Square hole flow channel wear-resistant fine-adjustment ball valve

A fine-tuning, flow channel technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problem of ball valve being washed, unable to linearly adjust the opening, etc., to reduce the medium flow rate, accurate linear characteristic adjustment function, ensure the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

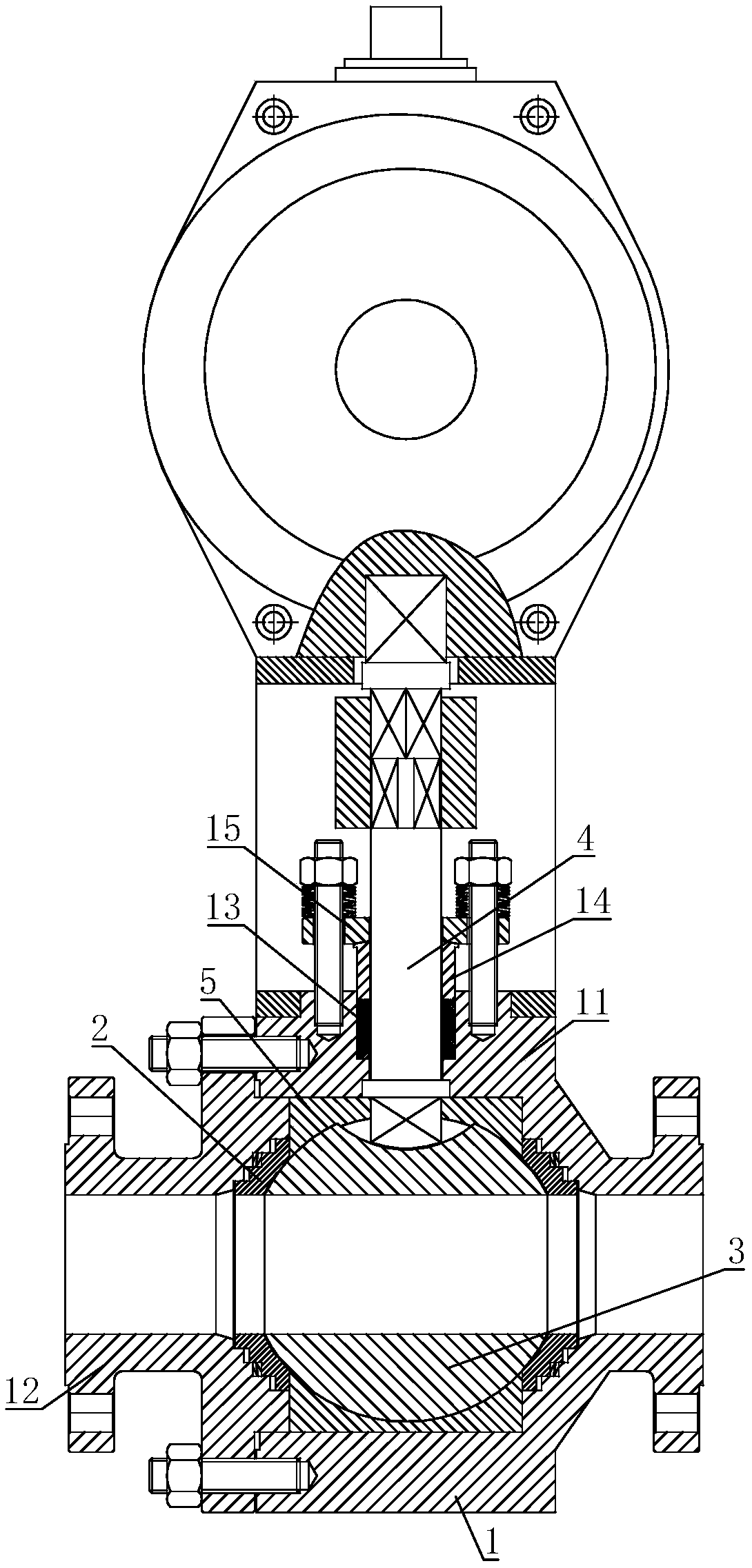

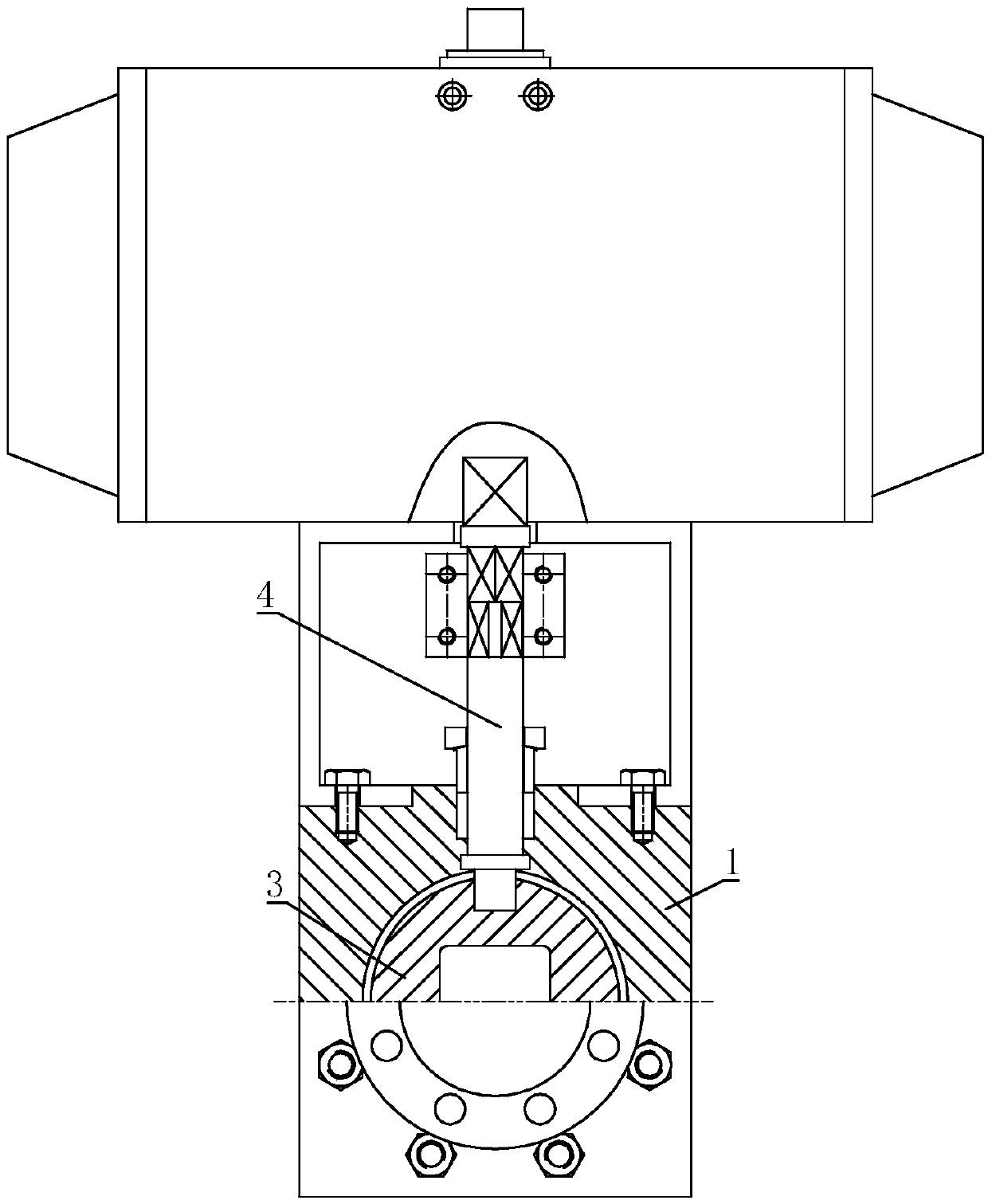

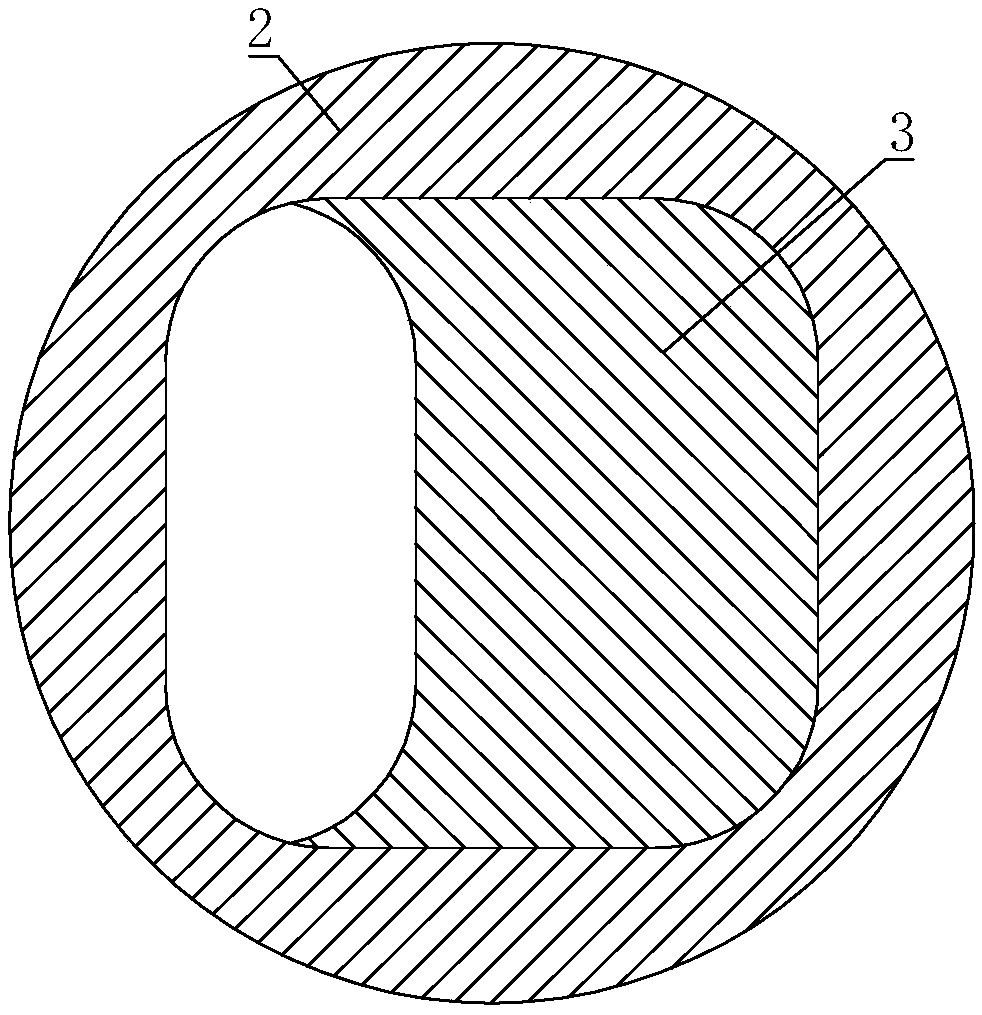

[0040] The invention includes a valve body 1, a valve seat 2 is installed in the valve body 1, a ball 3 is sleeved in the valve seat 2, a valve stem 4 is connected to the ball 3, and the valve stem 4 is sleeved in the valve body 1; its characteristics That is, the shape of the flow passage hole of the ball 3 and the flow passage hole of the valve seat 2 are both square holes.

