Patents

Literature

31results about How to "Reduce medium flow rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

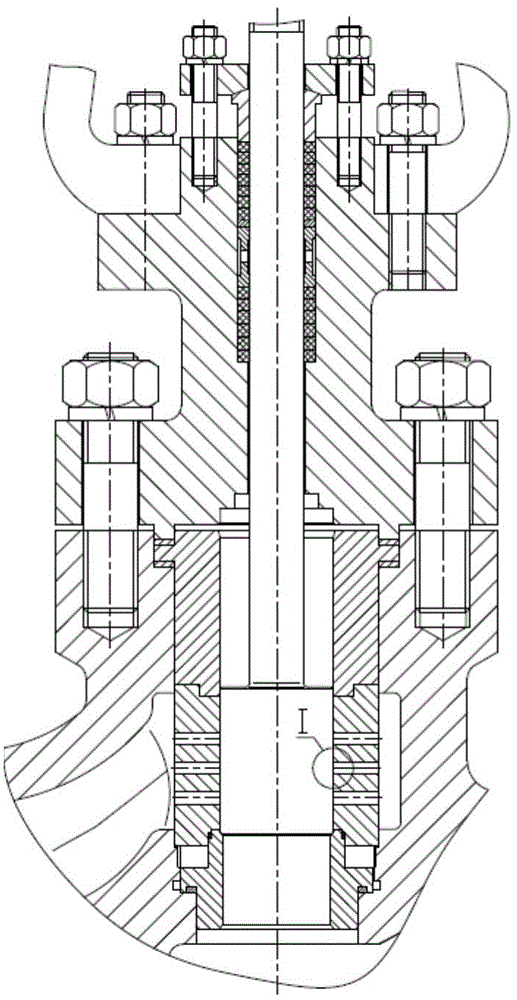

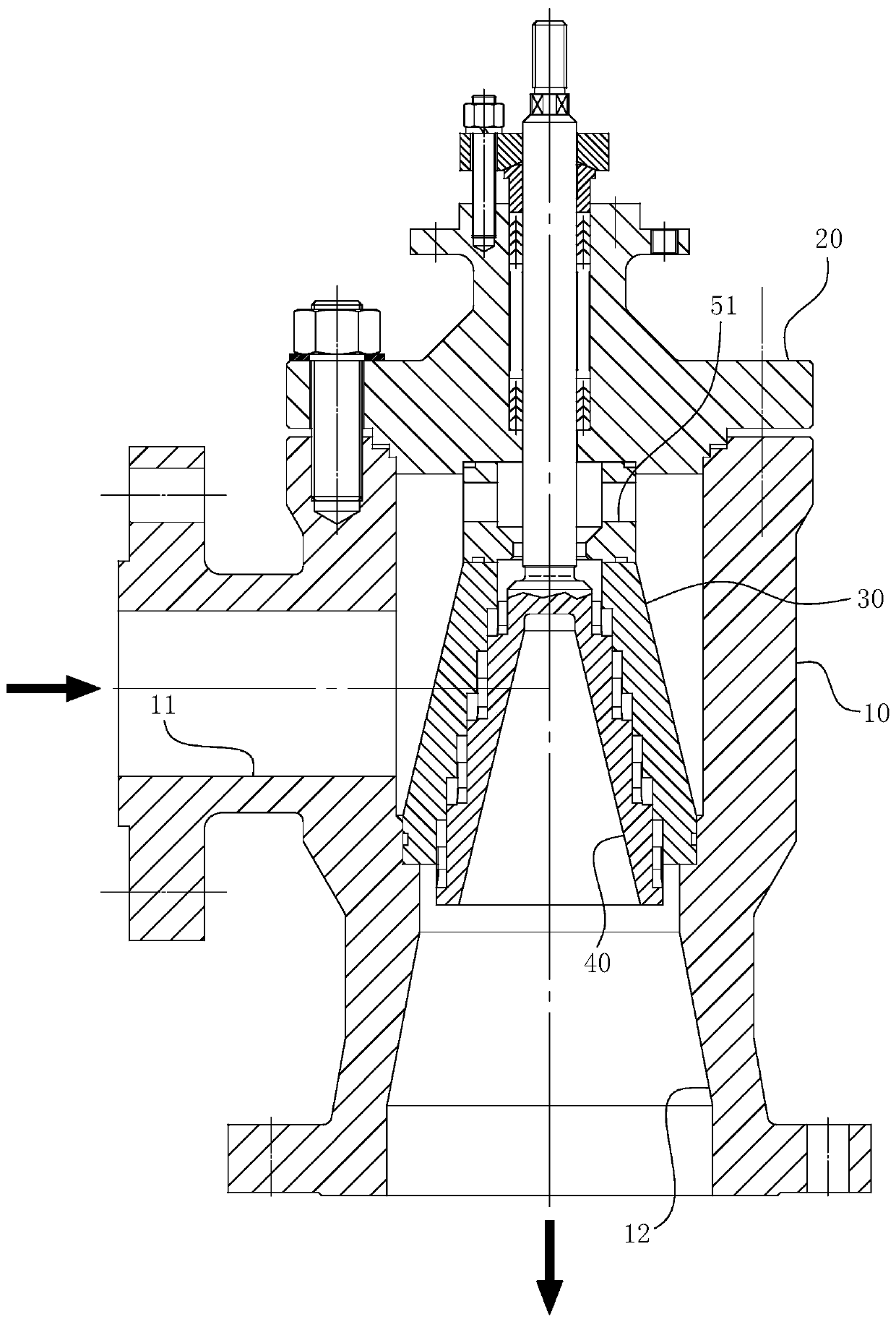

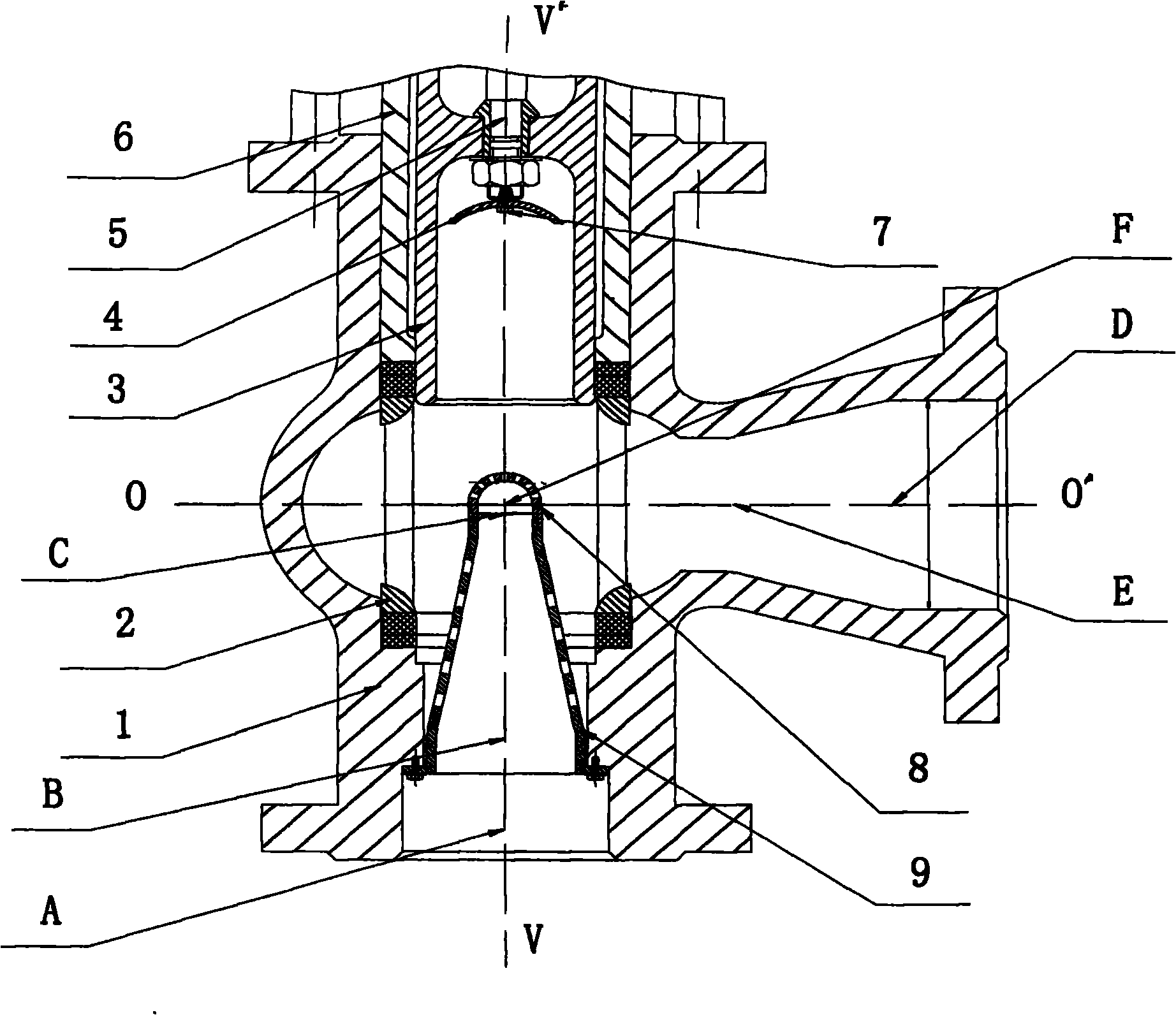

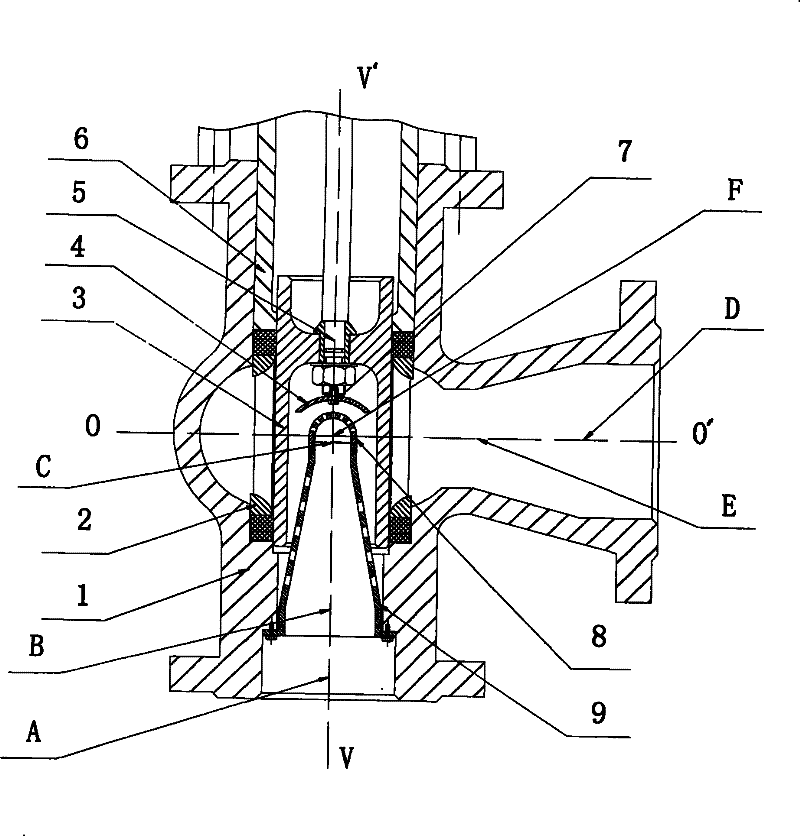

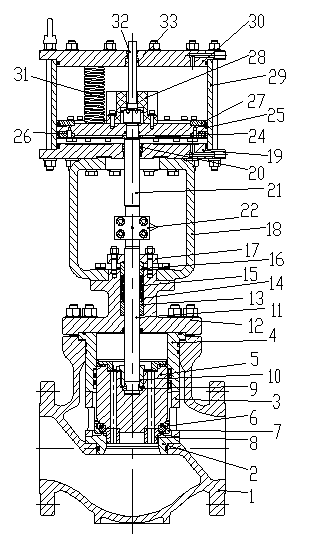

Throttling serial type multistage pressure reduction and adjustment valve

InactiveCN104455469APrecise pressure/flow controlEliminate cavitationValve members for absorbing fluid energyLift valveSolid particlePressure difference

The invention provides a throttling serial type multistage pressure reduction and adjustment valve. A valve rod and a valve element assembly are arranged inside a valve body; a valve seat assembly is provided with multistage pressure reduction units, and each stage of pressure reduction unit of the valve seat assembly is composed of a cylindrical fluid expansion unit and a throttling unit, wherein the throttling unit is shaped like a circular truncated cone, and the area of the throttling unit decreases gradually; correspondingly, the pressure reduction units are arranged on corresponding positions of the valve element assembly, wherein the stage number of the pressure reduction units in the valve element assembly is equal to that of the pressure reduction units in the valve seat assembly; each stage of the pressure reduction unit of the valve element assembly is composed of a bowl-shaped molded surface for controlling flow and a cylindrical shrinkage unit; the upper portion of the valve element assembly is provided with valve elements, and the lower portion of the valve element assembly is provided with guide rods; valve bottom drainage holes are formed in the positions, located on the outer sides of valve seat guide holes, of the bottom of the valve seat assembly; a flow diversion sleeve is arranged on the top of the valve seat assembly, and a flow diversion hole is formed in one side of the flow diversion sleeve. According to the throttling serial type multistage pressure reduction and adjustment valve, the service life of the valve can be prolonged, vibration and noise of pipelines behind the valve can be eliminated, and it is guaranteed that the adjustment accuracy of the valve is high and operation is stable under the working condition that the pressure difference is large and solid particles exist in media in the Texaco process of coal chemical industries.

Owner:BEIJING AEROSPACE PROPULSION INST +3

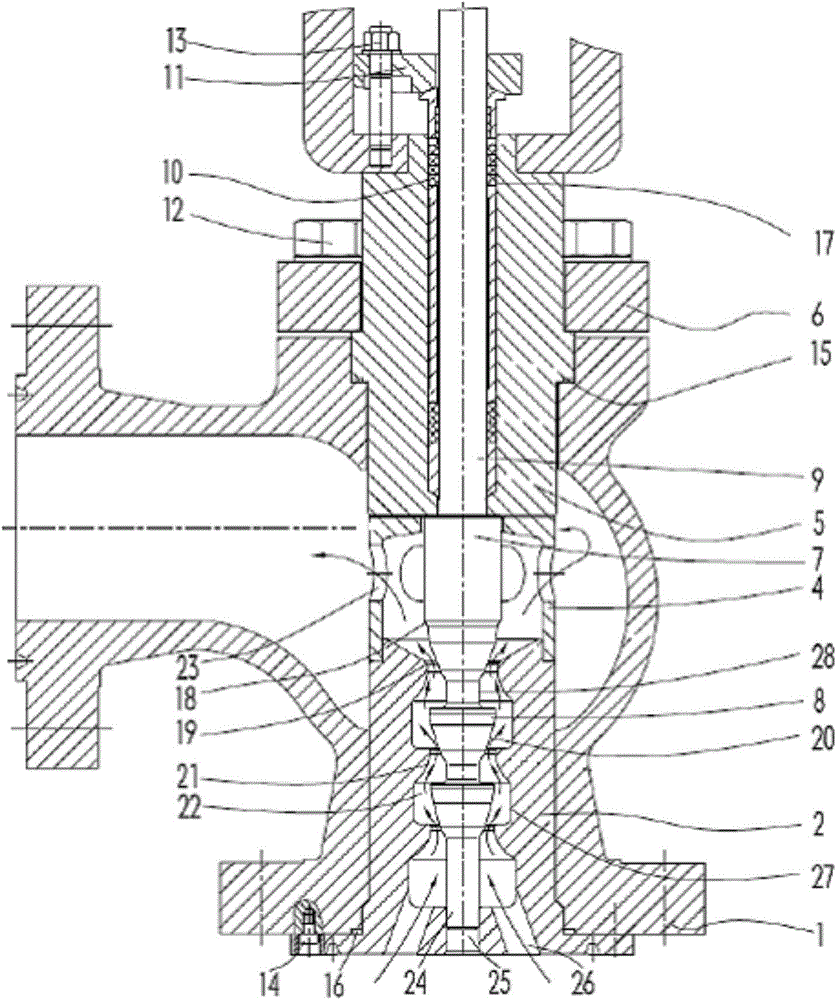

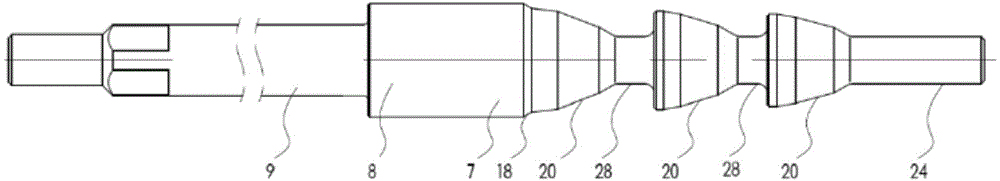

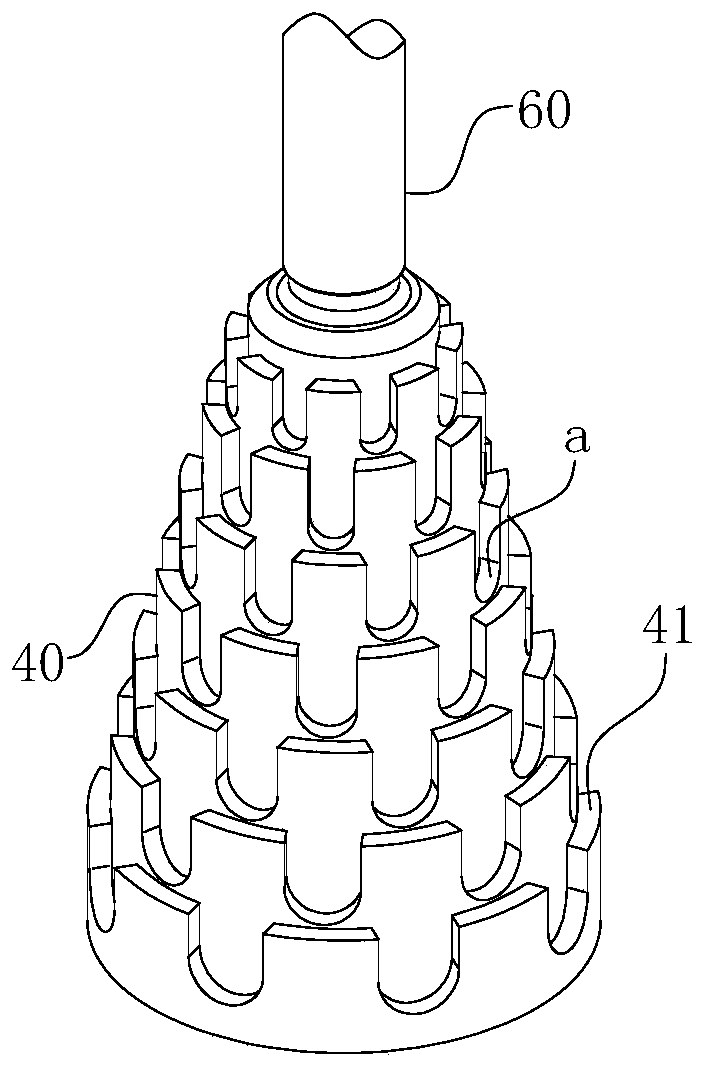

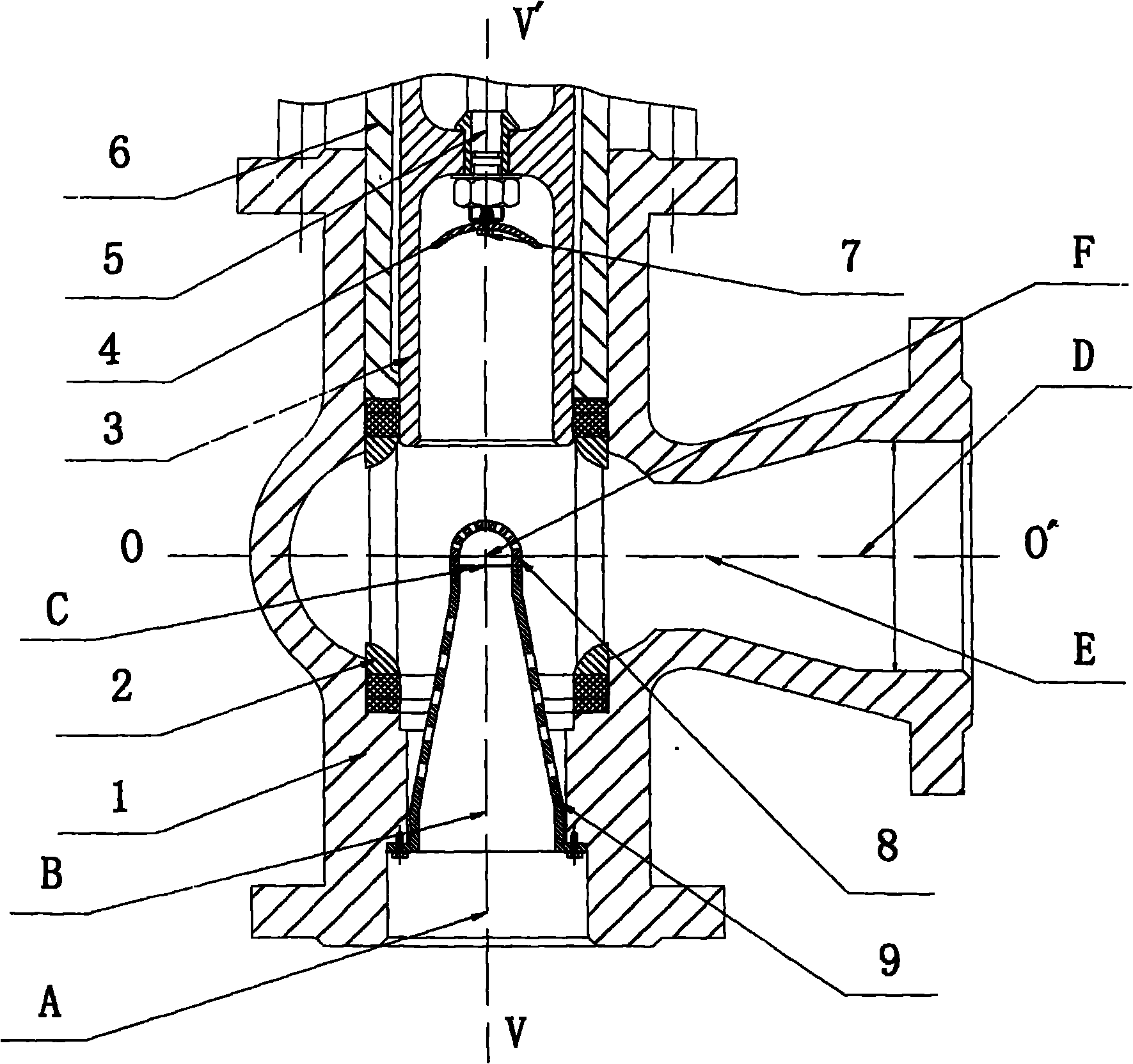

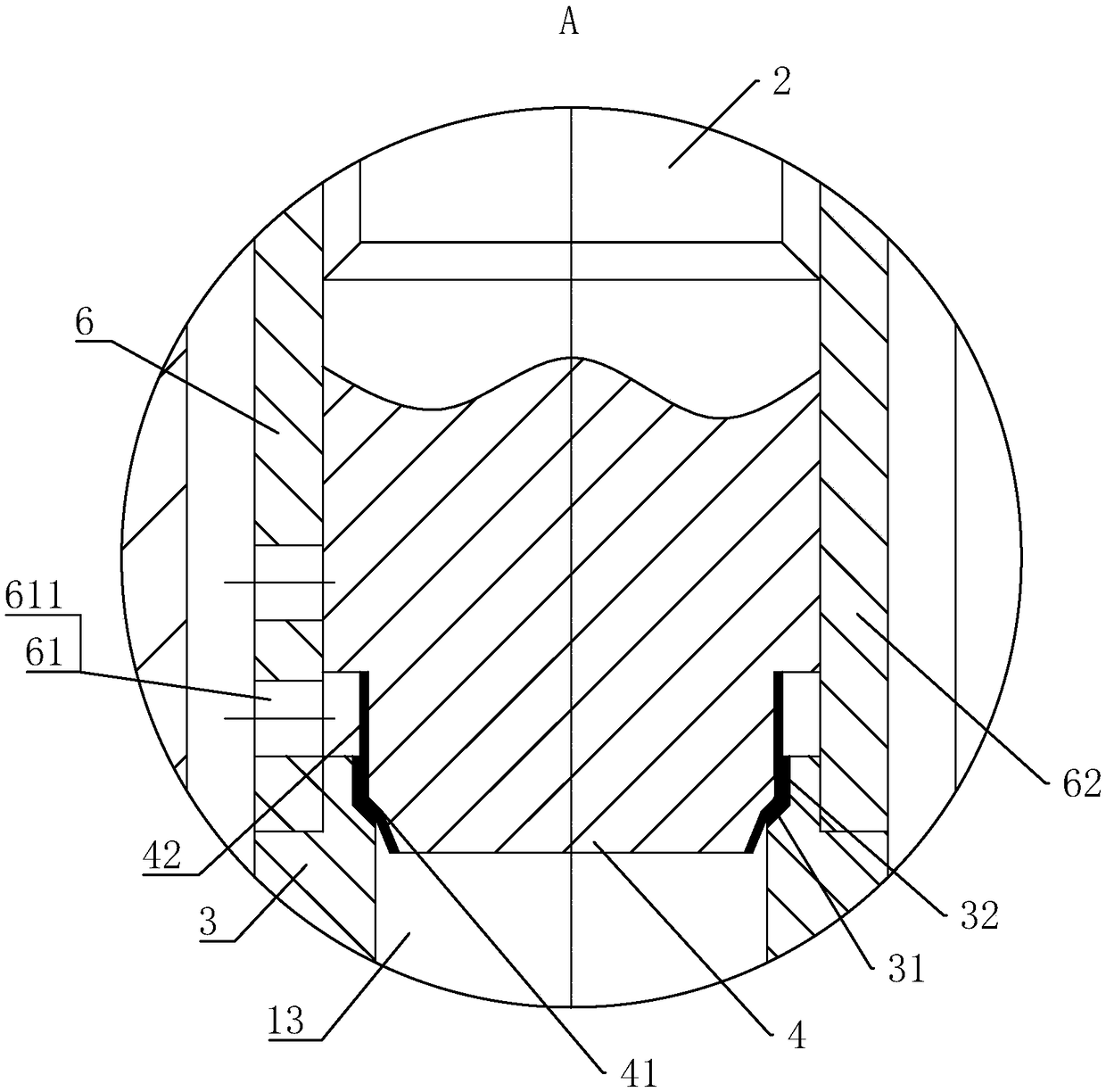

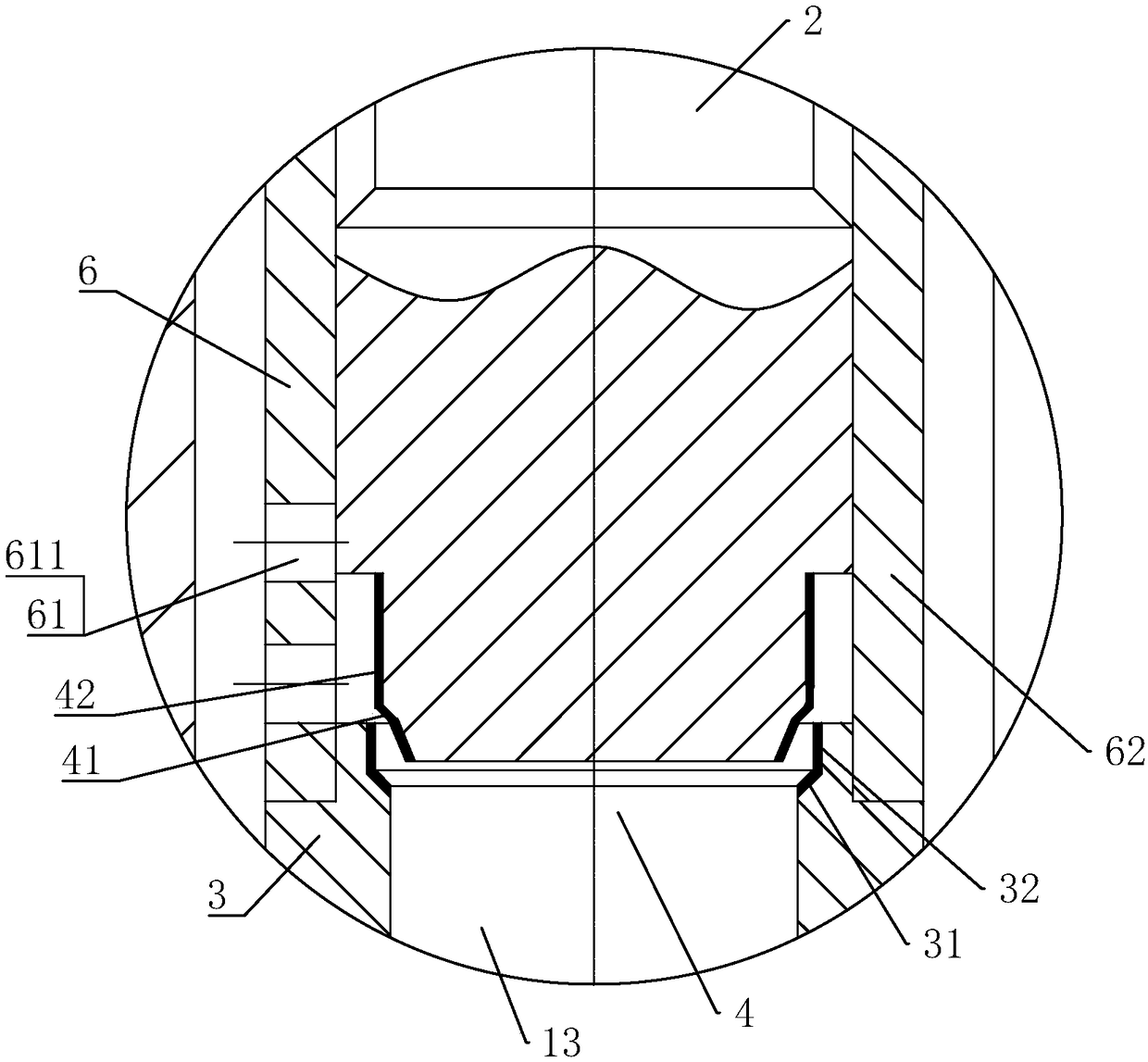

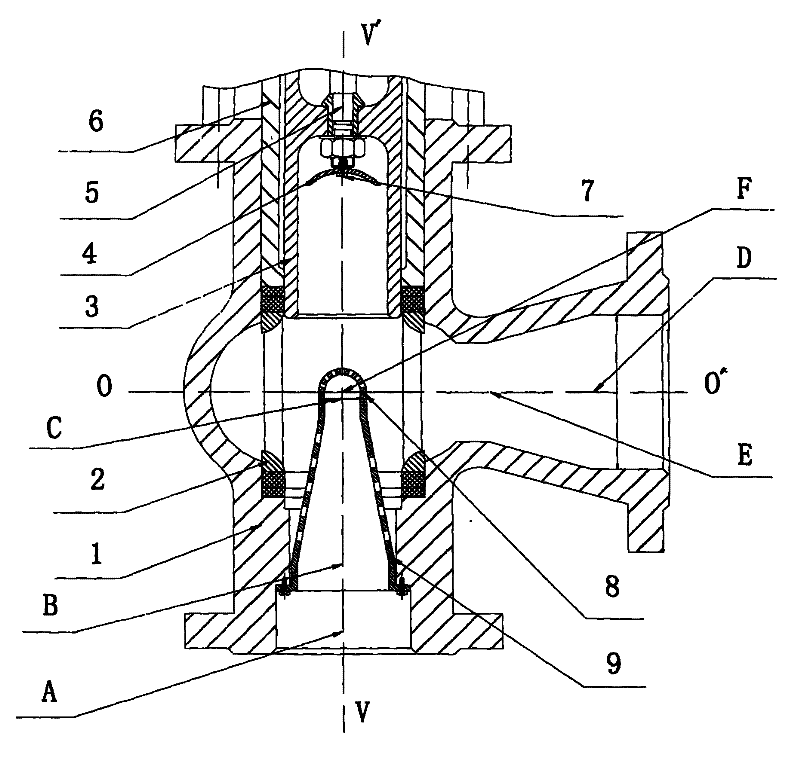

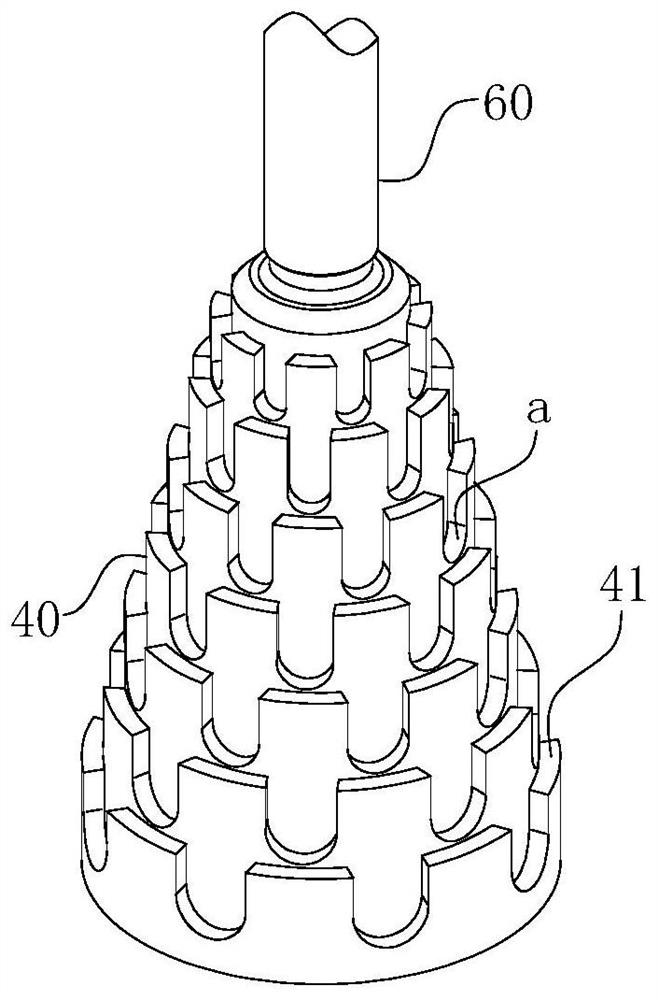

Champagne tower type multi-stage throttling control valve

ActiveCN111473155AGuaranteed tightnessRealize slow speed throttling functionValve members for absorbing fluid energyLift valveThrottle controlStructural engineering

