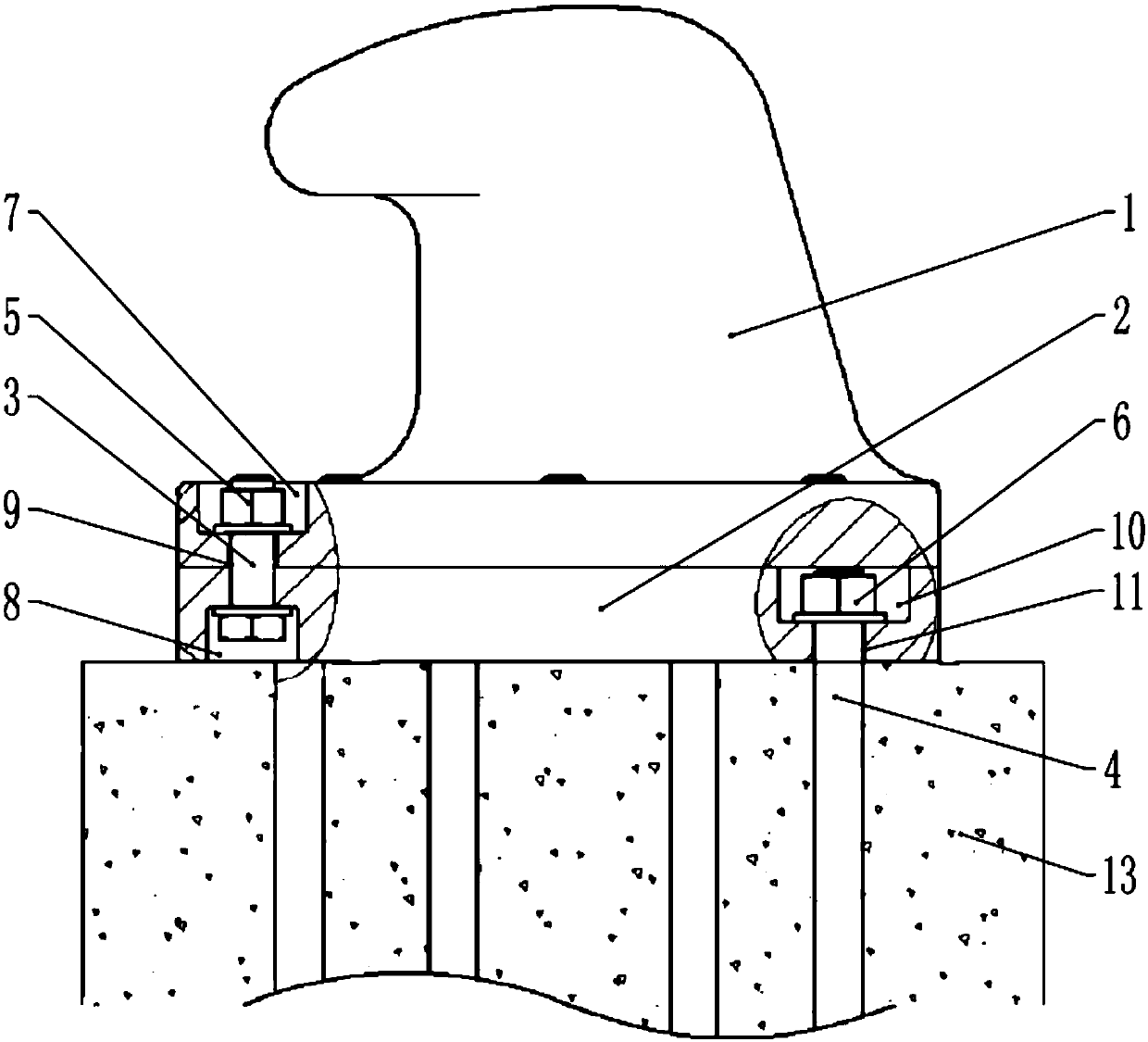

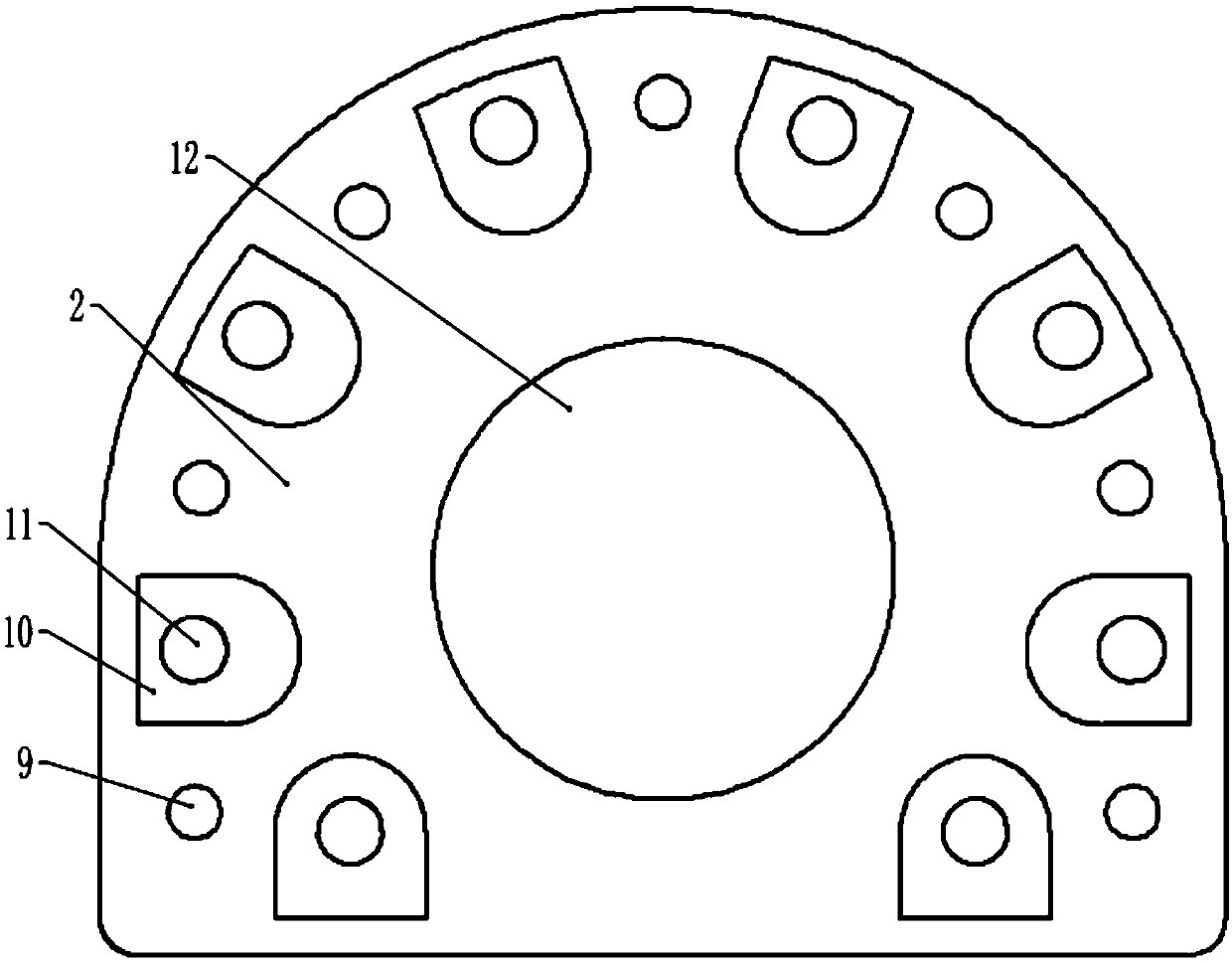

Device and method for suppressing bumps during hoisting of engine accessory case

ActiveCN110745693BGuaranteed Balance RequirementsEasy to adjustLoad-engaging elementsMachine partsRing device

The invention discloses a device and method for suppressing bruises during hoisting of an engine accessory casing. The invention relates to the technical field of aero-engine hoisting. hole; ring device, the ring device includes a ring and a ring fixing part connected to the bottom of the ring, the fixing part of the ring is matched with the first through hole and connected with the hanging plate, the first connecting shaft, the first connecting shaft and the second through hole go through Cooperate and connect with the hanging plate, the bottom of the first connecting shaft can be detachably connected with the engine accessory casing; the second connecting shaft, the second connecting shaft and the third through hole fit through and connect with the hanging plate, the bottom of the second connecting shaft can be It is detachably connected with the engine accessory case. The utility model has the advantages of convenient adjustment, and can effectively prevent engine accessories casing parts from being bruised and some parts from being scrapped.

Owner:PLA NO 5719 FACTORY

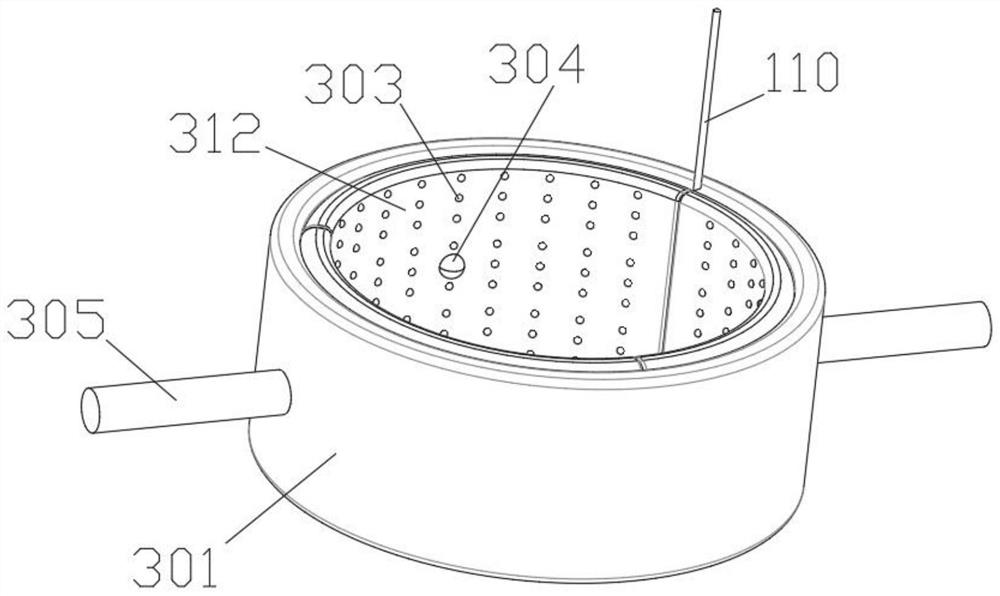

Apple harvesting device

The invention discloses an apple harvesting device. The apple harvesting device comprises a picking mechanism, a conveying hose and a collecting box, wherein the picking mechanism comprises a handheldrod, an action piece for cutting, a net bag for holding fruits and a supporting ring, wherein the end of the handheld rod is connected with the action piece; the supporting ring is welded to the front end of the action piece, and the supporting ring communicates with the conveying hose through the net bag; a connecting folding pipe is connected between the bottom end of the net bag and the conveying hose; a telescopic cavity is formed in the action piece; a knife is installed in the telescopic cavity through a knife rest; the tail end of the knife rest is connected with an electric telescopicrod; the electric telescopic rod is installed in an electric telescopic rod installation cavity of the handheld rod in an extending mode; and the electric telescopic rod installation cavity communicates with the telescopic cavity. According to the fruit picking device, a cutter driven by the electric telescopic rod is arranged in the fruit picking mechanism to advance and retreat into the supporting ring, so that the cutter on the knife rest moves out of the telescopic cavity and moves into the supporting ring, fruit stems of fruits are cut off, the fruits are separated from branches, the mode is simple and rapid, and fruit trees and fruits are not damaged.

