Production method of 5052 aluminum alloy tank cover base material

A production method and aluminum alloy technology, applied in the field of aluminum alloy manufacturing, can solve the problems of reducing product yield, increasing bruise defects, increasing machine times, etc., so as to improve yield, reduce the probability of being bruised, and reduce material wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

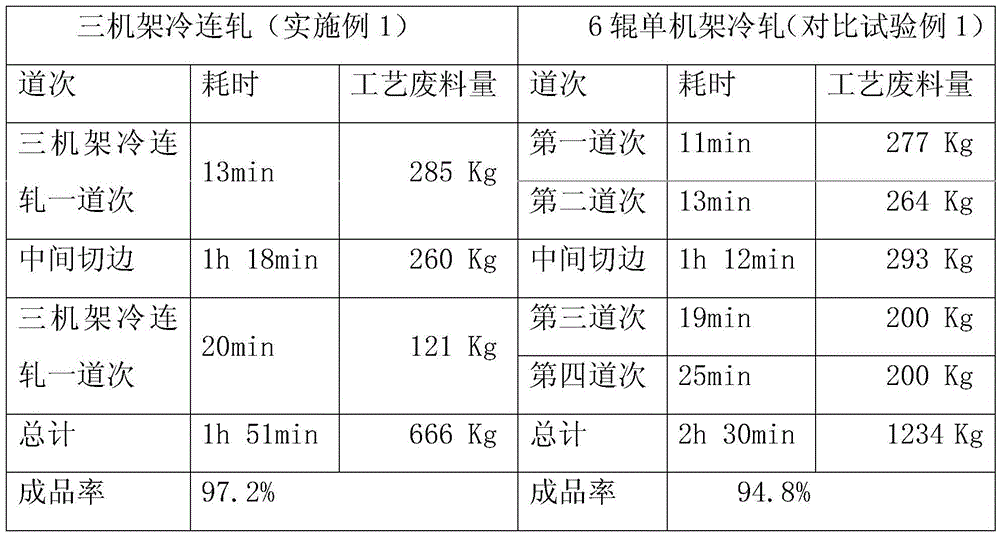

Embodiment 1

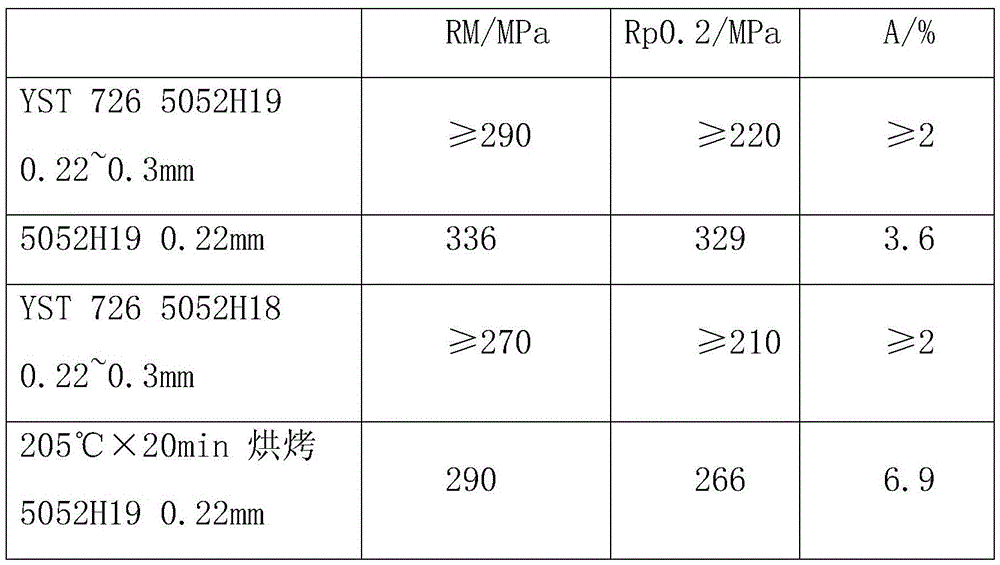

[0024] The alloy state of the 5052 aluminum alloy can lid material base material described in this example: 5052 / H19, the thickness of the finished product: 0.22mm, and its production process includes: melting and casting → sawing → milling → soaking → (1+4) thermal connection Rolling → three-stand cold rolling once → cleaning and trimming → three-stand cold rolling once → tension bending straightening → coating → finished product shearing.

