Rear mold structure of injection mold

A technology of injection mold and back mold, which is applied in the field of back mold structure of injection mold, can solve problems such as difficulty in mold design, and achieve the effects of reducing the probability of bruising, high processing efficiency, and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

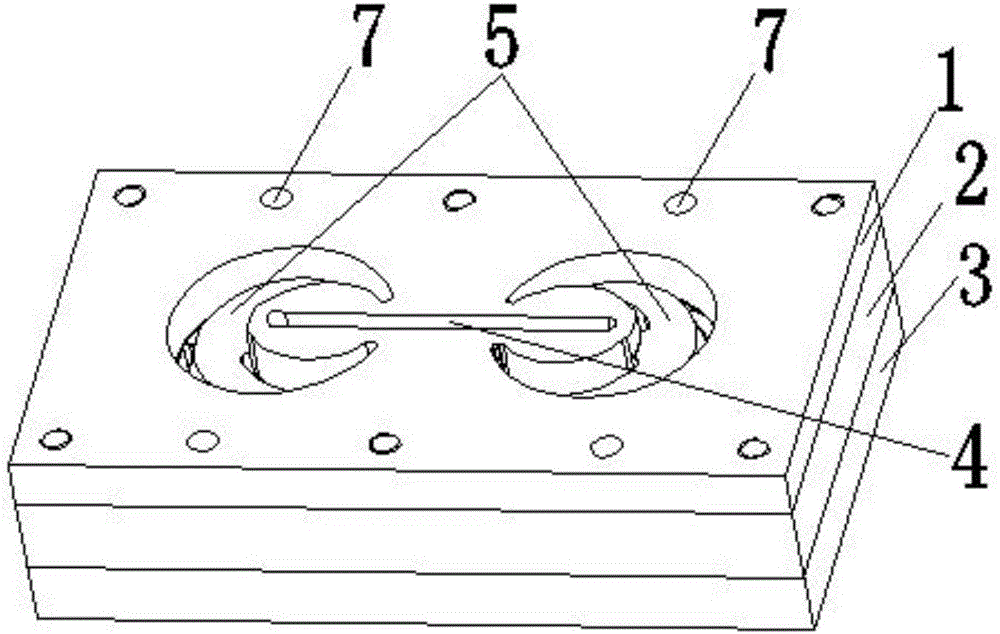

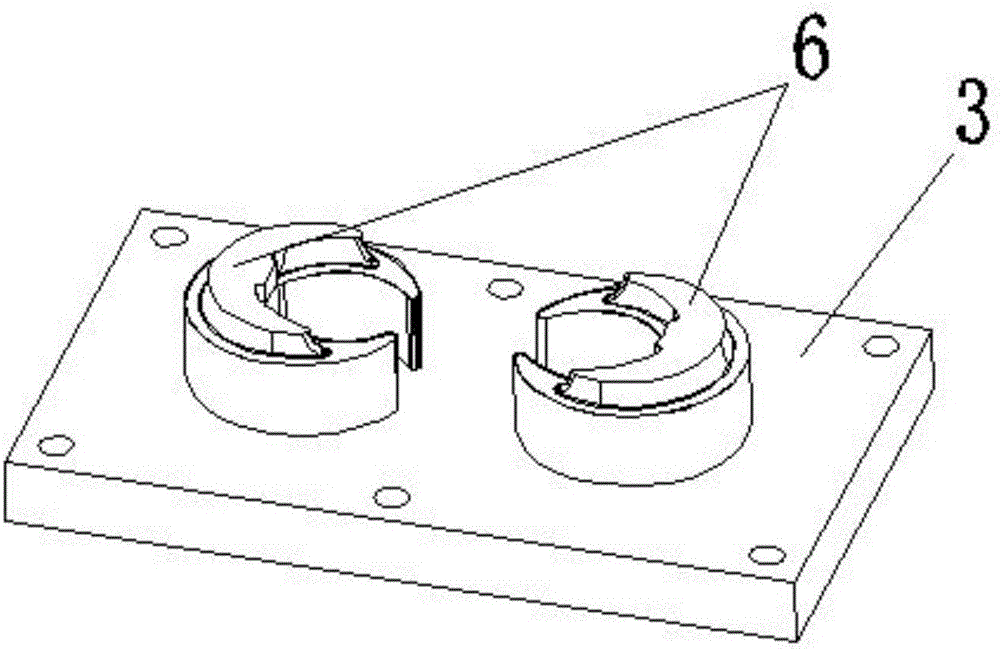

[0014] The back mold structure of the injection mold of the present invention, as attached Figure 1-2 As shown, it includes a cavity plate 1, a rear core plate 2 and a rear core backing plate 3 which are stacked sequentially from top to bottom; The cavity plate 1 and the rear mold core plate 2 are provided with two symmetrical insert cavities 5; the insert cavities 5 are in a left-right symmetrical crescent shape, and their crescent depressions are opposite; the insert cavities 5 vertically penetrate the cavity plate 1 and the rear mold core plate 2; the two insert cavities 5 are located on the left and right sides of the transverse flow channel 4; the cavity plate 1 is also provided with two left-right symmetrical latent feeding ports (not shown in the drawings drawn); the two latent feed ports respectively connect the insert cavities 5 on the left and right sides with the transverse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com