Owner:江苏省农机具开发应用中心

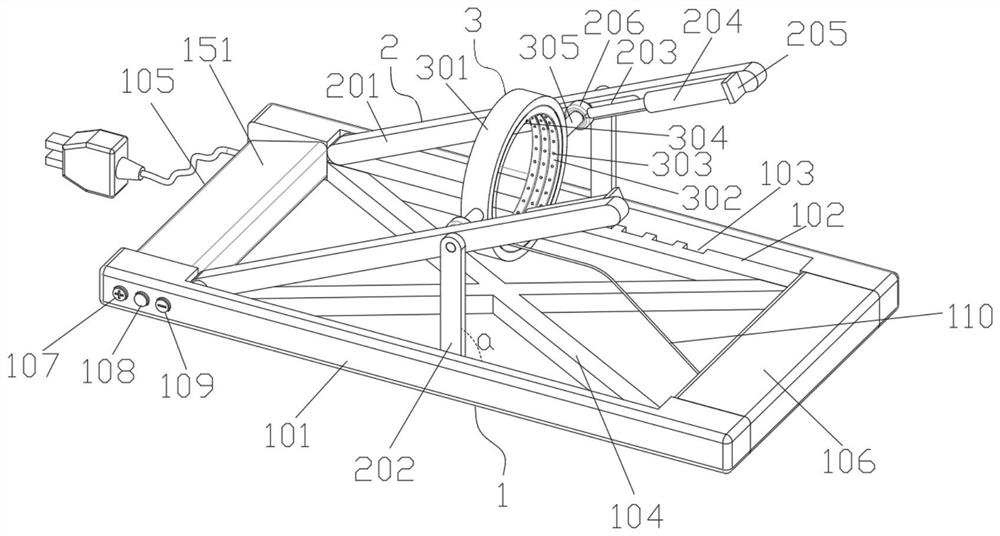

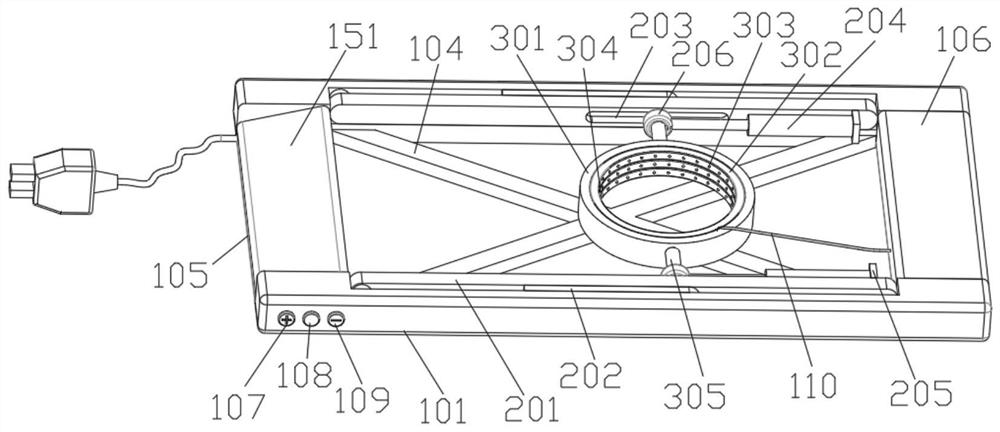

Rehabilitation massage device

InactiveCN113384441AEasy step by stepReduce contusionPneumatic massageSuction-kneading massagePhysical medicine and rehabilitationMassage

The invention provides a rehabilitation massage device which comprises an adjustable support, wherein the adjustable support comprises a bottom frame and an adjusting combined frame; and the adjusting combined frame is hinged to the bottom frame. The rehabilitation massage device further comprises a massage air bag ring; an adjusting rod is arranged on the adjusting combined frame; the bottom of the adjusting rod is connected with the bottom frame; a telescopic component is arranged on the adjusting combined frame; and the telescopic component is connected with the massage air bag ring. The rehabilitation massage device has the advantages of a reasonable structure, a good massage effect and a reliable massage process and can be conveniently collected.

Owner:昆山市康复医院(昆山市周市人民医院)