[0041] Since the flow passage holes of the ball 3 and the valve seat 2 are both square holes, when the valve is opened or closed with a small opening, the ball 3 cooperates with the valve seat 2 to form a rectangular flow passage shape, which is formed when the opening of the existing ball valve is small. The area of the elliptical mouth is greatly increased, thereby increasing the capacity of the flow channel, reducing the flow rate of the medium, reducing the impact of the fluid on the ball port and the valve seat port, and extending its service life.

[0042] The opening area of the rectangular c...

Embodiment 2

[0047] On the basis of Embodiment 1, the arc of the valve seat 2 close to the ball 3 is a sealing surface, and a section of the sealing surface close to the flow channel hole of the valve seat 2 is provided with a gap 21, and the sealing surface is far away from the flow channel hole of the valve seat 2 One section is in close contact with the sphere 3.

[0048] Due to the hidden design of the sealing port of the valve seat 2, the medium still does not damage the sealing port of the valve seat 2 when the valve is opened and closed by about 50%, and the service life of the sealing surface of the valve seat 2 is correspondingly improved.

Embodiment 3

[0050] On the basis of Embodiment 1 or Embodiment 2, the area surrounded by the valve body 1 , the ball 3 and the valve seat 2 is filled with a valve inner liner 5 .

[0051] The area surrounded by valve body 1, sphere 3 and valve seat 2 is filled with valve inner lining 5, which can prevent the medium from entering the valve cavity and damaging the surface of the sphere and the valve cavity during the switching process of the valve. Helps to increase the life of the ball valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com