Environmental functional composite material based on nano granule inorganic functional agent

A functional composite material and nanoparticle technology, applied in the field of high-performance environmental functional composite materials, can solve the problems of high-pressure head loss, difficulty in continuous use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

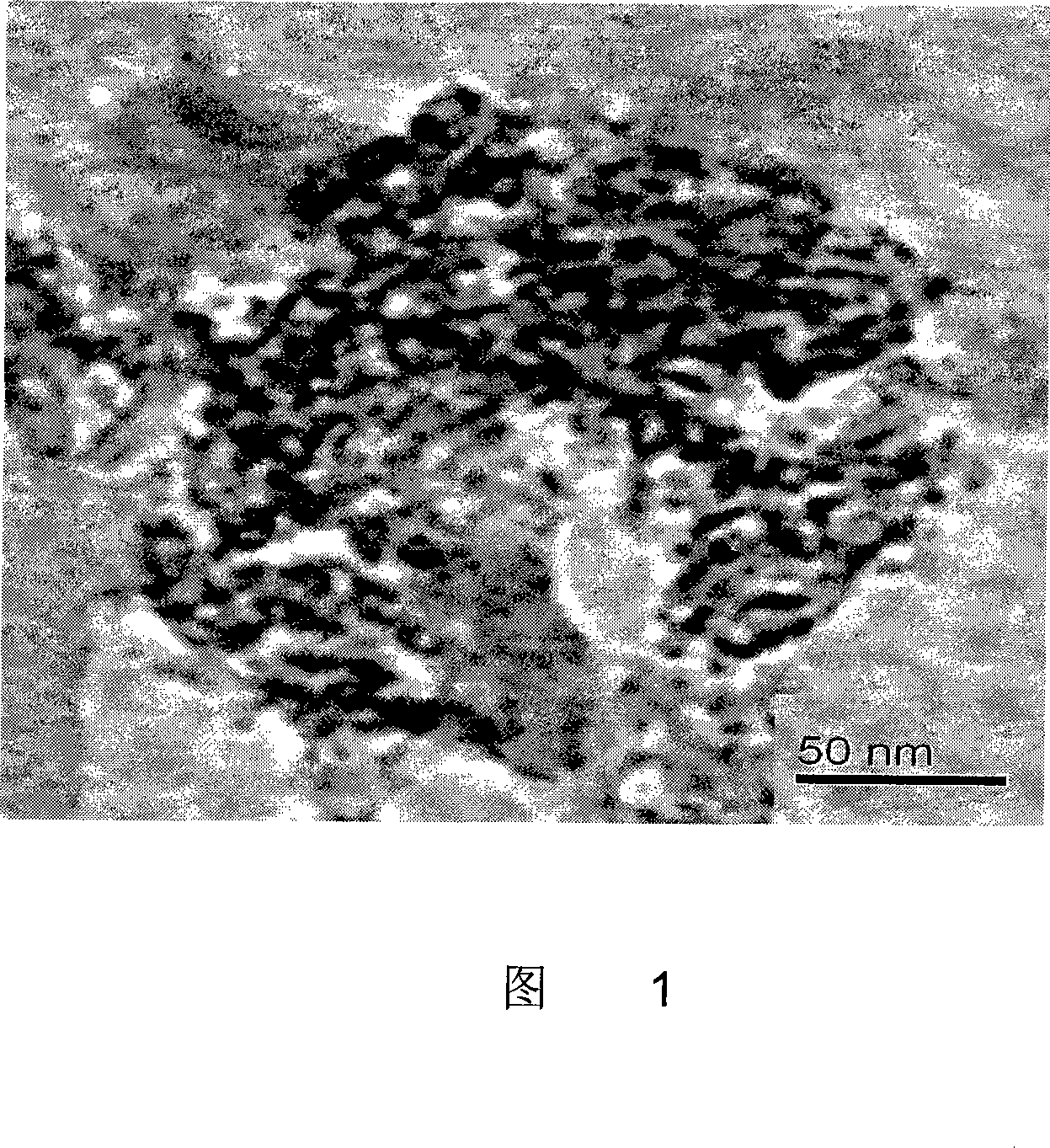

Embodiment 1

[0022] Environmentally functional composites based on nanoparticulate zirconium thiophosphate. Its basic structure can be expressed as: the carrier of the composite material is an ion exchange resin or adsorption resin with a nanoporous structure, and the average pore size is between 1-50nm; the carrier resin of the above-mentioned materials can be X-5, AB-8 (these two. The resins are produced by Nankai University Resin Factory), Amberlite XAD-4, XAD-7 (the above two resins are produced by American Rohm Haas Company), CHA-101, NDA-150, NDA-7 (the above three resins are produced by Jiangsu Nankai University) Gord Environmental Protection Technology Co., Ltd.) and other adsorption resins and NDA-88 (containing amino groups), NDA-99 (containing amino groups, the above two resins are produced by Jiangsu Nanda Gord Environmental Protection Technology Co., Ltd.), D-001 (containing sulfonic acid groups) ), D-201 (containing quaternary ammonium root, these two resins are produced by H...

Embodiment 2

[0026]Environmentally functional composites based on nanoparticulate titanium phosphate. Its basic structure can be expressed as: the carrier of the composite material is an ion exchange and adsorption resin with a nanoporous structure, the average pore size is between 1-50nm, and the surface of the resin has a sulfonic acid group or a carboxylic acid group or a phosphonic acid group or a quaternary ammonium group. Ion or tertiary amine group or secondary amine group or primary amine group or without functional agent, generally can be X-5, AB-8, CHA-101, XAD-4, NDA-150, XAD-7, NDA-7, etc. Adsorption resin and composite functional resin or ion exchange resin such as NDA-88, NDA-99, D-001, D-201, Amberlite IR-900, IRA-120, Purolite C-100, A-400, etc. Among them, D- 001, IRA-102, A-400 and other cation exchange resins. The pores of the resin are coated with nano-particle titanium phosphate, the weight percentage of which is between 10-40%, and the particle size is 0.5-30 nm.

...

Embodiment 3

[0030] Environmentally functional composites based on nanoparticulate hydrated manganese oxide. Its basic structure can be expressed as: the carrier of the composite material is a cation or anion exchange resin, the average pore size is between 1-60nm, and the resin surface has a sulfonic acid group or a carboxylic acid group or a phosphonic acid group or a quaternary ammonium ion or a tertiary amine group. Or secondary or primary amine, common resins are D-001, D-201, D-301, Amberlite IR-900, NDA-88, NDA-99 and other ion exchange resins. For the removal of cationic pollutants, cation exchange resins such as D-001, IRA-102, and A-400 are preferred, and for the removal of anionic pollutants such as As, cation exchange resins such as D-201, IRA-900, and C-100 are preferred. The pores of the resin are coated with nano-particle hydrated manganese oxide, the weight percentage of which is between 1-20%, and the particle size is 0.5-45nm.

[0031] The preparation method of the mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com