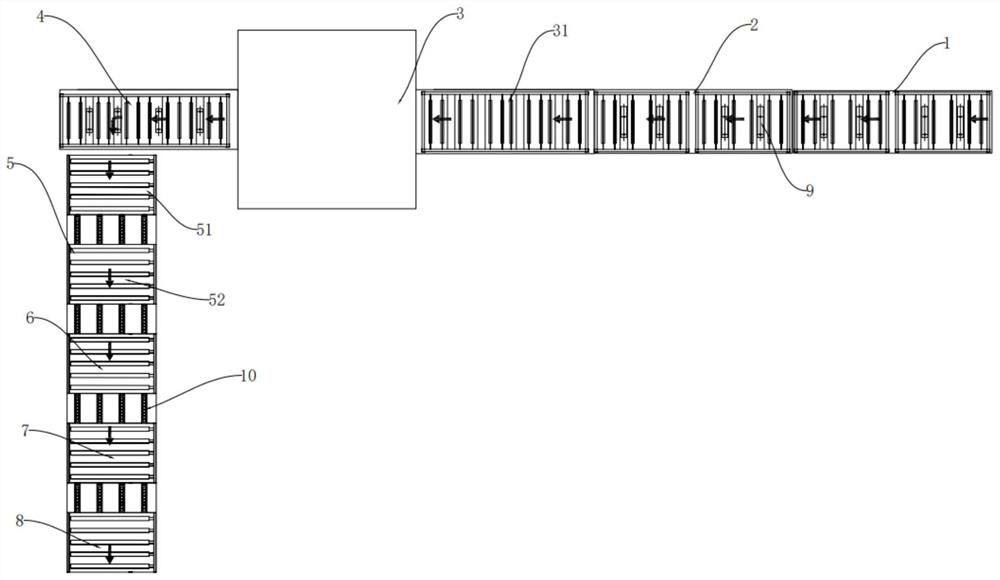

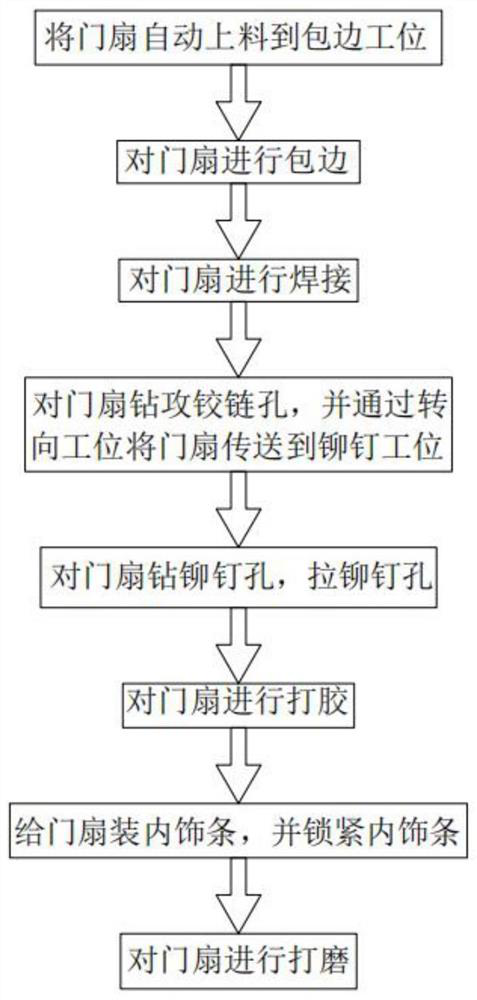

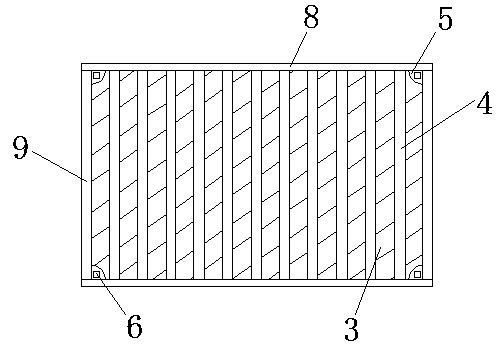

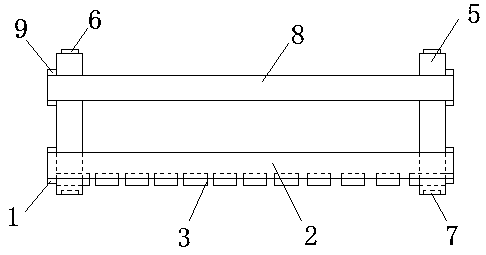

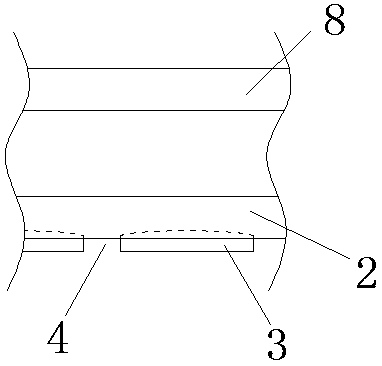

Machining assembly line and machining method for marine fireproof door with irregular size

PendingCN114147496AReduce chance of bruisingAvoid loading and unloadingOther manufacturing equipments/toolsDrill holePolishing

The invention relates to an irregular-size marine fireproof door processing assembly line which sequentially comprises an edge covering station, a welding station, a drilling station, a riveting station, a gluing station, an interior trim strip mounting station and a polishing station according to the direction of an assembly line processing procedure. A steering station is arranged between the drilling station and the riveting station, and the edge covering station, the welding station, the drilling station and the steering station are perpendicular to the riveting station, the gluing station, the interior trim strip mounting station and the polishing station. According to the processing assembly line and the processing method of the marine fireproof door with the irregular size, all procedures of an irregular door leaf are connected by adopting a streamline mode and utilizing a conveying streamline and a mechanical operation principle, so that the labor intensity is reduced, the labor cost is saved, and the working efficiency is improved; and the problem that workers are injured by collision and crashing in the feeding and discharging carrying process is also avoided, and the safety of the workers during working is improved.

Owner:华南建材(深圳)有限公司

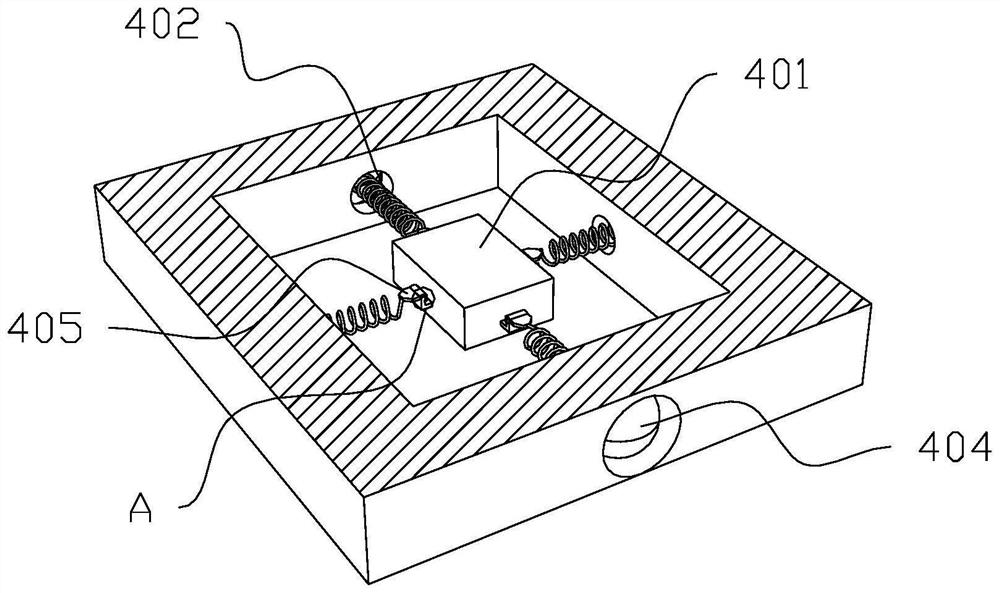

An anti-vibration device for placing cultural relics

ActiveCN111365407BAvoid leaningPrecise positioningSpringsNon-rotating vibration suppressionClassical mechanicsSlide plate

Owner:MIANYANG TEACHERS COLLEGE

Konjak seed turnover frame

ActiveCN109005950AReduce chance of bruisingIncrease the space betweenAgriculture tools and machinesHarvested fruit hanging devicesEngineering

Owner:勉县天适农业科技有限公司

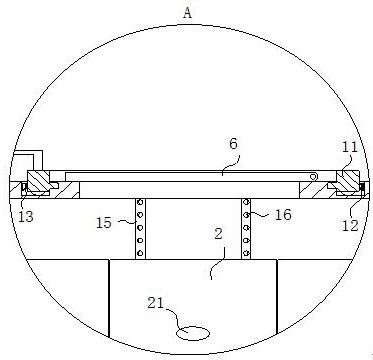

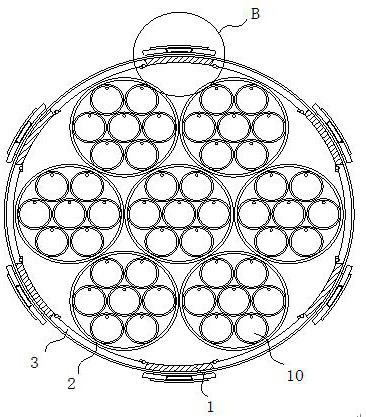

Combined surgical instrument storage cabinet for operating room nursing and combination method

PendingCN113925617AImprove sterilization efficiencyReduce chance of bruisingSurgical furnitureBio-packagingOperating theatresNursing care

