Nailing gun

A nailing gun and housing technology, applied in the field of nailing guns, can solve the problems of locking failure, the impact of the service life of the nailing machine, and the unsuitable design of the slot is too deep, so as to avoid locking failure, improve service life, and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

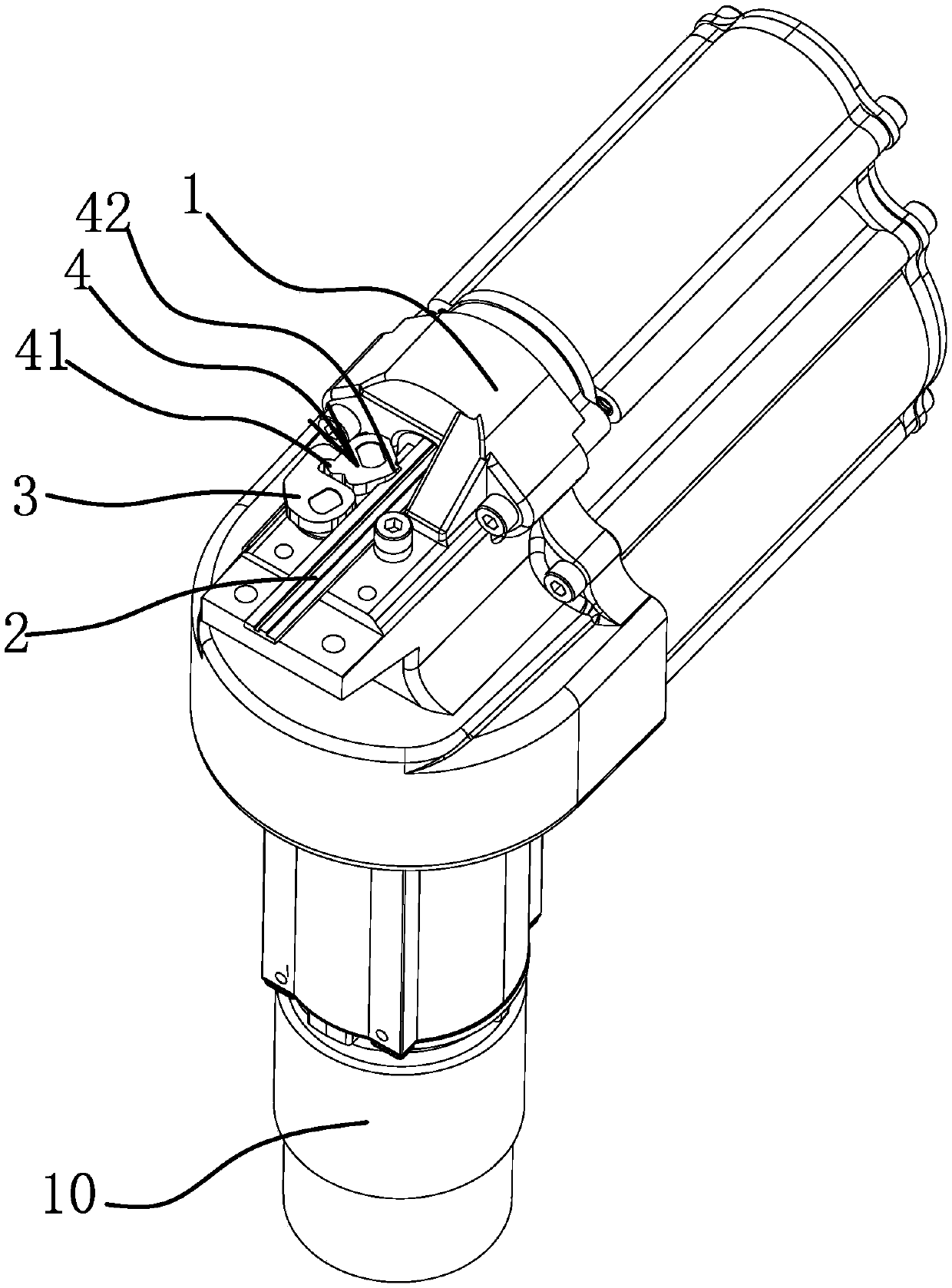

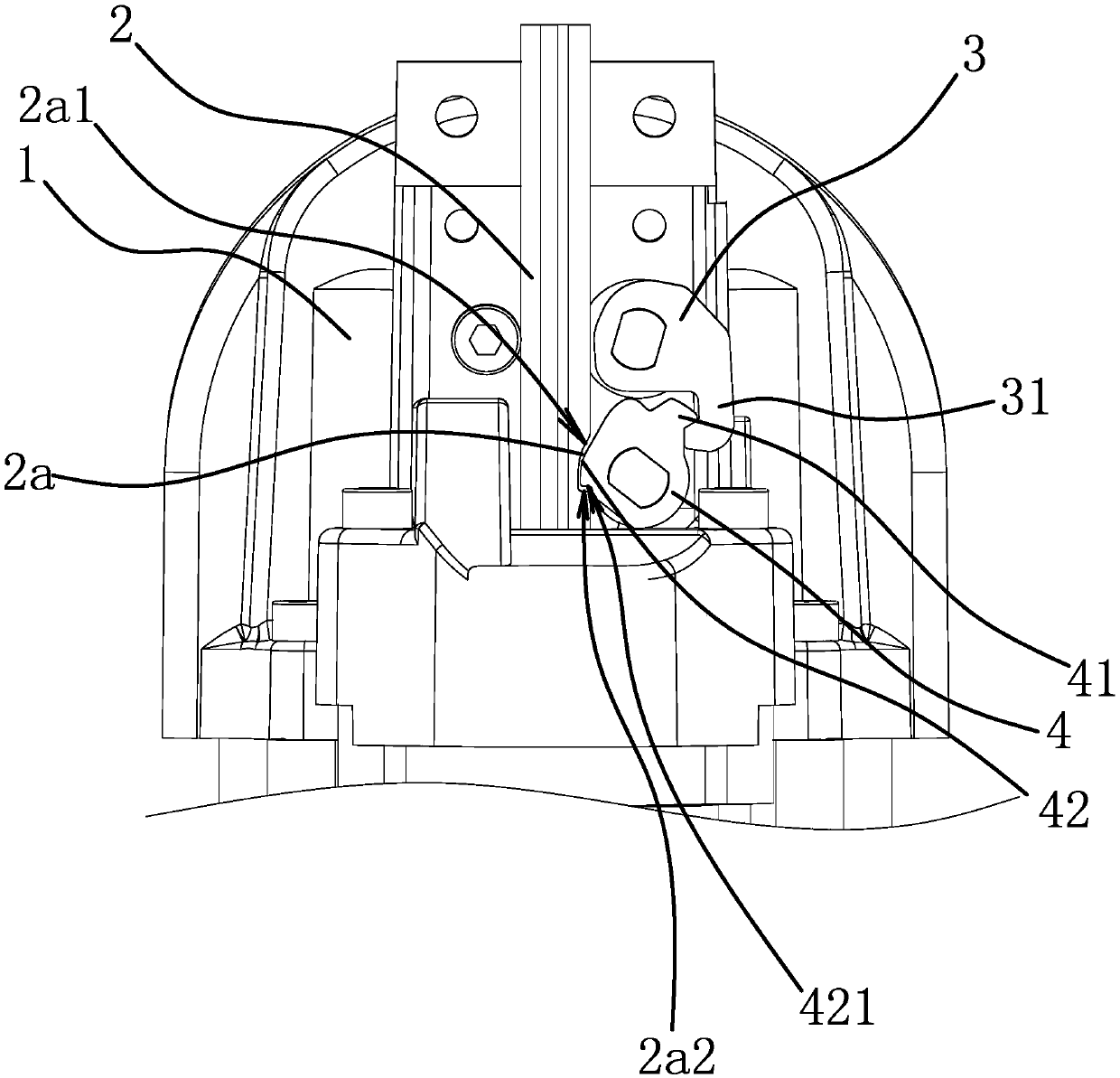

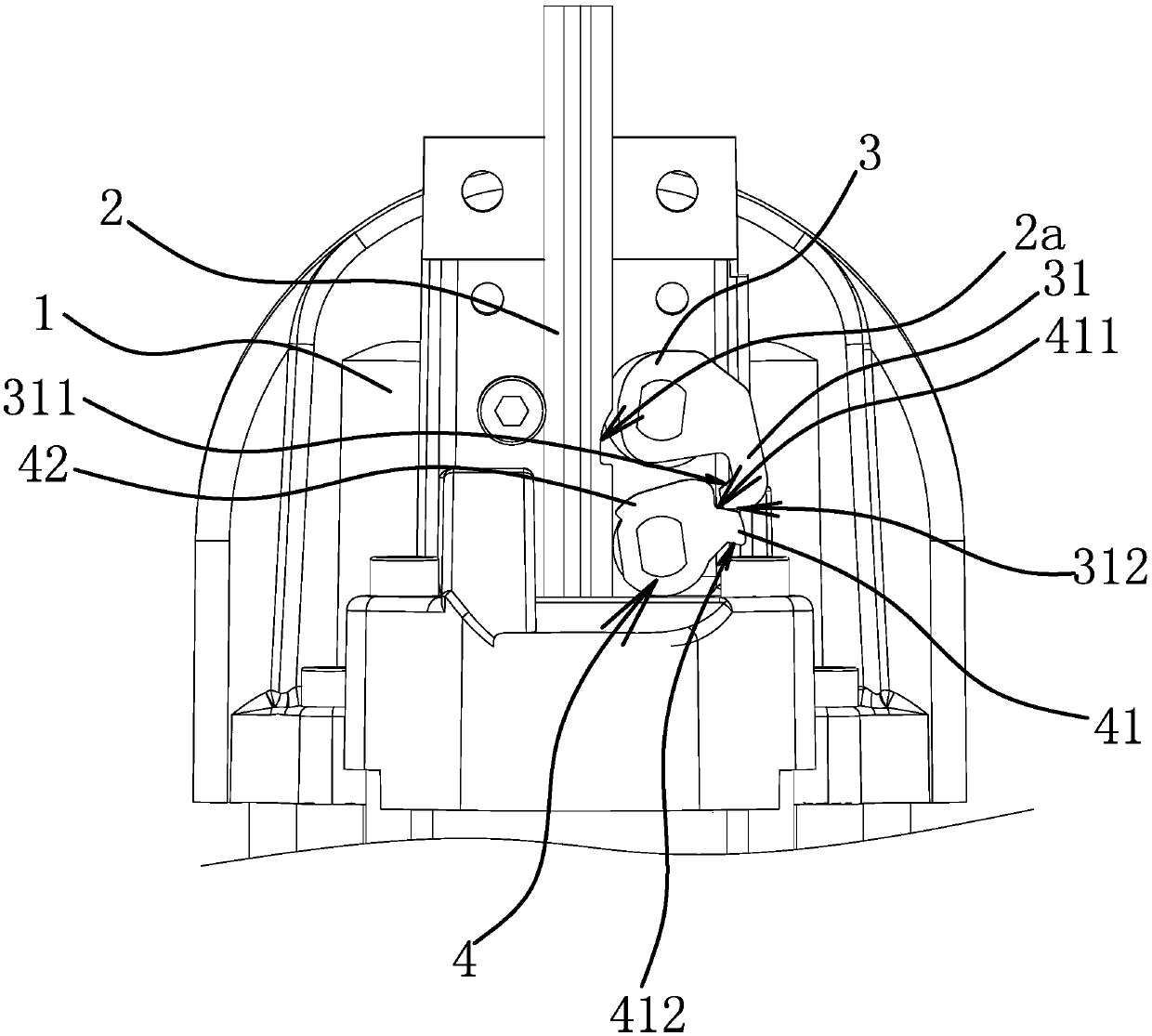

[0029] Specifically, as figure 1 As shown, the nailing gun includes a housing 1 and a striker 2 that can move back and forth relative to the housing 1 and has a groove 2a on one side, and a locking member 3 is rotatably connected to the housing 1, and the locking member 3 and the striker 2 An intermediate piece 4 is arranged between them, and the intermediate piece 