The invention relates to the field of valves, in particular to a Champagne tower type multi-stage throttling control valve applied to high-pressure-difference medium noise reduction cavitation damageresistance. The Champagne tower type multi-stage throttling control valve comprises a valve body, a valve cover, a throttling sleeve and a valve element. The appearance of a sleeve cavity of the throttling sleeve is in a ladder hole shape with two or more layers, the appearance of the valve element is in a ladder shaft shape with two or more layers and coaxial with the throttling sleeve, the number of shaft shoulders of the valve element is smaller than or equal to the number of hole shoulders of the sleeve cavity of the throttling sleeve, therefore, in the axial direction, each shaft shoulderof the valve element can be in seal face fit with the corresponding hole shoulder of the throttling sleeve, the hole shoulder of the throttling sleeve and / or the shaft shoulder of the valve element are / is axially or slantly provided with a runner groove, the structure is compact and simple, the action reliability is high, the valve machining difficulty and cost can be further reduced while effective noise reduction and cavitation damage resistance functions are achieved, and the valve is particularly suitable for being used in the high-pressure-difference medium control condition.

Owner:HEFEI GENERAL MACHINERY RES INST

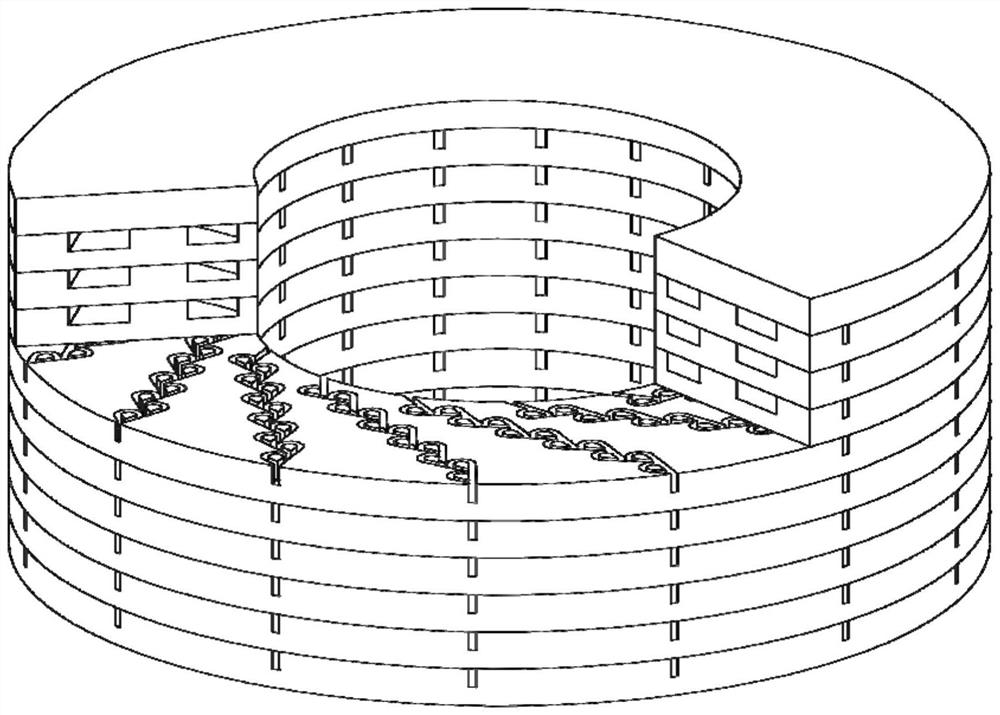

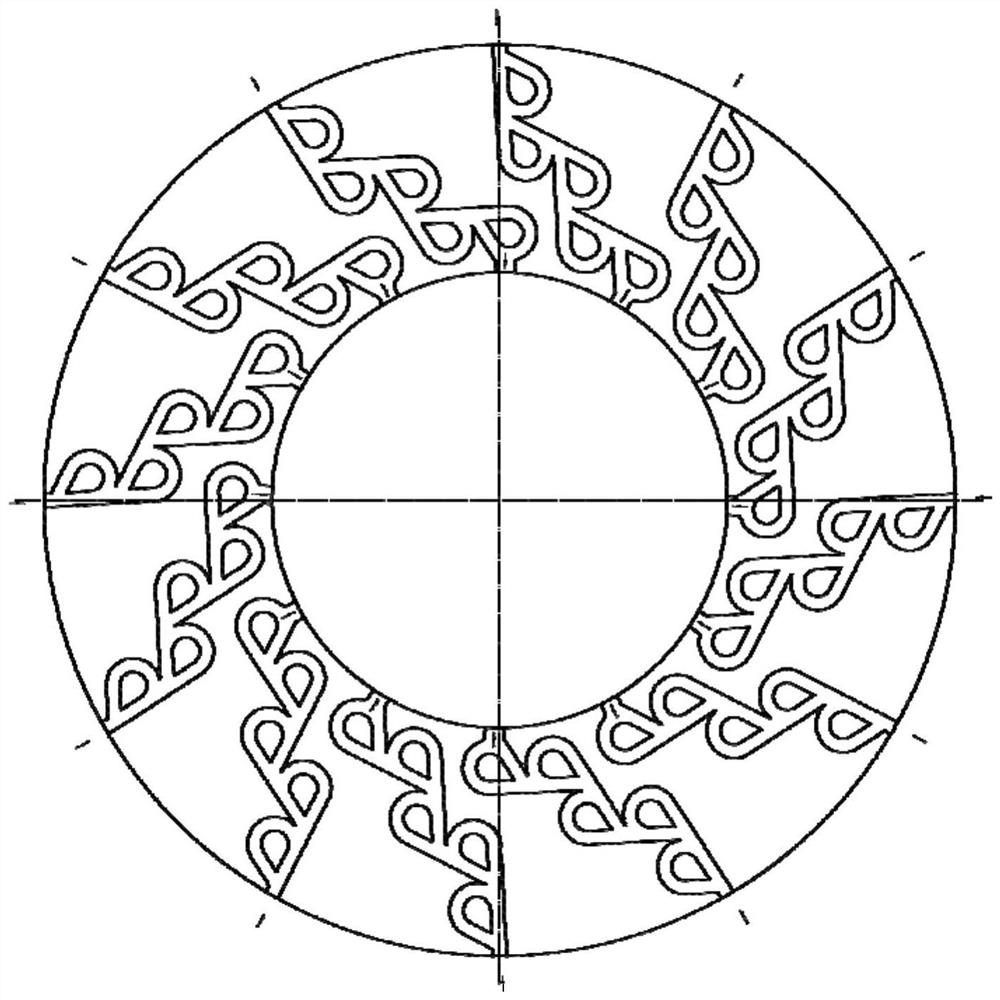

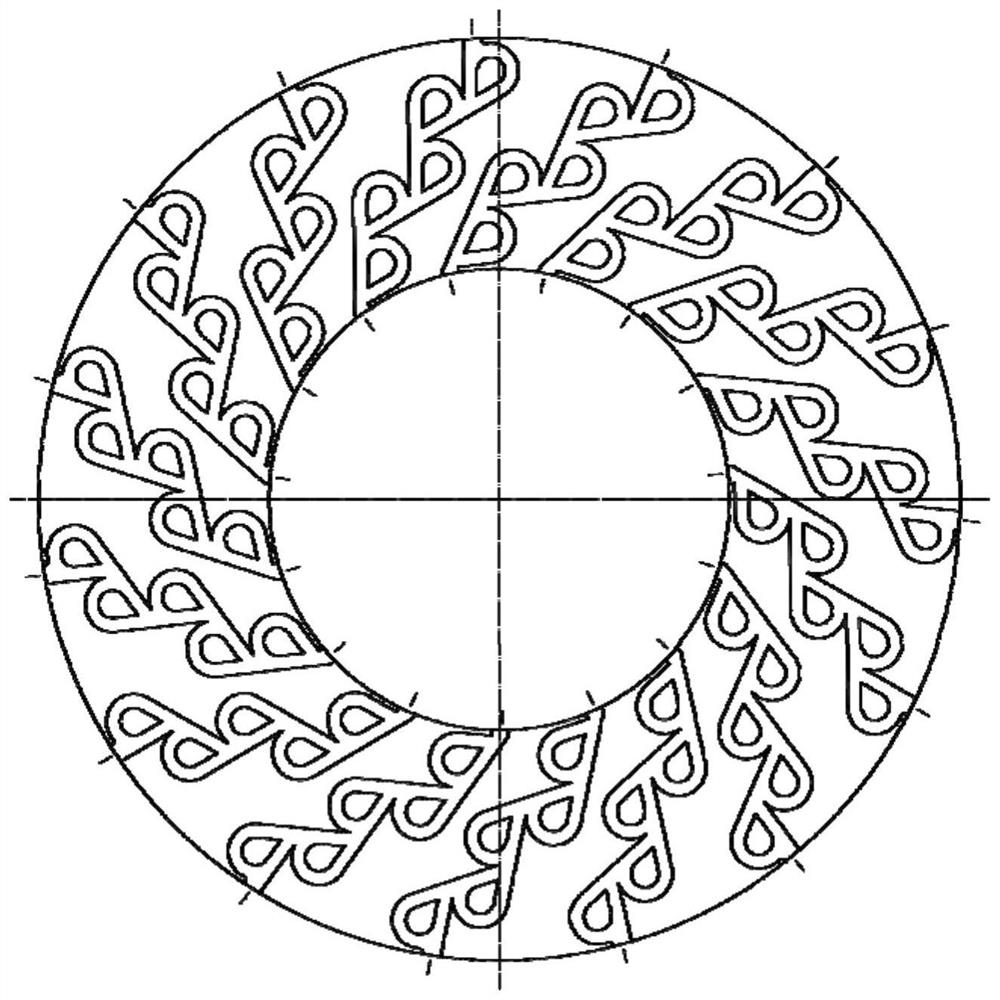

Labyrinth disc of high-pressure-difference pressure-reducing and noise-reducing control valve

PendingCN114352799AExtended maintenance cycleExtended service lifeValve members for absorbing fluid energyCavitationStructural engineering

The invention discloses a labyrinth disc of a high-pressure-difference pressure-reducing and noise-reducing control valve, a plurality of rotary labyrinth type channels are arranged on the labyrinth disc, each rotary labyrinth type channel comprises an inlet section, a pressure-reducing and noise-reducing section and an outlet section, and the inlet section and the outlet section are straight channels in the diameter direction of the round disc. Wherein the pressure reduction and noise reduction section comprises a plurality of semicircular and straight section combined double-convolution bent channels which alternately generate left and right; on the premise that flow required by working conditions is met, more efficient and stable pressure and noise reduction effects are achieved, the phenomena of cavitation, noise and vibration are effectively prevented, damage such as cavitation and scouring is avoided, the medium flow speed is greatly and stably reduced, and the maintenance period and the service life of the valve are prolonged.

Owner:江苏江恒阀业有限公司

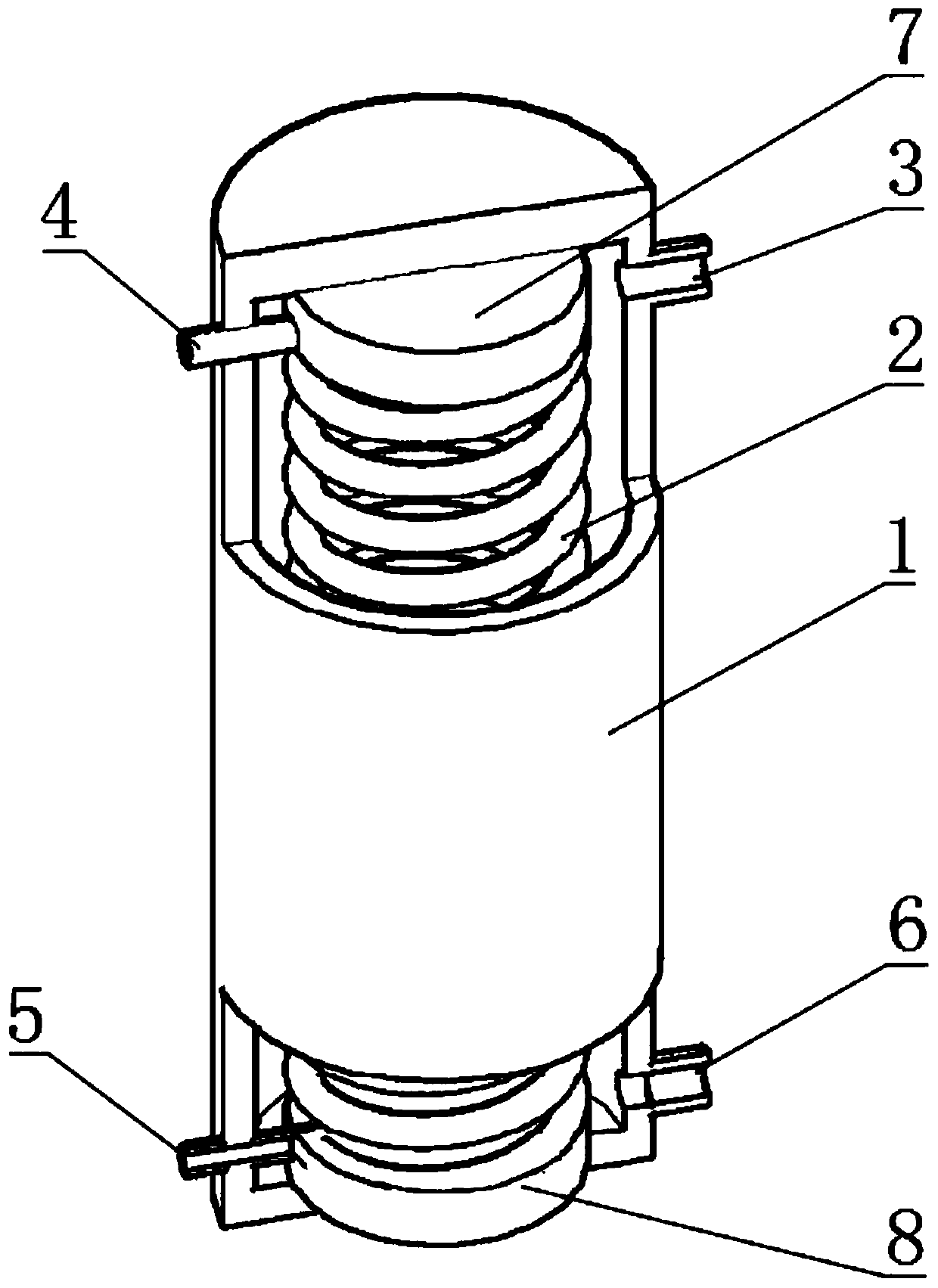

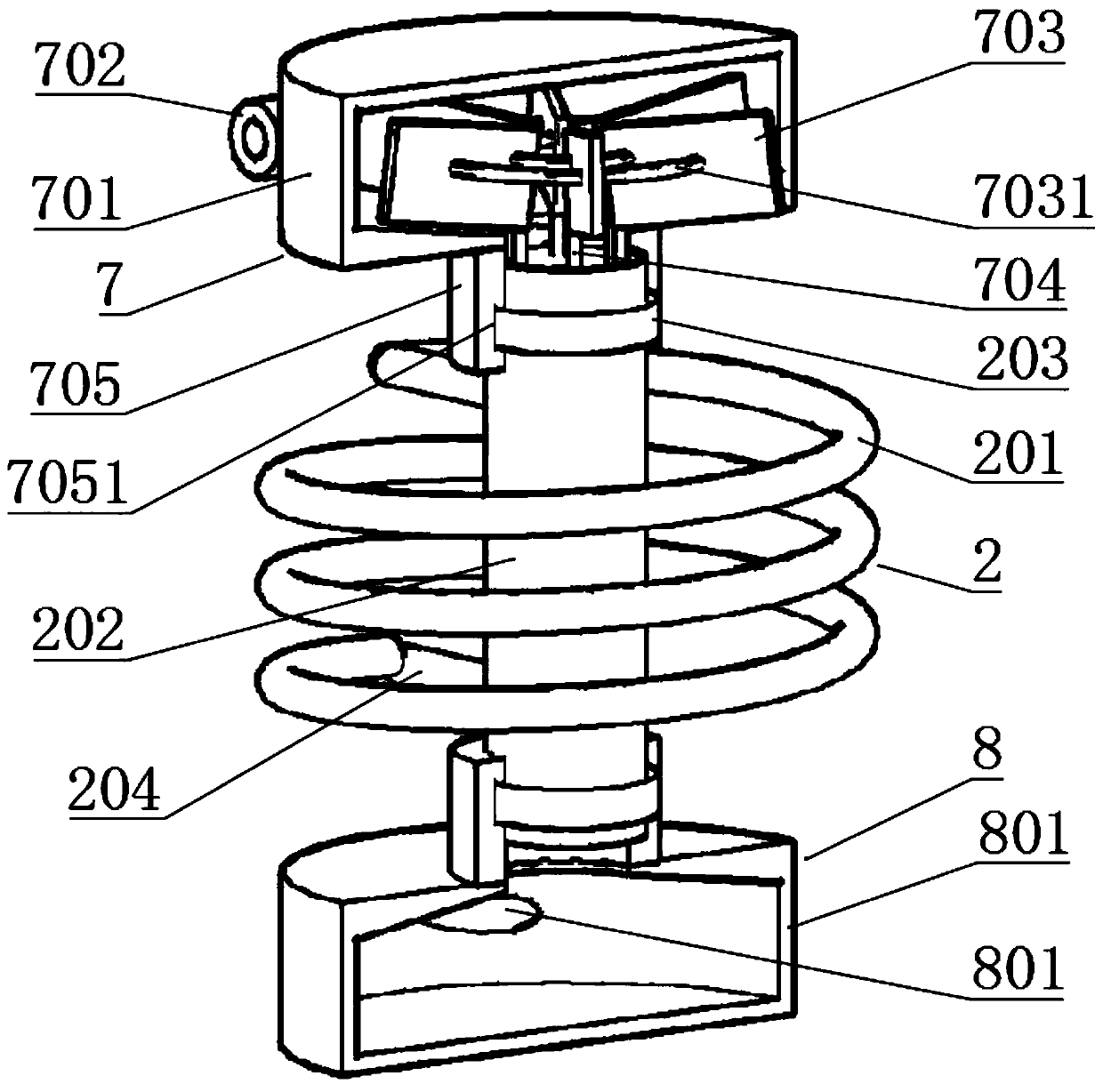

Air energy water heater

ActiveCN110793200AGuaranteed thermal conductivityReduce adhesionFluid heatersEngineeringWater heater

The invention provides an air energy water heater, and relates to the field of water heaters. The air energy water heater comprises a heat exchange box, wherein a heat exchange tube is arranged in theheat exchange box; the top end of the heat exchange tube is fixedly connected to a first rotary mechanism; the heat exchange tube communicates with the inner part of the rotary mechanism; the first rotary mechanism is fixedly arranged in the heat exchange box; the bottom end of the heat exchange tube is fixedly connected to a second rotary mechanism; and the second rotary mechanism is fixedly arranged in the heat exchange box. In the air energy water heater, the heat exchange tube rotates to generate friction with water, so that attachment of water scales is reduced, heat conduction of the heat exchange tube is guaranteed, water molecule motion speed can be increased, and therefore, heat exchange efficiency is improved, flowing time, in the heat exchange tube, of a medium is shortened, and the high-temperature medium is in sufficient contact with a heat exchanger to improve heat exchange degree; meanwhile, the medium can be sufficiently liquefied after releasing energy, so that a throttle device connected behind the heat exchanger is protected; and a connecting shaft is kept in sealing with the first rotary mechanism and the second rotary mechanism through a sealing ring.