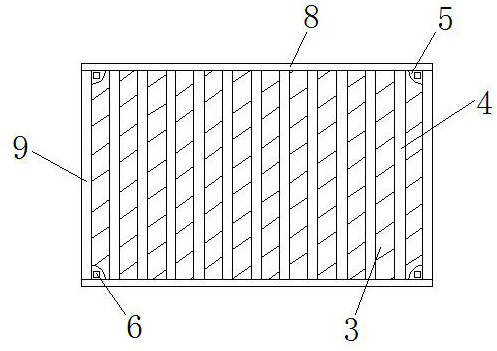

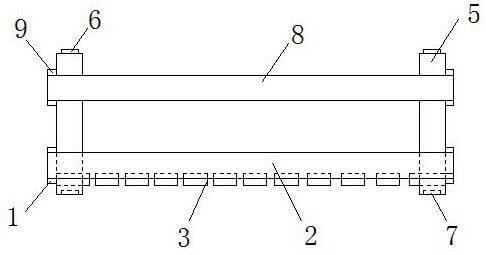

The invention belongs to the technical field of instrument cabinets, and particularly relates to a combined surgical instrument storage cabinet for operating room nursing and a combination method. The combined surgical instrument storage cabinet comprises a first-stage combined cylinder and a plurality of second-stage combined cylinders, the second-stage combined cylinders are located in the first-stage combined cylinder, one second-stage combined cylinder is located in the middle of the inner side of the first-stage combined cylinder, the other second-stage combined cylinders are uniformly distributed in the circumferential direction of the second-stage combined cylinder in the middle; a plurality of strip-shaped sealing doors are installed on the side face of the first-stage combined cylinder and correspond to the second-stage combined cylinders evenly distributed in the circumferential direction, the bottoms of the strip-shaped sealing doors are hinged to the first-stage combined cylinder through L-shaped rods, and baffles are fixedly connected to the positions, at the bottom ends of the L-shaped rods, of the bottom of the first-stage combined cylinder. According to the invention, a plurality of second-stage combined cylinders are combined and put into the first-stage combined cylinder, so that multiple persons can take the combined cylinders at the same time, the sterilization efficiency of the second-stage combined cylinder at the middle part is higher, and meanwhile, the first-stage combined cylinder is cylindrical, so that the probability of collision injury to the persons is reduced.

Owner:安徽华亿环境科技有限公司

Front mold structure of injection mold

The invention discloses a front mold structure of an injection mold. The front mold structure comprises a front mold core backing plate, a front mold core plate and a main runner hole which are sequentially arranged from top to bottom in a stacking manner, wherein a transverse runner is arranged at the middle part of the bottom end surface of the front mold core plate; the main runner hole penetrates the front mold core backing plate and the front mold core plate and communicates with the transverse runner; two insert cavities which are bilaterally symmetrical are formed in the front mold core plate and vertically penetrate the front mold core plate; the insert cavities are bilaterally symmetrical and crescent, and the crescent concave parts of the insert cavities are face to face; the two insert cavities are positioned at the left and right sides of the transverse runner; two front mold inserts are inserted in the front mold core plate; the front mold core backing plate is manufactured from hard metals; and hard materials are arranged at the bottoms of the inserts to prevent the inserts from retreating due to deformation of a mold base in production. The front mold structure is applicable to the injection mold, is used for producing crescent injection products and is high in production accuracy, capable of producing two injection products at the same time and high in machining efficiency.

Owner:SUZHOU HUACHUAN PLASTIC MOLD PROD FACTORY

Front mold core plate structure

The invention discloses a front mold core plate structure. The front mold core plate structure comprises a mold core plate body. A main runner hole is formed in the middle portion of the front mold core plate body and penetrates the front mold core plate body. A transverse runner is formed in the middle portion of the bottom end face of the front mold core plate body. The main runner hole communicates with the transverse runner. The front mold core plate body is further provided with two insert cavities symmetric left and right. The two insert cavities are located in the left side and the right side of the transverse runner. The front mold core plate body is further provided with a plurality of positioning pin holes penetrating the front mold core plate body. According to the front mold core plate structure, the insert cavities in the middle portions of the front mold core plate structure are designed to be in a crescent shape and are matched with crescent inserts, the bumping-damage probability of the inserts during assembly can be reduced to the maximum degree, and mounting and dismounting can be convenient. The insert cavities in the middle portions of a mold core combination are cut and machined through slow wires, and after the front mold core plate body, a mold cavity plate and a rear mold core plate are positioned through positioning pins, slow wire cutting machining is conducted in place, wherein the front mold core plate body is matched with the mold cavity plate and the rear mold core plate; and the assembly error is effectively avoided, and the precision of the front mold core plate structure can be obviously improved.