[0025] 1) Casting: Chemical composition of aluminum water after casting: Si: 0.109%, Fe: 0.304%, Cu: 0.015%, Mn: 0.085%, Mg: 2.512%, Cr: 0.203%, Zn: 0.008%, other single impurities ≤ 0.03%, total ≤0.15%, the rest is Al, melting temperature: 755-760°C, refining temperature: 776-780°C, casting temperature: 708-710°C.

[0026] 2) Soaking: ingot temperature 490°C, holding time: 2 hours.

[0027] 3) (1+4) continuous hot rolling: use 1+4 continuous hot rolling, 21 rough rolling passes, and then roll through a 4-stand continuous rolling mill. T...

Embodiment 2

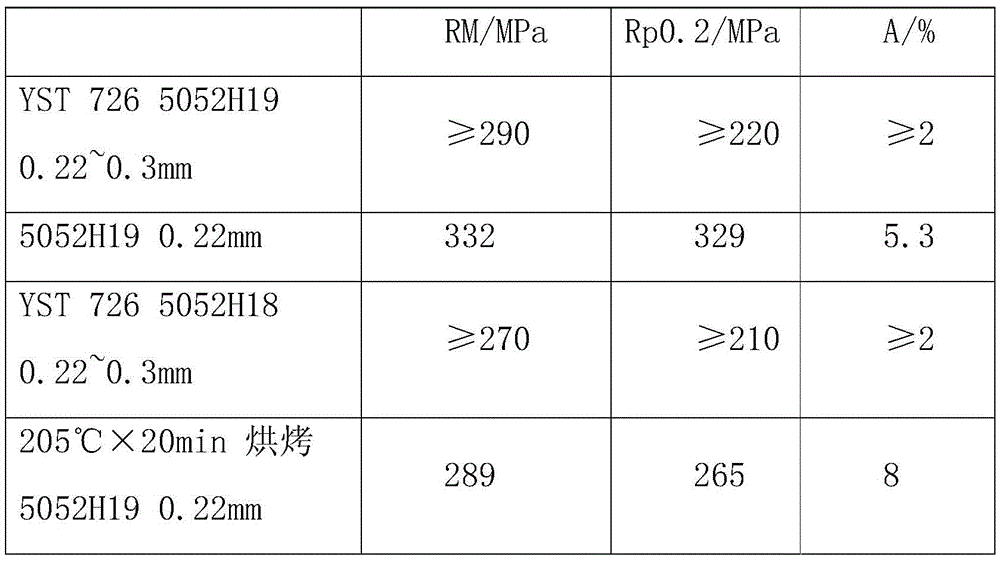

[0049] The alloy state of the 5052 aluminum alloy can lid material base material described in this example: 5052 / H19, the thickness of the finished product: 0.265mm, and its production process includes: melting and casting → sawing → milling → soaking → (1+4) thermal connection Rolling → three-stand cold continuous rolling one pass → cleaning and trimming → one pass for a single stand → two passes for a single stand → tension bending straightening → coating → finished product shearing.

[0050] 1) Casting: Chemical composition of aluminum water after casting: Si: 0.1007%, Fe: 0.3144%, Cu: 0.0211%, Mn: 0.0728%, Mg: 2.5659%, Cr: 0.1962%, Zn: 0.0071%, other single impurities ≤ 0.03%, total ≤0.15%, the rest is Al, melting temperature: 722-739°C, refining temperature: 740-745°C, casting temperature: 690-693°C.

[0051] 2) Soaking: ingot temperature 470°C, holding time: 3 hours.

[0052] 3) (1+4) continuous hot rolling: use 1+4 continuous hot rolling, 21 rough rolling passes, and t...

Embodiment 3

[0060] The alloy state of the base material of the 5052 aluminum alloy can lid material described in this example: 5052 / H19, the thickness of the finished product: 0.27mm, and its production process includes: melting and casting → sawing → milling → soaking → (1+4) thermal connection Rolling → three-stand cold continuous rolling one pass → cleaning and trimming → one pass for a single stand → two passes for a single stand → tension bending straightening → coating → finished product shearing.

[0061] 1) Melting and casting: Chemical composition of aluminum water after melting and casting: Si: 0.1109%, Fe: 0.3265%, Cu: 0.0217%, Mn: 0.0803%, Mg: 2.4946%, Cr: 0.1992%, Zn: 0.0087%, other single impurities ≤ 0.03%, total ≤0.15%, the rest is Al, melting temperature: 720-725°C, refining temperature: 740-745°C, casting temperature: 690-693°C.

[0062] 2) Soaking: ingot temperature 480°C, holding time: 3 hours.

[0063] 3) (1+4) continuous hot rolling: use 1+4 continuous hot rolling, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com