A fruit picking robot end effector

A technology for picking robots and end effectors, applied in picking machines, manipulators, harvesters, etc., can solve problems such as complex picking process, fruit damage, and low efficiency, and achieve improved picking efficiency, reduced vibration of fruit branches, and high transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

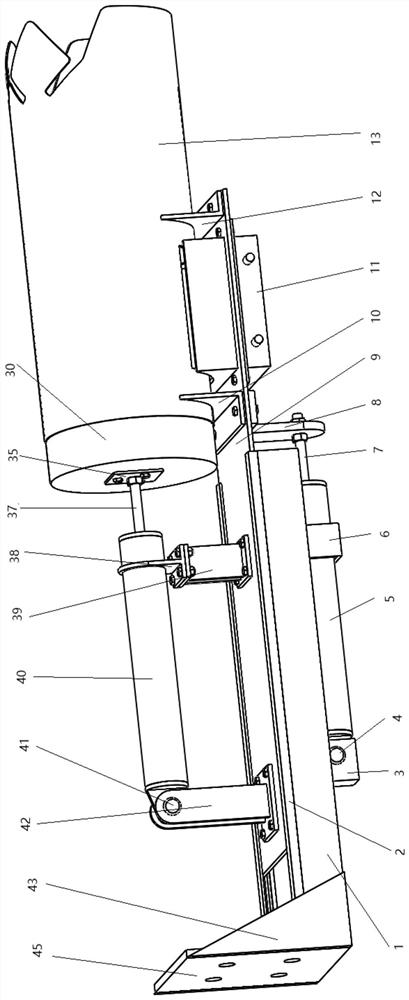

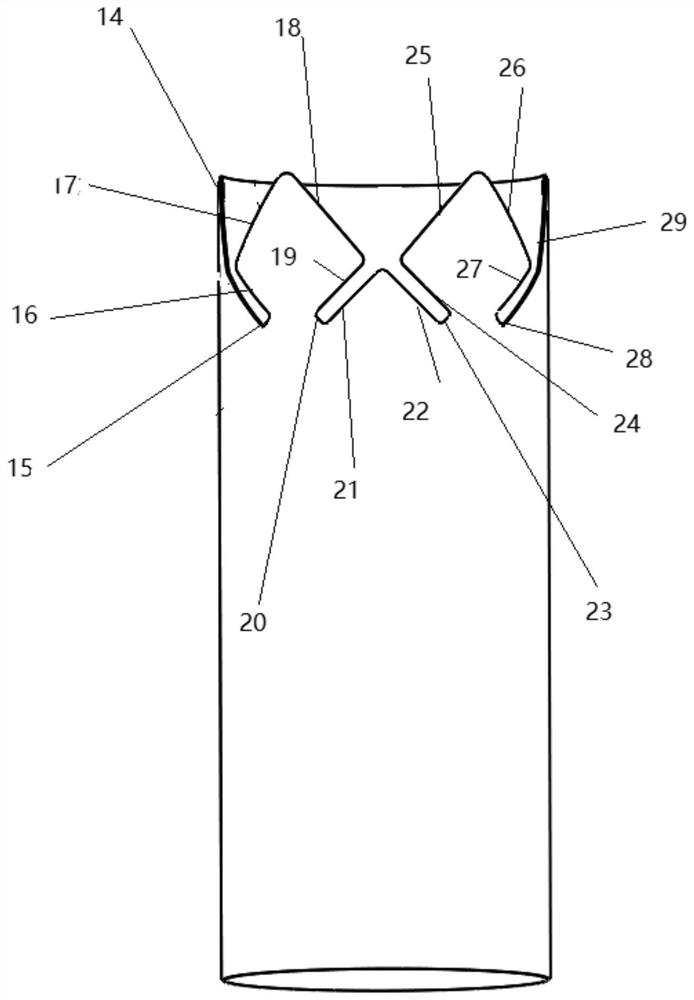

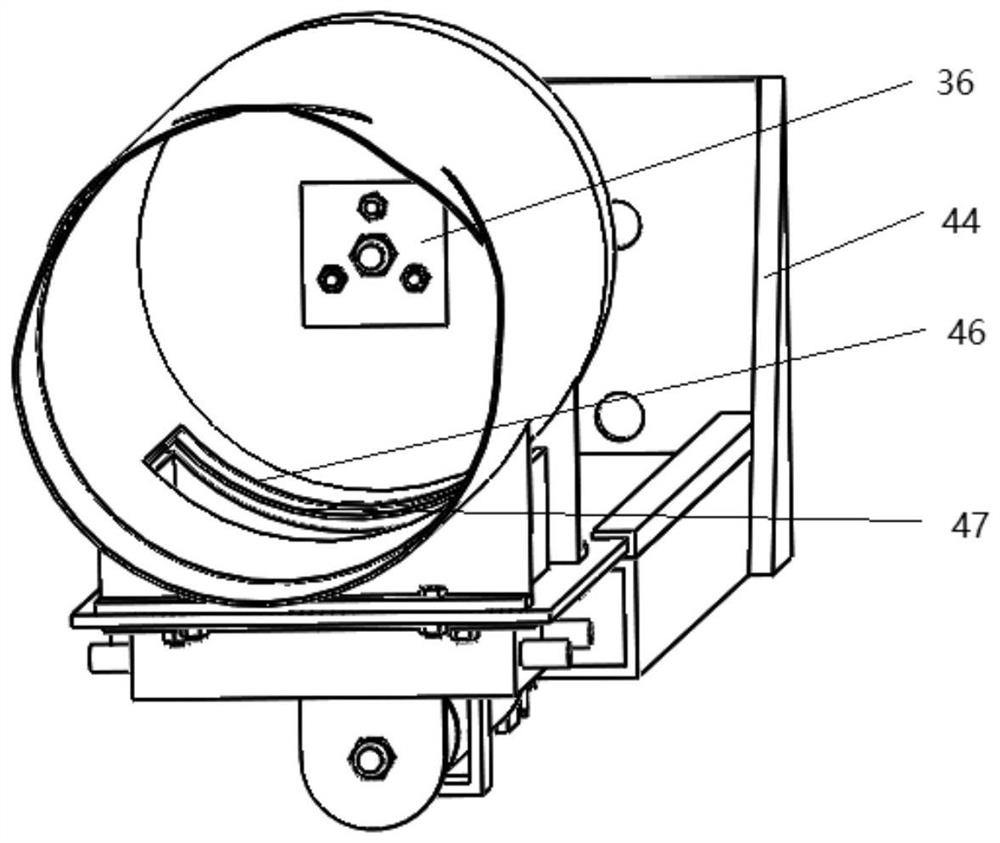

[0034] like Figure 1 to Figure 6 As shown, the end effector of a fruit picking robot according to the present invention includes a linear feed positioning assembly and a cylinder shear assembly, and the linear feed positioning assembly is equipped with a cylinder shear assembly, and the cylinder shear assembly The reciprocating linear motion can be performed on the linear feed positioning component, and the linear feed positioning component can be installed on the mechanical arm of the picking robot.

[0035] Further: the linear feed positioning assembly includes a base 1, a linear guide rail 2, a hydraulic cylinder fixed support 3, a first hydraulic cylinder 5, a hydraulic cylinder bracket 6, a movable bottom plate push piece 8 and a mobile bottom plate 9;

[0036] The movable bottom plate 9 is slidably installed on the base 1 through the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com