Device and method for suppressing bumps during hoisting of engine accessory case

An accessory casing and engine technology, which is applied in the directions of transportation and packaging, load suspending elements, etc., can solve the problems of disassembling the engine casing that damages the connecting part of the engine, unable to maintain the balance of the center point of the engine accessory casing, and parts rework and repair. , to reduce the bump rate, prevent bumps, and ensure the effect of balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

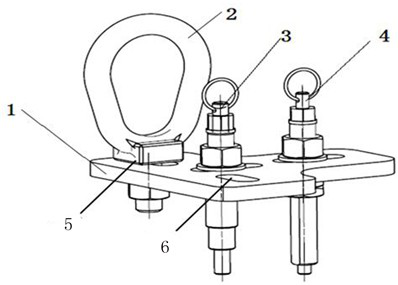

[0022] Such as figure 1 As shown, the embodiment of the present invention provides a device for suppressing bruises during hoisting of an engine accessory casing, which includes: a hanging plate 1, the hanging plate 1 is provided with a first through hole, a second through hole and a third through hole;

[0023] The suspension ring device, the suspension ring device includes suspension ring 2 and the suspension ring fixing part connected with the bottom of the suspension ring 2, the suspension ring fixing part penetrates and cooperates with the first through hole and is connected with the suspension plate 1,

[0024] The first connecting shaft 3, the first connecting shaft 3 fits through the second through hole and is connected with the suspension plate 1, the bottom of the first connecting shaft 3 can be detachably connected with the engine accessory case;

[0025] The second connecting shaft 4, the second connecting shaft 4 fits through the third through hole and is connecte...

Embodiment 2

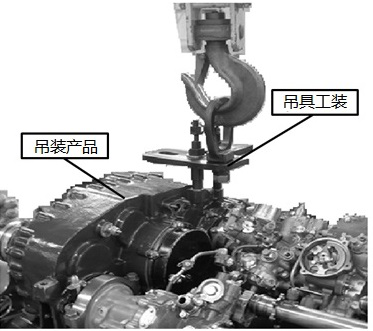

[0033] refer to figure 2 , this embodiment also provides a method for suppressing bruises during hoisting of an engine accessory casing, which includes: connecting the ring device, the first connecting shaft 3 and the second connecting shaft 4 to the hanging plate 1, and connecting the bottom of the first shaft And the bottom of the second shaft is threadedly connected with the threaded holes on the engine accessory casing respectively, and then the hoisting mechanism hooks the suspension ring 2 on the suspension ring device for lifting.

[0034] The invention has the following advantages: 1. It is convenient to adjust. The invention adopts hoisting by two stress points, which can conveniently adjust whether the main fuel pump is installed on the engine accessory casing, thereby ensuring the balance requirement of the engine accessory casing during the whole hoisting process.

[0035] 2. During the installation and disassembly process of the engine accessory casing, the dama...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com