Owner:SUZHOU HUACHUAN PLASTIC MOLD PROD FACTORY

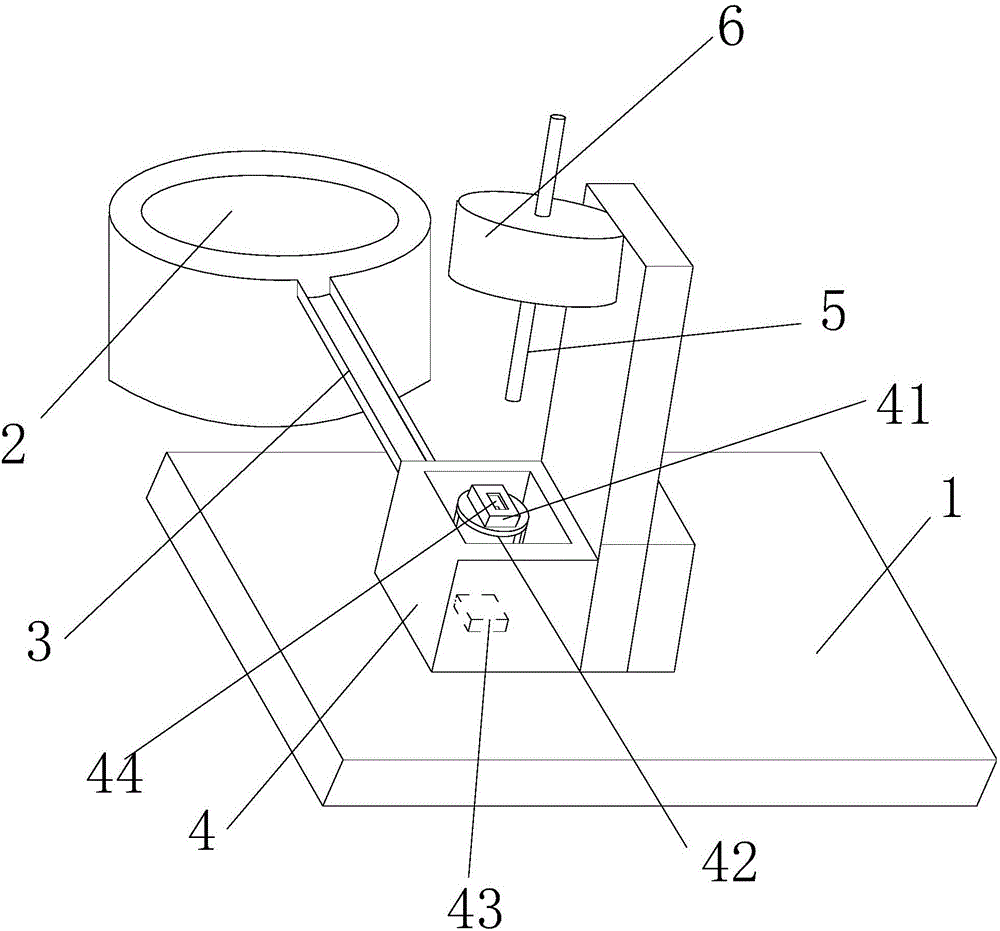

Semi-automatic silver point riveting machine

InactiveCN106451018AAvoid risk of punctureReduce risk of bruisesLine/current collector detailsPunchingReciprocating motion

The invention provides a semi-automatic silver point riveting machine, which comprises a table board, a silver point vibration plate, a silver point feeding track, a lower die, a punch rod and a drive device for driving the punch rod to carry out reciprocating motion up and down, wherein the lower die, the punch rod and the drive device all are arranged on the table board; a hollow cavity is formed in the upper end surface of the lower die; one end of the silver point feeding track is connected with the silver point vibration plate and the other end communicates with the bottom of the hollow cavity; a work block, a discharge device and a rotating and supporting mechanism for supporting and rotating the work block are arranged in the hollow cavity; a copper contact accommodating groove is formed in the work block; the copper contact accommodating groove is provided with two upper and lower open ends; and a push device for pushing a silver point to the bottom of the copper contact accommodating groove from the bottom of the hollow cavity is arranged at the bottom of the hollow cavity. Compared with the prior art, the semi-automatic silver point riveting machine has the advantages that the probability that a finger is injured by punching is greatly reduced and the security degree of the riveting process is improved.

Owner:HEFEI SHUSHI IND & TRADE CO LTD

Engine camshaft guide rod assembly with attraction function

PendingCN111195879AImprove fit tightnessImprove installation fitMetal-working hand toolsStructural engineeringCamshaft

The invention discloses an engine camshaft guide rod assembly with an attraction function. The engine camshaft guide rod assembly comprises a guide rod, a circular positioning nail, a pin and two magnets, wherein the guide rod is of a cylindrical structure; the circular positioning nail is arranged in the center of the front end face of the guide rod, and two grooves are symmetrically formed in the positions, located on the two sides of the circular positioning nail, of the front end face of the guide rod; the pin is arranged at the position, close to the edge, of the front end face of the guide rod and is arranged to be embedded into a hole in the end face of a camshaft in cooperation with the circular positioning pin to be positioned; and the two magnets are embedded into the two groovescorrespondingly and used for enabling the guide rod assembly to be attracted to the end face of the camshaft. According to the engine camshaft guide rod assembly with the attraction function, the installation cooperation degree of the engine camshaft is improved, the collision damage rate is reduced, and therefore the production efficiency is improved.

Owner:GUANGXI YUCHAI MASCH CO LTD

A konjac seed turnover box

ActiveCN109005950BReduce infectionReduce the chance of secondary cutsAgriculture tools and machinesHarvested fruit hanging devicesMechanical engineeringBotany

Owner:勉县天适农业科技有限公司

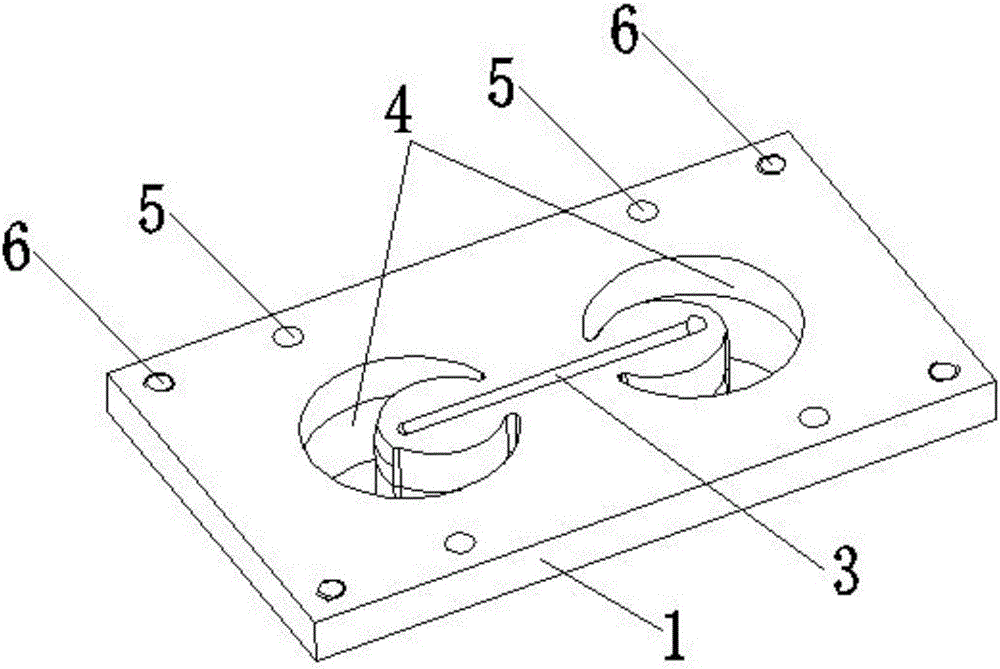

Crescent cavity injection mold

The invention discloses a crescent cavity injection mold. The crescent cavity injection mold comprises a front mold core base plate, a front mold core plate, a mold cavity plate, a rear mold core plate, a rear mold core base plate, main runner holes and transverse runners, wherein the front mold core base plate, the front mold core plate, the mold cavity plate, the rear mold core plate and the rear mold core base plate are sequentially stacked from top to bottom; each of the front mold core plate, the mold cavity plate and the rear mold core plate is provided with two insert cavities in left-right symmetry, the insert cavities are of crescent shapes in left-right symmetry, and the recessed parts of the crescent shapes are opposite to each other; two front mold inserts are embedded into the front mold core plate, and two rear mold inserts are embedded into the rear mold core plate; the front mold inserts, the rear mold inserts and the mold cavity plate form a product cavity. The crescent cavity injection mold is used for producing crescent injection molding products and is high in machining precision, capable of producing two products at the same time and high in machining efficiency.

