Manual drive conveying equipment used for side shell plate material of automobile body in white

A technology for conveying equipment and body-in-white, applied in welding equipment, conveyor objects, auxiliary welding equipment, etc., can solve the problems of large labor demand, complex manufacturing and debugging, low production efficiency, etc., to save labor, simplify processing and manufacturing, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

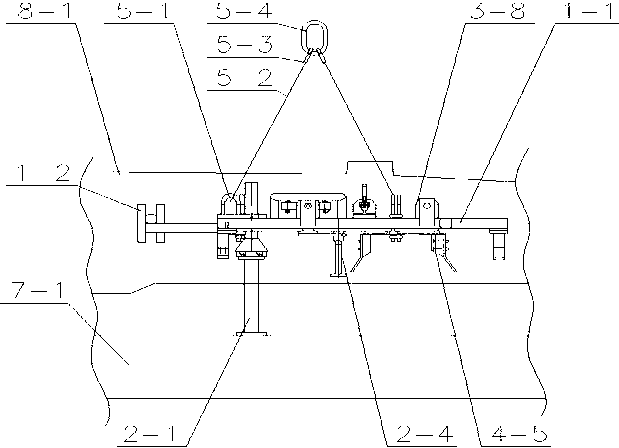

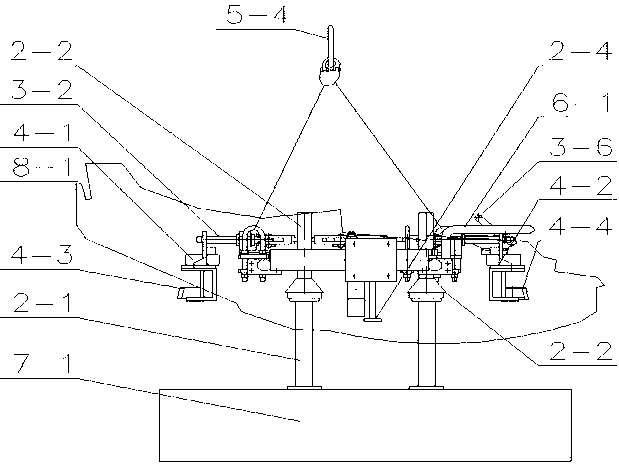

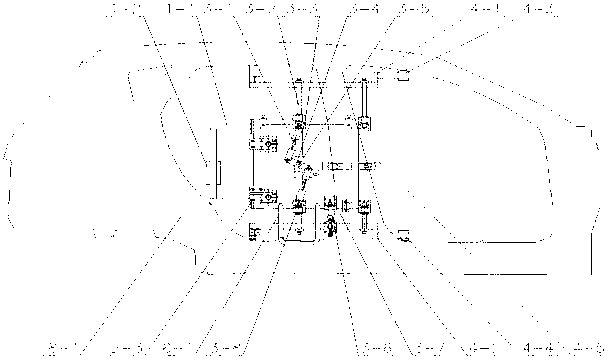

[0036] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

[0037] Such as Figure 1-Figure 3 As shown, (the equipment of the present invention and the automobile body-in-white side wall welding fixture 7-1, the automobile body-in-white side wall 8-1 installation and cooperation state schematic diagram);

[0038] The invention relates to a manual conveying device for the side wall panel of the automobile body in white, which includes a frame, a positioning and guiding mechanism, a supporting block telescopic mechanism, a workpiece lifting and positioning component, a lifting component of a spreader and an operating handle part.

[0039] The frame part includes a fixed frame 1-1 and a counterweight 1-2; the fixed frame 1-1 and the counterweight 1-2 are connected by bolts.

[0040] The setting and functional characteristics of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com