Owner:浙江德富新能源技术有限公司

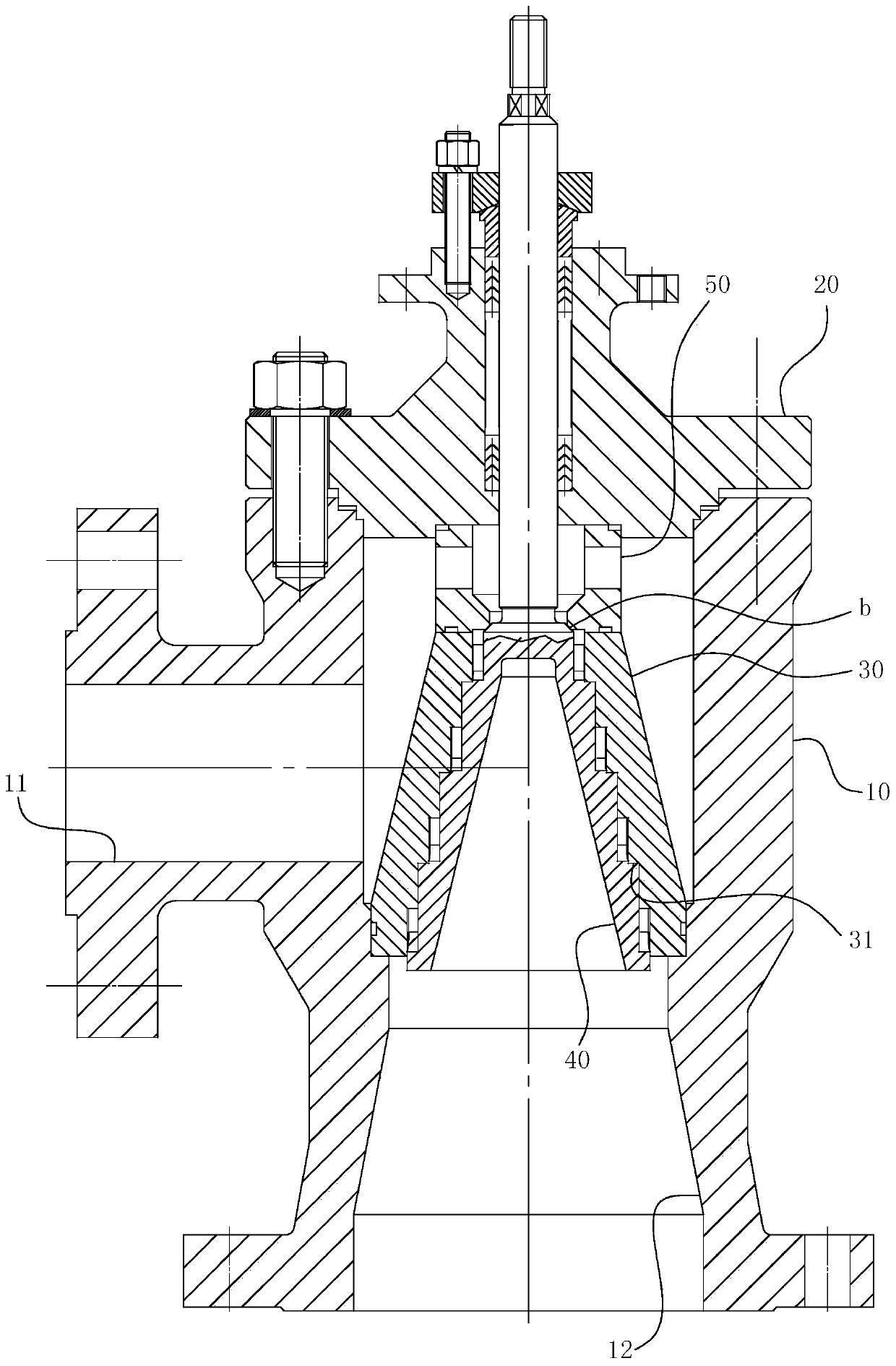

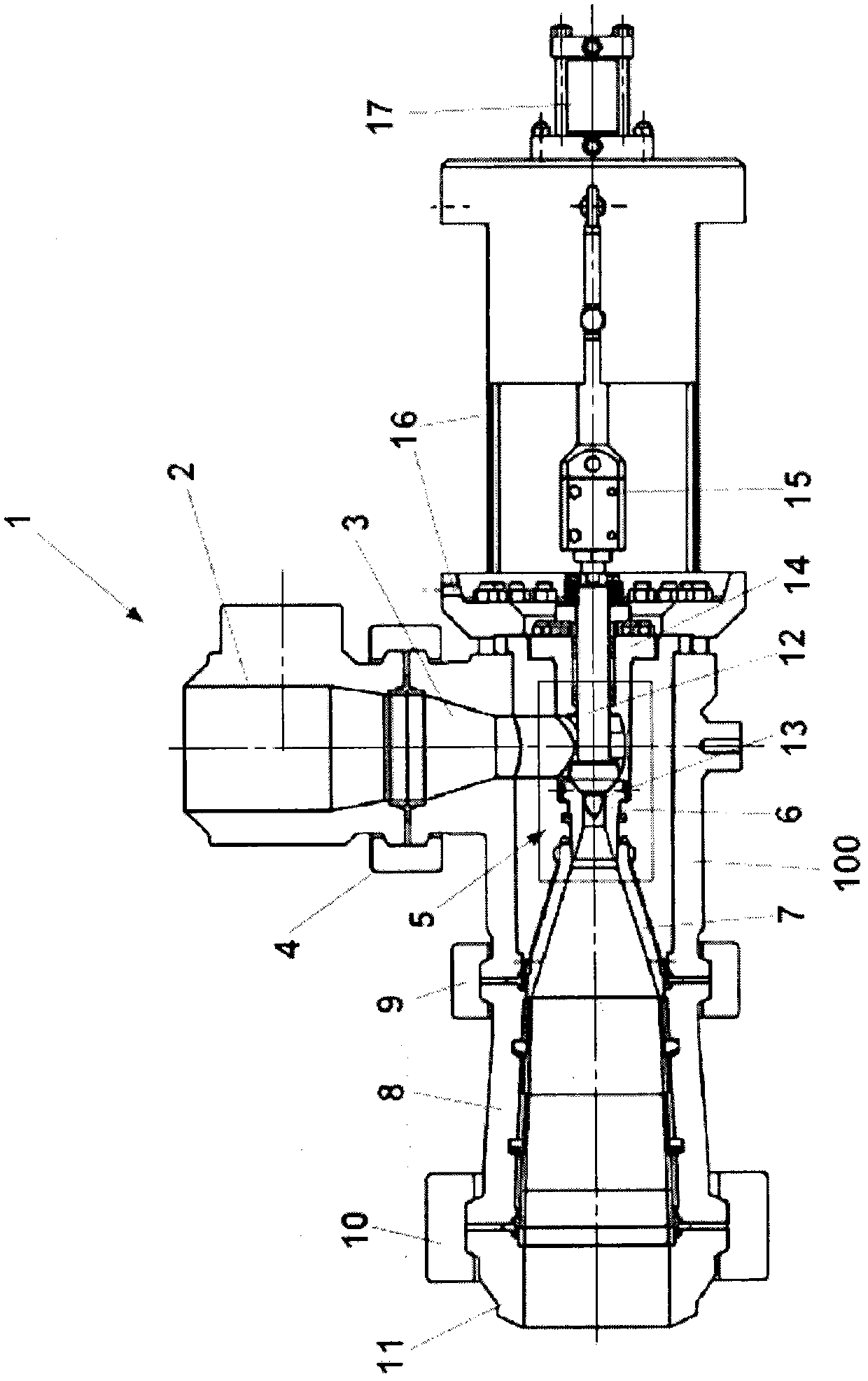

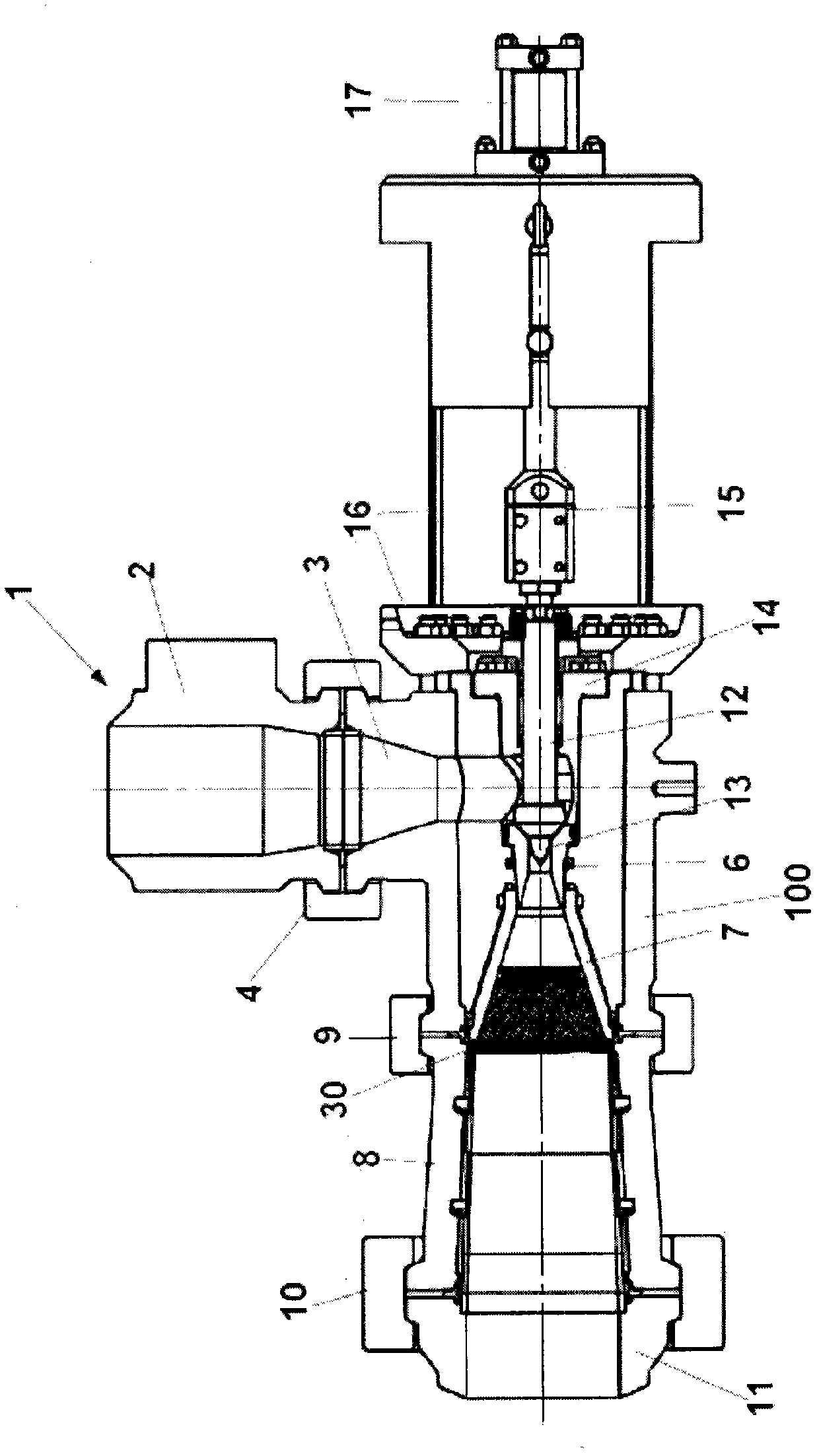

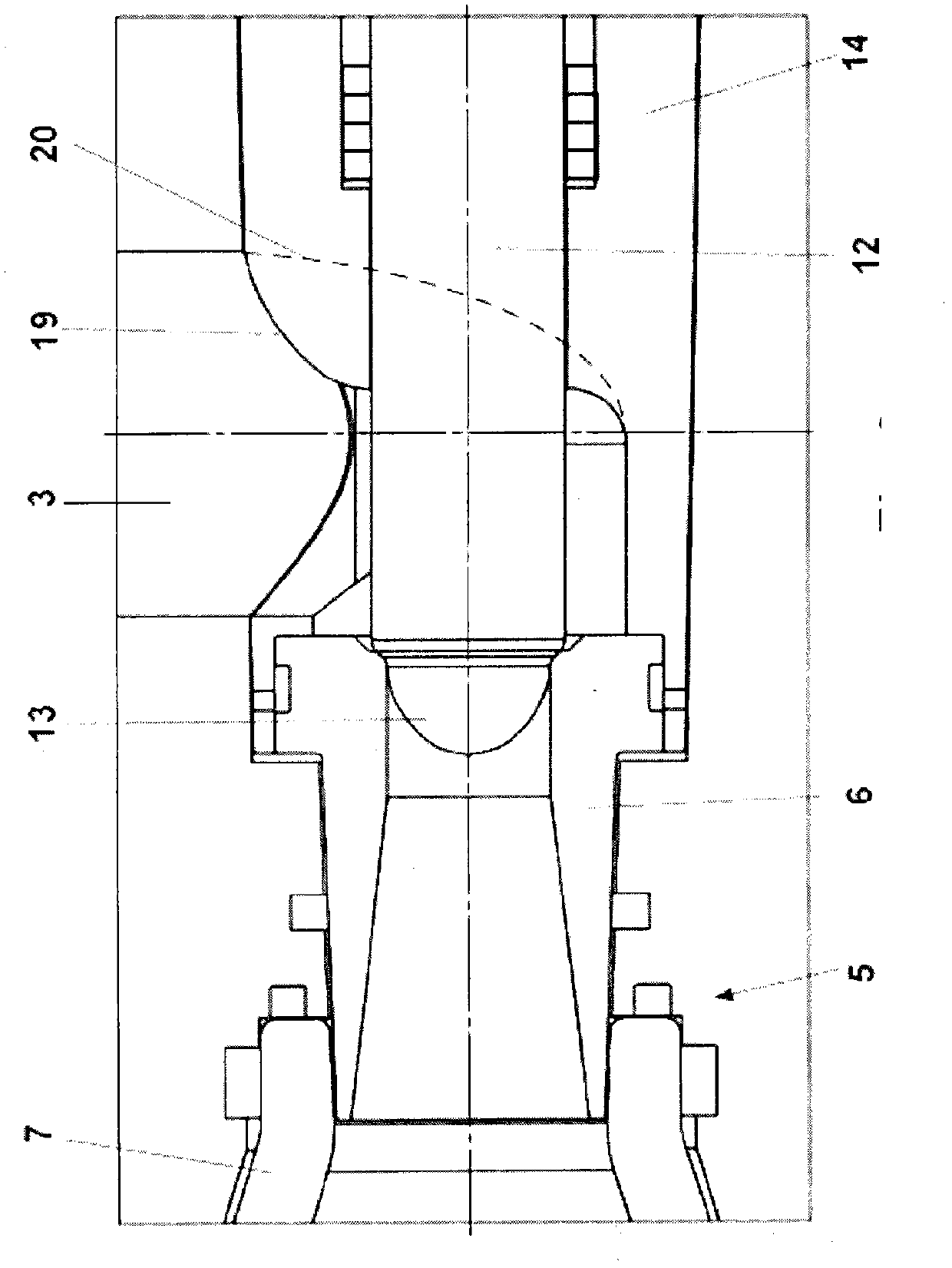

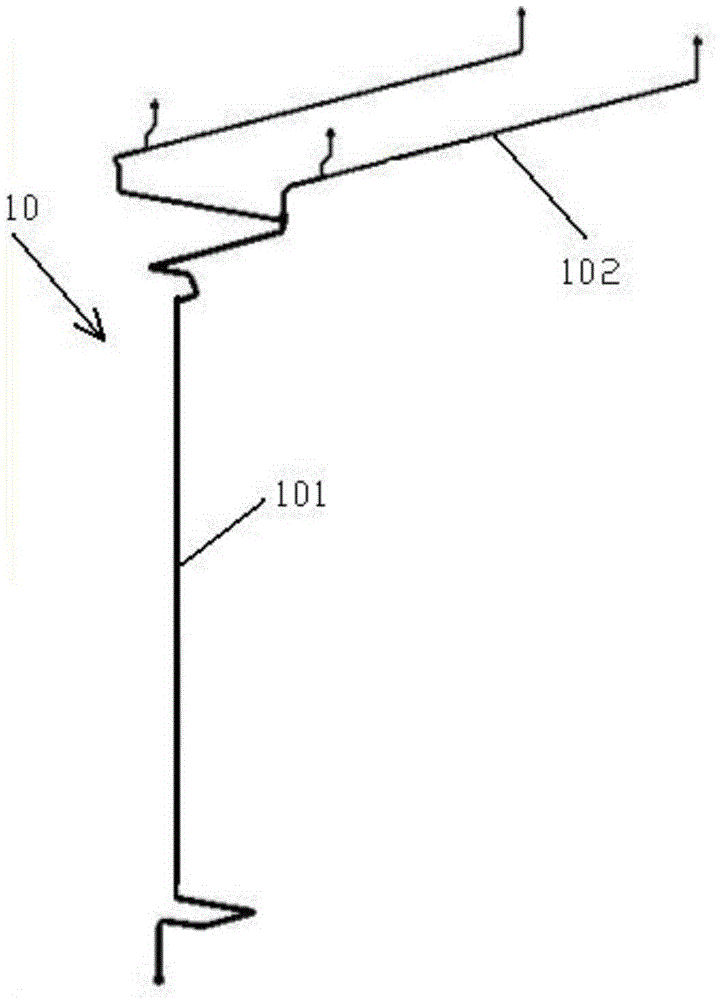

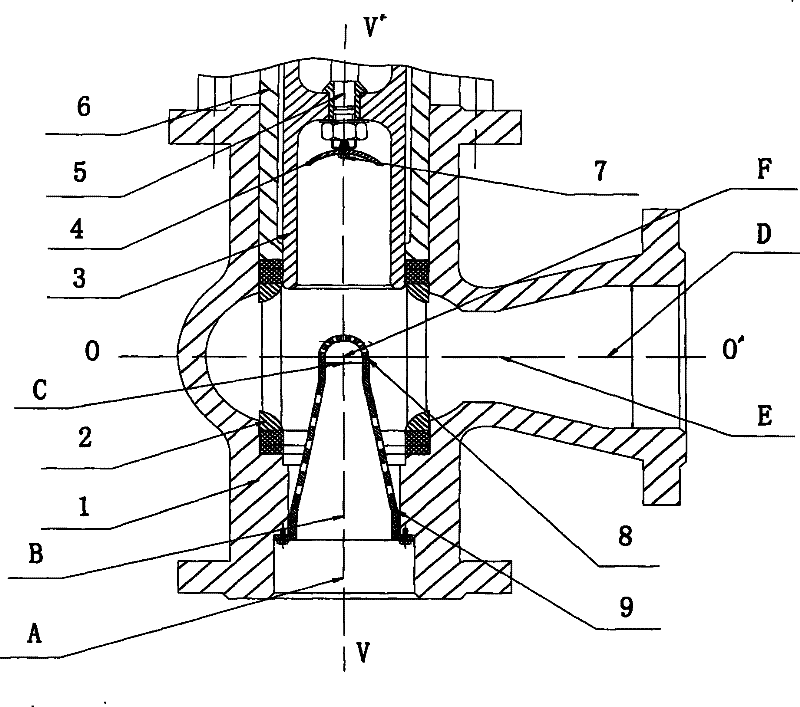

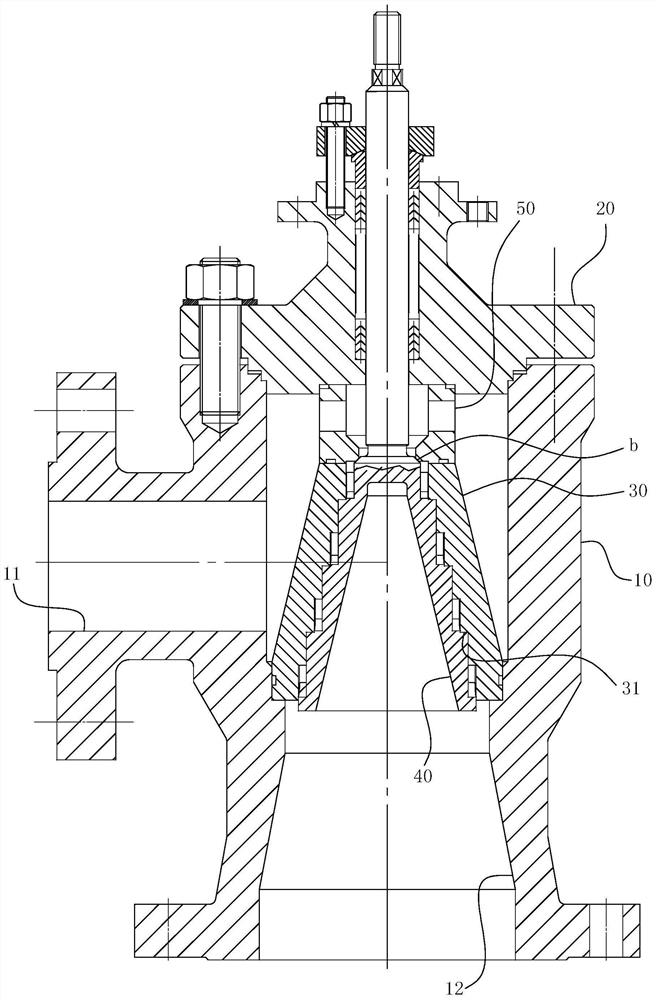

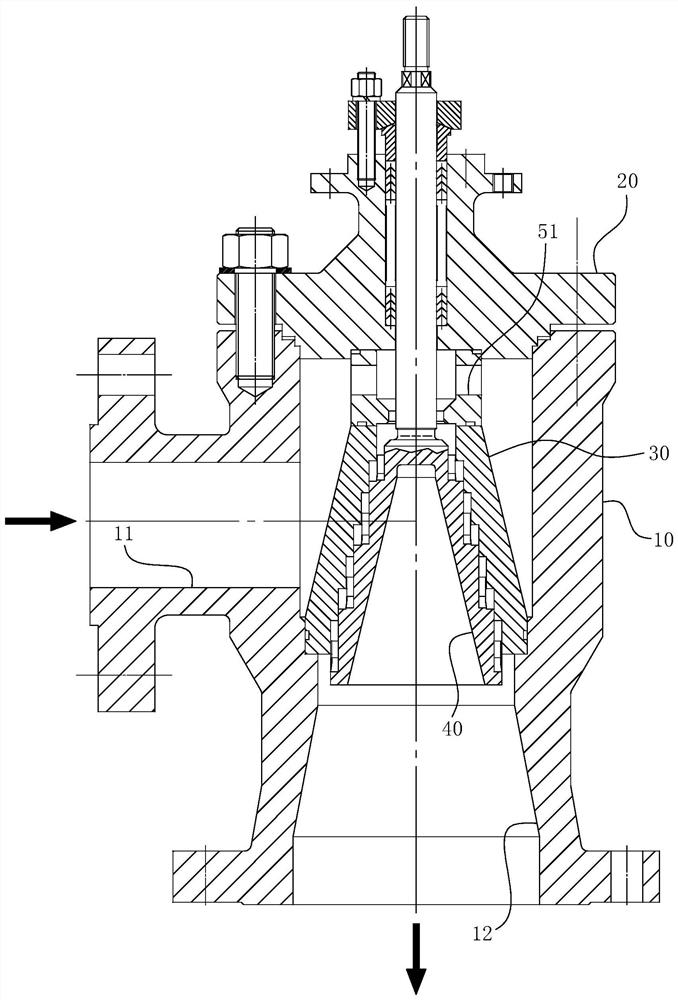

Control valve, in particular angle control valve and double control valve, also in the form of a straight-seat valve and inc.lined-seat valve for extreme control applications

ActiveCN102713383APrevent gasificationReduce vibration effectsThin material handlingValve member-seat contactsEvaporationEngineering

The invention relates to a control valve 1), in particular an angle control valve and double control valve, for extreme control applications, preferably for discharge or reduction for hot separators and vacuum distillation columns. The valve piston 12 and the valve head 13 are designed as one piece and consist of tungsten carbide. Furthermore, the control valve comprises different constructions across the entire control valve range. For example, the valve housing 100, the valve seat 6 and a packing retainer 14 are optionally shaped such that the inner hollow space tapers continuously from the valve inlet to the valve seat 6, which prevents evaporation upstream of the valve seat 6. Furthermore, the double control valve consists of a large sub-valve 36 and at least one small sub-valve 37, wherein the large sub-valve 36 is designed as an adjustable open-closed piston valve and the small sub-valve 37 is designed as a control valve.

Owner:SCHUF ARMATUREN & APPBAU

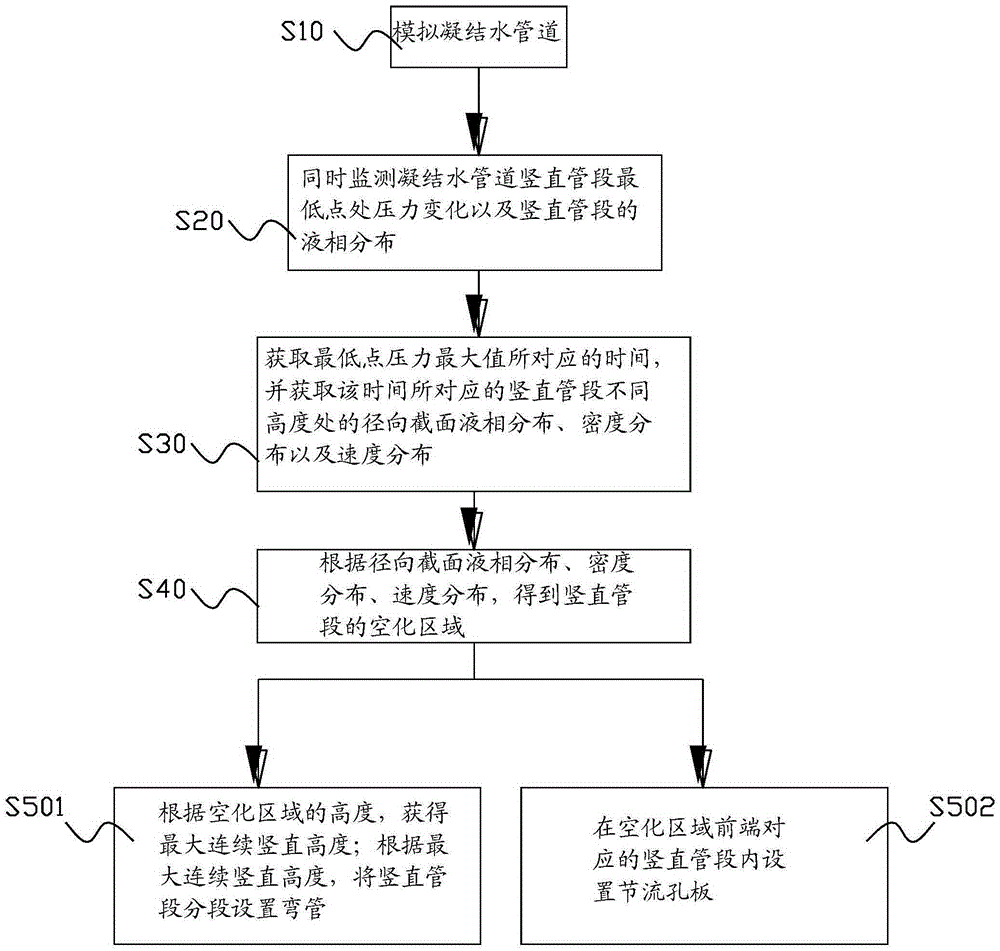

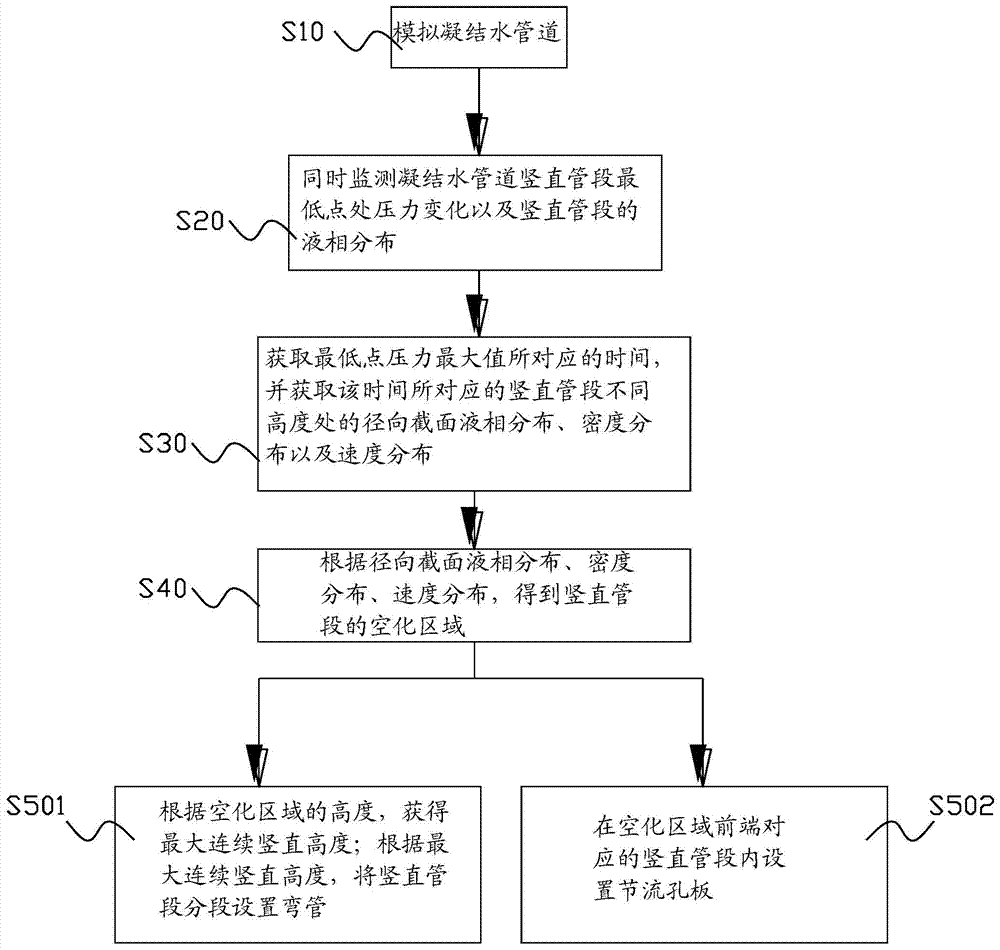

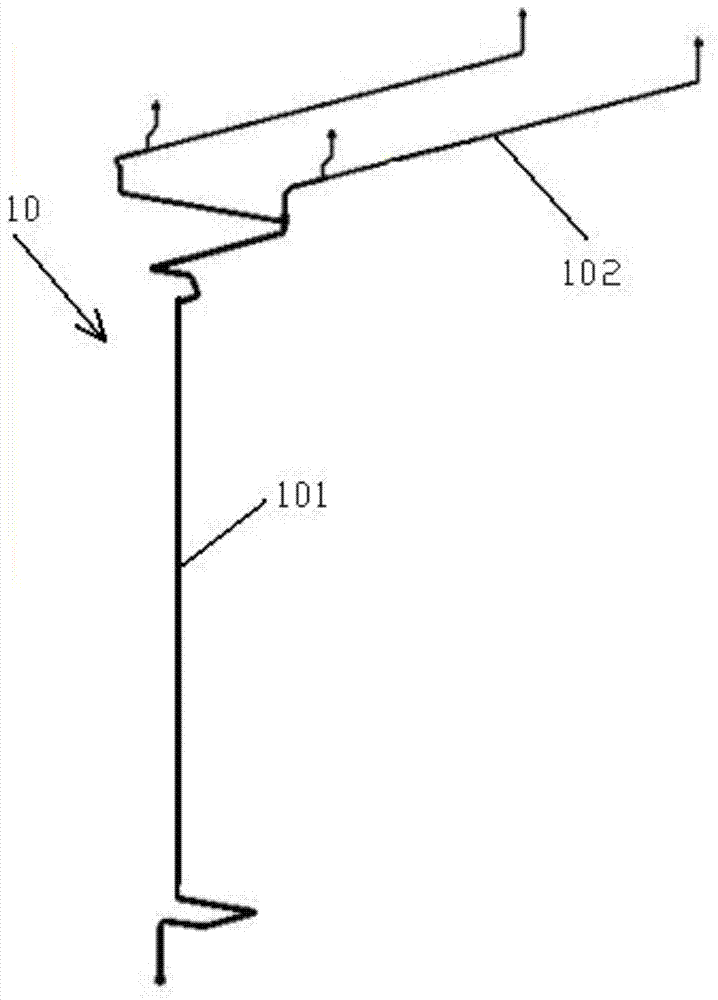

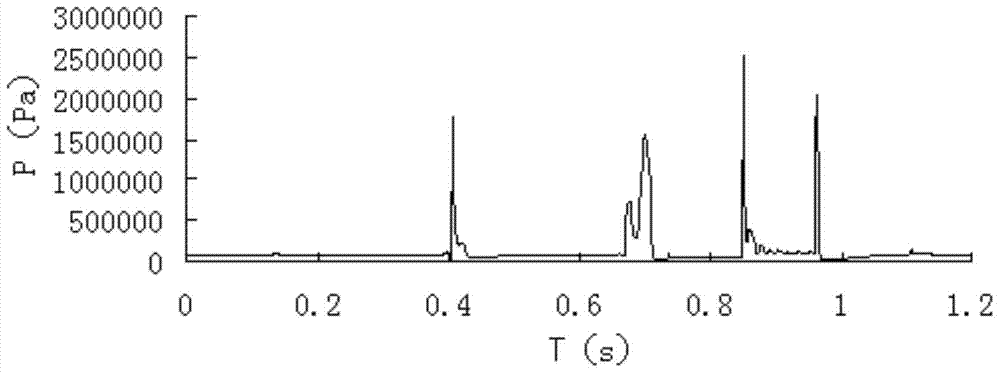

Condensation water pipe and method for reducing vibration of condensation water pipe

The invention discloses a condensation water pipe and a method for reducing vibration of the condensation water pipe. The method comprises the following steps that the condensation water pipe is simulated; the pressure change of the lowest point of a continuous vertical pipe segment of the condensation water pipe along with running time and the liquid phase distribution of the vertical pipe segment are monitored; the time corresponding to the maximum pressure value of the lowest point is obtained, and the liquid phase distribution, corresponding to the time, of the radial section of the vertical pipe segment is obtained; a cavitation area of the vertical pipe segment is obtained according to the liquid phase distribution of the radial section; and the maximum continuous vertical height not larger than the height of the cavitation area is obtained according to the height of the cavitation area; and according to the maximum continuous vertical height, the vertical pipe segment is provided with bent pipes in a segmented manner, and / or restriction orifices are arranged in the vertical pipe segment corresponding to the front end of the cavitation area. According to the scheme, it is found that vibration of the vertical pipe segment of the condensation water pipe is mainly caused by the cavitation effect; the medium flowing resistance is increased in the manner of arranging the bent pipes and the restriction orifices, the flowing speed is lowered, and cavitation is restrained; and therefore pipe vibration is effectively reduced.

Owner:HUADIAN HEAVY IND CO LTD

Silent throttling stop air release valve

InactiveCN104373675AReduce differential pressure vibrationPlay the role of noise reductionValve members for absorbing fluid energyLift valveEngineeringMechanical engineering

The invention discloses a silent throttling stop air release valve, and belongs to the field of valves. The silent throttling stop air release valve comprises a valve body, a valve rod, a support and a valve deck. A denoising assembly and a valve clack assembly are arranged in the valve body. The denoising assembly comprises a valve sleeve and a plate baffle. The valve sleeve is cylindrical and is vertically installed on the same axis as the valve rod. At least one set of throttling grooves of different lengths are formed in the circumference of the lower portion of the valve sleeve. The bottoms of the throttling grooves are located on the same axis. The throttling grooves are distributed in a symmetric periodic mode. The plate baffle is vertically arranged in an inlet passageway of the valve body. The plate baffle is in a hollow annular shape. Asymmetrical throttling holes are formed in the circumferential surface of the plate baffle. By means of the silent throttling stop air release valve, the problem that noise is produced by an existing throttling stop air release valve is effectively solved.