Owner:SUZHOU HUACHUAN PLASTIC MOLD PROD FACTORY

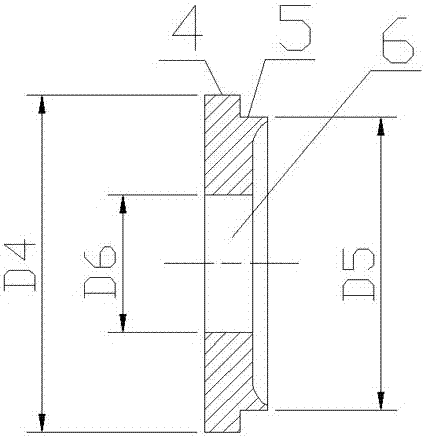

Improved concrete transmission and transformation electric power circuit pole and production method thereof

InactiveCN107150407AReduce chance of bruisingReduce the chance of being knocked offMouldsShaping reinforcementsEngineeringMethods of production

The invention relates to an improved concrete transmission and transformation electric power circuit pole and a production method thereof. The method comprises the steps that an electric pole cage-shaped framework is manufactured; a steel wire is wound automatically; an electric pole top part baffle board and a root part anchoring plate are manufactured; the electric pole cage-shaped framework is subjected to concrete grouting and centrifuging; and electric pole maintenance is conducted, an electric pole with the top diameter portion being in a circular truncated cone shape and a base being provided with a flange is obtained, the diameter portion of a metal baffle board body is anchored and attached with an electric pole steel mold top part end plate, the root part anchoring plate and the electric pole steel mold end plate are anchored and attached, the electric pole top part baffle board and the root part anchoring plate are bushed into the inner wall of an electric pole steel mold, and an inner hole is formed in the middle of the metal board body. By the adoption of the method, the electric rod root part and the top part can be made flat after being formed, and the root part end face impact probability of the electric pole in the hoisting or transporting process is lowered; and meanwhile, in the centrifugal forming process of the electric pole, due to the fact that a top part baffle board boss and an anchoring plate chamfer boss are bushed into the electric pole steel mold, a sealing effect is achieved, and the grout runout phenomenon of the electric pole top part and root part end face is reduced.

Owner:GUANGXI POWER LINE EQUIP FACTORY

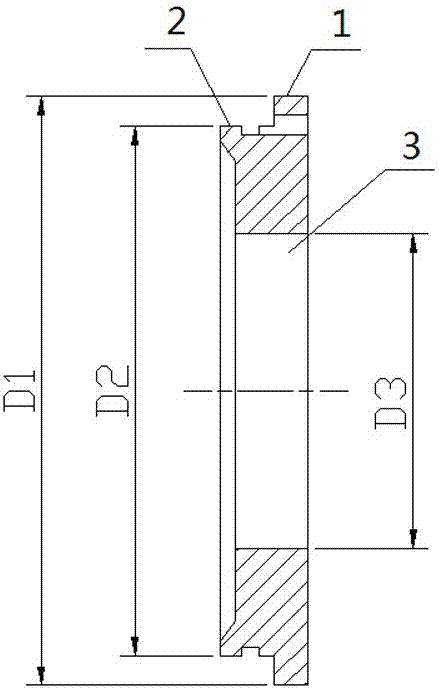

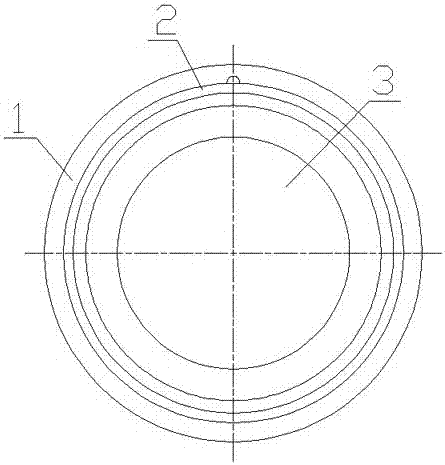

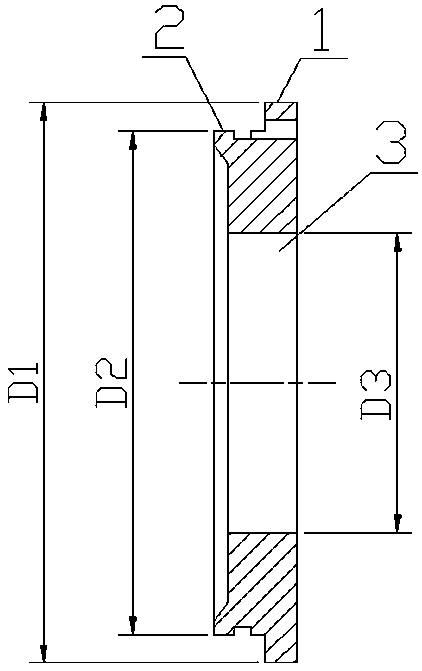

Concrete power transmission and transformation power line pole with improved anchor plate and production method thereof

ActiveCN107160552BReduce chance of bruisingReduce pulp run defectsCeramic shaping apparatusTowersCement slurryMechanical engineering

The invention relates to a concrete electric power circuit rod manufacturing method, in particular to an improved anchor plate concrete transmission and transformation electric power circuit electric rod and a production method thereof. The production method includes the steps that an electric rod cage-shaped framework is manufactured, a steel wire is automatically wound, an anchor plate at the root of the electric rod is manufactured, the electric rod cage-shaped framework is subject to concrete grouting and centrifugation, the electric rod is maintained, in the anchor plate improvement process, anchor plate at the root of the electric rod is manufactured firstly, a disc-shaped metal plate is cut, and the external diameter of the disc-shaped metal plate is phi D1 and is the same as the diameter of the electric rod; a boss is turned on the disc-shaped metal plate, the diameter of the boss is phi D2, and the boss is the smoothing end face of the anchor plate and is used for preventing cement slurry from running out from gaps of the anchor plate and an electric rod steel mold wall during electric rod centrifugation; and the phenomenon of end face slurry running defects at the root of the electric rod is reduced.

