Konjak seed turnover frame

A turnover frame, konjac technology, applied in agricultural machinery and implements, horticulture, botanical equipment and methods, etc., can solve problems such as affecting konjac planting, high planting taro casualty rate, etc., to reduce the probability of bumps and improve the space between , the effect of preventing wobble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

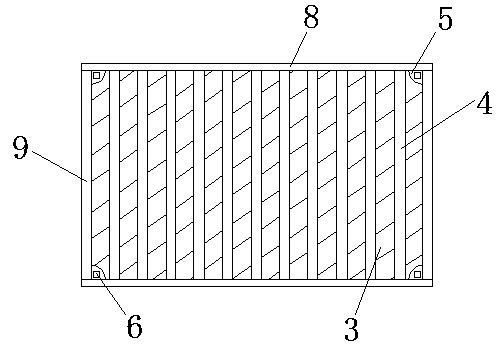

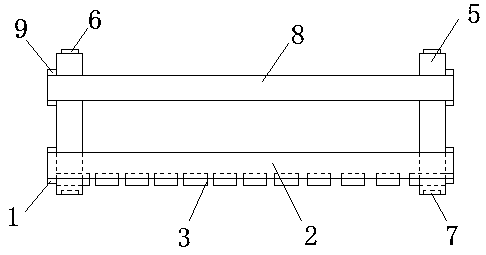

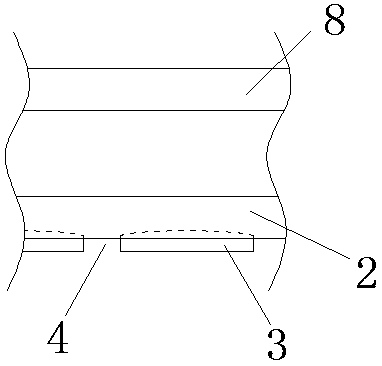

[0039] Such as figure 1 with figure 2 Shown, a kind of konjac kind turnover frame comprises frame body, and frame body is rectangular parallelepiped structure, and top is provided with opening, is characterized in that: frame body comprises bottom frame and upper frame, and bottom frame consists of two first connecting rods 1, two The second connecting rod 2 and the supporting rod 3 are composed of two first connecting rods 1 and two second connecting rods 2 spaced from each other end to end to form a square frame, the supporting rod 3 is placed in the square frame, and the two ends of the supporting rod 3 Connect with two second connecting rods 2 respectively, and parallel to the first connecting rod 1, there is a gap 4 between adjacent supporting rods 3, the upper frame is parallel to the bottom frame, and the upper frame is composed of two fourth connecting rods 9 Composed of two third connecting rods 8, two fourth connecting rods 9 and two third connecting rods 8 are con...

Embodiment 2

[0042] Based on Embodiment 1, there are four reinforcing columns 5, which are respectively located at the four corners of the frame body. The upper two adjacent surfaces of the reinforcing column 5 are connected to the upper frame, and the two adjacent surfaces of the lower part of the reinforcing column 5 are connected to the bottom frame. 5 The bottom passes through the support rod 3 vertically.

Embodiment 3

[0044] Based on the embodiment 2, the top of the reinforcement column 5 is provided with a protrusion 6 , and the bottom of the reinforcement column 5 is provided with a groove 7 , and the size of the groove 7 matches the size of the protrusion 6 .

[0045] In use, the protrusions and grooves provided on the reinforcement column can realize the stacking of multiple frames, and the protrusions and grooves can be snapped together to store a large number of konjac seeds in a limited space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com