Cement co-control processing system and method

A technology of treatment system and treatment subsystem, applied in the field of process system of sewage treatment and sludge treatment, can solve the problems of high collection cost, unsuitable sludge treatment and disposal mode, small batch size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

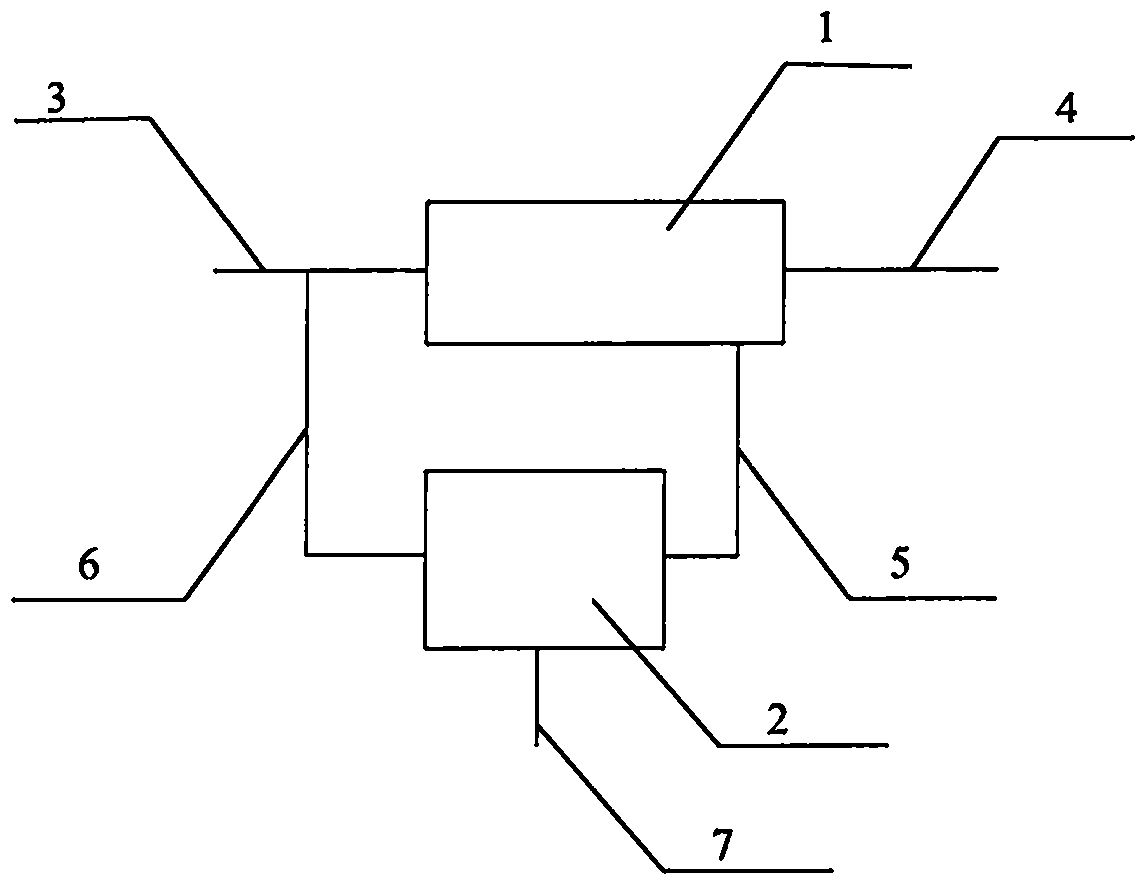

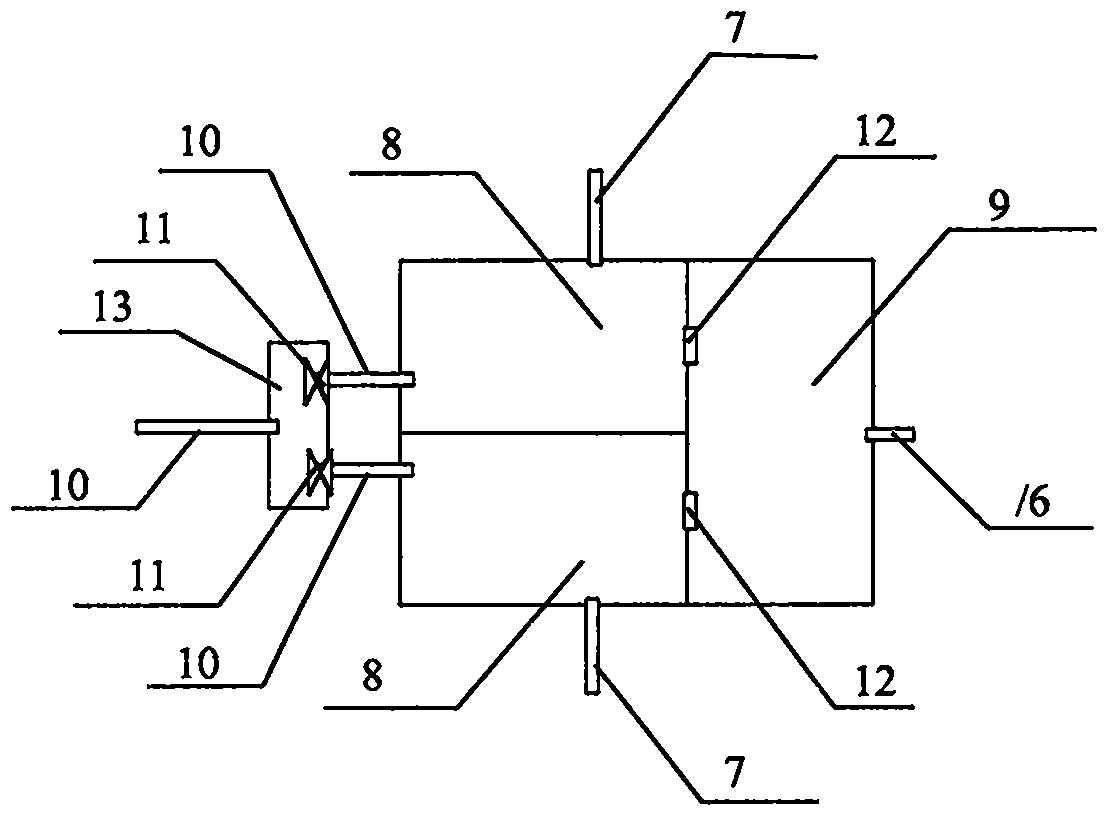

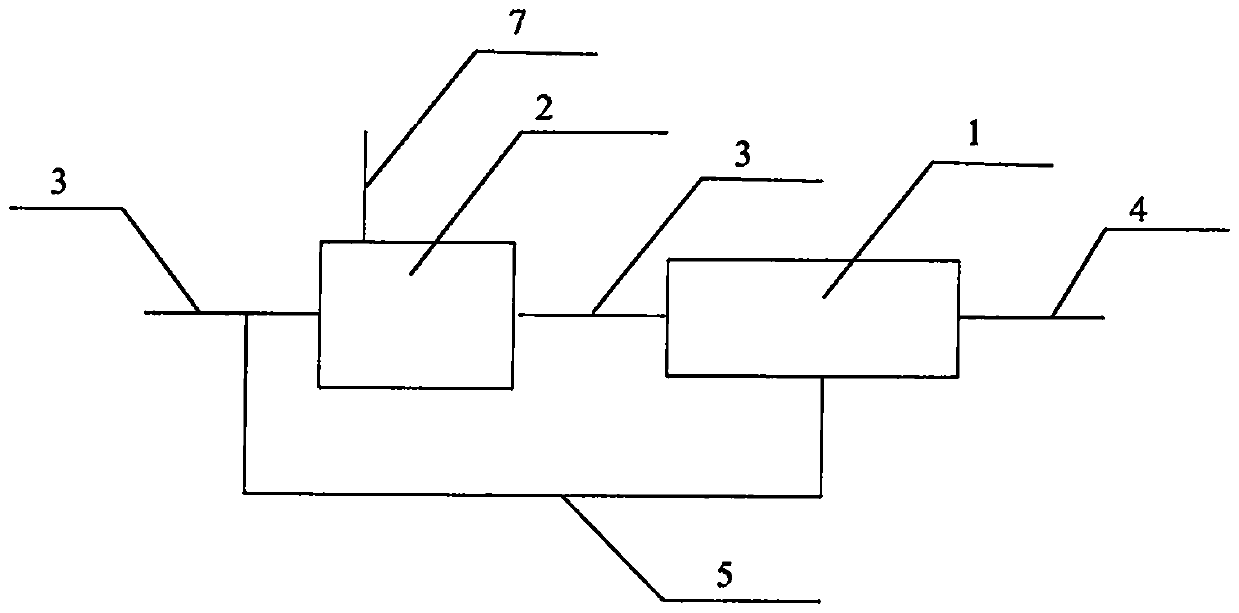

[0018] Such as figure 1 , 2In the shown embodiment 1, the sewage enters the sewage treatment unit 1 through the sewage inlet pipe 3, and the sewage purified and treated by the sewage treatment unit 1 is discharged from the drain pipe 4, and the sludge generated by the sewage treatment unit 1 is distributed by the remaining sludge distribution subsystem 5 Control the backflow into the sludge stabilization treatment unit 2, and the excess sludge distribution subsystem 5 has an excess sludge distribution pipe 10 that enters the water diversion diversion well 13, and leads two excess sludge from the water diversion diversion well 13 The distribution pipes 10 respectively enter into two sludge sedimentation and digestion sub-units 8, and the two remaining sludge distribution pipes 10 are equipped with opening and closing control devices 11. After the digestion sub-unit 8 is connected to the sewage treatment sub-unit 9, the sludge sedimentation digestion sub-unit 8 and the sewage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com