Owner:ZIGONG ZIGAO VALVE

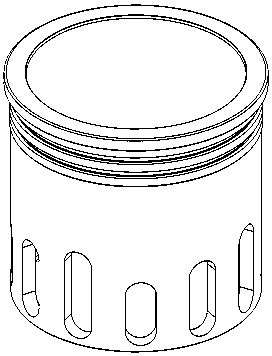

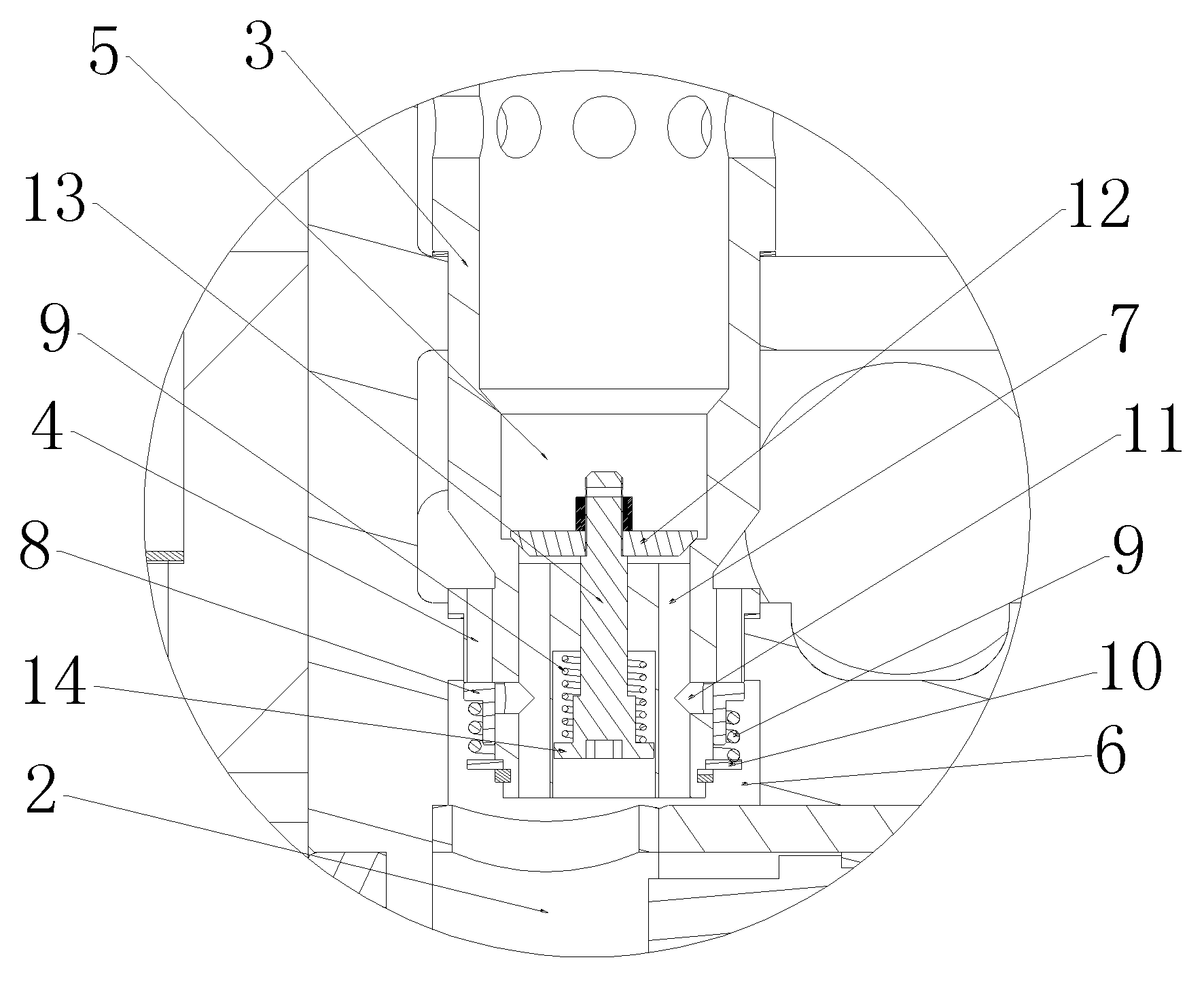

Floating type seal mouse cage valve

ActiveCN103133704AImprove erosion resistanceAvoid overwashingOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringMechanical engineering

The invention discloses a floating type seal mouse cage vale which comprises a valve body, a valve cover, a support frame, a seal seat in the valve body, a balance cylinder in the valve body, a spool in an inner hole of the balance cylinder, a lower valve rod connected with the spool and an upper valve rod connected with the upper end of the lower valve rod. A sleeve provided with a runner hole is disposed in the valve body. A valve positioner is disposed on the support frame. An annular connector is disposed on the outer contour of the lower end of the spool. A clamp piece with the diameter smaller than the connector is disposed at the inner bottom of the connector. A seal piece is disposed above the clamp piece in the connector. The outer diameter of the clamp piece presses the seal piece through seam allowance. The inner diameter of the connector presses the seal piece through seam allowance. Gaps are reserved among the seal piece, the connector and the clamp piece. The fixed seal piece of traditional valves are modified into the floating seal piece, and when valve processing errors and the like cause unsmooth contact of the seal piece, better seal effect can be achieved by automatic adjustment of the floating seal piece.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

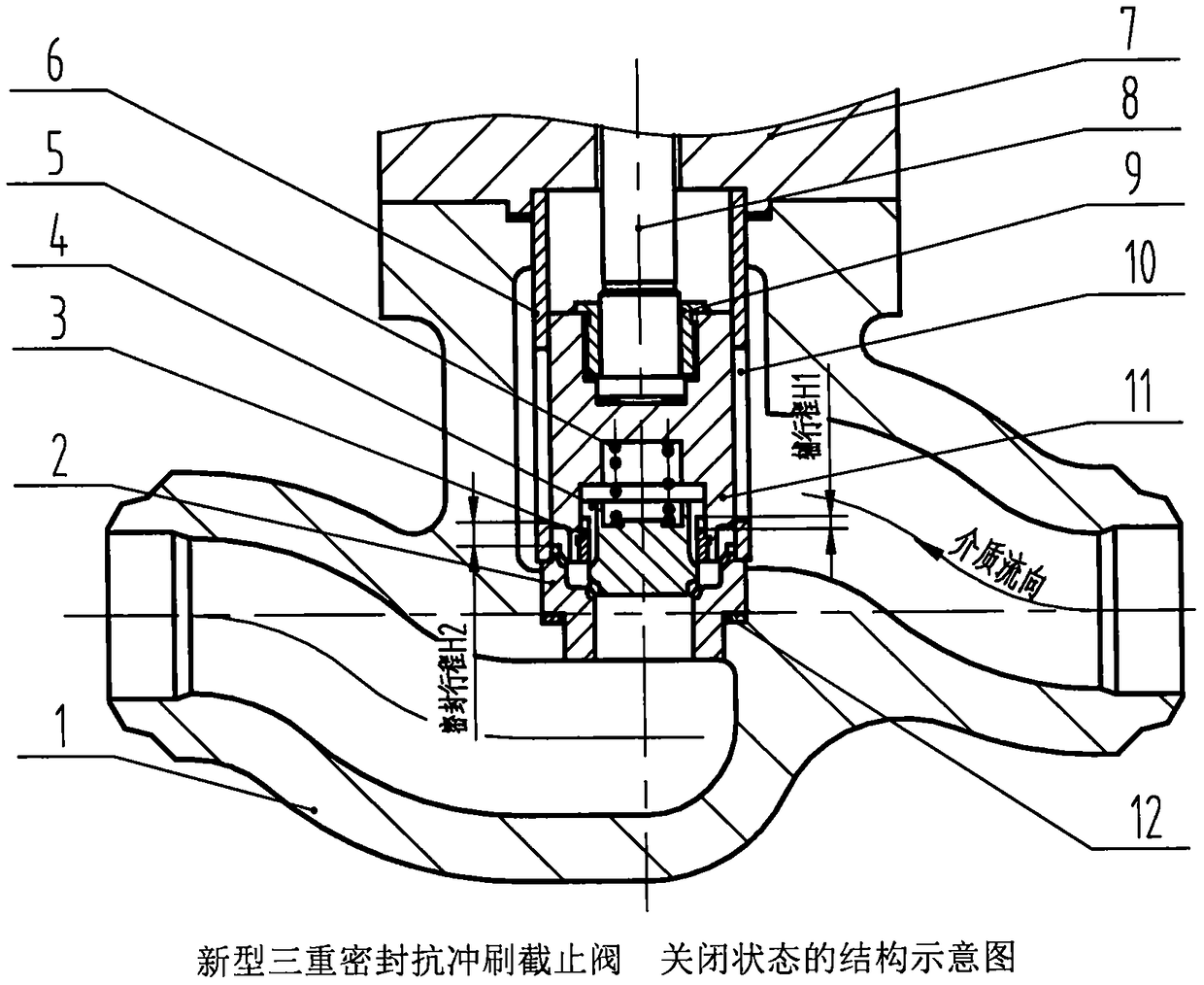

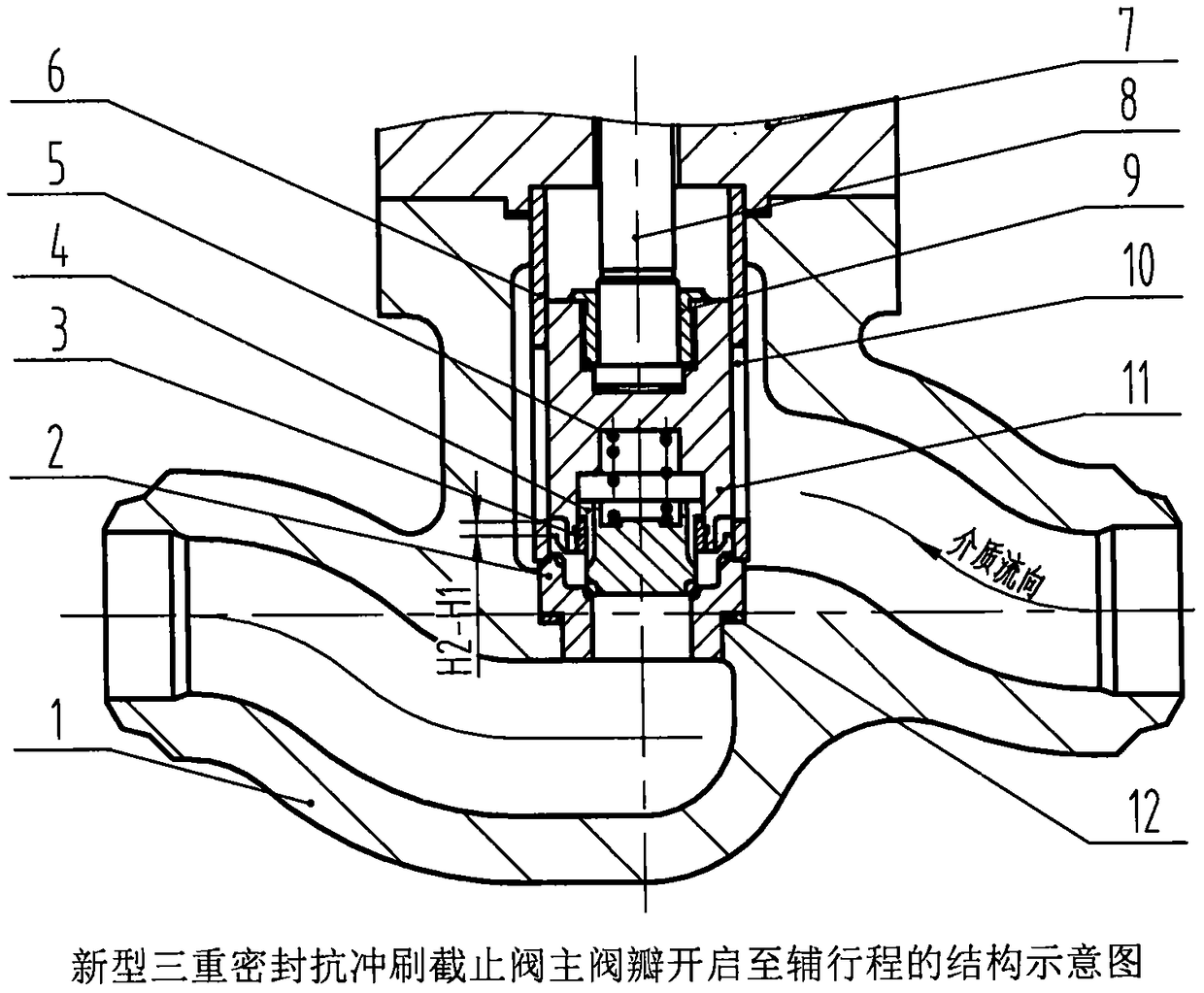

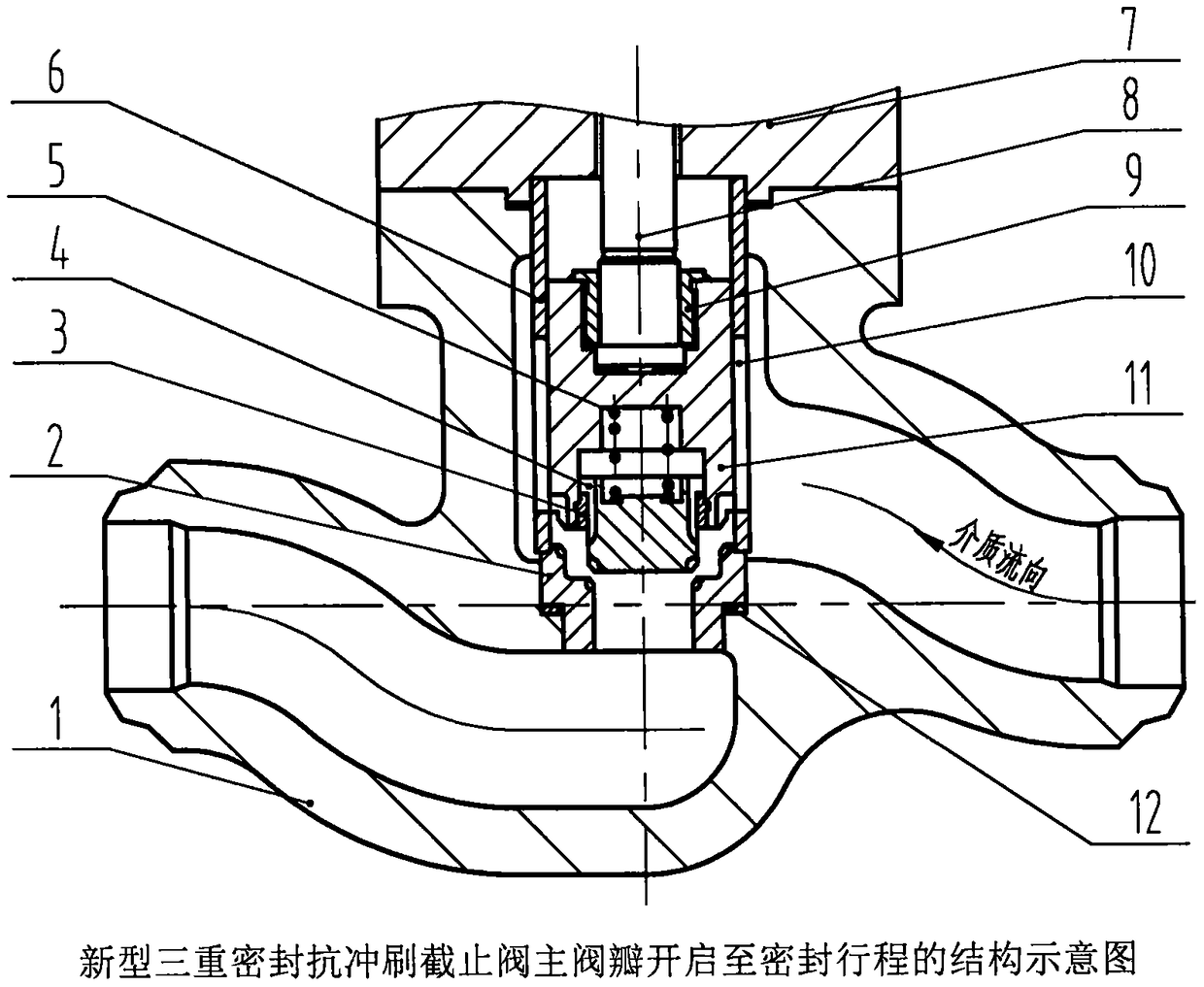

Novel triple-seal anti-scouring stop valve

The invention discloses a novel triple-seal anti-scouring stop valve which is widely applied to power station boilers and turbine systems. The novel triple-seal anti-scouring stop valve comprises a valve body, a liner, a valve seat, an auxiliary valve clack, an auxiliary valve gland, a main valve clack, a main valve gland, a spring, a throttle sleeve, a valve rod, a valve cover and valve rod, anda throttle window. The valve seat and the valve body are sealed by compressing the liner. Through the main valve gland, the valve rod drives the valve clack to be opened to move up and down along thethrottle sleeve. The main valve clack and the auxiliary valve clack are connected through the auxiliary valve gland. The main valve clack is provided with the spring. When the valve is opened, the main valve clack, the auxiliary valve clack and the throttle window are opened sequentially. When the valve is closed, the process is opposite. The novel triple-seal anti-scouring stop valve with a novelstructure has the advantages that three seals, including an annular seal and two conical-surface seals (or flat-surface seals) are realized when the valve is closed, damage of impurities to sealing surfaces is avoided, and scouring of media on main and auxiliary sealing surfaces is reduced, so that service life of the valve is prolonged, and good sealing effect is achieved.

Owner:HARBIN HBC VALVE

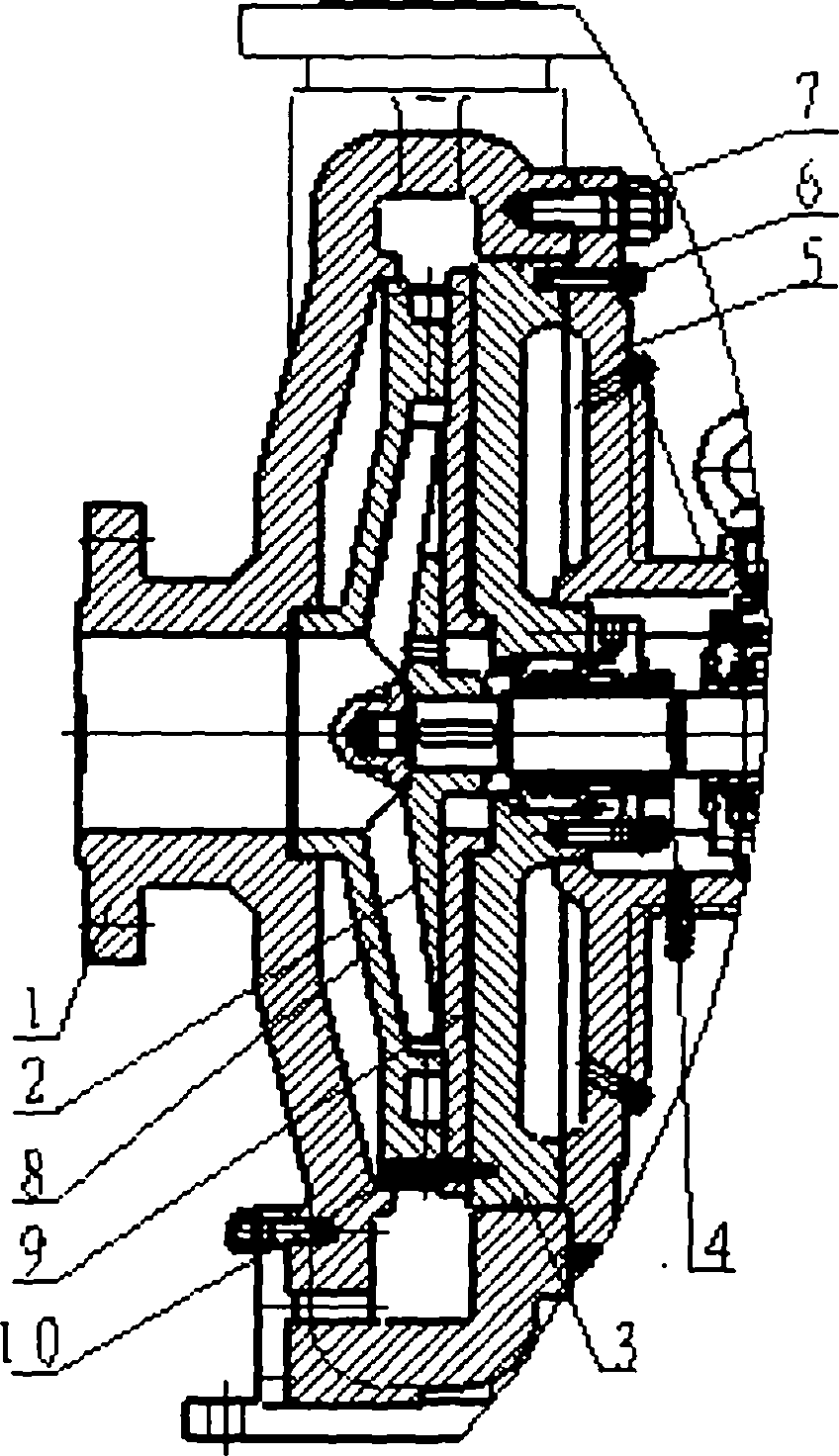

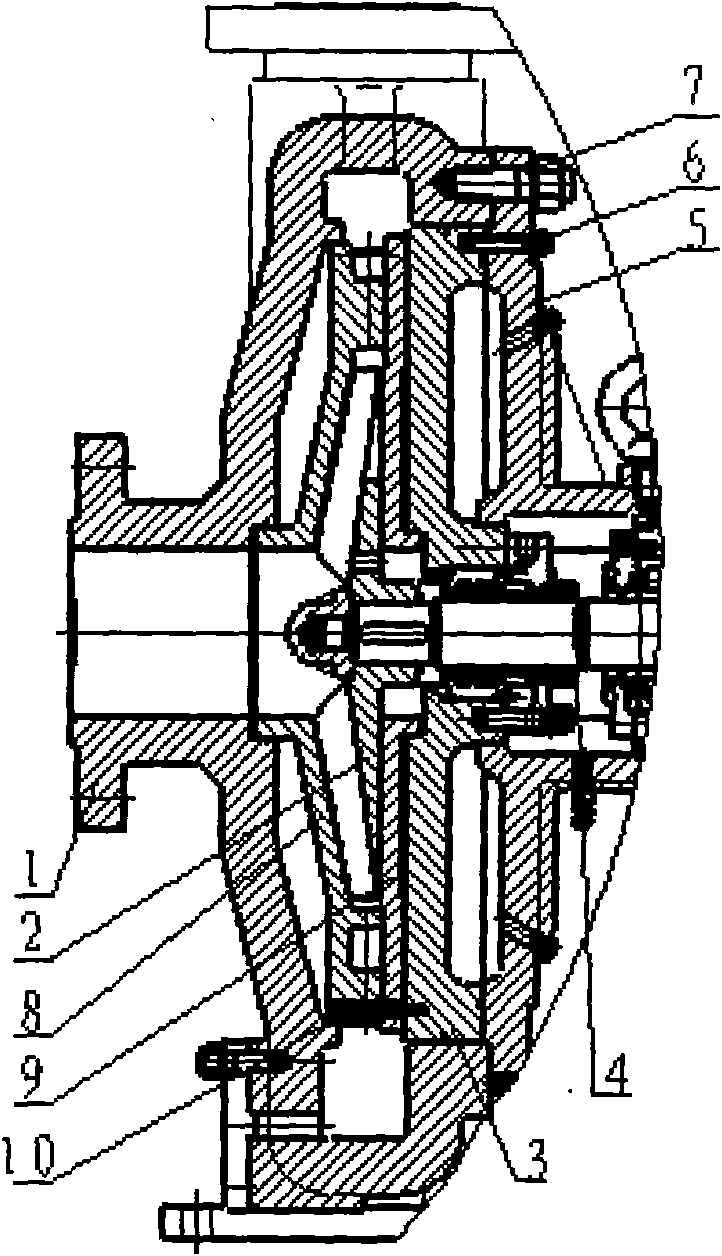

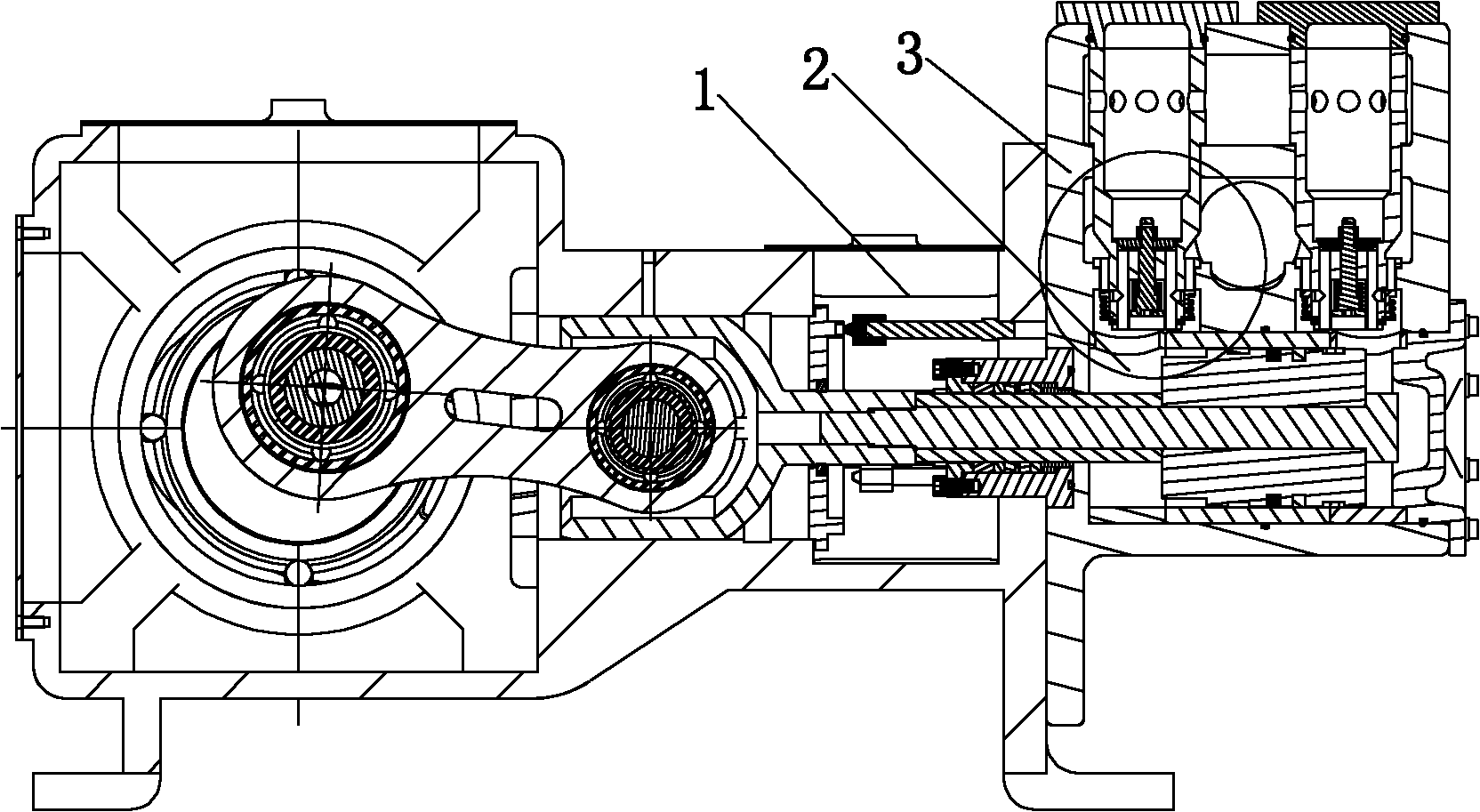

Axial-flow type air control balance stop valve

InactiveCN104633247ACompact structureSave installation spaceOperating means/releasing devices for valvesLift valveEngineeringHigh pressure

The invention relates to an axial-flow type air control balance stop valve and belongs to the field of air control stop valves. The axial-flow type air control balance stop valve comprises a shell 1, a valve seat assembly 2, a joint head 3 and a sealing gasket 4. An air source is controlled to enter the valve from a control port 5 and push a piston 6 and a reset spring 21 on a movable valve seat 7, the movable valve seat 7 and the sealing gasket 4 are disengaged, and then the valve is opened; after the air source is controlled to stop supplying air, the movable valve seat 7 makes contact with the sealing gasket 4 again and is sealed under the action of the reset spring 21, air flow in a system is cut off, and the valve is closed. The axial-flow type air control balance stop valve is small in size, low in flow resistance, convenient to install, capable of saving installation space, mainly applicable to a high-pressure fluid system and suitable for large-range popularization.

