Engine camshaft guide rod assembly with attraction function

A technology for guiding rods and camshafts, which is applied to hand-held tools, manufacturing tools, etc., can solve the problems of uneven horizontal placement of camshafts, high labor intensity of workers, and bruising the inner wall of the body, so as to reduce the bruising rate and improve production. Efficiency and the effect of improving the degree of installation cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

[0019] Unless otherwise expressly stated otherwise, throughout the specification and claims, the term "comprising" or its transformations such as "including" or "including" will be understood to include the stated elements or components, and not Other elements or other components are not excluded.

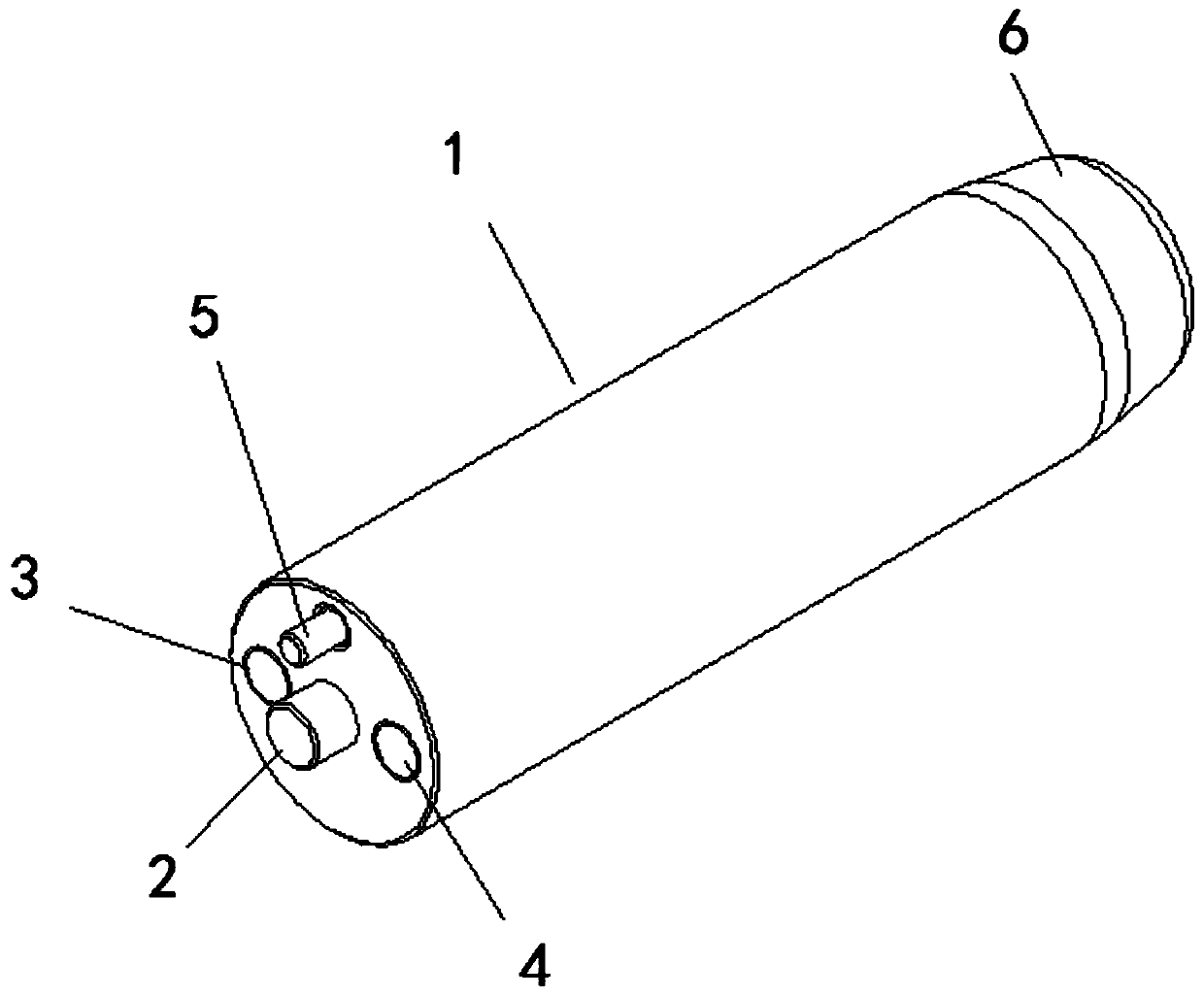

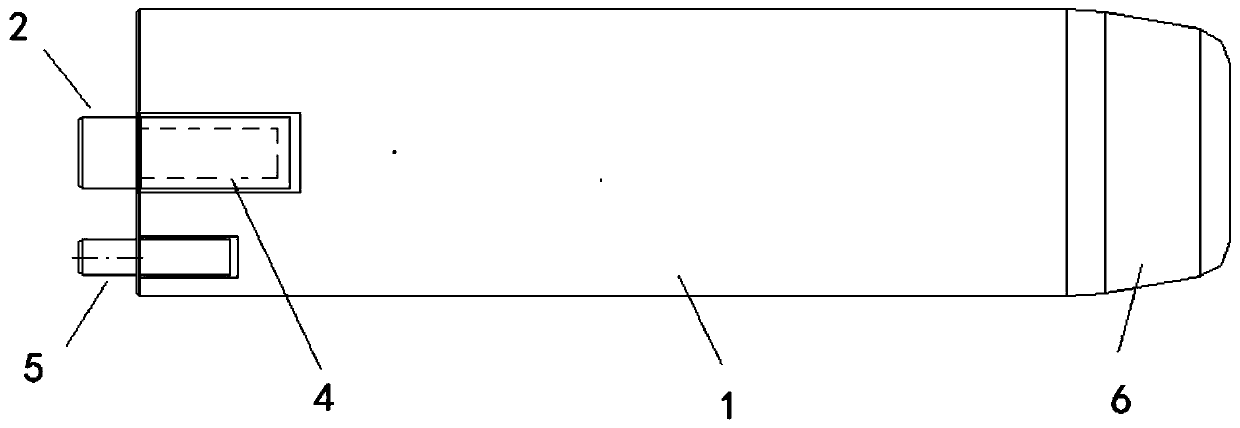

[0020] Such as Figure 1 to Figure 2 As shown, the guide rod assembly of an engine camshaft with suction function according to a preferred embodiment of the present invention includes: a guide rod 1, a circular positioning pin 2, a pin 5, and a magnet 4. The guide rod 1 has a cylindrical structure. The circular positioning nail 2 is arranged at the center of the front end surface of the guide bar 1, the front end surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com