4 is rotatably connected to the housing 1 . At the same time, the middle piece 4 has a locking part 1 41 and a locking part 2 42 respectively, and the middle piece 4 can rotate relative to the housing 1 so that the locking part 2 42 snaps into or escapes from the groove 2a. Such as figure 2 As shown, when the striker 2 is in the locked state, the intermediate piece 4 is engaged in the groove 2a of the striker 2 through the lock part 2 42 and has a movement tendency to rotate relative to the housing 1, and the lock part 3 can abut against the lock part 1 41 and prevent the middle piece 4 from rotating relative to ...

Embodiment 2

[0034] The technical solution in this embodiment is basically the same as the technical solution in Embodiment 1, the difference is that, as Figure 5 and Figure 6 As shown, in this embodiment, a chute 8 is provided on the housing 1, and the chute 8 is arranged obliquely relative to the advancing direction of the striker 2. The locking member 3 is located on one side of the chute 8 and is rotationally connected with the housing 1. Located on the other side of the chute 8. The middle piece 4 is slidably connected in the slide groove 8 , and the middle piece 4 can slide relative to the housing 1 so that the locking part 2 42 snaps into or escapes from the groove 2 a. The middle piece 4 is reset by the torsion spring 5, the torsion spring 5 is sleeved on the housing 1, the middle piece 4 has a boss 9, and the boss 9 has an annular groove, one end of the torsion spring 5 rests in the annular groove, and the other end against the housing 1. When the locking part 2 42 is stuck o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com