Owner:李春松

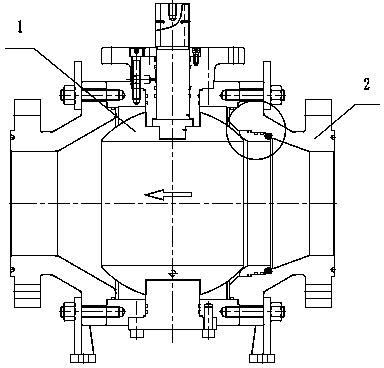

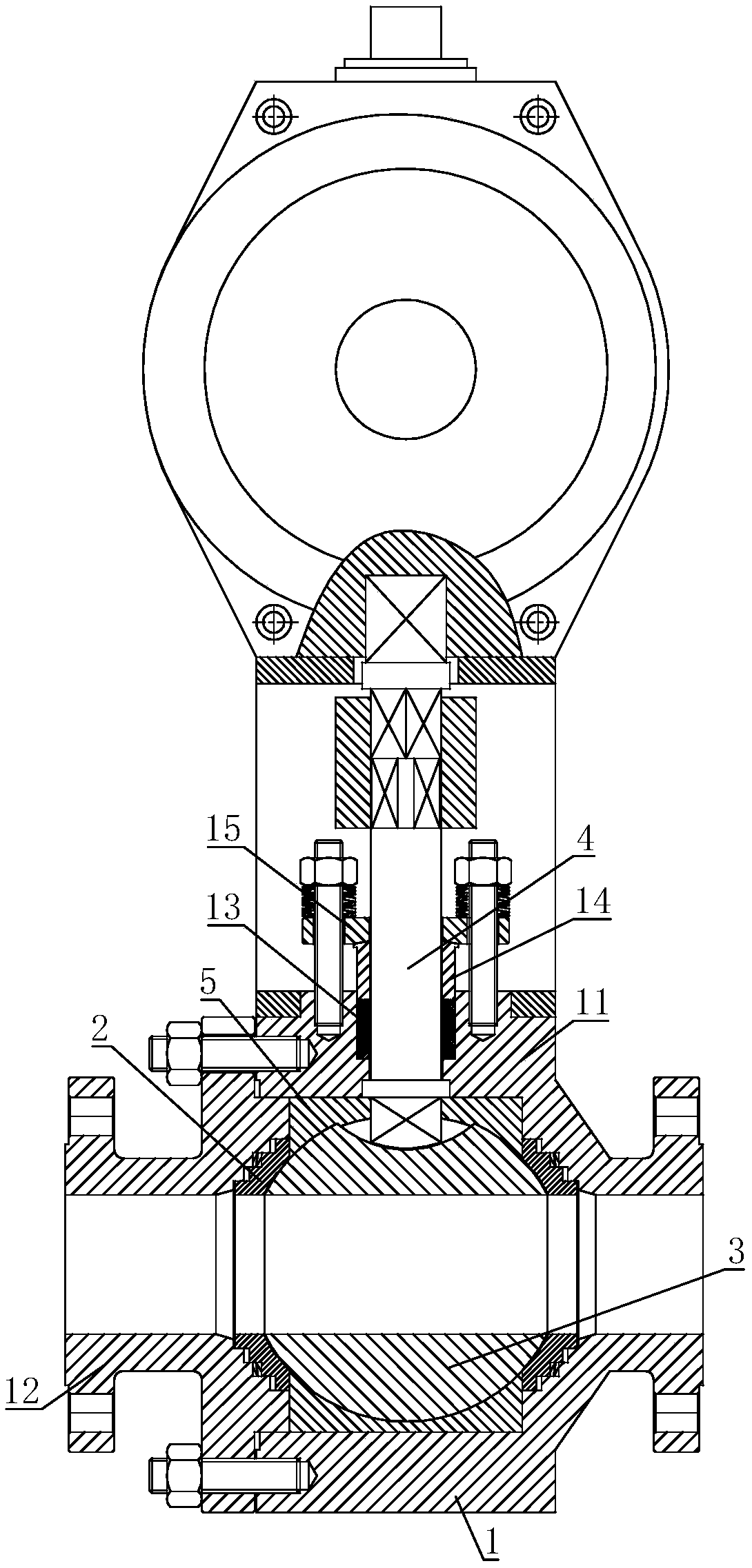

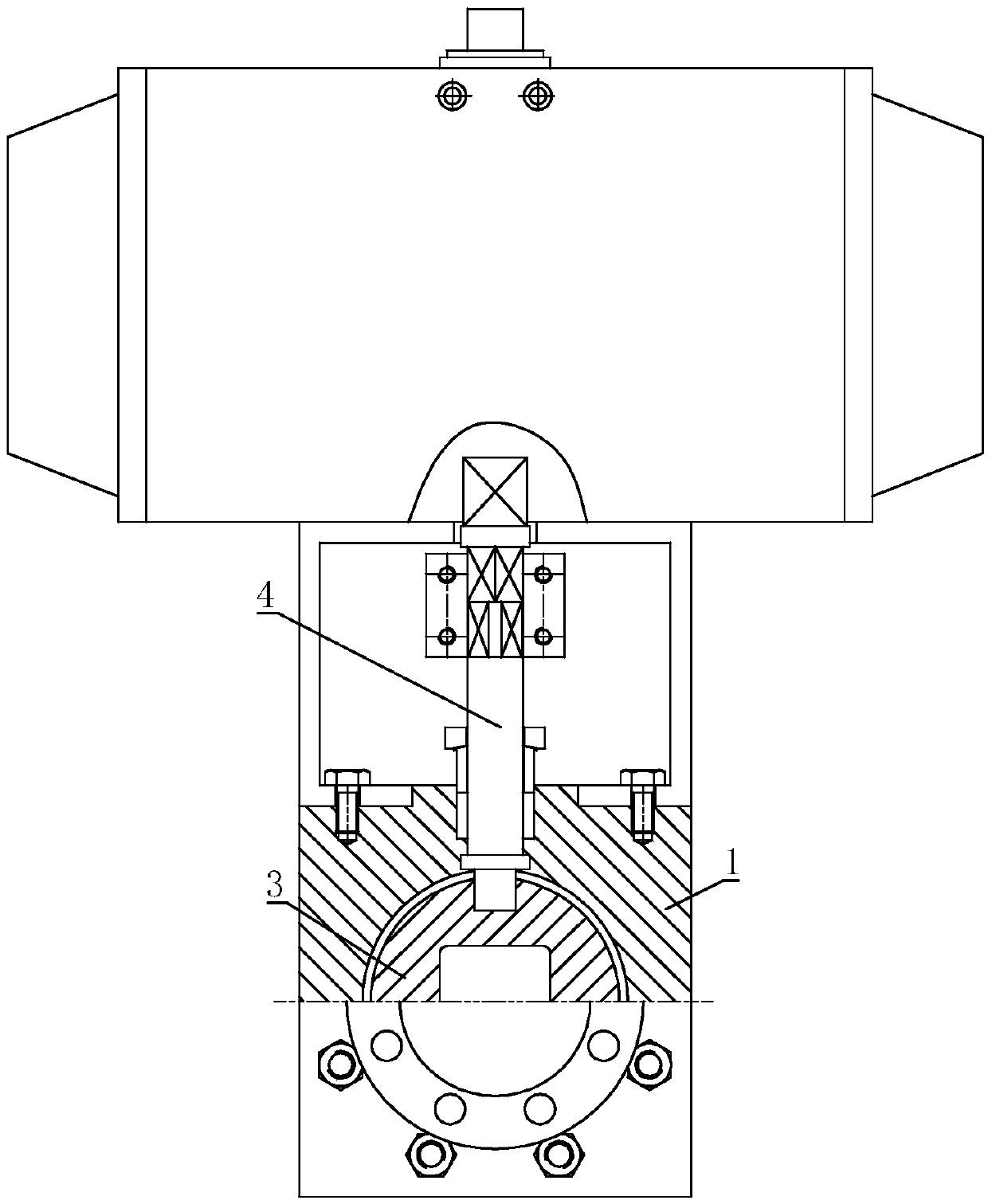

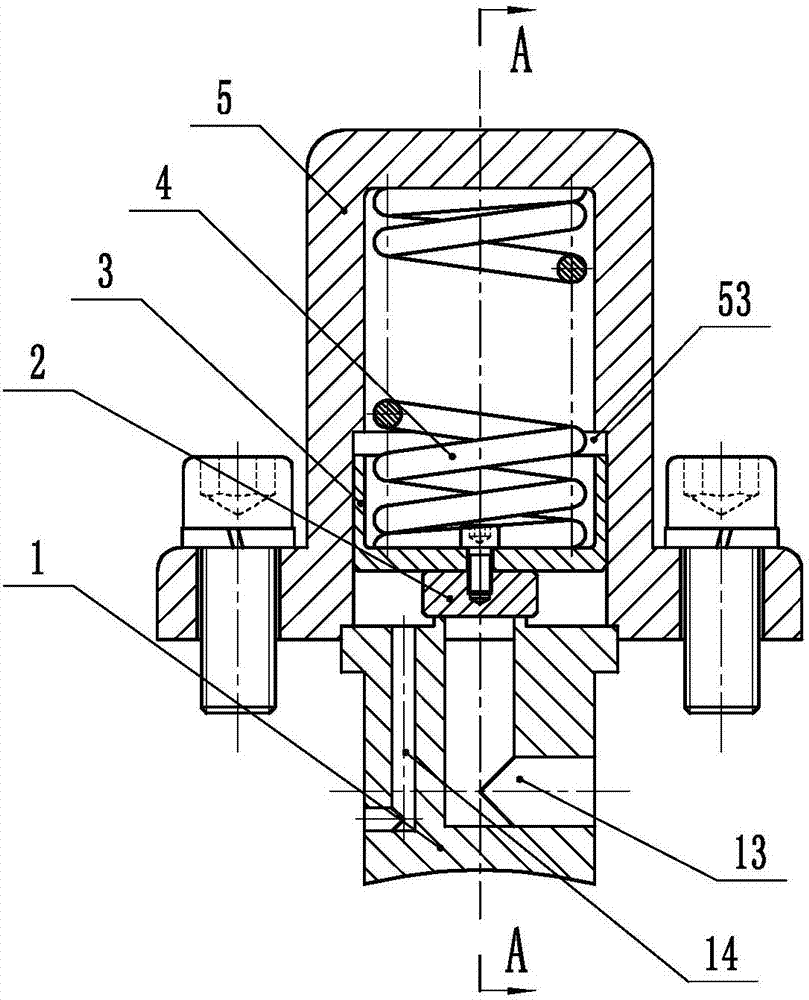

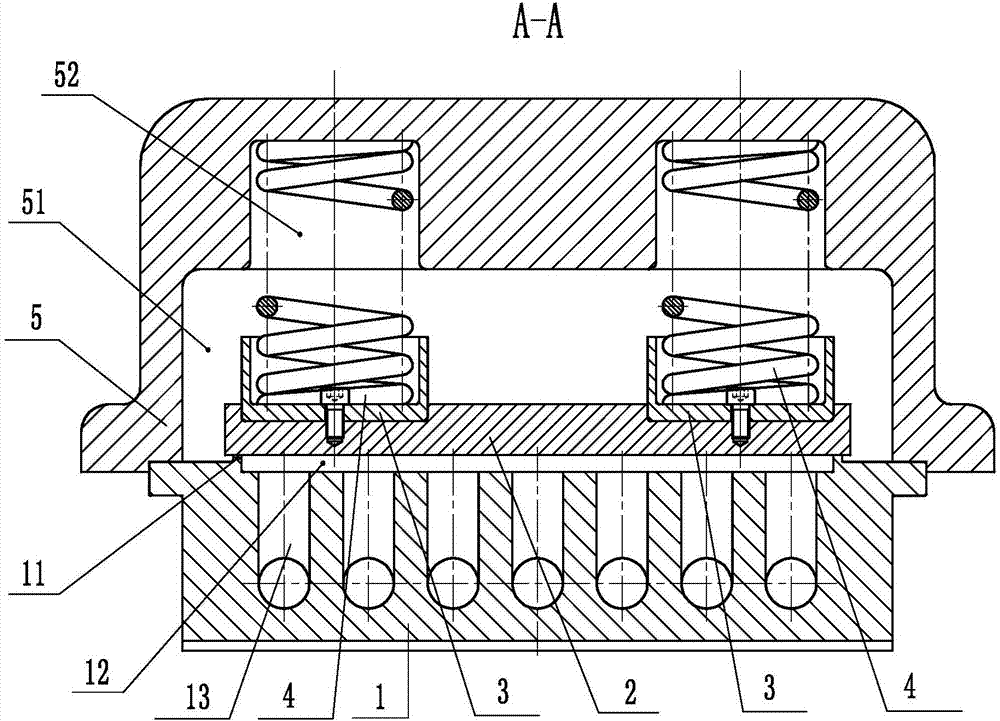

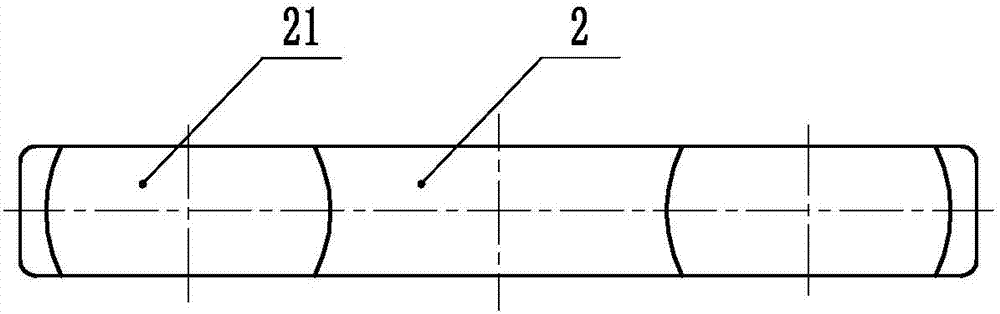

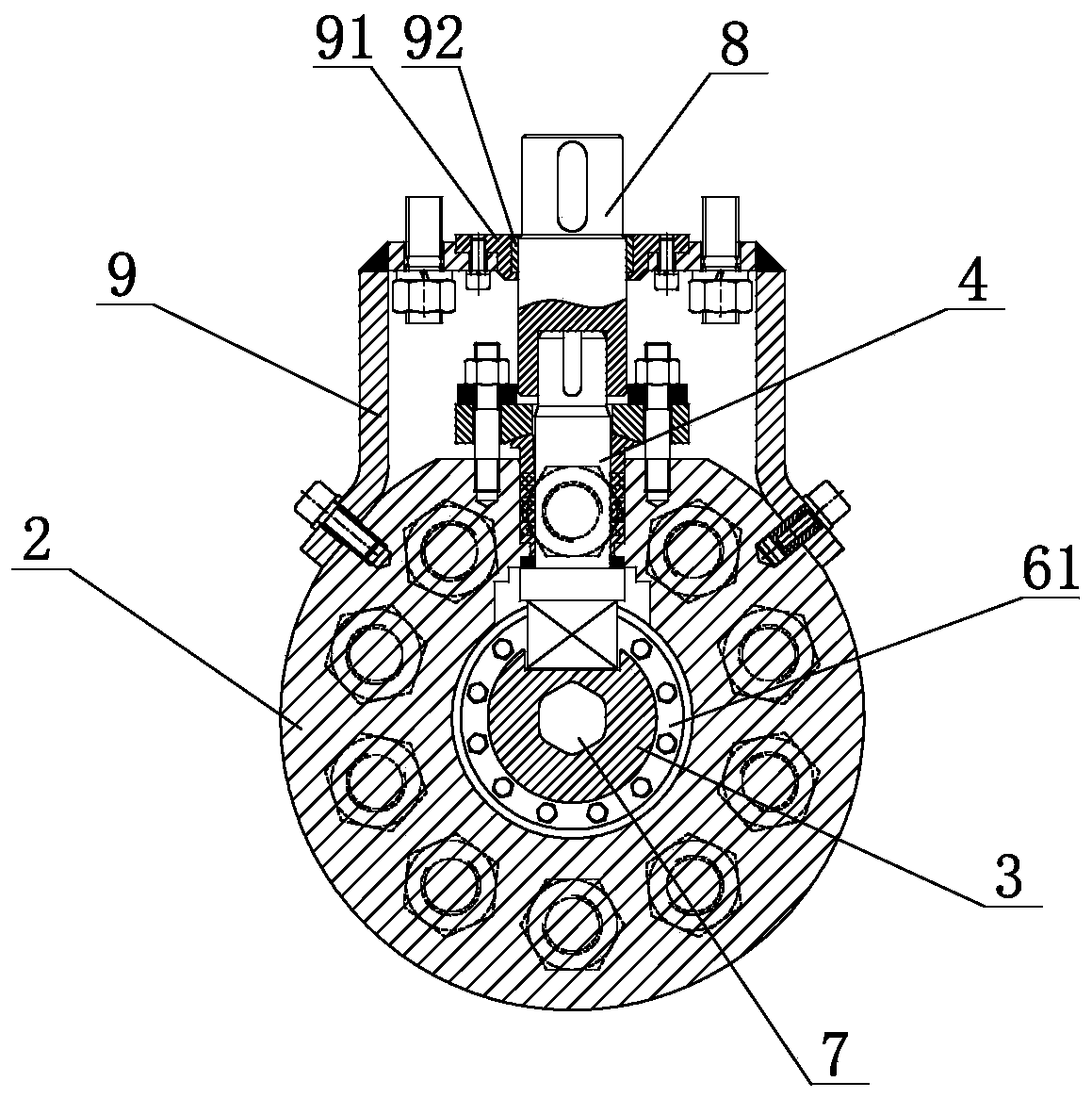

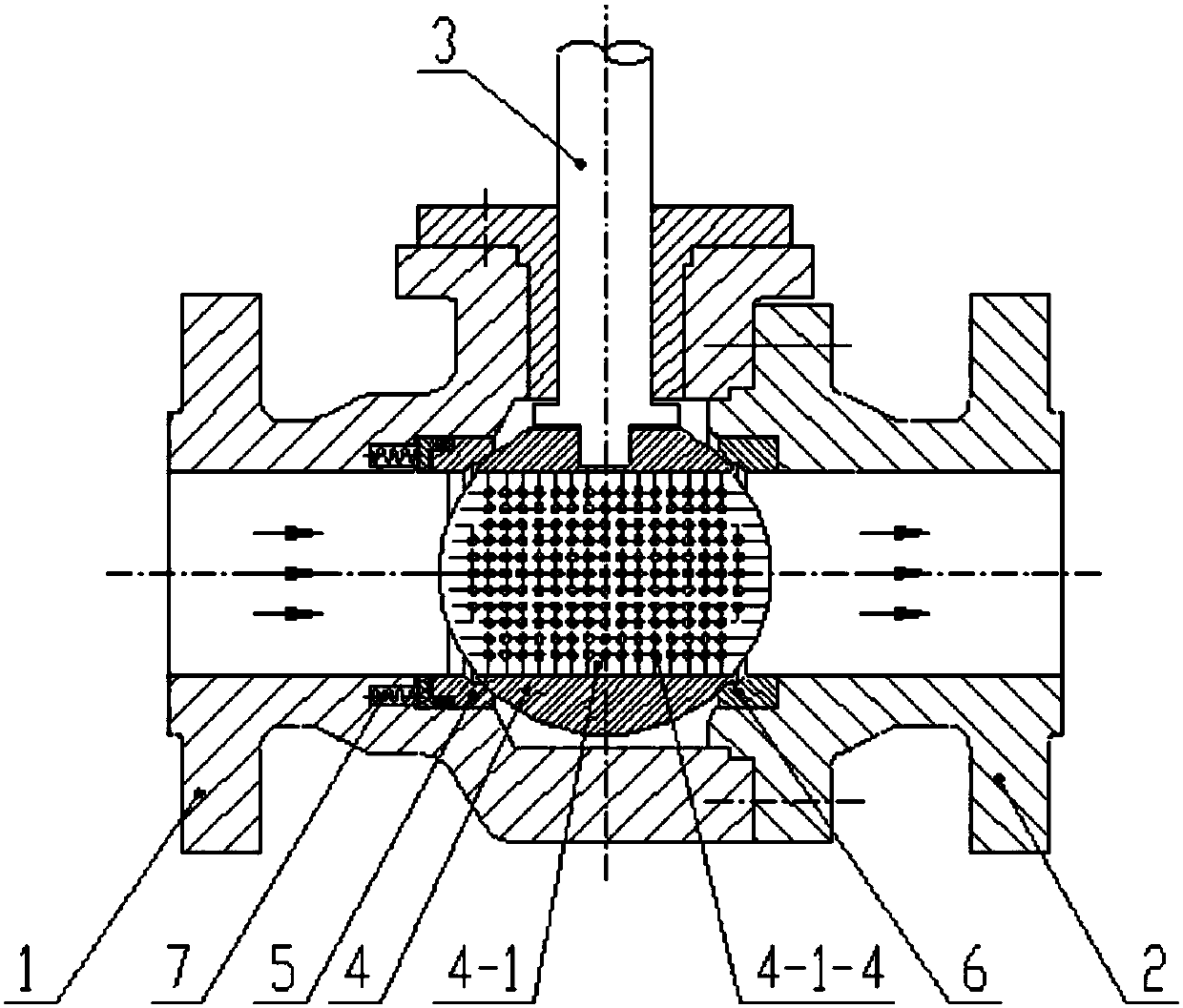

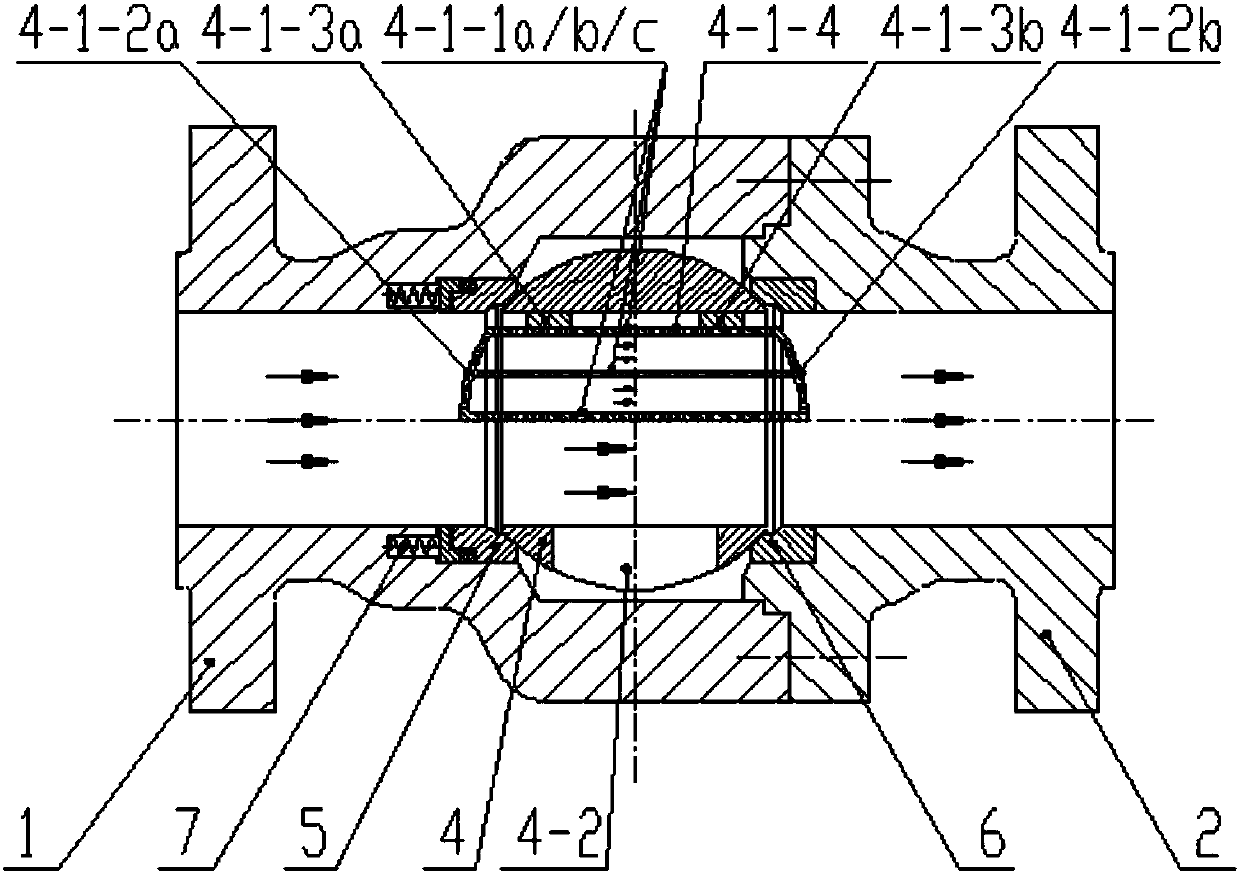

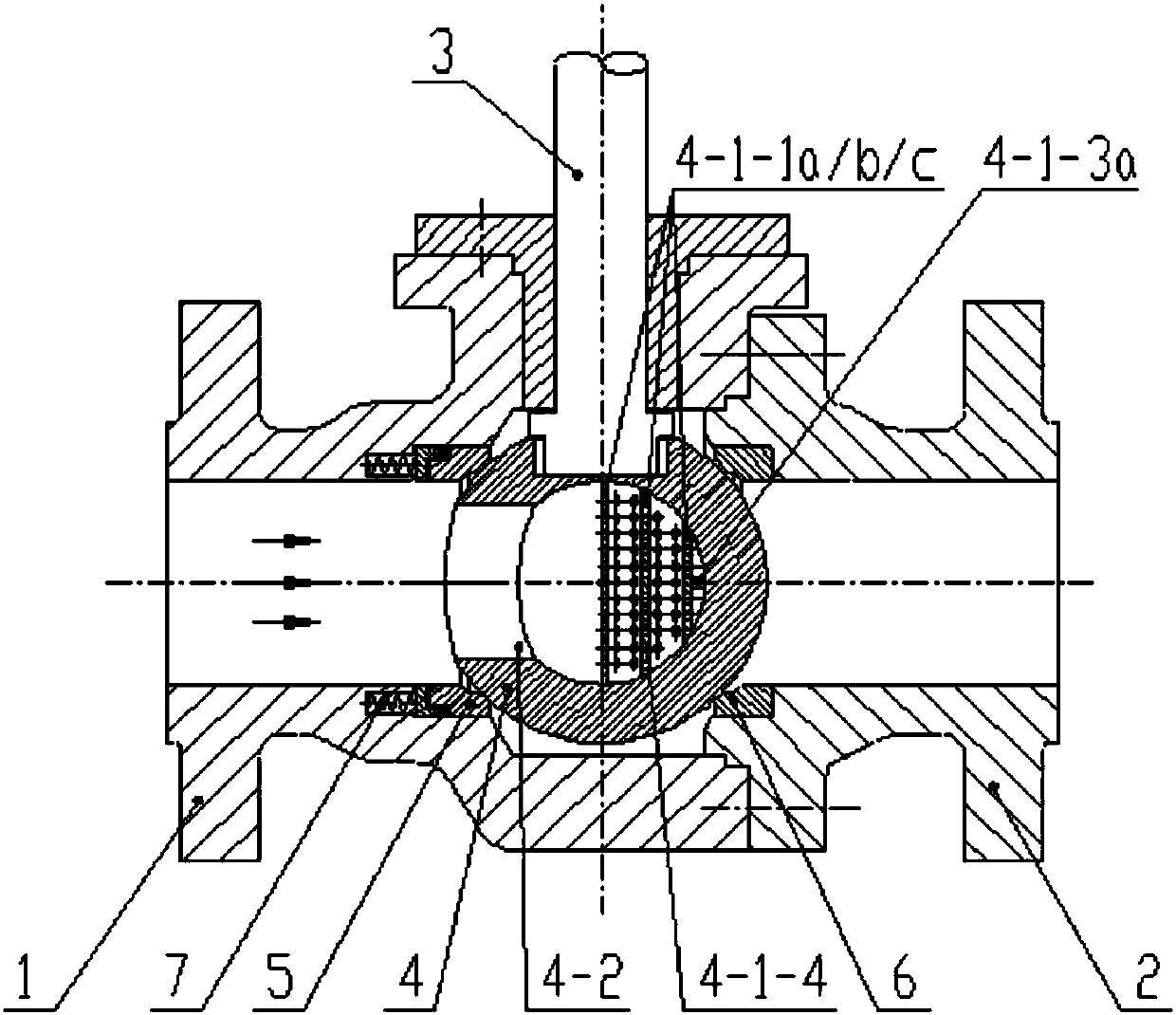

Slurry ball valve

The invention discloses a slurry ball valve and relates to a valve. The slurry ball valve comprises a valve body, a ball and two valve decks arranged on the two opposite sides of the ball. The hole diameters of the ends, close to the ball, of inner holes of the valve decks are larger than the hole diameters of the ends away from the ball, of the inner holes, a valve seat supporting ring is arranged between the valve deck located on the upstream and the ball, a valve seat is arranged at the end, close to the ball, of the valve seat supporting ring, the outer side wall of the valve seat supporting ring is in a stair shape, the outer diameter of the end, close to the ball, of the valve seat supporting ring is larger than the outer diameter of the end, away from the ball, of the valve seat supporting ring, O-shaped sealing rings are arranged on the surfaces of the two side walls, different in outer diameter, of the valve seat bearing ring respectively in the circumferential direction to form two radial sealing faces, a pre-tightening spring is arranged between the valve seat supporting ring and the corresponding valve deck, and the pre-tightening spring is arranged between the upper O-shaped sealing ring and the lower O-shaped sealing ring in the horizontal direction. The pre-tightening spring cannot be stuck by medium crystal substances, washing to the sealing faces by media can be overcome, the abrasion of the ball can be reduced, the service life of the valve can be prolonged, and high practicability is achieved.

