A forming method of mg-gd-y-zn-zr magnesium alloy bidirectional expansion equal channel extrusion billet

A technology of equal channel extrusion and magnesium alloy, applied in the direction of metal extrusion dies, etc., can solve the problems of small amount of strain, difficult to achieve ultra-refinement of materials, etc., to achieve small deformation force, promotion of grain refinement, deformation uniformity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

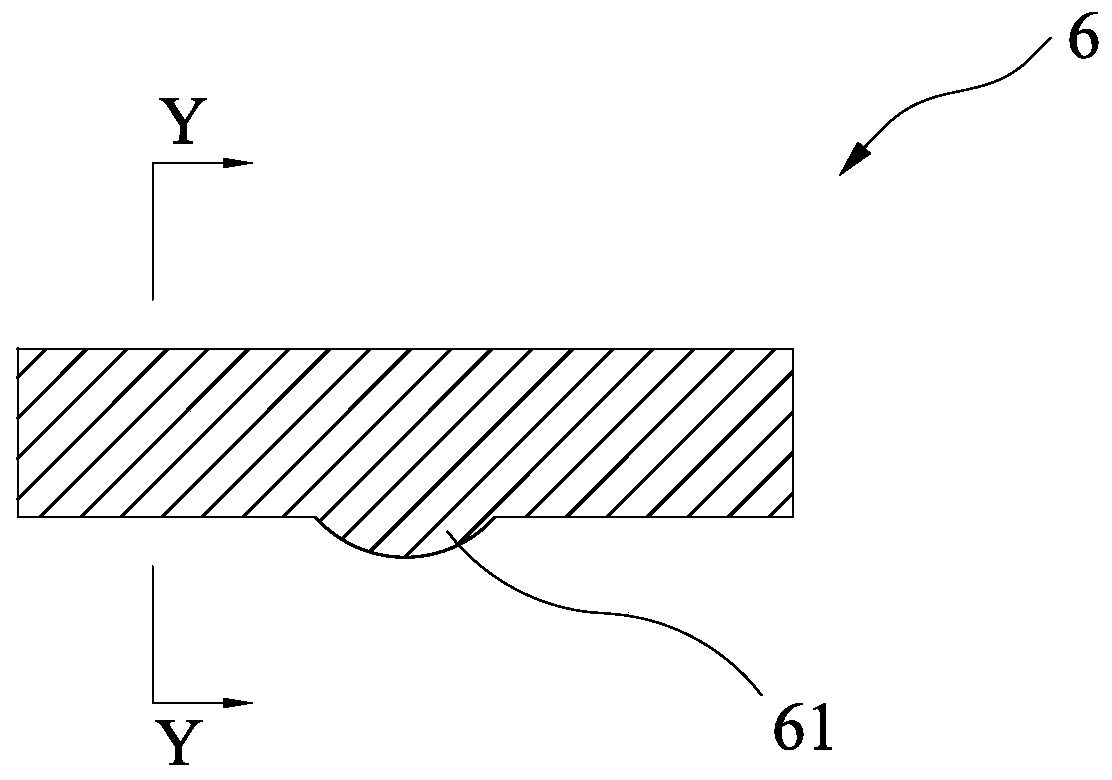

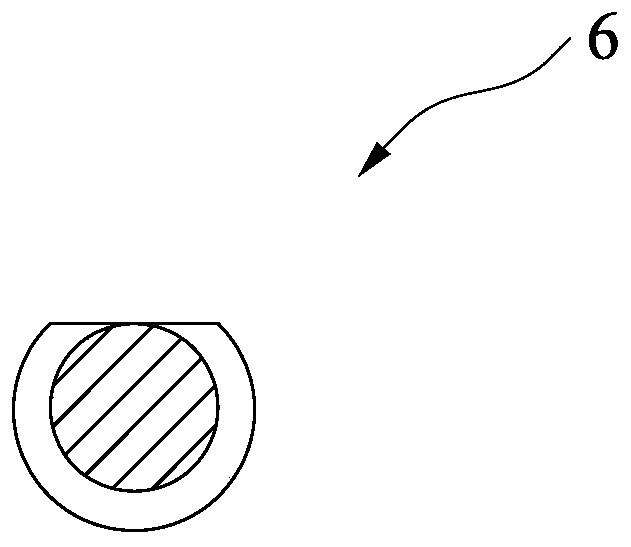

[0038]The invention discloses a method for forming a billet by bidirectional expansion equal-channel extrusion of a Mg-Gd-Y-Zn-Zr magnesium alloy, which involves a bidirectional expansion equal-channel extrusion of a Mg-Gd-Y-Zn-Zr magnesium alloy Forming dies for compacts, see Figure 1-15 , the mold includes an upper mold base 1, a punch 2 and a die 5.

[0039] like Image 6 As shown, the punch 2 is a cylinder, and the upper end of the punch 2 forms a radially extending fixing portion 21, and the fixing portion 21 is square, such as Figure 11 As shown, the upper mold base 1 is provided with a square groove 11 for the insertion of the fixed part 21. After the insertion is completed, the lower end of the upper mold base 1 is provided with a fastening nut 3, and an external thread that cooperates with the fastening nut 3 is formed. The nut 3 passes through the punch 2 to clamp the fixing part 21, so that the punch 2 is coaxially and vertically fixed on the upper die base 1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com