Owner:GUANGXI POWER LINE EQUIP FACTORY

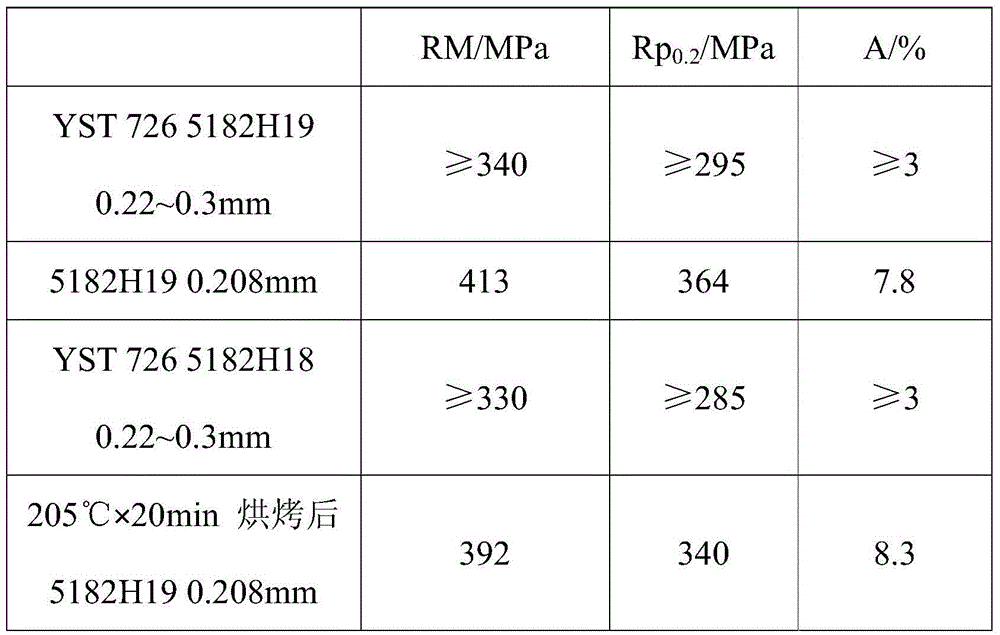

A kind of production method of 5182 aluminum alloy pull ring material base material

The invention discloses a production method for a 5182 aluminum alloy tab stock base material. The production method includes the production processes of fusion casting, saw cutting, surface milling, soaking, (1+4) hot continuous rolling, cold continuous rolling with three machine frames, cleaning and trimming, and cold continuous rolling with one machine frame. According to the production method, the effect that the mechanical properties of the 5182 aluminum alloy tab stock base material are stable and qualified is guaranteed, the production processes are shortened, and the production efficiency is improved.

Owner:SHANDONG NANSHAN ALUMINUM +3

Breakable connection device

PendingCN109594525AProtection securityProtection from damageShipping equipmentEngineeringMarine equipment

The invention relates to the technical field of marine equipment, and particularly discloses a breakable connection device. The connection device comprises a bollard and a base, wherein the base and the bollard are fixedly connected through a first fixing member, the base and concrete of a wharf are fixedly connected through a second fixing member, and the strength of the first fixing member is lower than that of the second fixing member. According to the scheme, the first fixing member and the second fixing member with different strength are connected, so that when cable tension on the bollard exceeds safe load, only connecting bolts are broken, and the problems of anchor bolt breakage, bollard breakage or cable breakage can be solved.

Owner:固蓝海事(重庆)工程技术有限公司

Rear mold structure of injection mold

The invention discloses a rear mold structure of an injection mold. The rear mold structure comprises a mold cavity plate, a rear mold core plate and a rear mold core backing plate which are sequentially laminated from top to bottom, and further comprises a cross runner. The mold cavity plate and the rear mold core plate are provided with two insert cavities which are symmetrical left and right. The insert cavities are in the shape of a left-right symmetrical crescent, and crescents are recessed and opposite to each other. The insert cavities vertically penetrate through the mold cavity plate and the rear mold core plate. The two insert cavities are located in the left side and right side of the cross runner. The mold cavity plate is further provided with two concealed feeding inlets which are symmetrical left and right. The two concealed feeding inlets make the insert cavities located in the left side and right side communicate with the cross runner. Two rear mold inserts are inlaid in the rear mold core plate. The rear mold core backing plate is made of hard metal. Hard materials are additionally arranged at the bottoms of the inserts so that the inserts can be prevented from retreating in production due to mold base deformation. The rear mold structure is used on the injection mold and used for manufacturing crescent-shaped injection products, and working accuracy is high. Meanwhile, two products can be produced at the same time, and thus working efficiency is high.

Owner:SUZHOU HUACHUAN PLASTIC MOLD PROD FACTORY

Manual drive conveying equipment used for side shell plate material of automobile body in white

ActiveCN102491082BReduce chance of bruisingReduce safety incidentsWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to manual drive conveying equipment used for a side shell plate material of an automobile body in white. The equipment is composed of a chassis, a positioning guide mechanism, a supporting block stretching mechanism, a workpiece lifting positioning assembly, a lifting appliance hoisting assembly and an operating handle which are connected, wherein the chassis comprises a fixing chassis and a counter weight; the positioning guide mechanism comprises a guide base, a guide sleeve, an adjustable guide sleeve mounting plate and an adjustable positioning rod; the supporting block stretching mechanism comprises a connecting rod, a telescopic shaft, a stretching linear bearing block, a connecting rod drive rod, a connecting rod drive rod installing base, a hand clamp, a handclamp mounting plate and a linear bearing; the workpiece lifting positioning assembly comprises a lower supporting block mounting plate, an upper supporting block mounting plate, a supporting block, a lower supporting block and a B pillar guide block; and the lifting appliance hoisting assembly comprises an adjustable hoisting loop chain fixed ring, a hoisting loop chain, a hoisting loop chain shackle and a hoisting ring. The equipment is arranged on an upper pneumatic or electric elevator of a side shell welding production line of an automobile body in white. The conveying equipment providedby the invention has the advantages of reasonable design, rapidness and high accuracy in operation and safe and reliable performance.

Owner:TIANJIN FUZHEN IND EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com