Owner:SICHUAN KAITZ VALVE MFG

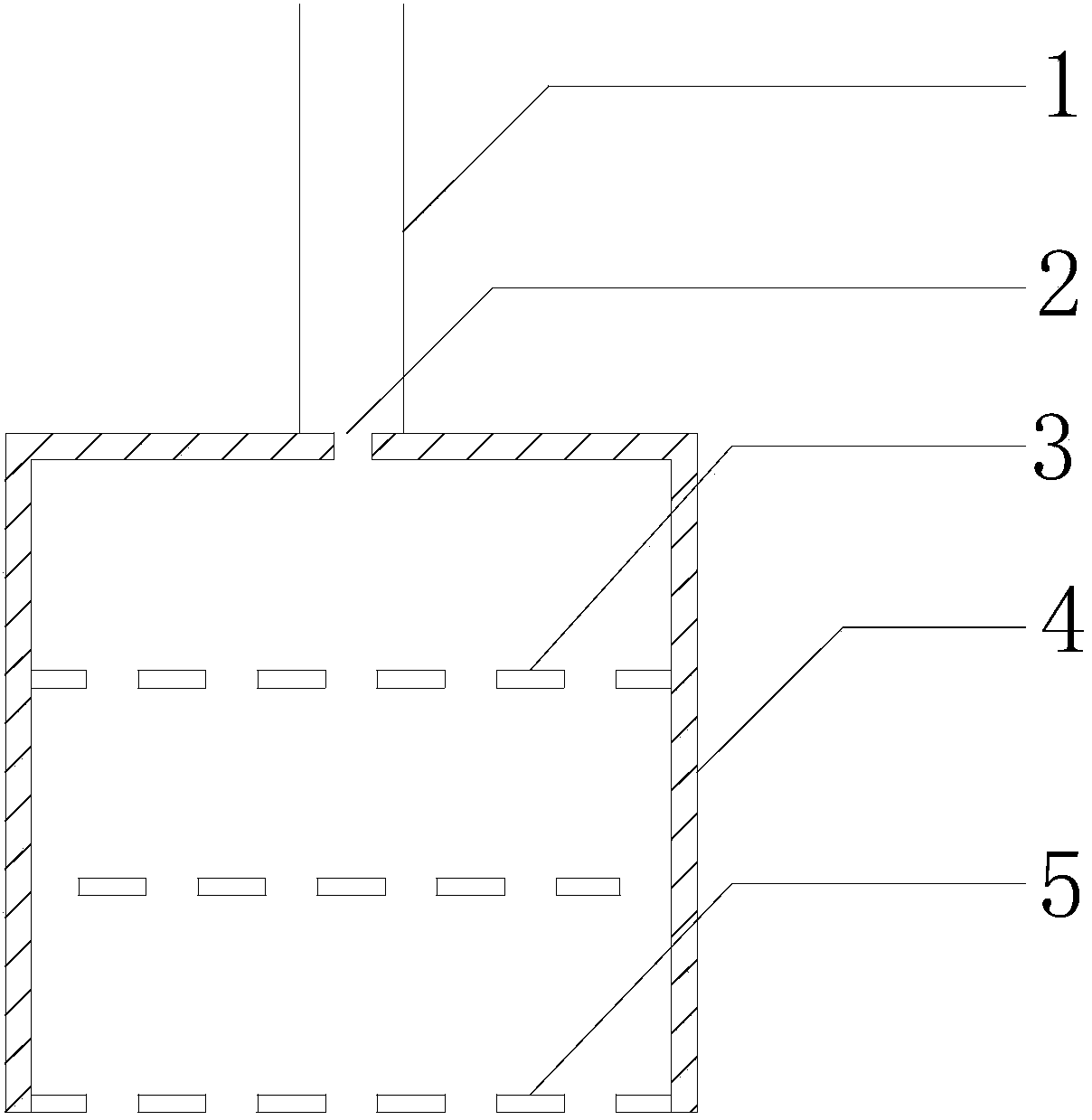

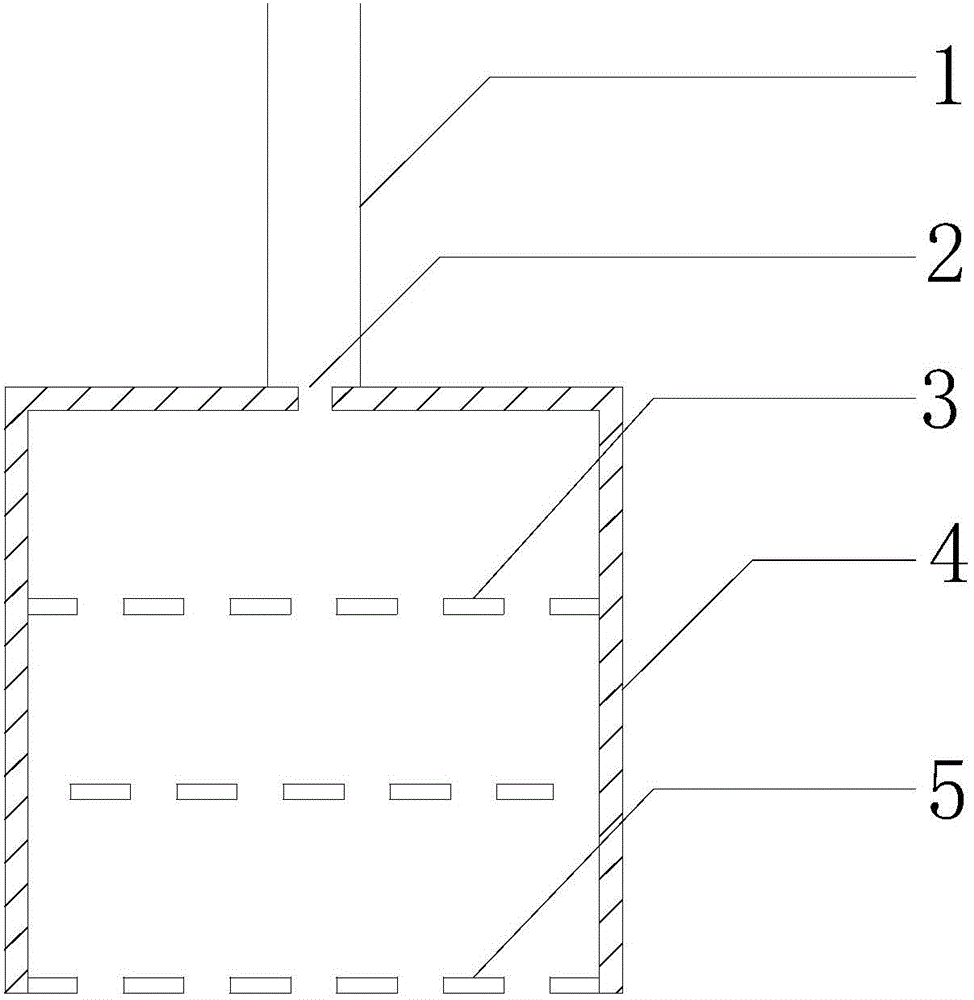

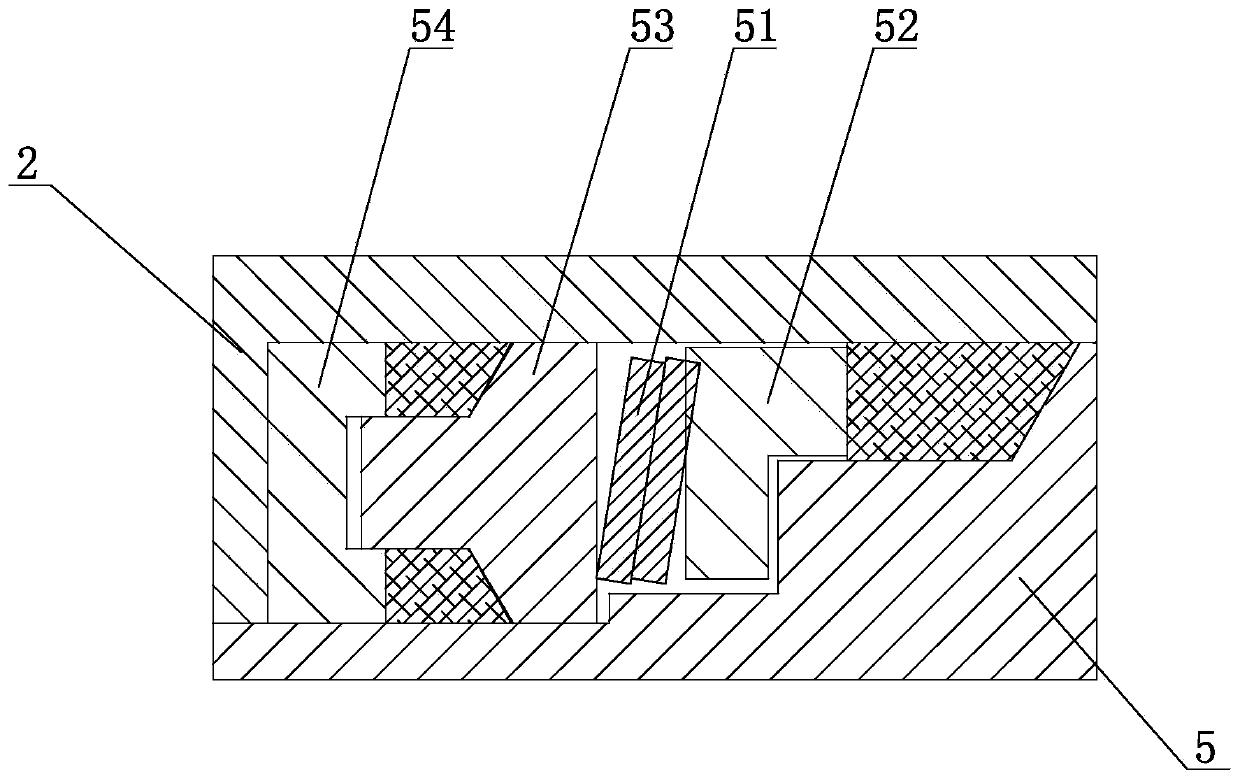

General release source device for building ventilation and smoke exhaust experiment

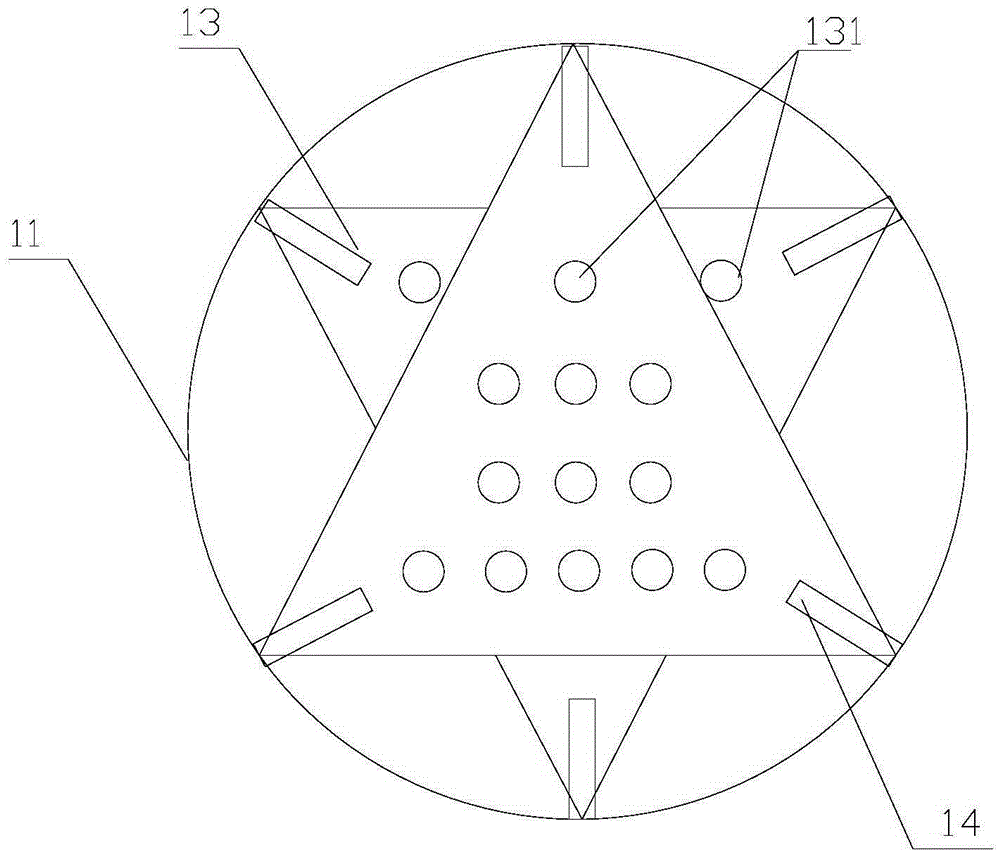

The invention relates to a general release source device for building ventilation and smoke exhaust experiment. The device comprises a medium injection pipe and a buffer cavity, wherein the buffer cavity is connected with the lower end of the medium injection pipe; the cavity wall at the joint of the buffer cavity and the medium injection pipe is provided with a medium injection port; the interior of the buffer cavity is provided with interior flow guide pore plates; the bottom of the buffer cavity is provided with an outlet flow guide pore plate; medium enters the interior of the buffer cavity through the medium injection port from the medium injection pipe and then flows through the interior flow guide pore plates, and flows out from the outlet flow guide pore plate; the medium flowing out from the outlet flow guide pore plate is fluid with low speed and high turbulence. Compared with the prior art, through combined action of the medium injection port and guide holes mutually staggered on the three pore plates, the fluid turbulence is increased while the medium flow speed is reduced, the problem that low speed and high turbulence cannot be achieved at the same time since the initial quantity of motion of a medium flow in a ventilation and smoke exhaust medium experiment is not zero is solved, and the error of the experiment is greatly reduced.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD +1

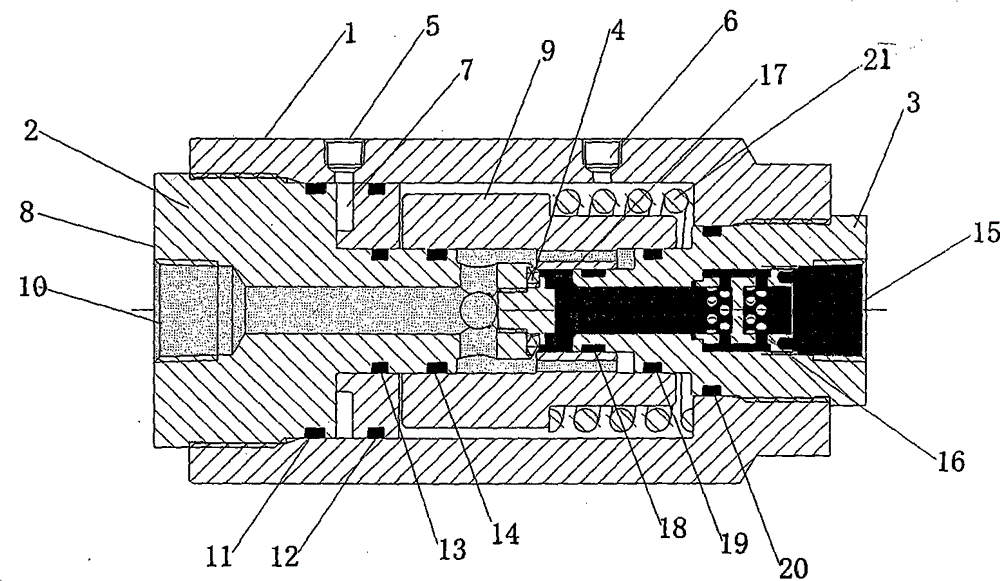

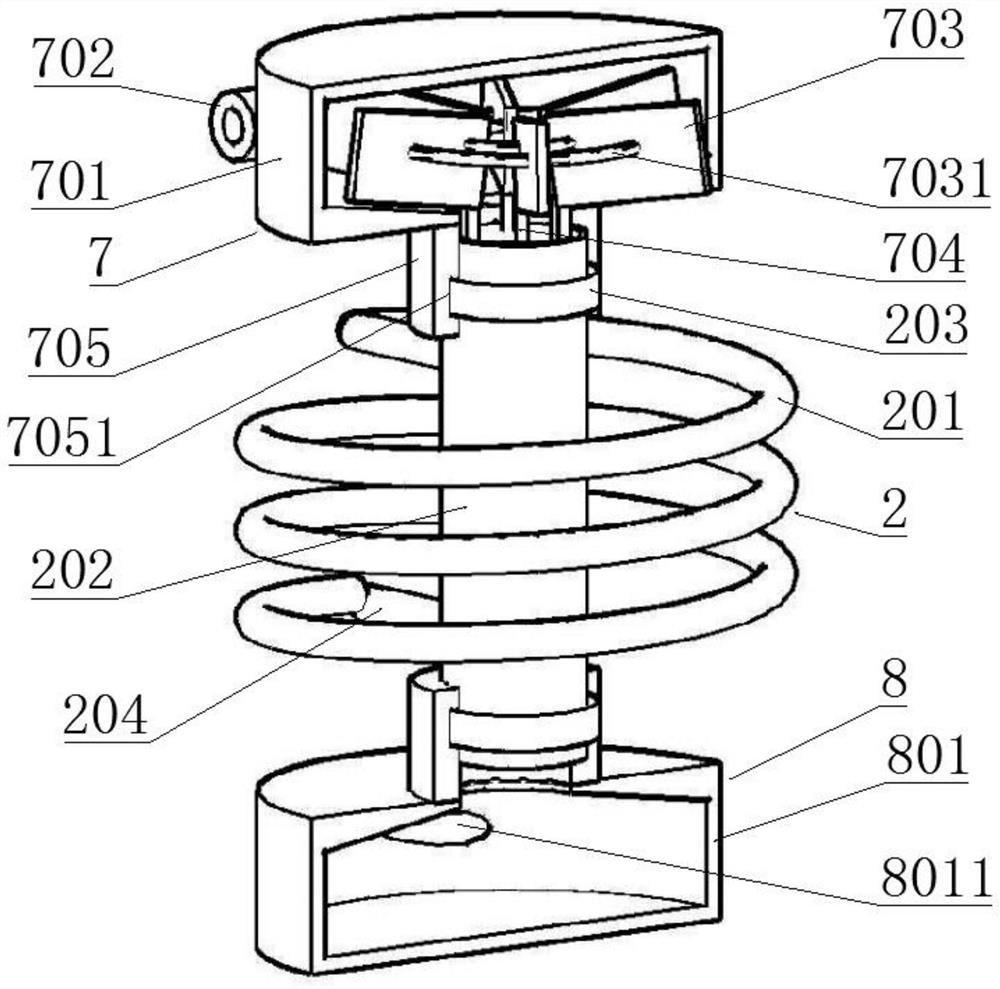

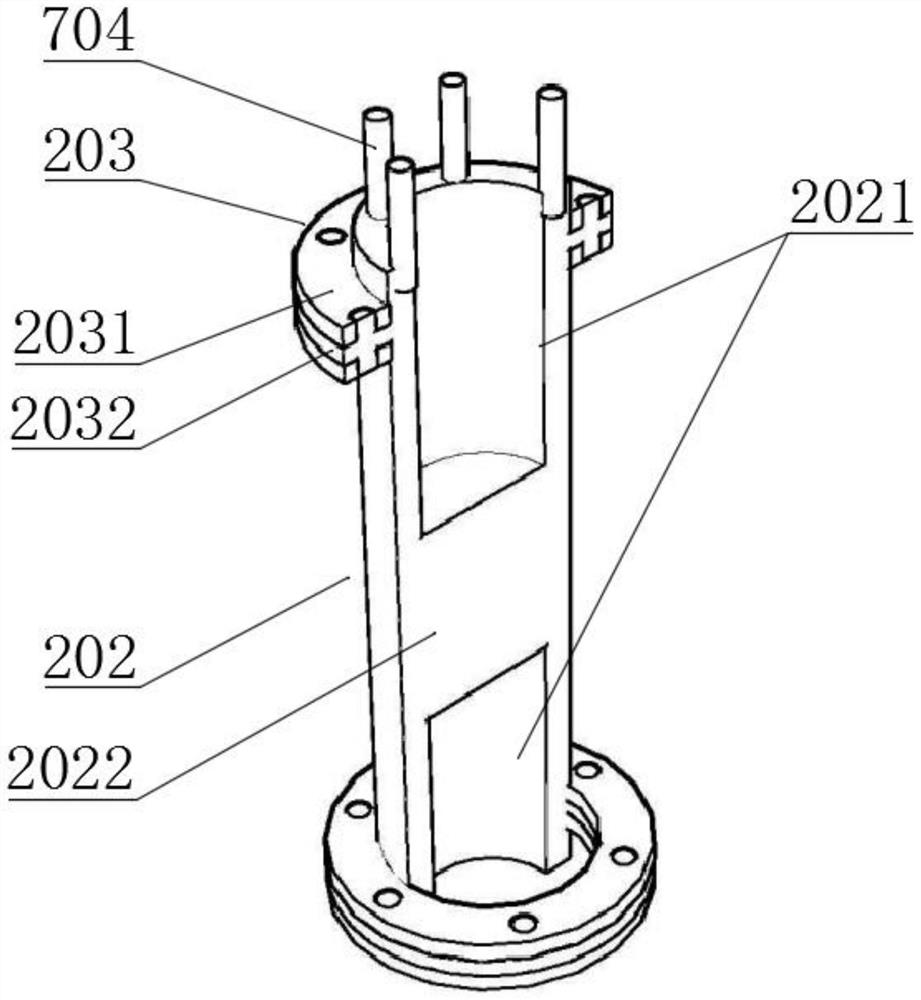

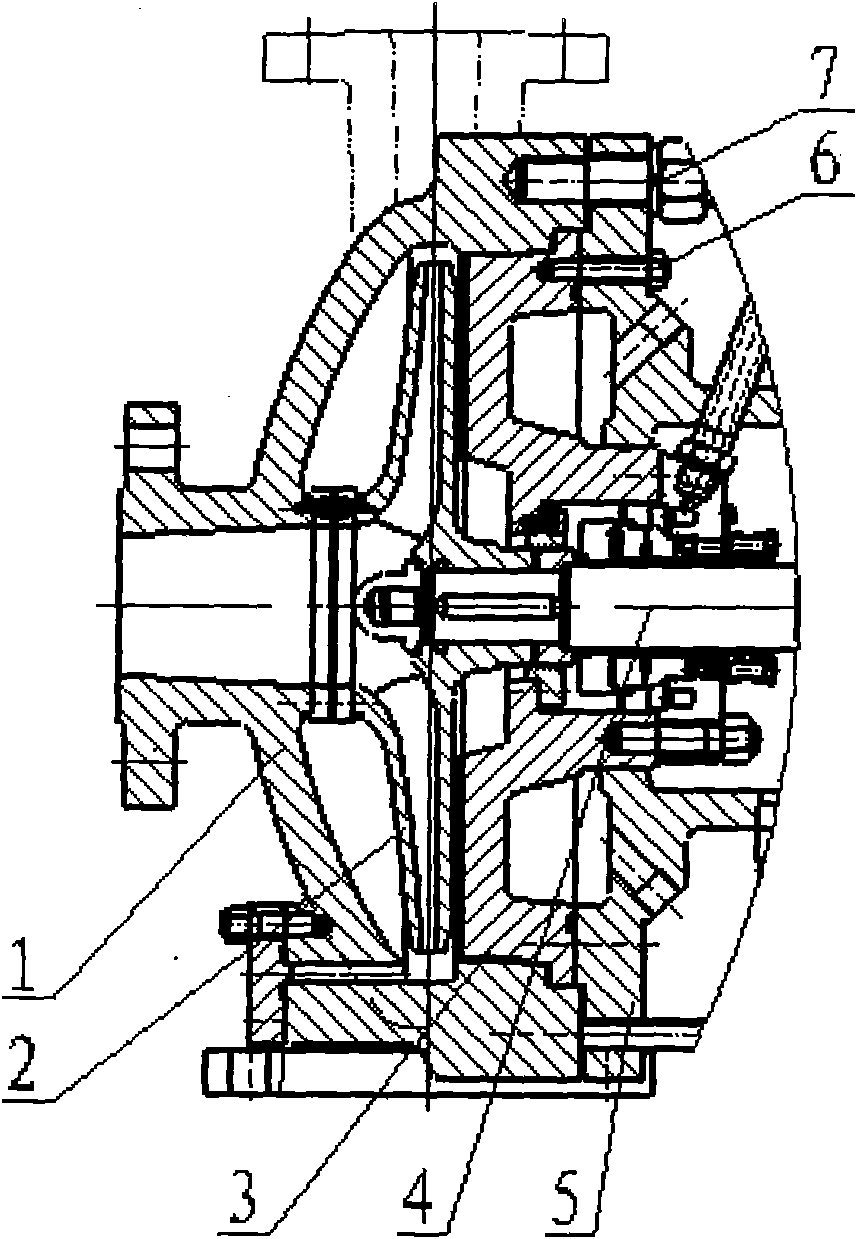

Axial-flow type pneumatic control balancing stop valve

InactiveCN105508673ASolution to short lifeSensitive opening and closingValve members for absorbing fluid energyEqualizing valvesEngineeringValve seat

The invention discloses an axial-flow type pneumatic control balancing stop valve which comprises a shell, wherein a valve seat assembly is arranged at one side in the shell, an outlet B is formed at one side of the valve seat assembly, a movable valve seat is arranged at the other side of the valve seat assembly, a movable valve is arranged in the movable seat assembly, a knot is arranged at one side of the movable valve, and a sealing pad is arranged at the end part of the knot. According to the design of the invention, axial-flow type design is adopted, the structure is compact, and required mounting space is small. The valve seat of existing stop valves on the market are all fixed, while the movable valve seat with a balancing hole, adopted by the stop valve disclosed by the invention, is long in life and flexible and reliable in opening and closing.

Owner:HENAN AEROSPACE HYDRAULIC & PNEUMATIC TECH

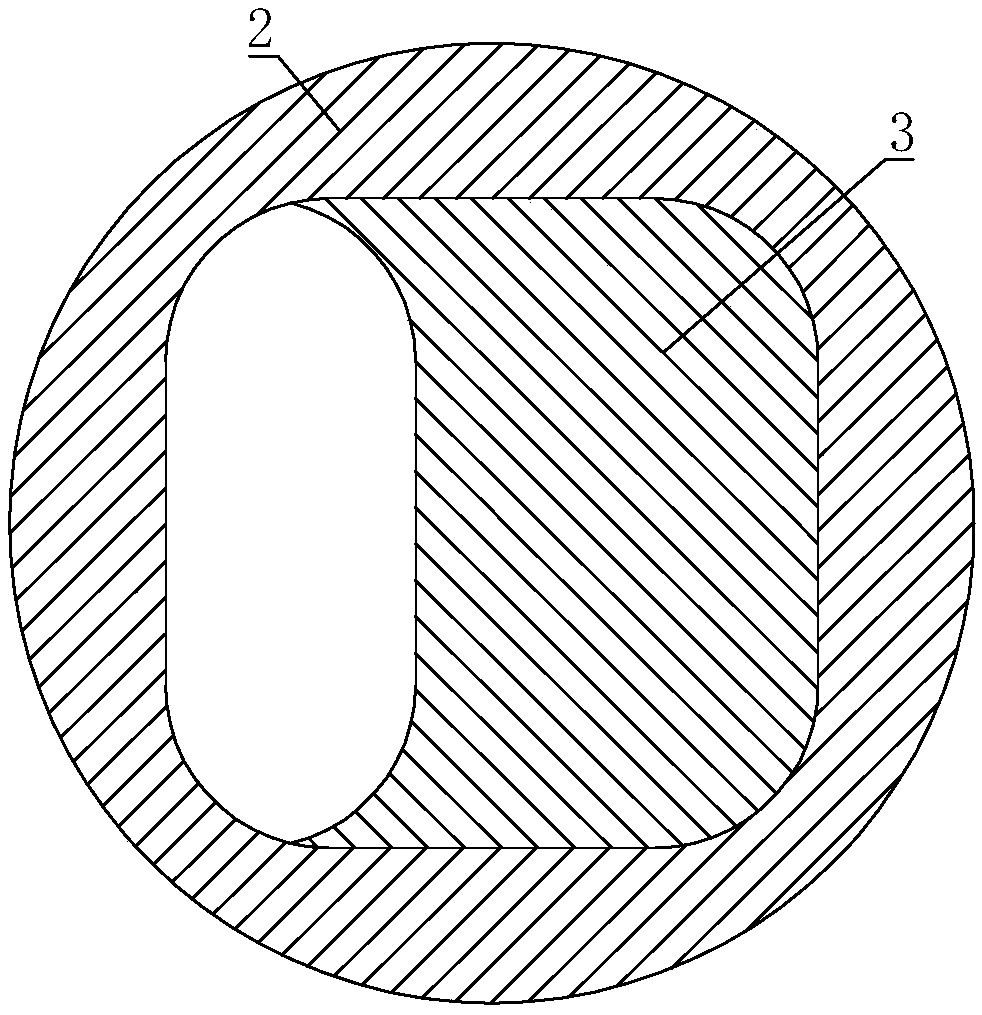

Square hole flow channel wear-resistant fine-adjustment ball valve

The invention relates to the field of ball valves, in particular to a square hole flow channel wear-resistant fine-adjustment ball valve. According to the technical scheme, the square hole flow channel wear-resistant fine-adjustment ball valve comprises a valve body; a valve seat is mounted in the valve body; a ball body is arranged in the valve seat in a sleeved manner; a valve rod is connected to the ball body and arranged in the valve body in a sleeved manner; the ball body and the valve seat are each internally provided with a square hole; and the square hole of the ball body and the square hole of the valve seat are both horizontally formed. By means of the square hole flow channel wear-resistant fine-adjustment ball valve, scouring to which a ball body flow channel and a valve seat flow channel is subjected is reduced, the open degree is adjusted linearly, the rotating angle of the ball body is small in the switching-on and switching-off process, and the scouring time is shortened; and the problems that an existing ball valve is scoured severely, and the open degree cannot be adjusted linearly are solved.

