Optical fiber cutter with bilateral cutting function

A kind of optical fiber cutter, double-sided technology, applied in the coupling of optical waveguide, etc., can solve the problems of easy damage to the end face of optical fiber, cumbersome operation, low efficiency, etc., and achieve the effect of reducing the probability of damage, reducing operation steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

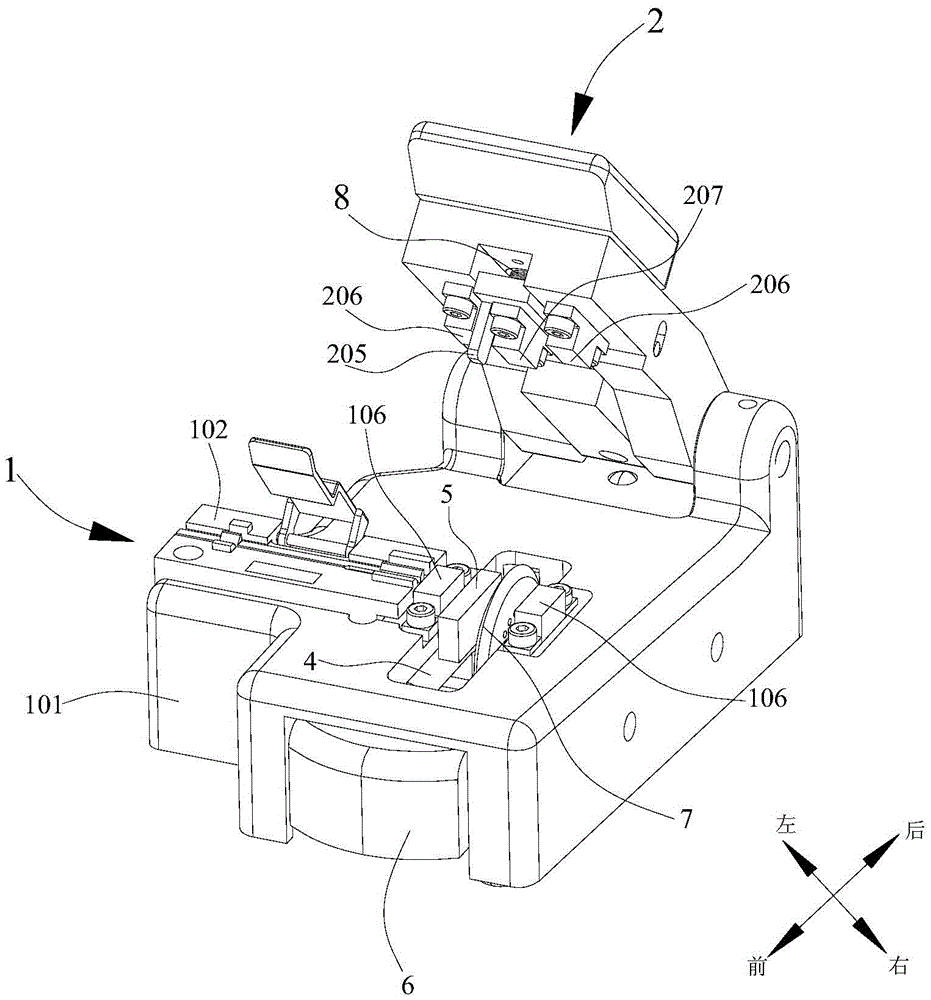

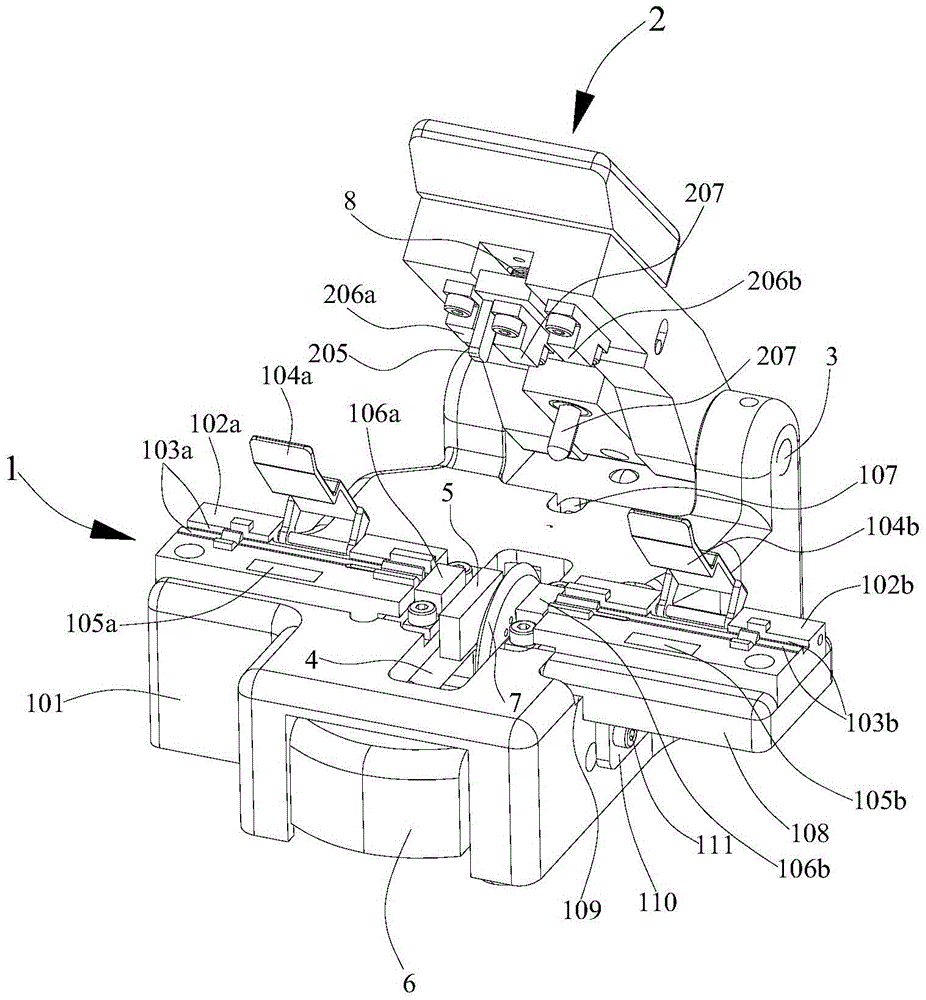

[0014] Fiber cleavers that cut on both sides, such as figure 2 As shown, it includes a main body 1 and a cover body 2 , and the cover body 2 is hinged on the rear side of the main body 1 through a hinge 3 in an openable and closable manner. The main body 1 includes a base 101, a left fiber holder 102a, a right fiber holder 102b, a left lower holder 106a, a right lower holder 106b, and a cutter. The base 101 has a substantially F-shaped section, consisting of an upper surface, The left side wall and the right side wall are integrally formed. The base 101 has a rectangular opening 4 on the right side. The rectangular opening 4 is located between the left side wall and the right side wall. The upper surface of the base 101 has a limit groove 109 on the right side, and the mounting platform 108 is stuck in the limiting groove 109. The lower part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com