Fruit tree bagging mechanical arm

A manipulator and bagging technology, applied in the field of manipulators, can solve the problems of scratching and damage of paper strips of fruit trees, low work efficiency, high labor intensity, etc., and achieve the effect of reducing labor intensity, improving efficiency, and changing work flow.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

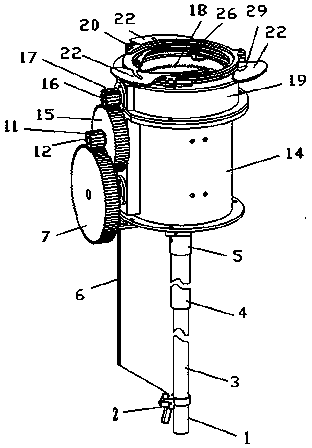

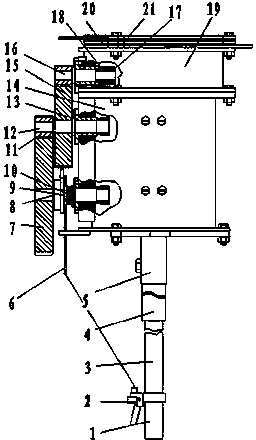

[0022] The present invention is made up of handle 1, power handle 2, casing 14, gear transmission device, tight mouth device.

[0023] As shown in the figure, the handle 1 is composed of a thin handle 3, a thick handle 4, and a base 5. The thin handle 3, thick handle 4, and base 5 are respectively connected by a set of slides, and the user can adjust the length of the handle 1. The power handle 2 is installed on the handle 1, and is connected with the power line 6 between the power handle 2 and the gear transmission. Pulling the power line 6 can drive the gear transmission to rotate and carry out bagging operations.

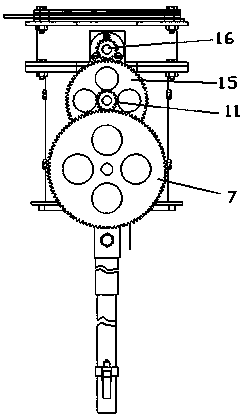

[0024] Shown in the figure, the box body 14 is installed on the handle 1 upper end, the gear transmission device is installed on the outer side wall of the box body 14, and the tight mouth device is installed on the upper end of the box body 14.

[0025] As shown in the figure, the gear transmission device is a two-stage transmission structure, and the gear trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com