Owner:成都斯杰化工机械有限公司

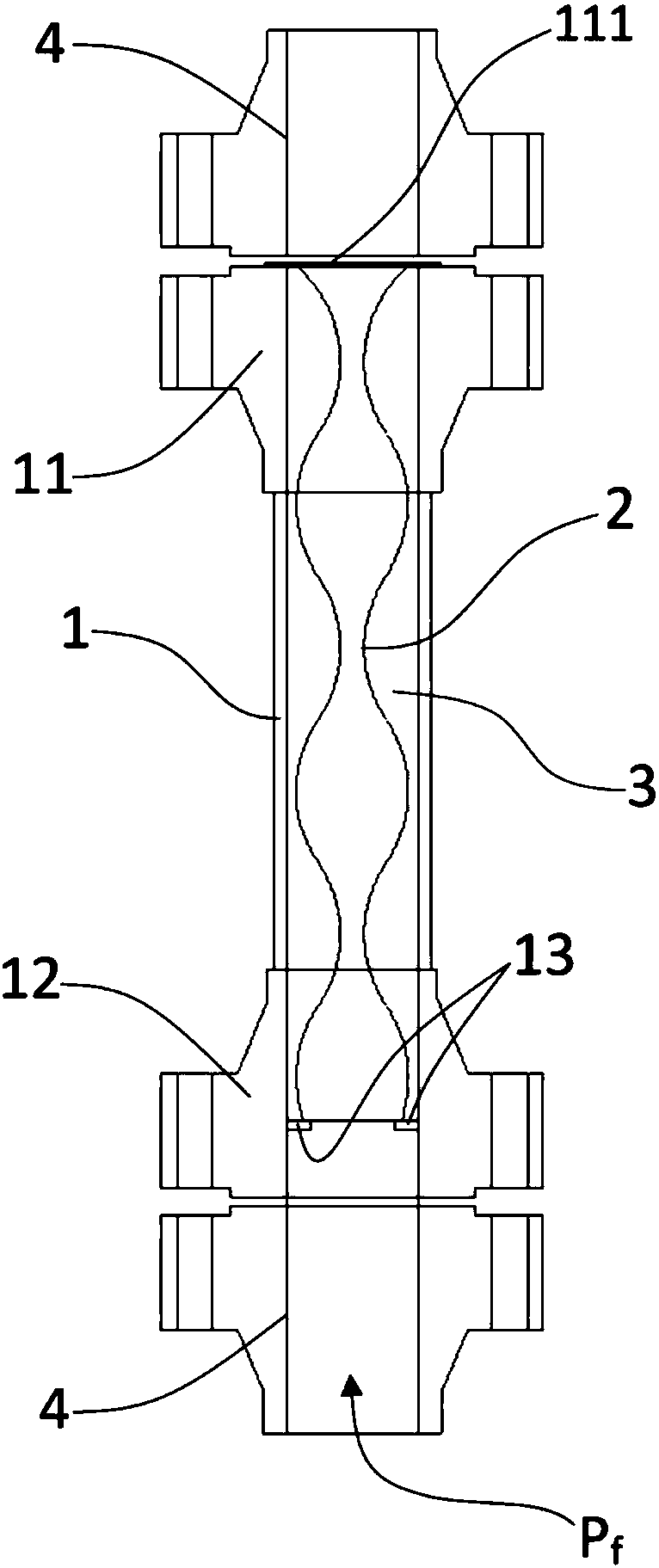

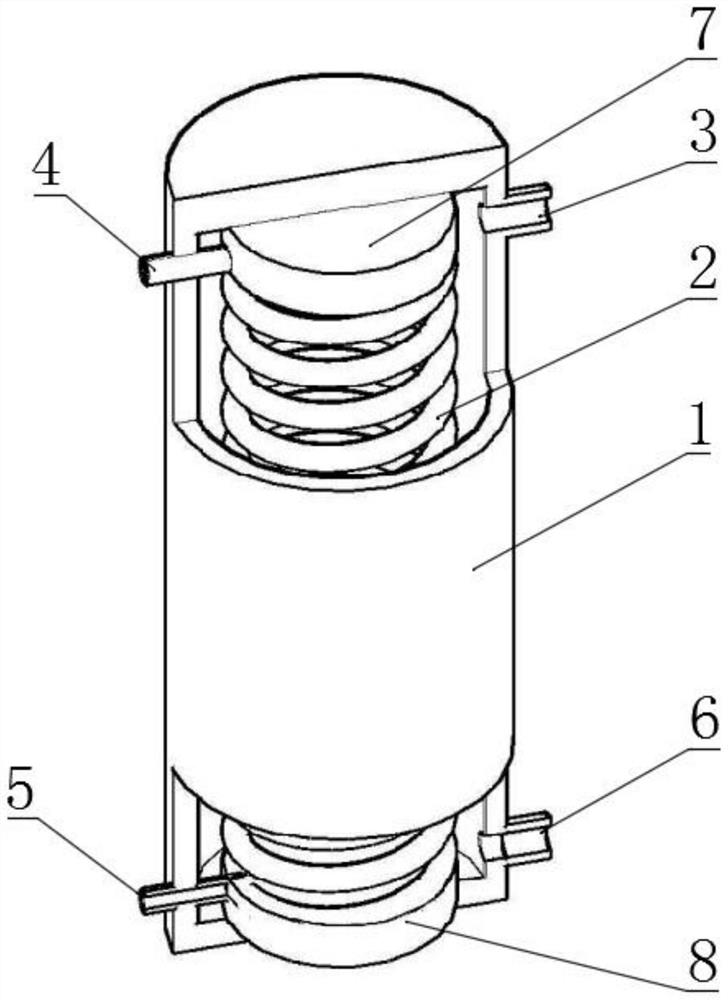

Wear-resistant multi-stage pressure reduction mechanism and application method thereof

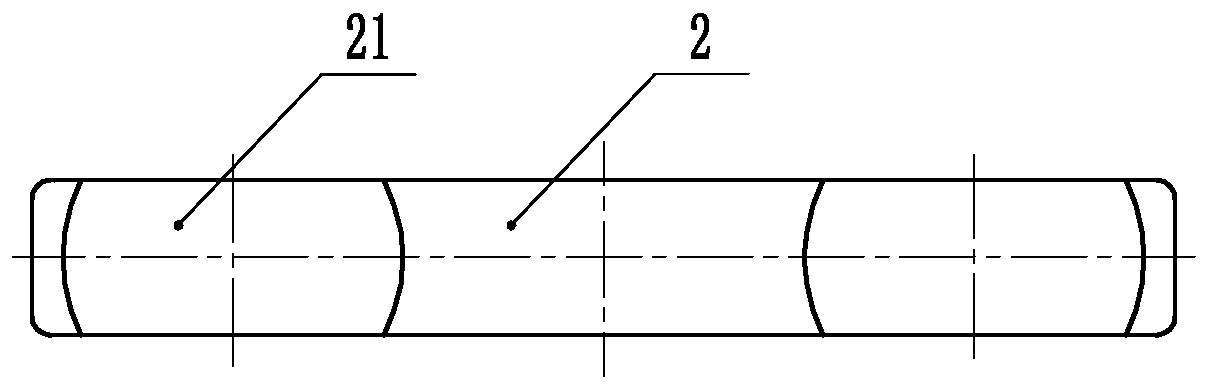

PendingCN107940054AExtended operating cycleReduced operating differential pressureEqualizing valvesSafety valvesWear resistantPressure difference

An embodiment of the invention provides a wear-resistant multi-stage pressure reduction mechanism. The wear-resistant multi-stage pressure reduction mechanism comprises an outer cylinder and an innercylinder, wherein the outer cylinder and the inner cylinder are connected in a sleeving mode, and a cavity is formed between the inner cylinder and the outer cylinder. A first connecting portion and asecond connecting portion are installed at the upper end and the lower end of the outer cylinder correspondingly, and locating plates are arranged on the inner side of the lower end of the outer cylinder. The inner cylinder is connected between the locating plates and the first connecting portion, and the two ends of the cavity are sealed by the locating plates and the first connecting portion correspondingly. The value of the inner diameter of the inner cylinder is repeatedly changed in the axial direction. When the wear-resistant multi-stage pressure reduction mechanism is connected to a pipeline, fluid circulates on the inner side of the inner cylinder. The embodiment of the invention further provides an application method of the wear-resistant multi-stage pressure reduction mechanism.Due to the fact that the wear-resistant multi-stage pressure reduction mechanism is installed on the downstream portion of a pressure reducing valve, the operating pressure difference of the pressurereducing valve can be remarkably reduced, the remaining pressure difference of a system is borne by the wear-resistant multi-stage pressure reduction mechanism, the flow velocity of media at the position of a valve element of the pressure reducing valve is remarkably reduced, the wear of the valve element is greatly reduced, the running period of the high-grade special pressure reducing valve issubstantially prolonged, and the wear of a pipeline located behind the valve is effectively reduced.

Owner:SHANGHAI HOTO PETROCHEM ENG +1

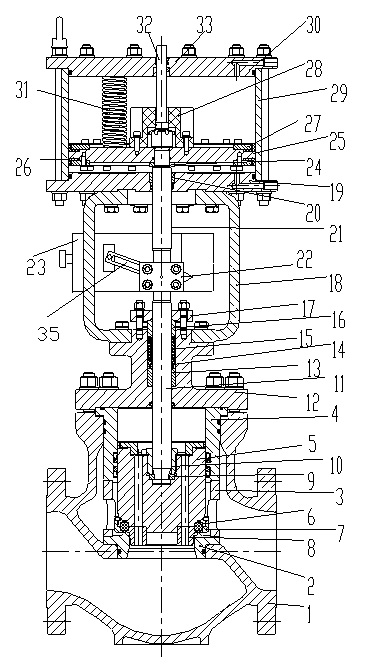

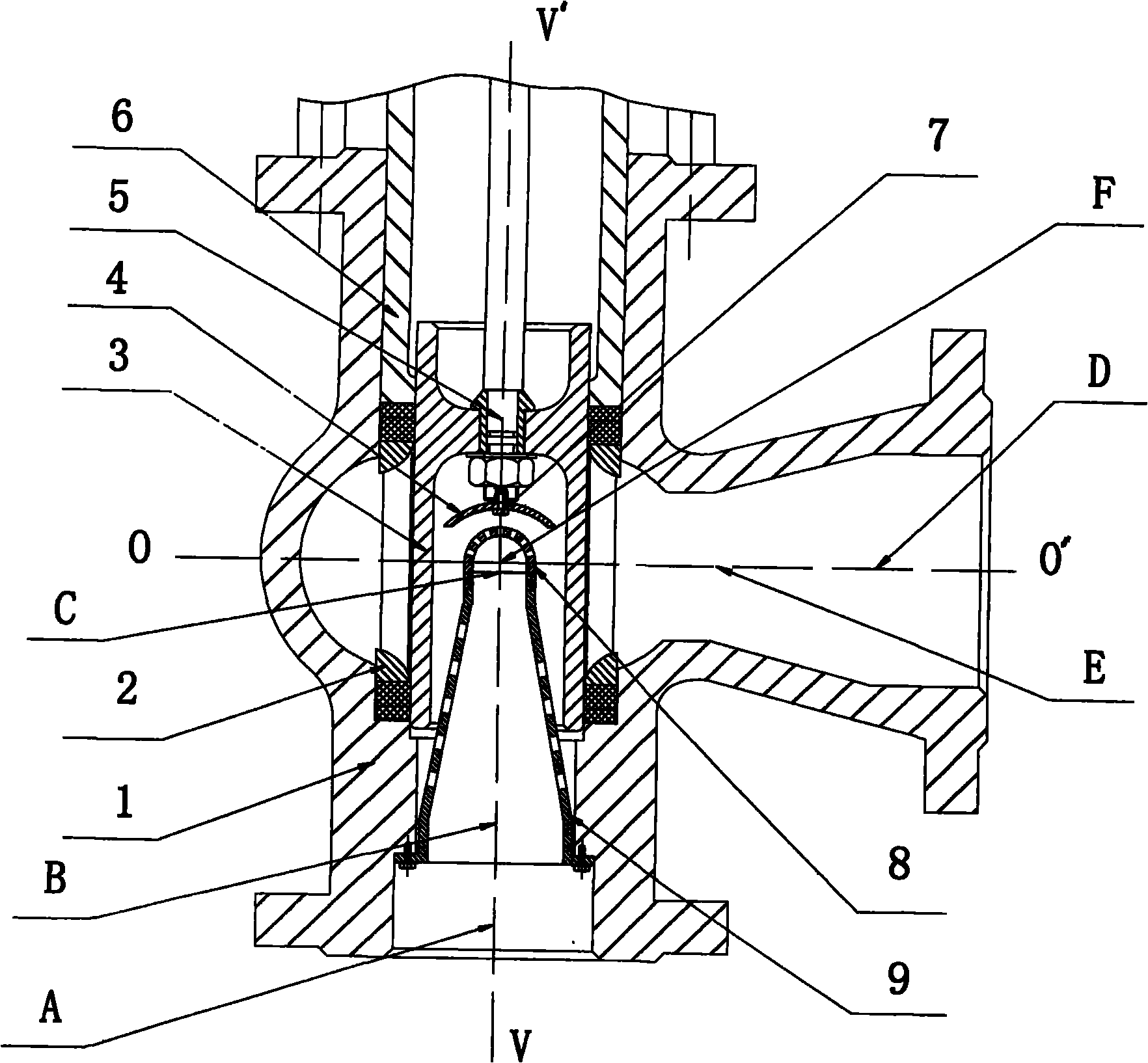

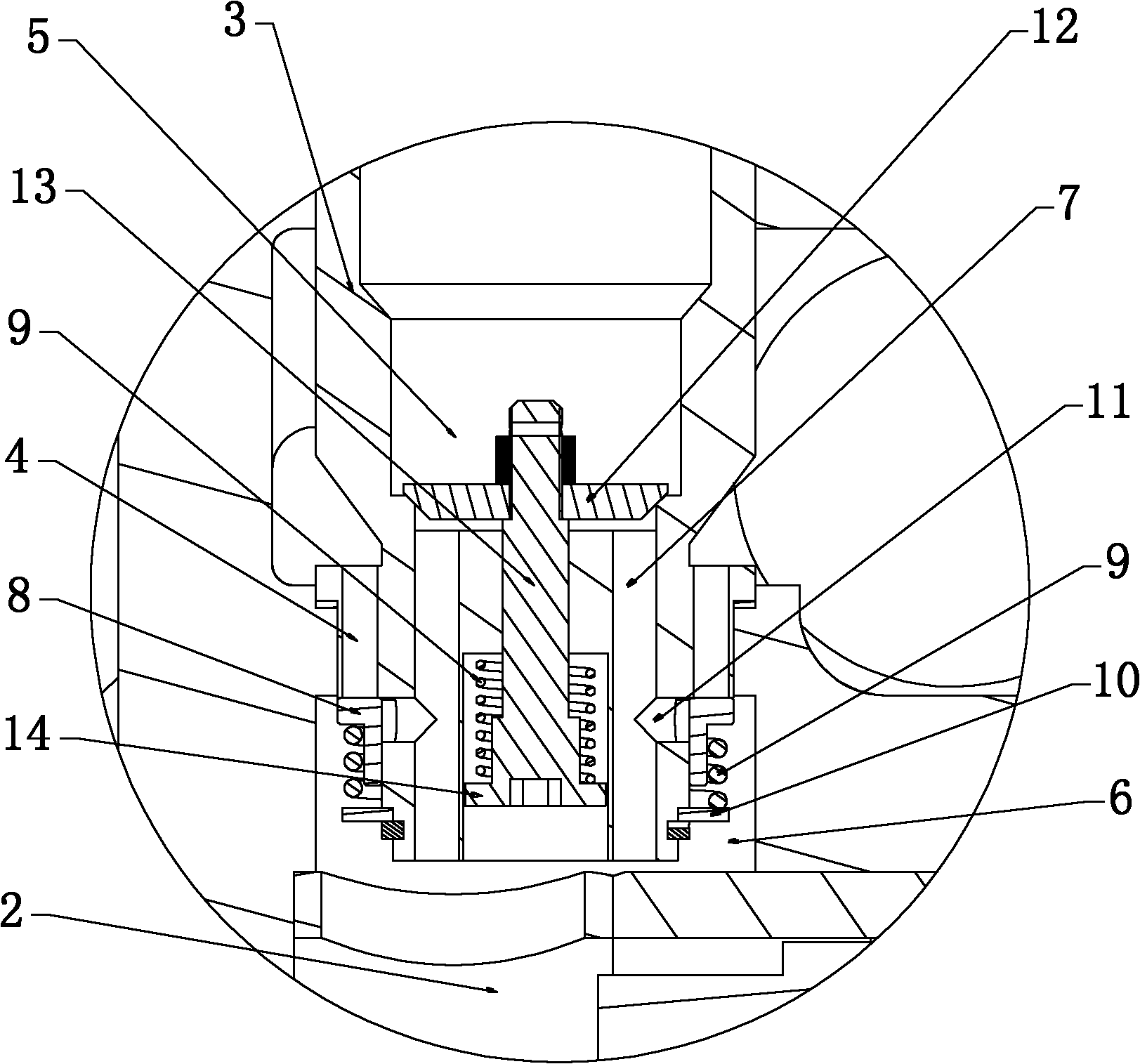

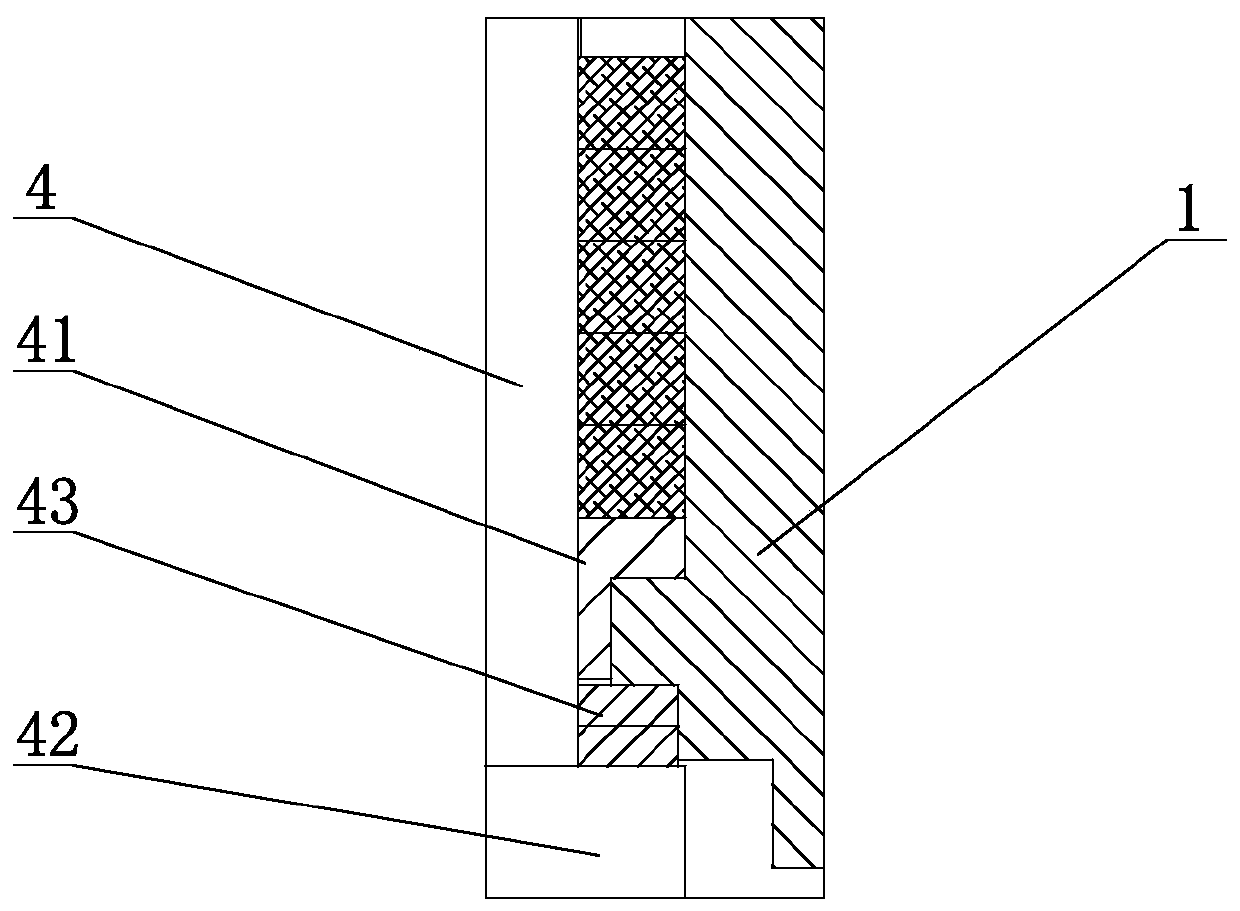

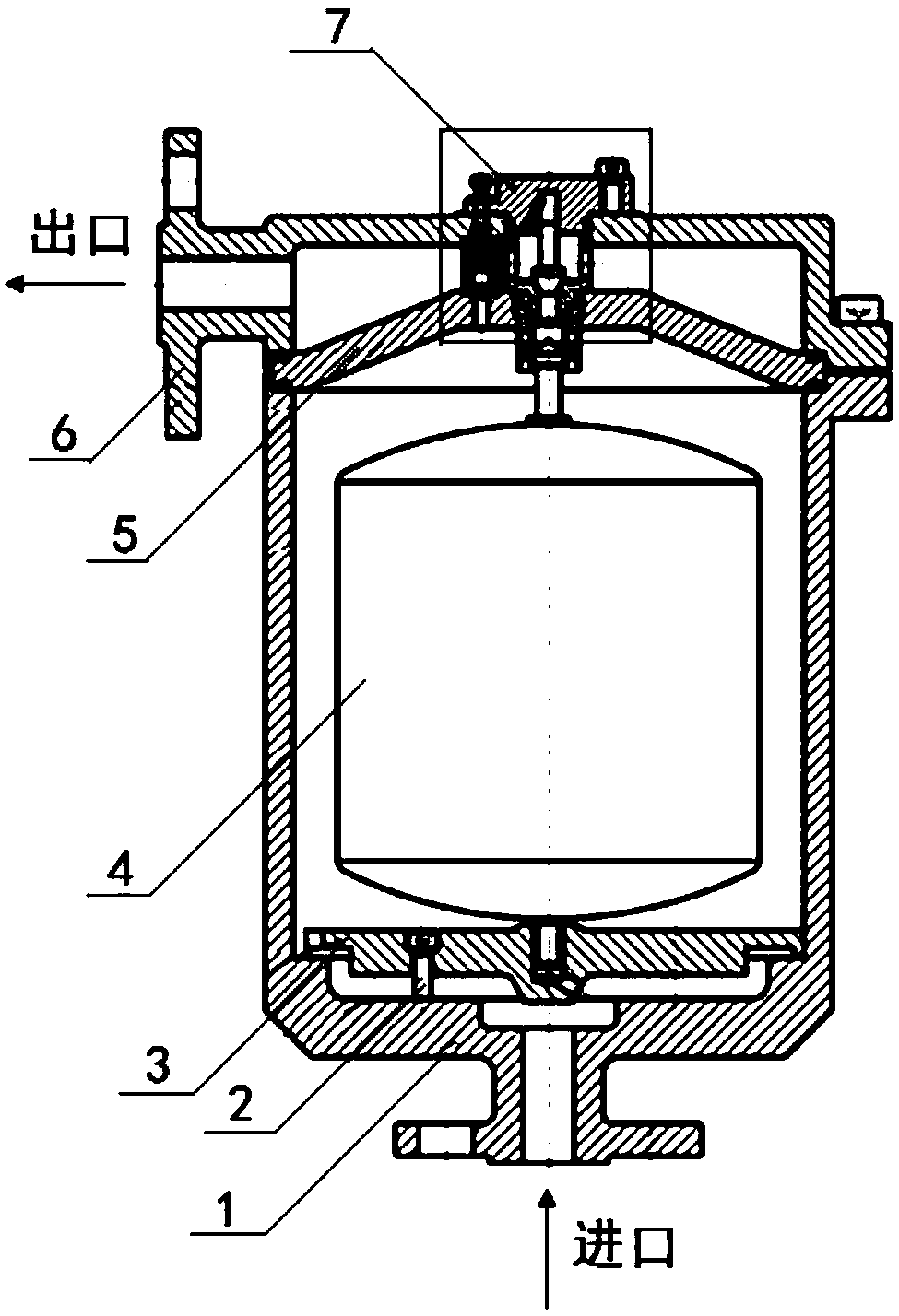

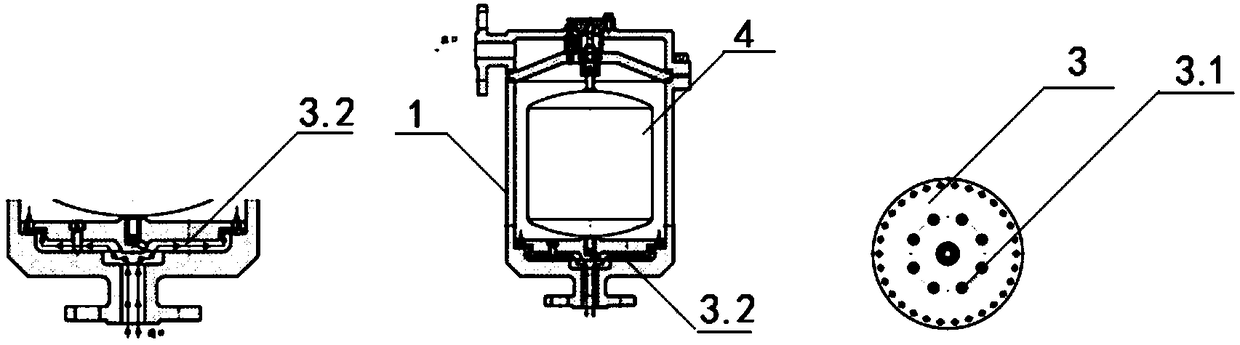

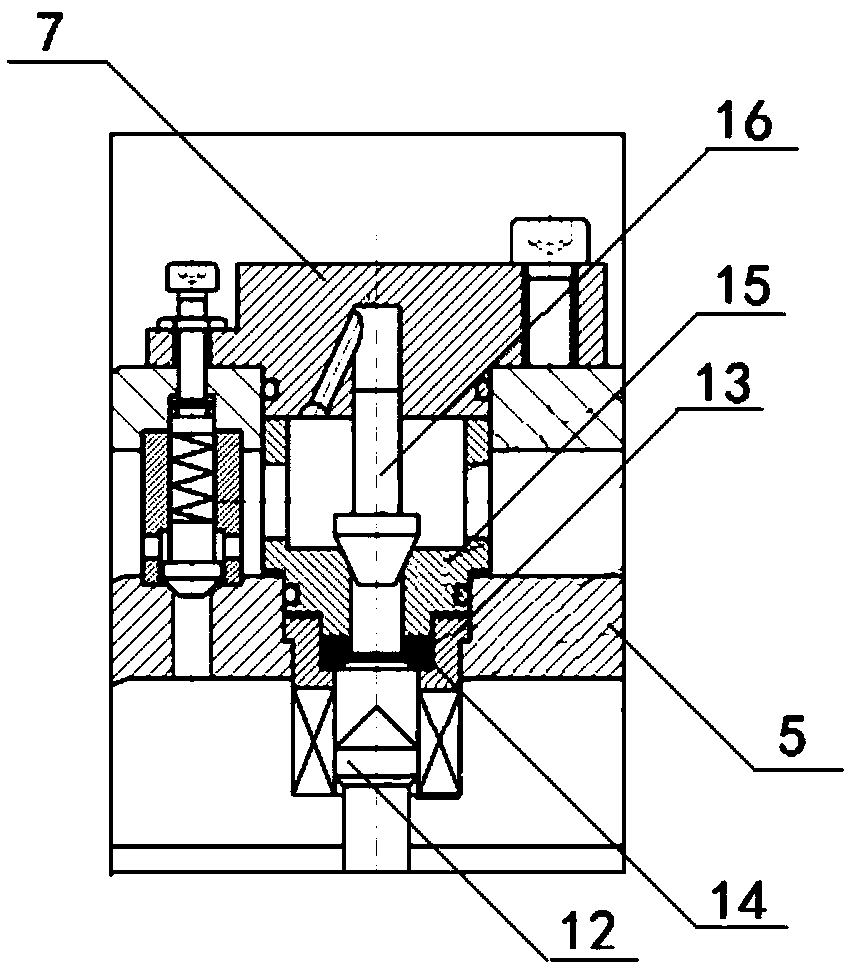

Expansion valve

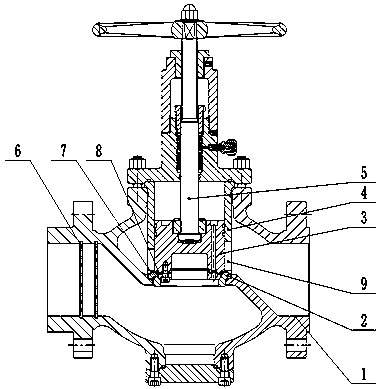

InactiveCN101818826AIncreased turbulenceIncrease spawn rateOperating means/releasing devices for valvesValve members for absorbing fluid energyEnergy lossVALVE PORT

The invention discloses an expansion valve, which comprises a valve body 1. A combined sealing ring 2 and a plunger piston 3 for controlling medium flow are arranged in a cavity inside the valve body 1; the upper part of the combined sealing ring 2 is provided with a valve cover 6 for positioning the combined sealing ring 2, and the valve cover 6 is fixedly arranged on the valve body 1; a valve rod assembly 5 is arranged on the plunger piston 3, and the lower part of the valve rod assembly 5 is provided with a condensate baffle plate 4; a conical intercepting screen 9 is arranged at a lower medium inlet A of the valve body 1, and the upper end of the conical intercepting screen 9 is provided with a hemispherical steam screen 8. By simplifying the internal structure of the expansion valve and a control element, the expansion valve reduces the medium flowing energy loss, has large treatment amount of refrigerating medium, simplifies a driving control device, and is convenient to maintain and operate.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

An air energy water heater

ActiveCN110793200BGuaranteed thermal conductivityReduce adhesionFluid heatersEngineeringWater heater

The invention provides an air energy water heater, and relates to the field of water heaters. The air energy water heater comprises a heat exchange box, wherein a heat exchange tube is arranged in theheat exchange box; the top end of the heat exchange tube is fixedly connected to a first rotary mechanism; the heat exchange tube communicates with the inner part of the rotary mechanism; the first rotary mechanism is fixedly arranged in the heat exchange box; the bottom end of the heat exchange tube is fixedly connected to a second rotary mechanism; and the second rotary mechanism is fixedly arranged in the heat exchange box. In the air energy water heater, the heat exchange tube rotates to generate friction with water, so that attachment of water scales is reduced, heat conduction of the heat exchange tube is guaranteed, water molecule motion speed can be increased, and therefore, heat exchange efficiency is improved, flowing time, in the heat exchange tube, of a medium is shortened, and the high-temperature medium is in sufficient contact with a heat exchanger to improve heat exchange degree; meanwhile, the medium can be sufficiently liquefied after releasing energy, so that a throttle device connected behind the heat exchanger is protected; and a connecting shaft is kept in sealing with the first rotary mechanism and the second rotary mechanism through a sealing ring.

Owner:浙江德富新能源技术有限公司

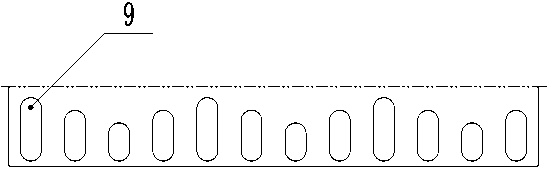

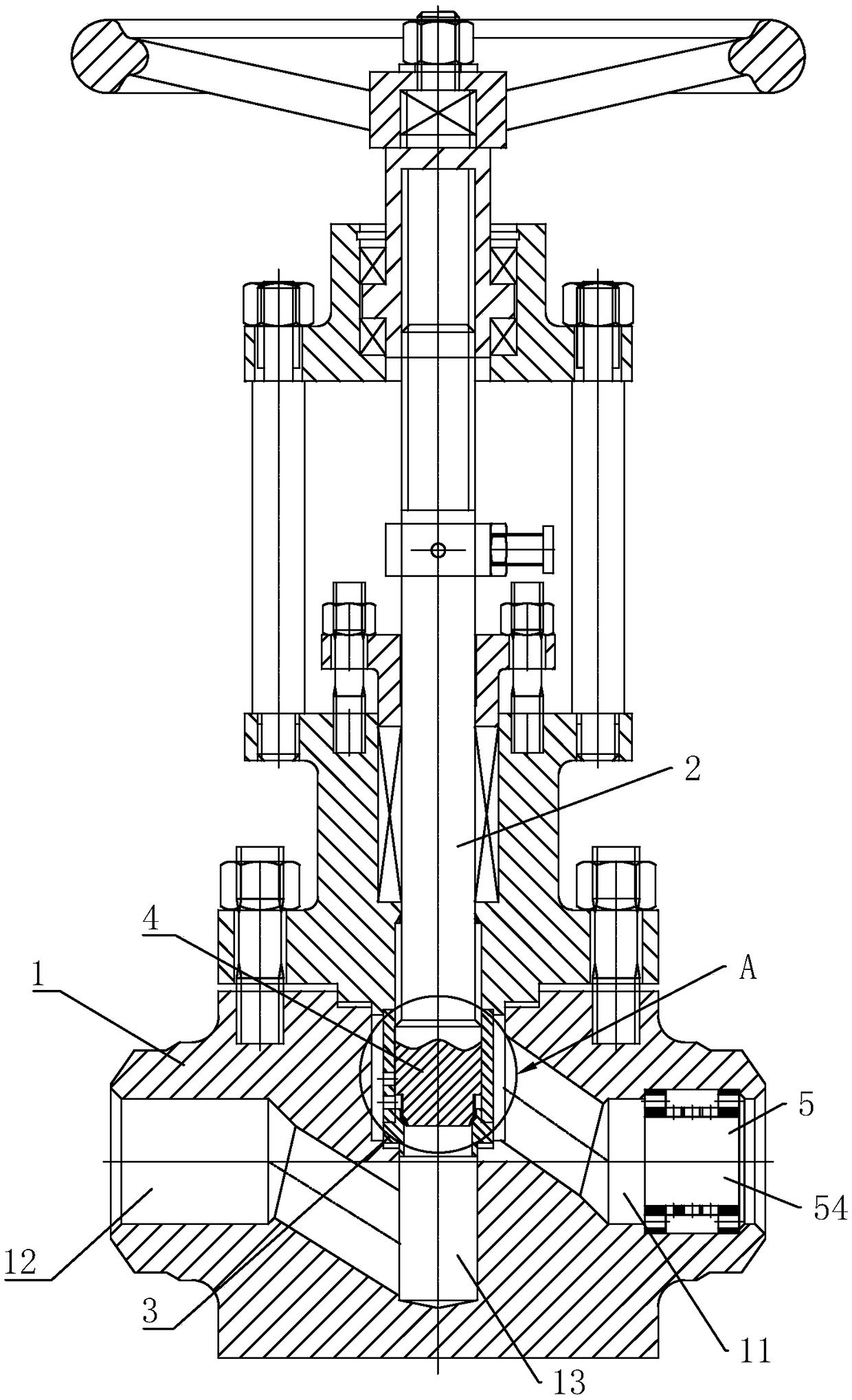

A keyway type safety valve

ActiveCN106989008BLarge flow areaReduce medium flow ratePositive displacement pump componentsLiquid fuel engine componentsEngineeringType safety

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

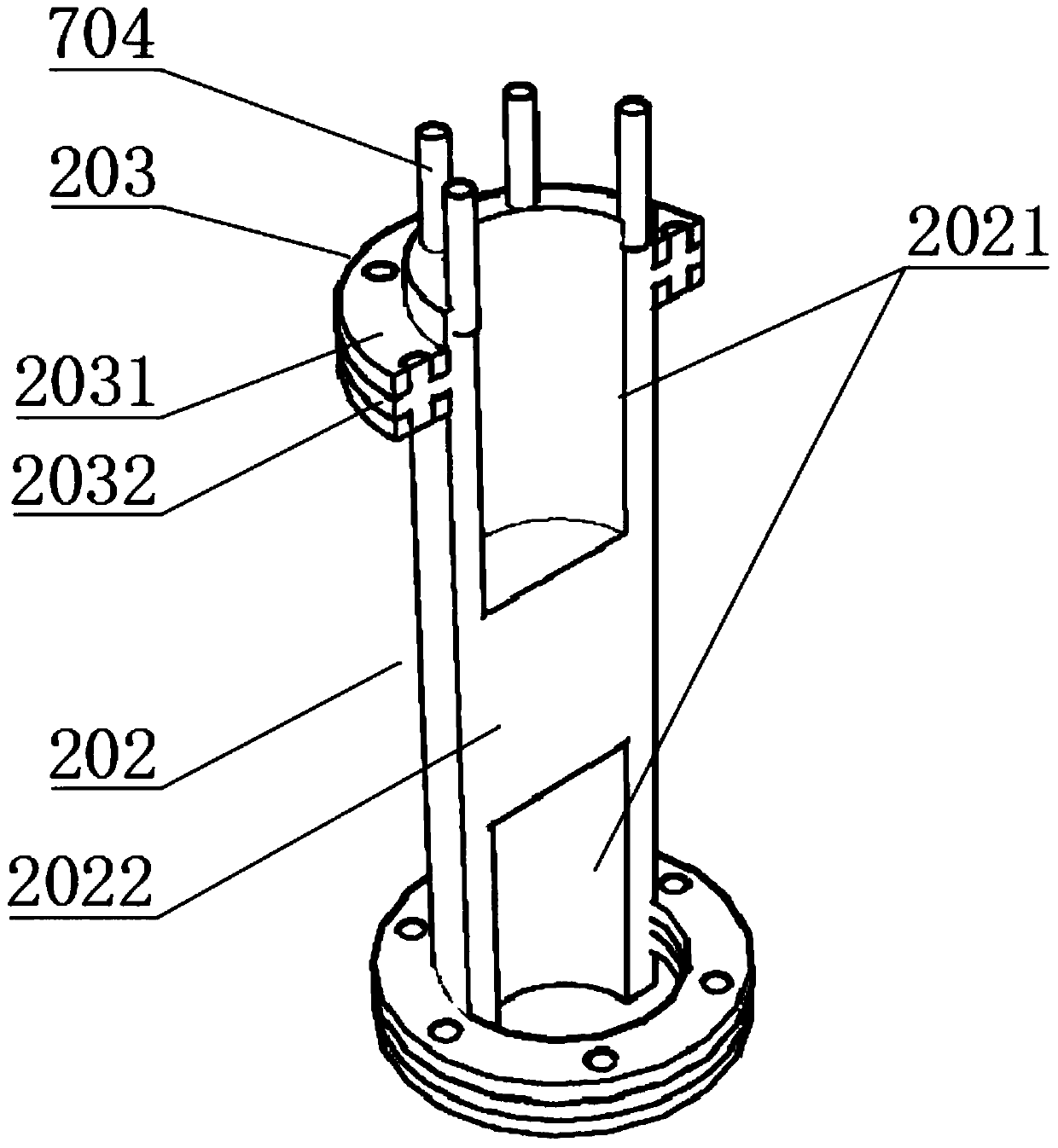

Flow passage component of high-temperature high-pressure coal chemical industry

ActiveCN101666317BReduced scour wearReduce medium flow rateSpecific fluid pumpsPump componentsImpellerLarge mouth

The invention relates to a flow passage component of a pump, in particular to a flow passage component of a high-temperature high-pressure coal chemical industry, belonging to the fluid machinery field. The flow passage component of the high-temperature high-pressure coal chemical industry comprises an impeller, a guide vane and a scaleboard; a female end of the scaleboard is located with a male end of an excircle surface of a large mouth end at right side of the guide vane in a matching way, a fastening screw penetrates through a cylindrical through hole to lead the guide vane and the scaleboard to be fixed on a pump cover, the impeller is arranged on a pump shaft and is arranged between the guide vane and the scaleboard. In the invention, the guide vane and the scaleboard are arranged in a pump body, the guide vane is used for protecting the pump body to reduce erosion wear of medium to the pump body, and the scaleboard can protect the pump cover to reduce abrasion of the medium to the pump cover. The flow passage component aims at overcoming the problems that a bearing pump body and the pump cover of the existing slurry pump are seriously wore at a circulating work station of aslurry tank, and the service life is short, thereby developing a new flow passage component of the high-temperature high-pressure coal chemical industry, improving the service life of the pump and reducing the maintenance cost of the pump.

Owner:XIANGYANG WU ER WU PUMP IND

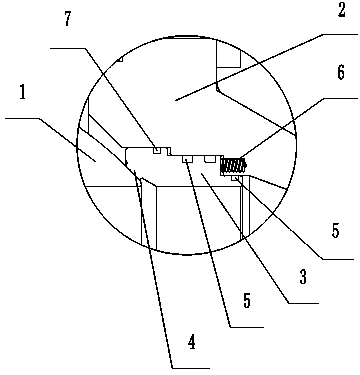

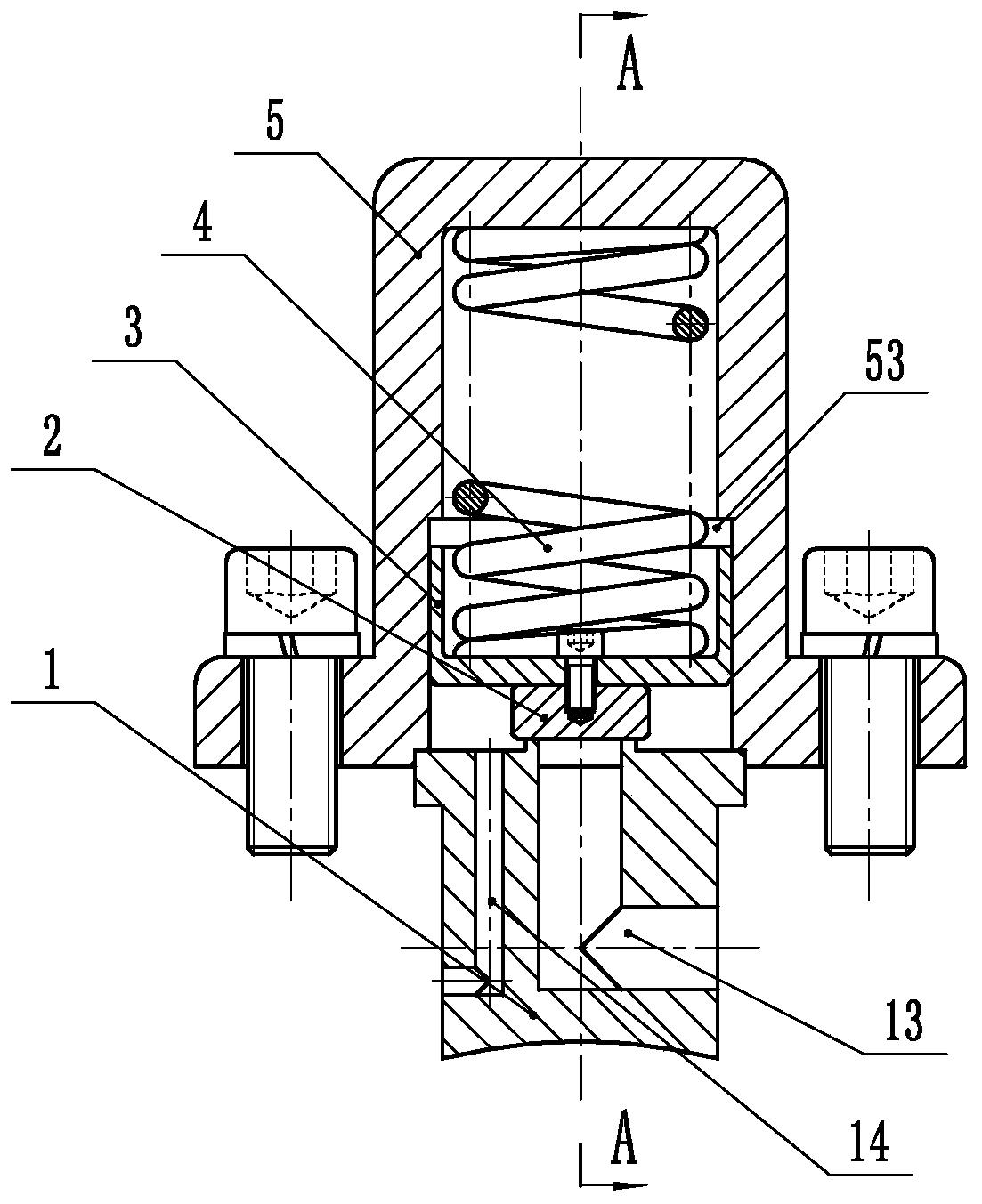

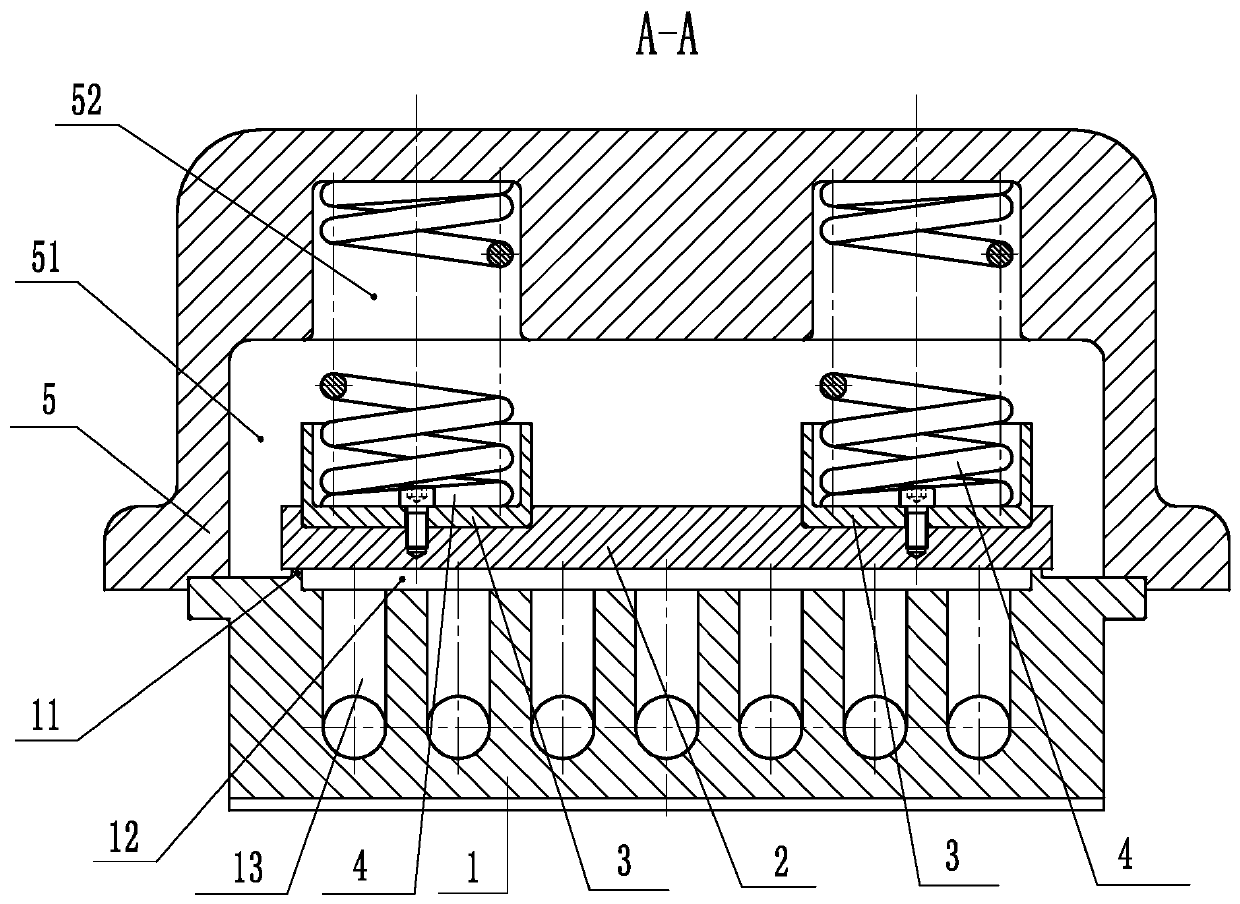

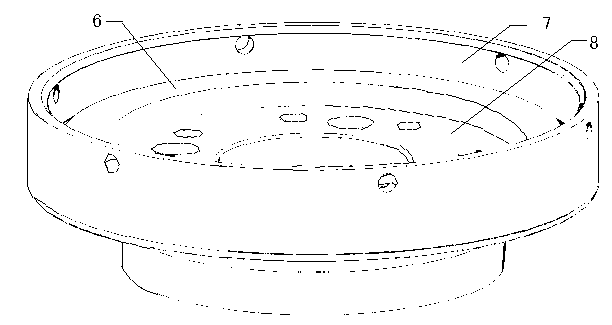

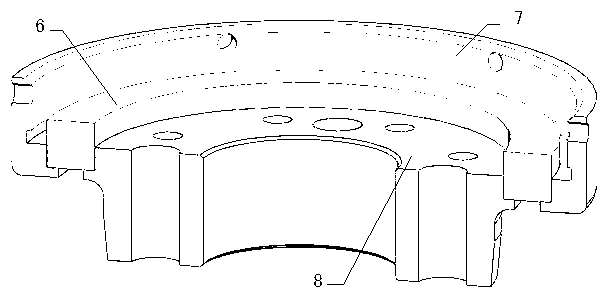

Key groove type safety valve

ActiveCN106989008ALarge flow areaReduce medium flow ratePositive displacement pump componentsLiquid fuel engine componentsEngineeringType safety

The invention relates to a key groove type safety valve. A flat key type step is arranged on the surface, directly facing a valve body inner cavity, of a valve seat and internally sinks to form a flat key type groove. A plurality of high-pressure medium flowing channels are distributed in the flat key type groove. The high-pressure medium flowing channels communicate with a plurality of low-pressure medium flowing channels distributed outside the flat key type step through the valve body inner cavity. A valve plate assembly is arranged at a valve body and comprises a flat key type valve plate, double springs acting on the flat key type valve plate and double valve sleeves. The valve plate assembly and the flat key type step are arranged correspondingly so as to open or close the high-pressure medium flowing channels. The safety valve adopts the flat key type valve plate, so that the flowing area is increased, and the flowing speed of a medium become low; under the condition of the same flowing area, the flat key type valve plate bears less force, bearing force of the springs is improved, accordingly the using reliability of the valve can be improved, and the service life of the valve can be prolonged; and in addition, by adopting the double-spring and double-guiding structure, the bearing force of the single spring can be decreased by one half, and stationarity is better through double guiding.

Owner:NINGBO HELI MECHANICAL PUMP CO LTD

Double-seal stop valve

The invention discloses a double-seal stop valve. A valve base comprises a valve base conical surface and a valve base annular surface which is arranged along a moving direction of a valve clack, thevalve clack comprises a valve clack conical surface and a valve clack annular surface which is arranged along the moving direction of the valve clack, the valve base conical surface and the valve clack conical surface are mutually cooperate to form a conical surface sealing pair, the valve base annular surface and the valve clack annular surface are mutually cooperate to form a ring surface sealing pair, relative to the annular surface sealing pair, the conical surface sealing pair is arranged on the side closer to an outlet cavity. The double-seal stop valve has a dual-sealing auxiliary structure, in a valve closing process, the annular surface sealing pair is firstly sealed, the effect of the pressure reducing throttling in advance is achieved, and then impurities are blocked from entering the area of the conical surface sealing pair, then a small amount of medium after throttling is used for flushing, so that the sealing surface is self-cleaned, and the impurities are effectively prevented from remaining on the sealing surface; and meanwhile, the problem that the valve is not tightly closed or the sealing surface is damaged by pressing is effectively solved, the flushing of thehigh-speed medium on the sealing surface is avoided as well, and the working reliability of the stop valve is greatly improved.

Owner:浙江双华阀门科技有限公司

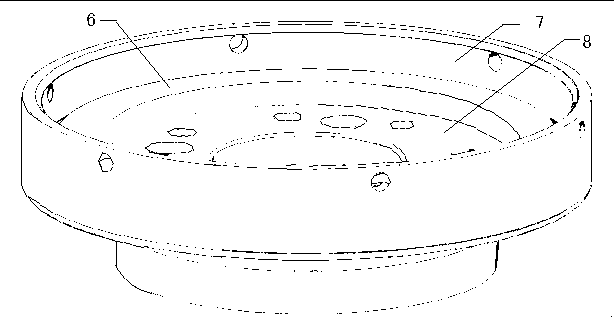

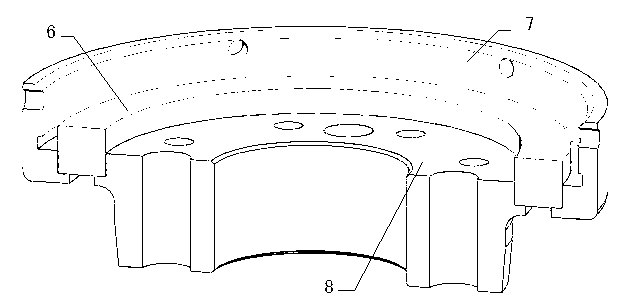

Vertical type one-way combination valve for reciprocating type gas-liquid two-phase mixture conveying pump

InactiveCN102207081AImprove suction performanceReduce vibration and noisePositive displacement pump componentsLiquid fuel engine componentsEngineeringLag

The invention provides a vertical type one-way combination valve for a reciprocating type gas-liquid two-phase mixture conveying pump, which mainly comprises a valve body, a valve inlet, a valve outlet, an inlet chamber and an outlet chamber, wherein the valve outlet is arranged at an inner ring of the valve body, the valve inlet is arranged at an outer ring of the valve body, a valve ring is arranged in the inlet chamber, a through hole is arranged in the valve body between the inlet chamber and the outlet chamber, and the valve outlet is provided with a valve plate. In the vertical type one-way combination valve for the reciprocating type gas-liquid two-phase mixture conveying pump, as the valve outlet is arranged at the inner ring of the valve body, and the valve inlet is arranged at the outer ring of the valve body, the flow path area of the valve inlet is increased, and the flow rate of a medium at the valve inlet is decreased, so that energy waste can be reduced, and the suction performance of the pump can be improved; and meanwhile, as a flow dividing hole is arranged in the valve body between the inlet chamber and the outlet chamber, a double-flow path structure is realized, and the flow rate of the medium at the valve inlet is further decreased, so that the opening height of the valve ring can be reduced, a lag angle of closing the valve ring can be reduced, and the pressure loss and the energy waste can be reduced.

Owner:杭州佳湖科技有限公司

A Universal Release Source Device Used in Building Ventilation and Smoke Exhaust Experiments

The invention relates to a general release source device for building ventilation and smoke exhaust experiment. The device comprises a medium injection pipe and a buffer cavity, wherein the buffer cavity is connected with the lower end of the medium injection pipe; the cavity wall at the joint of the buffer cavity and the medium injection pipe is provided with a medium injection port; the interior of the buffer cavity is provided with interior flow guide pore plates; the bottom of the buffer cavity is provided with an outlet flow guide pore plate; medium enters the interior of the buffer cavity through the medium injection port from the medium injection pipe and then flows through the interior flow guide pore plates, and flows out from the outlet flow guide pore plate; the medium flowing out from the outlet flow guide pore plate is fluid with low speed and high turbulence. Compared with the prior art, through combined action of the medium injection port and guide holes mutually staggered on the three pore plates, the fluid turbulence is increased while the medium flow speed is reduced, the problem that low speed and high turbulence cannot be achieved at the same time since the initial quantity of motion of a medium flow in a ventilation and smoke exhaust medium experiment is not zero is solved, and the error of the experiment is greatly reduced.

Owner:TONGJI UNIV ARCHITECTURAL DESIGN INST GRP CO LTD +1

High-temperature hexagonal hole wear-resisting ball valve

PendingCN111173953AIncrease the circulation areaReduce medium flow rateSpindle sealingsPlug valvesBall valveEngineering

The invention relates to a high-temperature hexagonal hole wear-resisting ball valve. The high-temperature hexagonal hole wear-resisting ball valve comprises a valve body, a valve deck, a ball body and a valve rod, the ball body is arranged in an inner cavity of the valve body, the valve deck is fixed on the front side of the inner cavity of the valve body, the valve rod is connected with the upper end of the ball body, a front valve seat and a rear valve seat are arranged on positions, located on the front side and the rear side of the ball body, of the inner cavity, the rear valve seat is pressed tightly and fixed in the valve body through a valve seat pressing ring, the valve seat pressing ring is fixed in the valve body through a bolt, the front valve seat is arranged in the valve deckin a penetrating manner, a belleville spring set which enables the front valve seat to press tightly the ball body is arranged between the valve deck and the front valve seat, hexagonal hole runnersare formed in the ball body, the hexagonal hole runners are formed in the front valve seat and the rear valve seat which are matched, a valve rod bearing is installed between the valve rod and the valve body in a sealing manner, the upper end of the valve rod extends to the outer side of the valve body and is connected with a driving sleeve in a key manner, the driving sleeve is rotationally connected with a bracket, and the bracket is fixed on the upper end of the valve body. According to the high-temperature hexagonal hole wear-resisting ball valve, the flow area at the moment of opening isincreased, the medium flow speed is reduced, the scouring resistance of the ball body is improved, the service life of the valve is prolonged, and the daily maintenance cost is reduced.

Owner:无锡市亚迪流体控制技术有限公司

Noise-reduction ball valve

PendingCN107740869AReduce noiseReduce vibrationPlug valvesValve members for absorbing fluid energyCavitationWorking environment

The invention discloses a noise-reduction ball valve. A floating ball valve structure of the ball valve comprises a valve body comprising a first valve body part and a second valve body part; the valve body comprises a ball body; an inlet valve seat is arranged on one side of the ball body; springs are arranged on the inlet valve seat; an outlet valve seat is arranged on the other side of the ballbody; the ball body and the outlet valve seat form a spherical seal; a valve rod drives the ball body to rotate to complete opening and closing actions; when the noise-reduction ball valve is in theclosed state, under the effect of medium pressure, the ball body shifts and closely presses against the outlet valve seat, and the spherical seal is formed; an inner piece is arranged in a flow channel of the ball body and comprises at least two side plates, at least two end plates and at least two supporting plates; through holes are formed in the side plates and the end plates; and a channel isformed in the inlet spherical surface of the ball body. By the aid of the ball valve, noise and vibration can be eliminated substantially, meanwhile, cavitation can be prevented, the energy consumption of the valve is reduced, the working environment of an operator is improved, and the valve adopts the simple structure, is convenient to machine and assemble and has the characteristics of capability of saving energy and high efficiency.

Owner:CHANGZHENG ENG +1

Condensate pipeline and method for improving vibration of condensate pipeline

The invention discloses a condensation water pipe and a method for reducing vibration of the condensation water pipe. The method comprises the following steps that the condensation water pipe is simulated; the pressure change of the lowest point of a continuous vertical pipe segment of the condensation water pipe along with running time and the liquid phase distribution of the vertical pipe segment are monitored; the time corresponding to the maximum pressure value of the lowest point is obtained, and the liquid phase distribution, corresponding to the time, of the radial section of the vertical pipe segment is obtained; a cavitation area of the vertical pipe segment is obtained according to the liquid phase distribution of the radial section; and the maximum continuous vertical height not larger than the height of the cavitation area is obtained according to the height of the cavitation area; and according to the maximum continuous vertical height, the vertical pipe segment is provided with bent pipes in a segmented manner, and / or restriction orifices are arranged in the vertical pipe segment corresponding to the front end of the cavitation area. According to the scheme, it is found that vibration of the vertical pipe segment of the condensation water pipe is mainly caused by the cavitation effect; the medium flowing resistance is increased in the manner of arranging the bent pipes and the restriction orifices, the flowing speed is lowered, and cavitation is restrained; and therefore pipe vibration is effectively reduced.

Owner:HUADIAN HEAVY IND CO LTD

Expansion valve

InactiveCN101818826BIncreased turbulenceIncrease spawn rateOperating means/releasing devices for valvesValve members for absorbing fluid energyEngineeringMechanical engineering

The invention discloses an expansion valve, which comprises a valve body 1. A combined sealing ring 2 and a plunger piston 3 for controlling medium flow are arranged in a cavity inside the valve body 1; the upper part of the combined sealing ring 2 is provided with a valve cover 6 for positioning the combined sealing ring 2, and the valve cover 6 is fixedly arranged on the valve body 1; a valve rod assembly 5 is arranged on the plunger piston 3, and the lower part of the valve rod assembly 5 is provided with a condensate baffle plate 4; a conical intercepting screen 9 is arranged at a lower medium inlet A of the valve body 1, and the upper end of the conical intercepting screen 9 is provided with a hemispherical steam screen 8. By simplifying the internal structure of the expansion valve and a control element, the expansion valve reduces the medium flowing energy loss, has large treatment amount of refrigerating medium, simplifies a driving control device, and is convenient to maintain and operate.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Champagne tower multi-stage throttle control valve

ActiveCN111473155BGuaranteed tightnessRealize slow speed throttling functionValve members for absorbing fluid energyLift valveThrottle controlStructural engineering

The invention relates to the field of valves, in particular to a champagne tower type multi-stage throttling control valve that can be applied to high-pressure differential media for noise reduction and cavitation damage resistance. The invention includes a valve body, a valve cover, a throttle sleeve and a valve core; the cavity of the throttle sleeve is in the shape of a stepped hole with more than two layers, and the shape of the valve core is a stepped shaft coaxial with the throttle sleeve with more than two layers shape, and the number of shoulders at the spool is less than or equal to the number of shoulders in the cavity of the throttle sleeve, so that each set of shoulders at the valve core in the axial direction can form a sealing surface with the corresponding shoulder at the corresponding throttle sleeve; The hole shoulder of the throttling sleeve and / or the shaft shoulder of the valve core are provided with flow channel grooves axially or obliquely. The invention has a compact and simple structure and high operational reliability. It can not only effectively reduce noise and resist cavitation damage, but also further reduce the processing difficulty and cost of the valve, and is especially suitable for use under the control conditions of high-pressure differential media. .

Owner:HEFEI GENERAL MACHINERY RES INST

Forged isolation type vacuum starting valve

PendingCN109373001AAvoid shockPrevent accidental floatingCheck valvesValve members for absorbing fluid energyWater flowEngineering

The invention provides a forged isolation type vacuum starting valve which comprises a valve body, a valve cover, an end cover, a floating cylinder and a valve base. An impact preventing structure forpreventing water flow from impacting the floating valve is arranged on the bottom of a lower valve cavity in a water inlet of the valve body. The valve base is an isolation type valve base mechanism.The isolation type valve base mechanism is composed of the valve base arranged on the partition plate, a floating cylinder guide inner ring arranged on the lower portion of the valve base, and a sealing ring arranged on the floating cylinder guide inner ring. An adjusting valve clack operating back and forth from bottom to top forms a lower portion closing or opening mechanism between the lower valve cavity and an upper valve cavity of the valve body. Meanwhile, a check valve clack arranged on the end cover forms a closing or opening mechanism between the lower valve cavity and the upper valve cavity of the valve body and a water outlet of the valve body. A pressure adjusting and relieving mechanism composed of the adjusting valve clack, an adjusting guide part, a spring, an adjusting piston and an adjusting screw is arranged between the partition plate and the end cover.

Owner:MINGZHU VALVE GRP

Floating type sealed mouse cage valve

InactiveCN102927290AImprove erosion resistanceAvoid overwashingSpindle sealingsOperating means/releasing devices for valvesMachining

The invention discloses a floating type sealed mouse cage valve comprising a valve body, a valve cover, a supporting frame, a sealing base inside the valve body, a balance cylinder inside the valve body, a valve core in an inner hole of the balance cylinder, a lower valve rod connected with the valve core, and an upper valve rod connected with the upper end of the lower valve rod. A sleeve is arranged inside the valve body; a runner hole is formed in the sleeve; a valve positioning device is arranged on the supporting frame; a circular connection piece is arranged on the outer outline of the lower end of the valve core; a circular clamping sheet with the diameter less than that of the connection piece is arranged below the inside of the connection piece; a sealing piece is arranged above the clamping sheet inside the connection piece; the external diameter of the clamping sheet presses the sealing sheet through seam allowance; the internal diameter of the connection piece presses the sealing sheet through the seam allowance; and clearances are reserved between the sealing piece and the connection piece, and between the sealing piece and the clamping sheet respectively. With the adoption of the floating type sealed mouse cage valve provided by the invention, a fixed sealing sheet of the traditional valve is designed to be a floating sealing sheet, so that the good sealing effect can be realized by automatically adjusting the floating sealing sheet when the sealing sheet is in non-flat contact due to factors, such as a valve machining error and the like.

Owner:SICHUAN TIANYI SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com